The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Kraversoft

Seoul, South Korea

A

1-10 Employees

2016

Key takeaway

The company, KRAVER SOFT, provides 3D CAD-based mechanical component design software and automation services, which could be relevant for CNC milling applications.

Reference

Product

KRAVER SOFT

3D Mechanical Component Design Software and Service

DY

Gimhae-si, South Korea

A

1-10 Employees

1999

Key takeaway

The company specializes in custom metal fabrication and has an experienced engineering team capable of producing customized products based on client designs, making it well-suited for CNC milling projects. They also ensure quality control and can expedite production for urgent orders.

Reference

Core business

대용기계, DY (기계부품 가공)

항공기 부품, 자동차 부품, 기계가공, JIG제작, 자동화 기계 부품 가공,

fabWeaver

Seoul, South Korea

A

1001-5000 Employees

2021

Key takeaway

fabWeaver emphasizes its commitment to precision and quality in 3D printing, utilizing advanced technology to optimize the printing process. Their focus on providing end-to-end solutions for 3D printing may be relevant for those interested in CNC milling as part of the broader manufacturing and prototyping landscape.

Reference

Core business

fabWeaver Industrial 3D Printers, Professional 3D Printers, Prototyping 3D Printers | fabWeaver

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Huwin

Seongnam-si, South Korea

A

11-50 Employees

-

Key takeaway

Huwin has over 20 years of experience in engineering solutions, which may include advanced manufacturing techniques relevant to CNC milling. Their expertise in design and simulation could be beneficial for precision engineering applications.

Reference

Product

EMCoS - Product/Solutions - Huwin

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

CNC Machining

Go to product

Product

CNC Milling

Go to product

Service

CNC Machining

Go to product

Service

CNC machining

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

CNC Machining Parts for Machinery

Machinery, Automotive, Medical

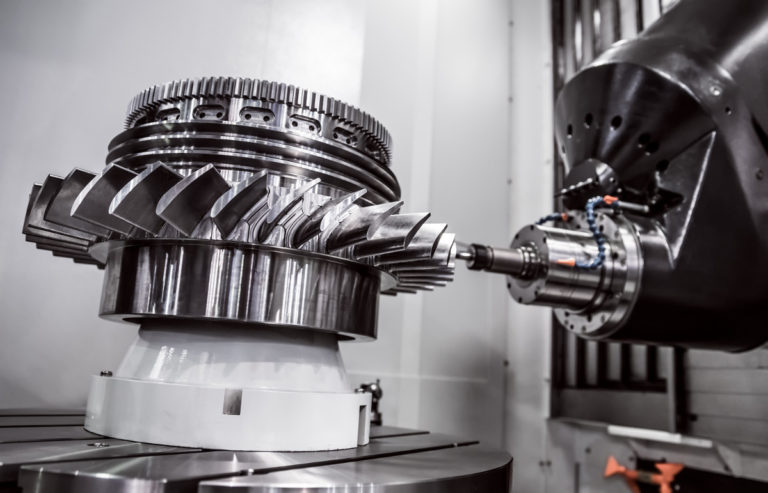

CNC machining (Computer Numerical Control machining) is a manufacturing process in which pre-programmed computer software manages the movement of tools and machinery. This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

Use case

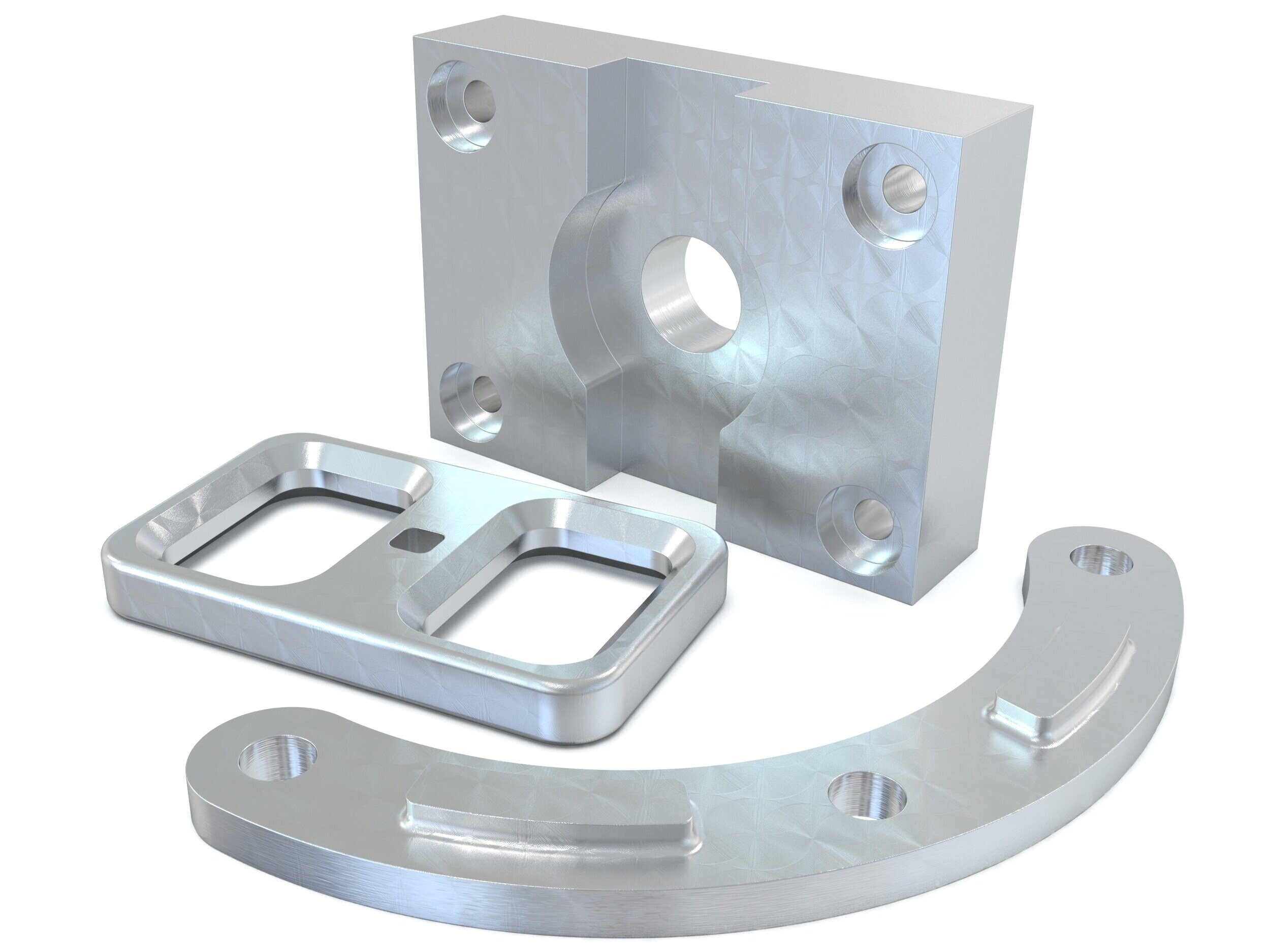

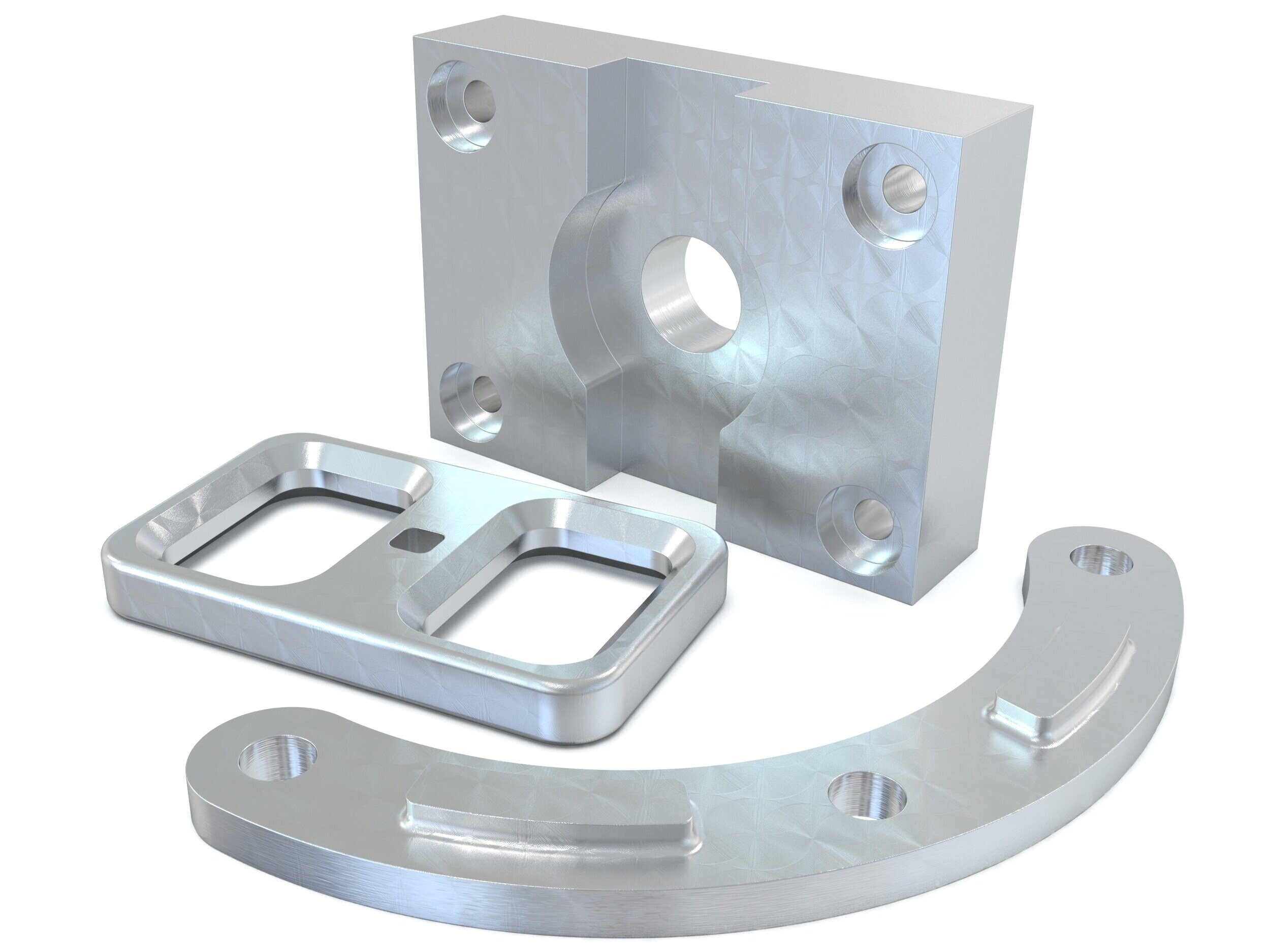

CNC Milling Parts

machinery, automotive, electronics, construction machinery, heavy equipment, farming equipment, construction

CNC Milling process is highly versatile and capable of producing flat or curved profiles and intricate shapes with a high degree of accuracy and excellent surface finish. Milling machines are a fundamental component in modern machine shops due to their efficiency and capability in shaping a wide range of materials into precise parts and components.

Use case

HLH helps Swiss Smartflyer achieve 5X faster CNC lead times

Aerospace, Aviation, Electric Aircrafts

HLH helps Swiss Aviation Company, Smartflyer, build precision aircraft components via CNC Machining (4 and 5 axis) and CNC turning for their hybrid-electric aircraft. ✔ Precision milled and turned parts like actuator, bearings, push rods, bellcranks, fuselage mount, rudder mount, etc. ✔ Supplied 10+ different CNC parts within 1-week lead time. ✔ Smartflyer immediately saw an immediate improvement in lead times - 5 times faster than local suppliers.

Use case

Fast and precise: Parker Hannifin relies on state-of-the-art Online Manufacturing of turned and milled parts by FACTUREE

aerospace, motion technologies, control technologies, actuators, fittings, couplings

Fast and precise: Parker Hannifin relies on state-of-the-art Online Manufacturing of turned and milled parts by FACTUREE Berlin, March 25th 2020 In today’s world, a high level of precision and fast delivery times are crucial to the production of individual components. Online Manufacturer FACTUREE (www.facturee.de) is meeting these new requirements with its wide range of manufacturing services, quick response times and on-time delivery. To benefit from this cutting-edge procurement process, leading engineering company Parker Hannifin commissioned FACTUREE to produce special turned and milled parts for mounting devices in their engineering department. The move enables the company to efficiently drive its own digital transformation without being affected by capacity bottlenecks and disproportionate personnel involvement.

Use case

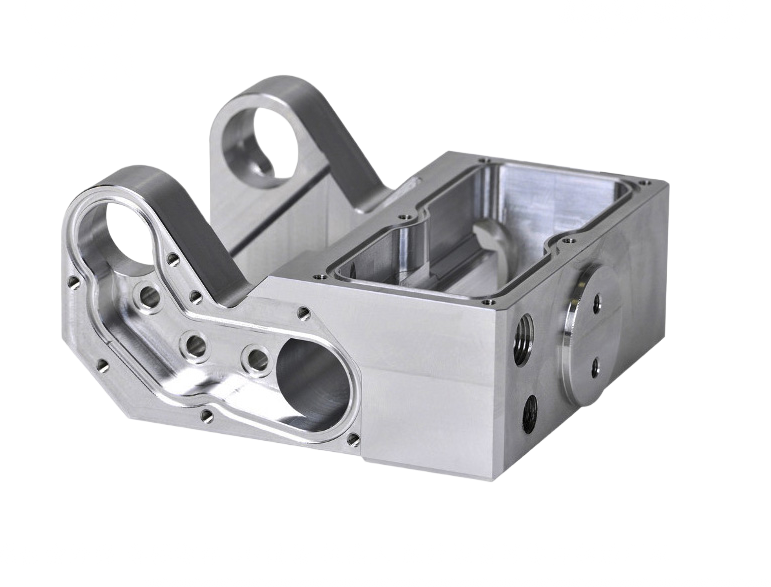

Custom CNC Machined Parts for Automotive Applications

Automotive, Electric Vehicles, Mobility Solutions, OEM Manufacturing

FutureParts delivers high-precision CNC machined components for the automotive industry, supporting both traditional and electric vehicle applications. From engine brackets and transmission housings to battery enclosures and interior fixtures, our CNC machining services ensure top-tier accuracy, repeatability, and strength. We work with a wide range of materials including aluminum, stainless steel, and engineering plastics to meet automotive-grade requirements for thermal resistance, strength, and dimensional precision. Whether you're developing prototypes or require low-to-mid volume production, FutureParts offers efficient lead times, tight tolerance machining, and reliable quality control for every part. Trusted by automotive OEMs and Tier 1 suppliers, we help drive innovation, performance, and production efficiency.

Use case

CNC Machining Parts for Machinery

Machinery, Automotive, Medical

CNC machining (Computer Numerical Control machining) is a manufacturing process in which pre-programmed computer software manages the movement of tools and machinery. This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

In the CNC milling industry in South Korea, several key considerations are essential for effective research. First, the country's advanced technology infrastructure supports high-quality manufacturing processes, making it a competitive player in the global market. Understanding local regulations is crucial, as South Korea has stringent safety and quality standards that companies must comply with, which can influence operational costs and timelines. Additionally, the industry faces challenges such as rising labor costs and competition from low-cost manufacturing countries. However, opportunities abound in sectors like automotive and electronics, where precision machining is in high demand. Environmental concerns also play a significant role; companies are increasingly required to adopt sustainable practices and reduce their carbon footprint. The competitive landscape consists of both established firms and emerging startups, which are pushing innovation and efficiency. It's vital to consider global market trends, as South Korean companies often export CNC machined parts, impacting pricing and demand. Finally, building relationships with local suppliers and understanding cultural nuances can provide a competitive advantage in this dynamic industry.

Some interesting numbers and facts about your company results for CNC Milling

| Country with most fitting companies | South Korea |

| Amount of fitting manufacturers | 3 |

| Amount of suitable service providers | 3 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1999 |

| Youngest suiting company | 2021 |

Some interesting questions that has been asked about the results you have just received for CNC Milling

What are related technologies to CNC Milling?

Based on our calculations related technologies to CNC Milling are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on CNC Milling?

The most represented industries which are working in CNC Milling are Automation, Electronics and Electrical engineering, IT, Software and Services, Machinery Manufacturing

How does ensun find these CNC Milling Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.