The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

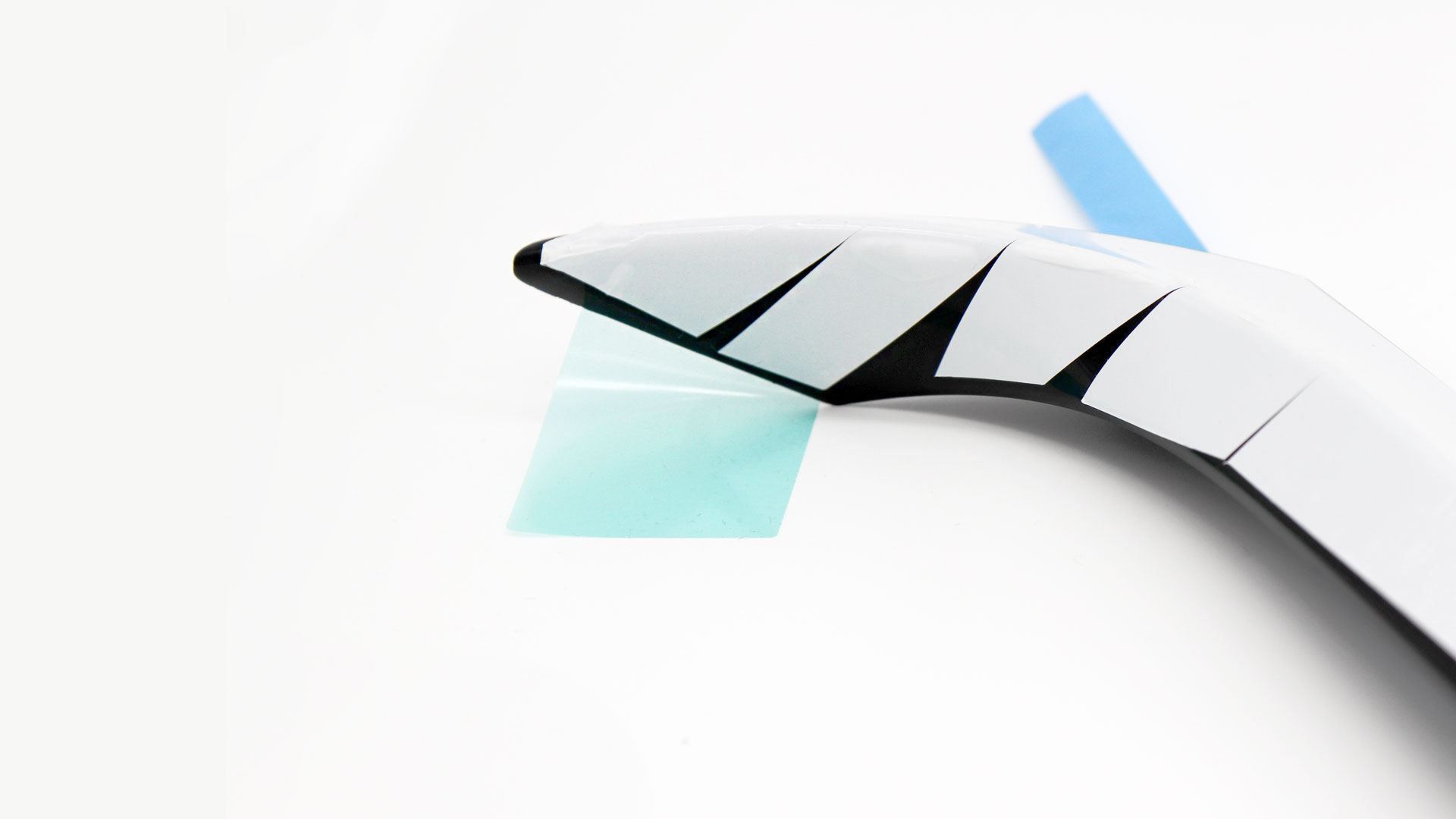

Assembly of an aerofin

Go to product

Product

Roof antenna sealing

Go to product

Die cutting is a manufacturing process used to create specific shapes and designs from materials such as paper, cardboard, plastic, and metal. This technique involves the use of a die, which is a specialized tool that cuts the material into predetermined shapes with precision. The die is pressed onto the material, allowing for efficient and consistent production of complex shapes in bulk. This method is widely utilized in various industries, including packaging, printing, and crafts, due to its ability to produce intricate designs while minimizing waste. The versatility of die cutting enables manufacturers to create a range of products, from custom packaging solutions to decorative elements for arts and crafts.

The die cutting process involves using a specialized machine to cut material into specific shapes and designs. Initially, a custom die, which is a sharp metal blade, is created based on the desired shape or pattern. This die is then mounted into the cutting machine. Once set up, sheets of material, such as paper, cardboard, or plastic, are fed into the machine. The die is pressed down onto the material, applying significant pressure to cut through it cleanly. This method allows for high precision and can produce intricate designs quickly, making it suitable for various applications in packaging, crafts, and manufacturing. The process is efficient and can be scaled for large production runs.

A variety of materials can be effectively used in die cutting processes. Paper and Cardstock These are the most common materials, widely utilized for creating intricate shapes and designs. Fabrics Various textiles, including cotton, felt, and synthetic options, can be die cut for applications in fashion, upholstery, and crafts. Plastics Materials such as acrylic, polycarbonate, and PVC are suitable for die cutting, allowing for precision in creating components for signage, packaging, and models. Foam Soft and rigid foams can be cut into specified shapes for use in insulation, padding, and crafting. Leather Die cutting can effectively shape leather for fashion and accessory production, ensuring clean edges and consistent designs. These materials highlight the versatility of die cutting across different industries.

Various industries leverage die cutting for their specific needs.

1. Packaging

The packaging industry frequently employs die cutting to create custom shapes and designs for boxes, labels, and inserts. This ensures that products are presented attractively while providing necessary protection.

2. Automotive

In the automotive sector, die cutting is used for fabricating components such as gaskets, seals, and insulation materials. This process allows for precise cuts that meet stringent safety and performance standards.

3. Textiles

Textile manufacturers utilize die cutting to produce patterns and shapes in fabrics. This technique enhances efficiency in garment production and allows for intricate designs not easily achieved by other methods.

4. Electronics

The electronics industry benefits from die cutting for creating parts like insulation layers, adhesive components, and custom enclosures, ensuring that each piece fits perfectly within the device.

5. Printing

In printing, die cutting is essential for producing business cards, invitations, and promotional materials with unique cut shapes, enhancing the visual appeal and effectiveness of marketing materials.

Each of these industries relies on die cutting to improve production efficiency, enhance product design, and meet specific functional requirements.

1. Precision

Die cutting offers exceptional accuracy, allowing manufacturers to create intricate shapes and designs with tight tolerances. This precision minimizes waste and ensures that components fit together perfectly in the final product.

2. Efficiency

The process is highly efficient, enabling rapid production runs. Once a die is created, it can quickly produce large quantities of parts, reducing labor costs and production time compared to manual cutting methods.

3. Versatility

Die cutting can be applied to various materials, including paper, cardboard, plastics, and metals. This versatility makes it suitable for numerous industries, from packaging to automotive, ensuring that manufacturers can meet diverse needs.

4. Cost-Effectiveness

Although there is an initial investment in die creation, the long-term savings on material waste and labor make die cutting a cost-effective solution for large production volumes.

5. Consistency

With die cutting, each piece produced is identical, ensuring uniformity across products. This consistency is crucial for quality control and maintaining brand integrity.

Some interesting questions that has been asked about the results you have just received for Die Cutting

What are related technologies to Die Cutting?

Based on our calculations related technologies to Die Cutting are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

How does ensun find these Die Cutting Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.