The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Midwest Laser Cleaning

Grand Rapids, United States

B

1-10 Employees

2021

Key takeaway

Midwest Laser Cleaning offers advanced laser cleaning technology that effectively restores materials to their original finish by using laser pulses to eliminate contaminants. Their services include removing corrosion and preparing surfaces for welding or finishing.

Reference

Core business

About | Laser Cleaning

Laser Tec - Laser Cleaning

South Oxfordshire, United Kingdom

A

11-50 Employees

2021

Key takeaway

LaserTec offers a variety of nonabrasive laser cleaning systems suitable for multiple industries, highlighting their effectiveness as a safe and environmentally friendly cleaning alternative. They provide both on-site and off-site laser cleaning services, along with training and maintenance, ensuring high-quality solutions for applications like automotive and aerospace cleaning.

Reference

Core business

Laser Tec • Laser Cleaning from UK Leading Professionals

Professional laser cleaning from the UK’s leading service provider. • Cleaning lasers available to rent or buy. • Learn more about cutting-edge technology. →

Laser Clean Ltd

Ōtara-Papatoetoe, New Zealand

A

1-10 Employees

2019

Key takeaway

Laser Clean Ltd specializes in laser cleaning, offering advanced technology that significantly reduces secondary waste without damaging substrates. This innovative solution is applicable across various industries, making it a valuable option for companies looking to enhance their cleaning processes.

Reference

Core business

Laser Cleaning | Laser Clean Ltd – Auckland, New Zealand

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Adapt laser systems

Kansas City, United States

B

1-10 Employees

2003

Key takeaway

The company specializes in advanced laser cleaning systems, providing tailored solutions for various industries such as automotive, welding, and aerospace. Their technology offers a wide range of laser power and includes both handheld and automated units, ensuring effective and damage-free cleaning methods for diverse client needs.

Reference

Core business

cleanLASER - Adapt Laser

Our Partnership With Industry Leader, cleanLASER, Allows Us To Provide Custom Laser Cleaning Solutions To Our Clients. Learn More Here.

Advanced Laser Cleaning

Manchester, United Kingdom

A

1-10 Employees

2022

Key takeaway

Advanced Laser Cleaning specializes in mobile, non-abrasive laser cleaning solutions that effectively remove contaminants and coatings without damaging the substrate. Their technology is particularly beneficial for pre and post-weld cleaning and surface preparation, making it an ideal choice for the engineering and manufacturing industries.

Reference

Core business

Home - Advanced Laser Cleaning

Our laser systems remove contaminants and coatings from various materials. Contact us today to discover the power of advanced laser cleaning.

LaserAge Ltd

Cork, Ireland

A

1-10 Employees

2017

Key takeaway

P-Laser specializes in developing and producing advanced industrial laser cleaning equipment, including the AiMC-1000, designed for both manual and automated applications.

Reference

Product

AiMC-1000 - P Laser UK - Laser Cleaning and Laser Rust Removal Specialists

P-Laser

Heusden-Zolder, Belgium

A

1-10 Employees

1997

Key takeaway

P-Laser is set to launch their QF Outdoor, which may enhance laser performance in challenging environments. They also provide laser cleaning services, including research, consultancy, and on-site cleaning.

Reference

Service

Laser cleaning services | P-Laser

P-Laser offers a variety of services such as research and consultancy, renting and in-house/on-site cleaning.

GYC Laser

Guangzhou City, China

D

51-100 Employees

2009

Key takeaway

The company, GYC Laser, specializes in providing efficient laser solutions, including laser cleaning, cutting, and welding for steel and metal fabrication. With a focus on R&D and manufacturing of industrial laser equipment, they emphasize their expertise in the laser industry.

Reference

Product

LASER CLEANING - The Manufacturer of Fiber Laser Cutting Machine

Lasersonic

Forfar, United Kingdom

A

1-10 Employees

2021

Key takeaway

Lasersonic offers cutting-edge laser cleaning technology, featuring the most powerful laser in the UK, which provides an innovative solution for various industrial cleaning needs.

Reference

Service

Services

The UK's most powerful laser providing an innovative cleaning solution alongside many other industrial services!

Elements Laser Cleaning

Melbourne, Australia

A

11-50 Employees

2018

Key takeaway

Laser Restoration Australia specializes in advanced laser cleaning systems that effectively remove contaminants from various surfaces without causing damage. Their technology is particularly suited for restoring and conserving buildings and monuments affected by fire, water, graffiti, and environmental wear.

Reference

Core business

Laser Conservation | Laser Cleaning | Laser Restoration Australia

Laser systems such as the those use by Laser Restoration Australia are designed and built by specifically for art and architecture conservation and offer unmatched precision, control, and efficiency in non-destructive restoration of historic surfaces.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

SHARK P CL 1000M

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

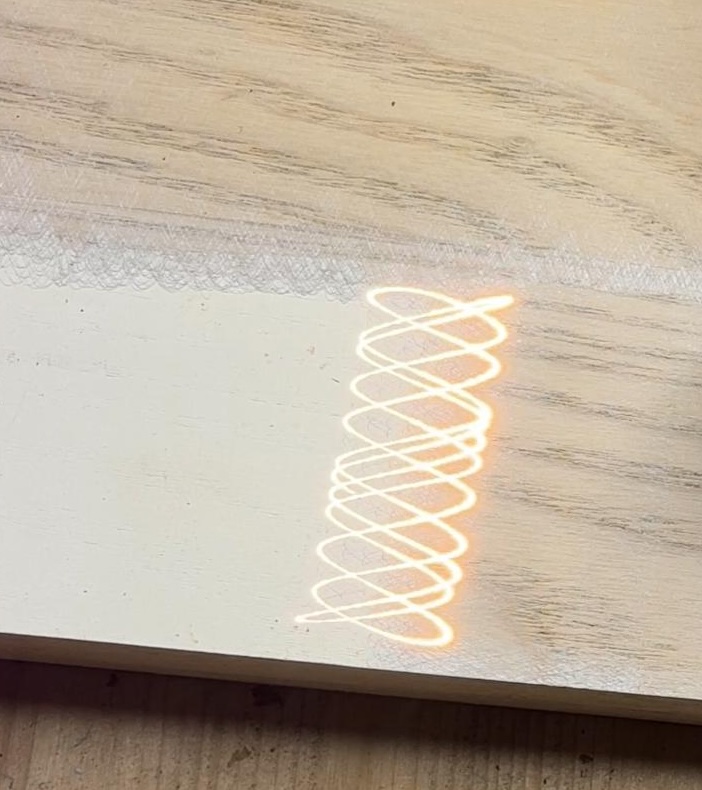

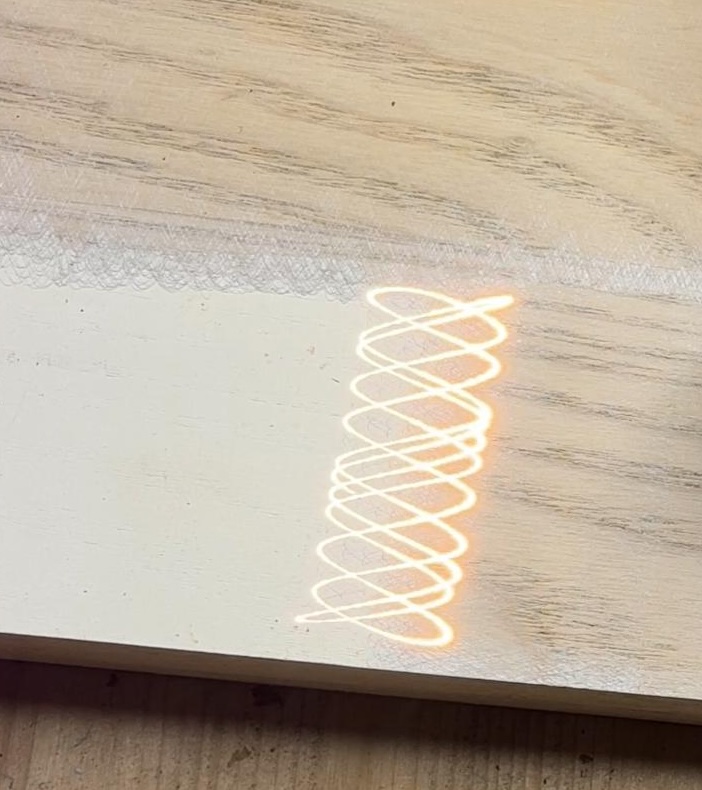

striping paint from wood

restorator

Its gentleness to surfaces makes it an ideal tool for restorers to restore historical and artistic works without risk of damaging the original material. If you need to remove paint from wood, windows or doors, the SHARK is the perfect helper. Laser cleaning uses laser pulses to remove contaminants such as rust, paint, grease, oxides or adhesives without damaging the base material. The dirt absorbs the energy of the laser beam, causing it to evaporate or flake off. The process is non-contact and does not require chemicals or abrasive materials, making it environmentally friendly.

Use case

striping paint from wood

restorator

Its gentleness to surfaces makes it an ideal tool for restorers to restore historical and artistic works without risk of damaging the original material. If you need to remove paint from wood, windows or doors, the SHARK is the perfect helper. Laser cleaning uses laser pulses to remove contaminants such as rust, paint, grease, oxides or adhesives without damaging the base material. The dirt absorbs the energy of the laser beam, causing it to evaporate or flake off. The process is non-contact and does not require chemicals or abrasive materials, making it environmentally friendly.

A Laser Cleaning System utilizes focused laser beams to remove contaminants, rust, and other unwanted materials from surfaces. This advanced technology offers precise control, allowing for effective cleaning without damaging the underlying substrate. Applications range from industrial machinery maintenance to historical artifact preservation, showcasing its versatility and efficiency. The process is environmentally friendly, as it often minimizes the need for chemical solvents and reduces waste.

A Laser Cleaning System operates by using high-intensity laser beams to remove contaminants from surfaces. The technology focuses on directing a concentrated beam of light onto the material that needs cleaning. As the laser energy interacts with the surface, it causes the contaminants—such as rust, paint, or dirt—to absorb the energy and rapidly heat up, leading to their vaporization or disintegration. This process is highly efficient, as it minimizes damage to the underlying substrate while achieving effective cleaning. The system's precision allows for selective removal of materials, making it suitable for various applications across industries, including manufacturing, restoration, and maintenance. The environmentally friendly nature of laser cleaning also reduces the need for chemicals, aligning with sustainable practices.

1. Environmentally Friendly

Laser cleaning systems utilize minimal or no chemicals, making them a sustainable choice for removing contaminants. This reduces environmental impact while ensuring a safer working atmosphere.

2. Precision and Control

These systems offer high precision in targeting specific areas without damaging the underlying material. This level of control enhances the effectiveness of the cleaning process, especially on delicate surfaces.

3. Versatility

Laser cleaning can be applied to various materials, including metals, plastics, and ceramics. This versatility makes it suitable for a wide range of industries, from automotive to aerospace.

4. Reduced Downtime

Since laser cleaning is often faster than traditional methods, it can significantly reduce equipment downtime. This efficiency helps maintain productivity and improve operational schedules.

5. Minimal Waste Generation

The process generates very little waste, as it often converts contaminants into gases or vapors. This characteristic simplifies waste disposal and minimizes cleanup efforts.

Various industries benefit from the use of Laser Cleaning Systems due to their efficiency and precision.

1. Manufacturing

In manufacturing, these systems are used for surface preparation, removing contaminants from parts before coating or assembly. They enhance product quality and extend the lifespan of machinery.

2. Automotive

The automotive industry employs laser cleaning for rust removal and surface preparation on components. This process helps in maintaining the performance and appearance of vehicles.

3. Aerospace

Aerospace companies utilize laser cleaning to maintain critical components and structures. The technology ensures that surfaces are free from debris, which is essential for safety and performance.

4. Marine

In the marine sector, laser cleaning systems are used to remove marine growth and corrosion from ship hulls. This maintenance improves fuel efficiency and prolongs the life of vessels.

5. Restoration

Restoration professionals apply laser cleaning for delicate tasks, such as removing graffiti or cleaning historical artifacts. The precision of laser technology minimizes damage to original surfaces.

Overall, the versatility of Laser Cleaning Systems makes them valuable across a broad range of applications.

When using a laser cleaning system, several safety precautions are essential to ensure the well-being of operators and bystanders. First, personal protective equipment (PPE) is crucial; this includes protective eyewear specifically designed to filter out harmful laser wavelengths, gloves, and flame-resistant clothing. Furthermore, proper ventilation in the working area is necessary to mitigate the accumulation of hazardous fumes and particles that may be released during the cleaning process. Operators should also be trained in laser safety protocols and emergency procedures to respond effectively to any incidents. Lastly, establishing a clear safety perimeter around the laser cleaning area helps prevent unauthorized access and potential accidents.

Some interesting numbers and facts about your company results for Laser Cleaning System

| Country with most fitting companies | United Kingdom |

| Amount of fitting manufacturers | 7423 |

| Amount of suitable service providers | 7967 |

| Average amount of employees | 1-10 |

| Oldest suiting company | 1997 |

| Youngest suiting company | 2022 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Laser Cleaning System

What are related technologies to Laser Cleaning System?

Based on our calculations related technologies to Laser Cleaning System are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Who are Start-Ups in the field of Laser Cleaning System?

Start-Ups who are working in Laser Cleaning System are Midwest Laser Cleaning, Laser Tec - Laser Cleaning, Advanced Laser Cleaning, Lasersonic

Which industries are mostly working on Laser Cleaning System?

The most represented industries which are working in Laser Cleaning System are Other, Machinery Manufacturing, Administration, Manufacturing, Electronics and Electrical engineering

How does ensun find these Laser Cleaning System Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.