The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

High-Tech Industries (HTI)

-

11-50 Employees

1983

Key takeaway

The company specializes in precision parts manufacturing and integrates advanced CNC machining technology, including CNC turning, to meet high-quality standards and urgent delivery timelines. Their commitment to adding value and providing top-notch service is central to their operations, ensuring customers receive a strategic advantage in a competitive market.

Reference

Service

CNC Turning

H & H PRECISION ENGINEERING LTD

Portadown, United Kingdom

A

1-10 Employees

-

Key takeaway

HUM Precision Engineering Ltd specializes in producing high-quality precision components for various industries, including those that require CNC turning. Their modern machinery and skilled workforce ensure a high standard in manufacturing, with the capability to offer short lead times.

Reference

Service

CNC Turning

Rother Machine

Hastings, United States

B

11-50 Employees

1971

Key takeaway

Rother Machine specializes in the design and manufacturing of custom equipment, including CNC turning and machining, which can help address production challenges like slow rates and quality control. Their expertise from concept to completion ensures that they can assist customers in developing specialized machines and automated systems.

Reference

Service

CNC Turning

CNC Machining

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

ST Metal Manufacturer Limited

Shenzhen, China

D

11-50 Employees

2010

Key takeaway

ST Metal offers a specialized CNC turning service, emphasizing its expertise in the customized production of metal parts. With over 10 years of experience and advanced processing equipment, the company provides precise and cost-effective solutions for various industries.

Reference

Service

CNC Turning Service

WHITE ENGINEERING (PORTLAND) LIMITED

United Kingdom

A

1-10 Employees

-

Key takeaway

White Engineering offers CNC turning services, ensuring quality from the initial quote to the delivery of components.

Reference

Service

» CNC Turning

Tornado CNC Turning Workshop LLC

Dubai, United Arab Emirates

C

1-10 Employees

-

Key takeaway

TCNC specializes in CNC turning, offering a fully equipped workshop that can handle various machining projects with high precision. Their commitment to advanced technologies and detail-oriented practices ensures that they meet client requirements effectively.

Reference

Core business

CNC Turning Workshop Dubai - Tornado CNC

One-stop workshop for all things CNC- from milling services to turning, our facility that is fully equipped to successfully tackle all kinds of machining.

3D Machine Inc

Goodland, United States

B

11-50 Employees

1996

Key takeaway

3D Machine Inc. specializes in CNC turning services, offering fast turnaround times for both prototyping and contract manufacturing. With a commitment to quality and excellence, they cater to projects of all sizes, making them a trusted partner in the CNC machining industry.

Reference

Service

CNC Turning Services, Precision CNC Turning Companies - 3D Machine Inc.

As one of the top precision CNC turning companies nationwide, 3D Machine provides expert CNC turning services for prototyping & contract manufacturing

Huachen Precision Manufacturing Co., Ltd.

Dongguan, China

D

11-50 Employees

2011

Key takeaway

The company offers precise CNC turning capabilities with a diameter of 35mm and a tolerance of 0.005mm, highlighting its expertise in advanced machining.

Reference

Service

Precise CNC Turning

shengyuan mechanical equipment engineering co.,Ltd.

Dongguan, China

D

251-500 Employees

1997

Key takeaway

SYM is a precision machining manufacturer with over 20 years of experience, offering a range of custom machining services, including CNC turning. Their expertise in CNC turning ensures high precision for parts used in various mechanical and engineering applications.

Reference

Product

CNC turning parts - Precision machining shop

Bset Parts Technology

Shenzhen, China

D

251-500 Employees

2000

Key takeaway

Shenzhen Best Parts Co., Ltd. specializes in CNC turning, offering a wide range of CNC turned parts and services that cater to various industries, including medical, automotive, and aerospace. With over 20 years of experience, they provide rapid prototyping and precision machining, ensuring high quality and tight tolerances for custom CNC turned parts.

Reference

Service

CNC Turning - Best Parts-Online CNC Machining Service Supplier

Rapid CNC Turning Service Online. Custom CNC Turned Parts, CNC turning is frequently requested for a certain category of parts.

Technologies which have been searched by others and may be interesting for you:

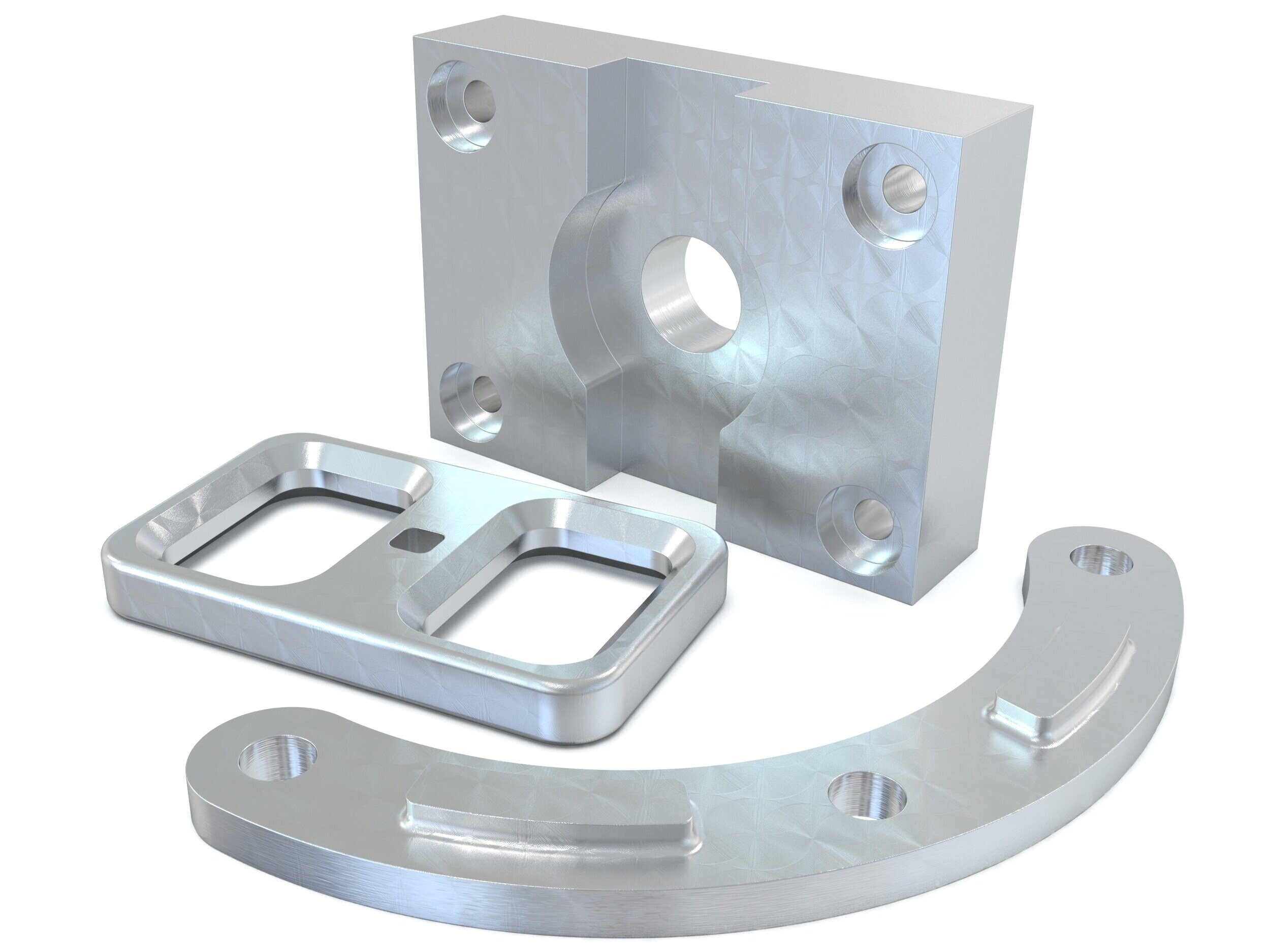

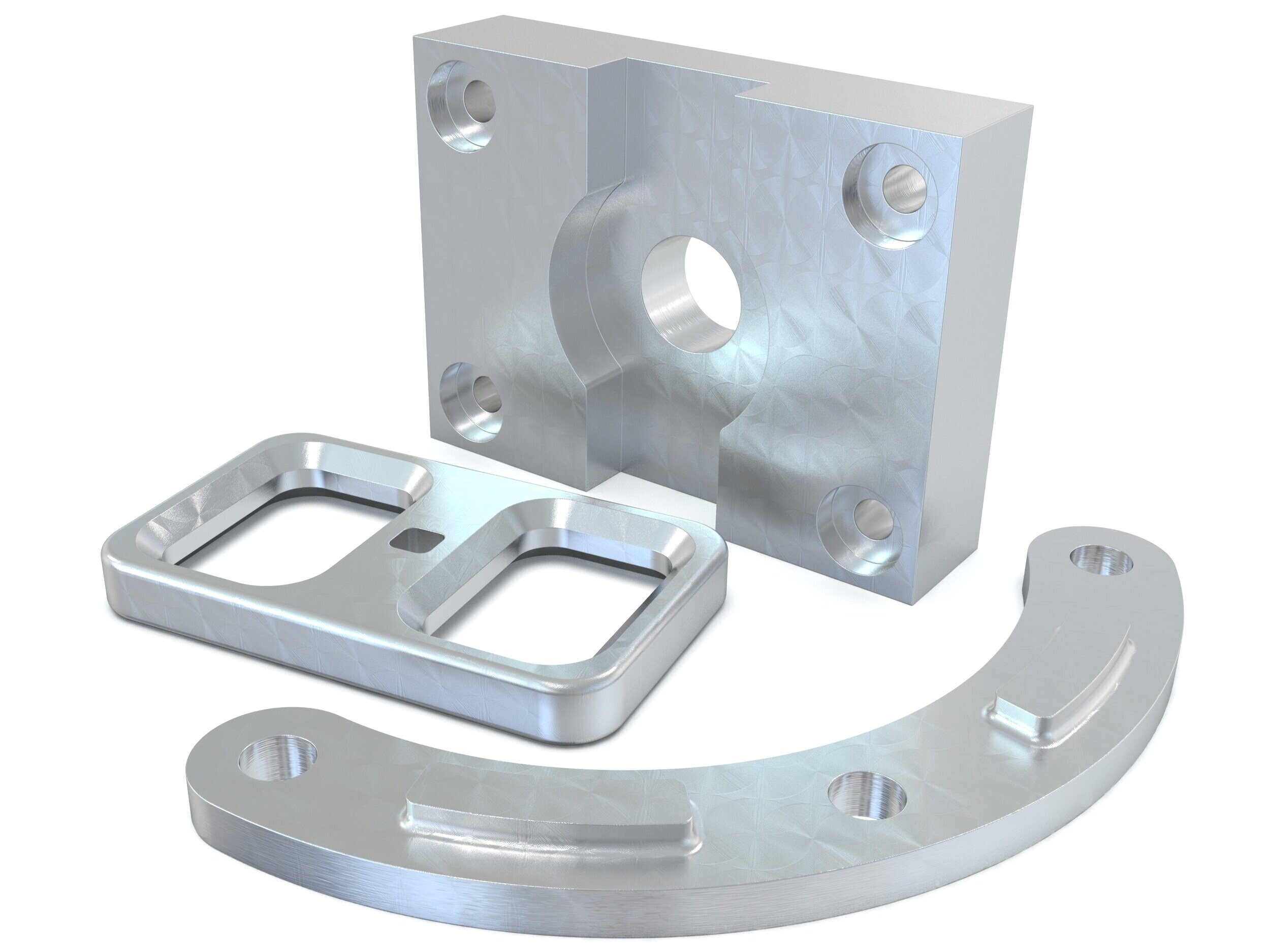

A selection of suitable products and services provided by verified companies according to your search.

Product

CNC Machining

Go to product

Product

CNC Turning Parts

Go to product

Product

CNC Milling

Go to product

Service

MR 20 V7

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

CNC Machining Parts for Machinery

Machinery, Automotive, Medical

CNC machining (Computer Numerical Control machining) is a manufacturing process in which pre-programmed computer software manages the movement of tools and machinery. This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

Use case

CNC Turning Parts

Machinery, Shipbuilding, Energy, Automotive

Shafts: These are long, cylindrical pieces used to transmit power or motion. Pins: Precision pins are used in various applications, including as hinge pins, dowels, or locator pins in machinery and equipment. Bushings: These are cylindrical linings designed to reduce friction or provide a protective interface between two parts in mechanical systems. Spacers: Used to create a space between two components in an assembly to ensure proper positioning and alignment. Valves and Valve Components: Essential in controlling the flow of liquids or gases in systems. Pulleys: These parts support movement and change of direction of a belt in machines. Bolts and Screws: Precision threading can be produced with CNC turning. Hydraulic Components: Parts like pistons, cylinders, and connectors, used in hydraulic systems. Carbon Steels: Low carbon steels (like 1018) are more ductile and weldable, while high carbon steels (like 1045) are harder and wear-resistant but less ductile. Alloy Steels: These steels are often used for their strength, toughness, wear resistance, and hardness. Examples include 4140 and 4340 steels. Tool Steels: Tool steels are high-carbon steels .They are known for their hardness and resistance to abrasion. Examples are D2, A2, and O1. Stainless Steels: Common grades used in CNC turning include 304 and 316, known for their good formability and corrosion resistance.

Use case

CNC Milling Parts

machinery, automotive, electronics, construction machinery, heavy equipment, farming equipment, construction

CNC Milling process is highly versatile and capable of producing flat or curved profiles and intricate shapes with a high degree of accuracy and excellent surface finish. Milling machines are a fundamental component in modern machine shops due to their efficiency and capability in shaping a wide range of materials into precise parts and components.

Use case

HLH helps Swiss Smartflyer achieve 5X faster CNC lead times

Aerospace, Aviation, Electric Aircrafts

HLH helps Swiss Aviation Company, Smartflyer, build precision aircraft components via CNC Machining (4 and 5 axis) and CNC turning for their hybrid-electric aircraft. ✔ Precision milled and turned parts like actuator, bearings, push rods, bellcranks, fuselage mount, rudder mount, etc. ✔ Supplied 10+ different CNC parts within 1-week lead time. ✔ Smartflyer immediately saw an immediate improvement in lead times - 5 times faster than local suppliers.

Use case

Fast and precise: Parker Hannifin relies on state-of-the-art Online Manufacturing of turned and milled parts by FACTUREE

aerospace, motion technologies, control technologies, actuators, fittings, couplings

Fast and precise: Parker Hannifin relies on state-of-the-art Online Manufacturing of turned and milled parts by FACTUREE Berlin, March 25th 2020 In today’s world, a high level of precision and fast delivery times are crucial to the production of individual components. Online Manufacturer FACTUREE (www.facturee.de) is meeting these new requirements with its wide range of manufacturing services, quick response times and on-time delivery. To benefit from this cutting-edge procurement process, leading engineering company Parker Hannifin commissioned FACTUREE to produce special turned and milled parts for mounting devices in their engineering department. The move enables the company to efficiently drive its own digital transformation without being affected by capacity bottlenecks and disproportionate personnel involvement.

Use case

Custom CNC Machined Parts for Automotive Applications

Automotive, Electric Vehicles, Mobility Solutions, OEM Manufacturing

FutureParts delivers high-precision CNC machined components for the automotive industry, supporting both traditional and electric vehicle applications. From engine brackets and transmission housings to battery enclosures and interior fixtures, our CNC machining services ensure top-tier accuracy, repeatability, and strength. We work with a wide range of materials including aluminum, stainless steel, and engineering plastics to meet automotive-grade requirements for thermal resistance, strength, and dimensional precision. Whether you're developing prototypes or require low-to-mid volume production, FutureParts offers efficient lead times, tight tolerance machining, and reliable quality control for every part. Trusted by automotive OEMs and Tier 1 suppliers, we help drive innovation, performance, and production efficiency.

Use case

CNC Machining Parts for Machinery

Machinery, Automotive, Medical

CNC machining (Computer Numerical Control machining) is a manufacturing process in which pre-programmed computer software manages the movement of tools and machinery. This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

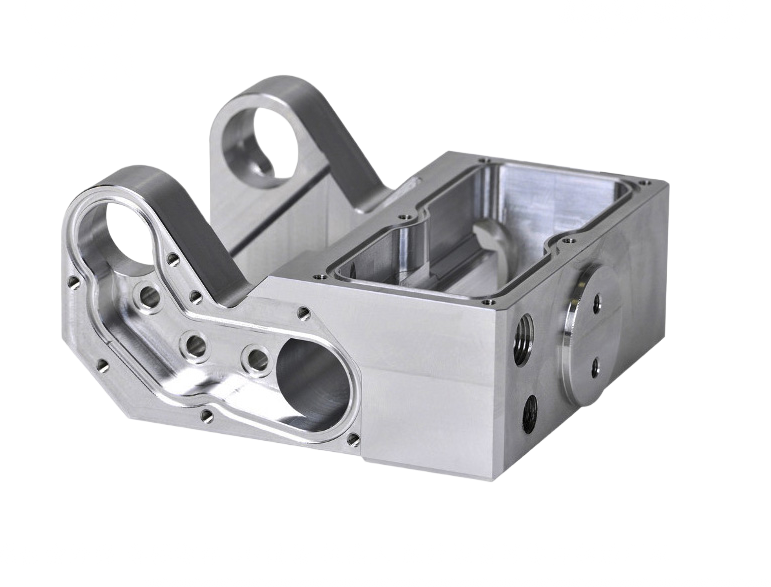

CNC turning is a precision machining process that utilizes computer numerical control (CNC) technology to produce cylindrical parts. This method involves the rotation of a workpiece on a lathe while cutting tools shape the material into desired profiles. The CNC system automates the movement of the cutting tools, allowing for high accuracy and repeatability in producing complex geometries. This process is widely used in various industries, including automotive and aerospace, for creating components such as shafts, bushings, and fittings. The ability to program intricate designs and specifications makes CNC turning an efficient choice for both small and large production runs, ensuring that each piece meets stringent quality standards.

CNC Turning operates by utilizing computer numerical control technology to automate the lathe machining process. The procedure begins with a pre-programmed computer that dictates the movement of the lathe and the cutting tools. A workpiece is mounted on the lathe, which rotates at high speeds. As the workpiece spins, the cutting tool moves in a linear motion along the length of the material, precisely shaping it according to the specifications in the digital design. This technology allows for intricate designs and tight tolerances, as the computer continuously adjusts the tool's position and speed in real-time. By employing advanced software and hardware, CNC Turning enables manufacturers to produce complex components efficiently and consistently, reducing the risk of human error and increasing overall production quality.

CNC Turning is compatible with a variety of materials, making it a versatile option for manufacturing. Metals such as aluminum, brass, steel, and stainless steel are commonly used due to their machinability and strength. Plastics like nylon, acetal, and polycarbonate are also suitable, offering lightweight and durable alternatives. Additionally, composite materials can be utilized, allowing for unique applications where both strength and reduced weight are essential. The choice of material often depends on the specific requirements of the project, including tolerance, finish, and mechanical properties.

1. Precision and Accuracy

CNC turning offers exceptional precision and accuracy in the manufacturing process. This technology enables the production of intricate components with tight tolerances, making it ideal for industries requiring high-quality parts.

2. Efficiency and Speed

Utilizing CNC turning enhances production efficiency and speed. Automated processes reduce cycle times and minimize human error, allowing for faster turnaround on projects and increased overall productivity.

3. Versatility

CNC turning can handle a wide range of materials, from metals to plastics, providing versatility in applications. This adaptability makes it suitable for various industries, including automotive, aerospace, and medical.

4. Cost-Effectiveness

Through automation and reduced labor costs, CNC turning can be more cost-effective than traditional machining methods. It optimizes material usage and minimizes waste, contributing to overall cost savings for businesses.

CNC Turning is widely utilized across various industries due to its precision and efficiency in producing complex parts.

1. Aerospace

This industry relies on CNC Turning for manufacturing components like turbine blades and structural parts, which require high accuracy and adherence to strict safety standards.

2. Automotive

In automotive production, CNC Turning is essential for fabricating engine components, transmission parts, and various fittings that demand precision and consistency.

3. Medical

The medical field benefits from CNC Turning in the production of surgical instruments and implants, where precision is critical for functionality and patient safety.

4. Electronics

CNC Turning is used to create housings, brackets, and other components in the electronics industry, ensuring that parts fit together seamlessly in complex assemblies.

5. Oil and Gas

Components for drilling equipment and valves are often produced using CNC Turning, as durability and precision are vital in this demanding sector.

Some interesting numbers and facts about your company results for CNC Turning

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 8188 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1971 |

| Youngest suiting company | 2011 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for CNC Turning

What are related technologies to CNC Turning?

Based on our calculations related technologies to CNC Turning are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on CNC Turning?

The most represented industries which are working in CNC Turning are Machinery Manufacturing, Manufacturing, Other, Mining, Automation

How does ensun find these CNC Turning Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.