The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Materials Testing Equipment Ltd

Penrith, United Kingdom

A

1-10 Employees

1988

Key takeaway

Materials Testing Equipment Ltd is a well-established manufacturer and supplier of laboratory testing equipment, offering a comprehensive range of tools used in quality control across various industries. Their equipment is designed to meet stringent regulations related to waste, pollutants, and emissions, ensuring compliance with the latest standards.

Reference

Core business

Materials Testing Equipment – long established manufacturer and supplier of laboratory testing equipment

HUMBERSIDE MATERIALS LABORATORY LIMITED

United Kingdom

A

1-10 Employees

-

Key takeaway

The materials testing company, established in 1997 and operating from a specialized laboratory in Brigg, North Lincolnshire, offers a comprehensive range of materials testing services. Their focus on high-quality, cost-efficient, and tailored testing solutions makes them a valuable resource in the field of materials testing.

Reference

Service

Materials Testing

Materials Testing Laboratory Site Aggregate Materials Particle Size distribution Density Strength and durability including frost susceptibility and LA Compaction characteristic Sampling Density/compaction Plate bearing Lightweight drop hammer Concrete Materials Testing Cube and core density and stre...

METSS Corporation

Westerville, United States

B

11-50 Employees

1994

Key takeaway

METSS Corporation specializes in materials testing, offering extensive capabilities to evaluate the chemical, physical, and mechanical properties of various materials and industrial fluids. With three decades of experience, the company provides innovative solutions and supports both commercial and military applications.

Reference

Core business

Materials Testing – METSS Corporation

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

www.kiyorndlab.com

Chennai, India

D

11-50 Employees

2000

Key takeaway

KIYO R&D Center & Laboratory is a leading provider of materials testing services, specializing in plastic, rubber, and metals. Their state-of-the-art laboratory offers a wide range of testing services, including tensile, flexural, and thermal testing, ensuring accurate and reliable results for their clients.

Reference

Service

Material Testing Lab in Chennai

Welcome to our world-class material testing laboratory, proudly standing as the best in Chennai. As a trusted hub for testing various materials, we ensure the quality and safety of materials across different industries. Clients choose us for our precision, dedication, and the accuracy we bring to every testing endeavor.

Materials and Testing Laboratories

Waitematā, New Zealand

A

11-50 Employees

1973

Key takeaway

The company, Materials & Testing Laboratories, is an IANZ accredited laboratory that specializes in a wide range of materials testing, including ferrous and non-ferrous metals, welds, and composite materials. With over 45 years of experience, they ensure high standards of quality and compliance, making them a reliable partner for all testing needs in New Zealand and the Pacific region.

Reference

Service

OUR SERVICES – Materials & Testing Laboratories

Materials & Testing Laboratories offers a comprehensive range of mechanical testing, NDT, welding, and metallurgical services.

AMETEK STC

Denmark

A

251-500 Employees

-

Key takeaway

AMETEK Test Instruments specializes in manufacturing instruments for testing various material properties, including tensile strength, compressibility, hardness, elasticity, and adhesion. Their focus on material testing solutions positions them as a key player in this field.

Reference

Product

Material Testing Solutions

Cincinnati Testing Laboratories

Cincinnati, United States

B

101-250 Employees

1948

Key takeaway

The company specializes in materials testing, offering comprehensive evaluations of both metallic and non-metallic materials. Their services include property tests for various mechanical properties, ensuring they meet customer and standard specifications across diverse applications.

Reference

Service

Testing Services

Materials testing at CTL includes evaluation of both metallics and nonmetallics. We conduct property tests in virtually any environment. We test to customer and standard specifications for all types of mechanical properties including tensile, compressive, shear, fatigue, flexural, electrical, peel, impact, and other miscellaneous standards.

Laboratory Testing

East Hertfordshire, United Kingdom

A

101-250 Employees

1984

Key takeaway

Laboratory Testing Inc. is a leading provider of material testing services, offering a comprehensive range of solutions including mechanical testing, metallurgical analysis, chemical testing, and corrosion analysis. With a commitment to quality and fast turnaround times, they serve mission-critical industries and ensure precise results for both R&D and production testing.

Reference

Service

Material Testing Fast Turnaround | Laboratory Testing Inc.

A&A Consultants Inc.

Pittsburgh, United States

B

11-50 Employees

1996

Key takeaway

A&A Consultants offers comprehensive materials testing services for soil, aggregates, asphalt, concrete, and ballast materials. Their experienced staff specializes in various fields of civil engineering, ensuring high-quality testing and analysis.

Reference

Service

Material Testing – A&A Consultants

MTA LABORATORY SDN BHD

Malaysia

C

11-50 Employees

2020

Key takeaway

Material Testing and Analysis Sdn Bhd (MTA) boasts one of the most advanced metallurgical test labs in Malaysia, equipped with the latest technology to offer comprehensive services such as mechanical testing, chemical analysis, and corrosion testing. Their commitment to quality and reliability positions them as a key player in the materials testing industry.

Reference

Core business

MTA LABORATORY SDN BHD – Total Solution Provider Material Testing and Analysis

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

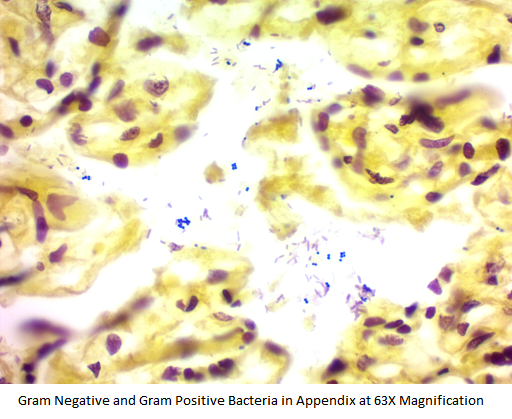

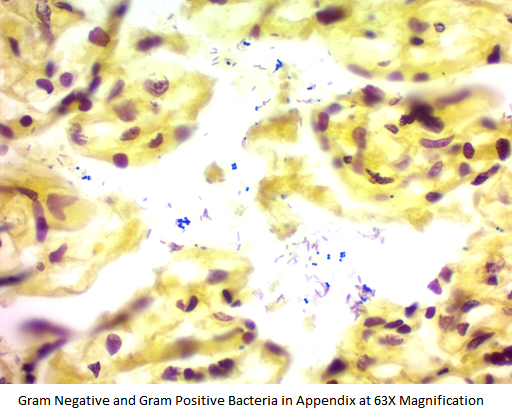

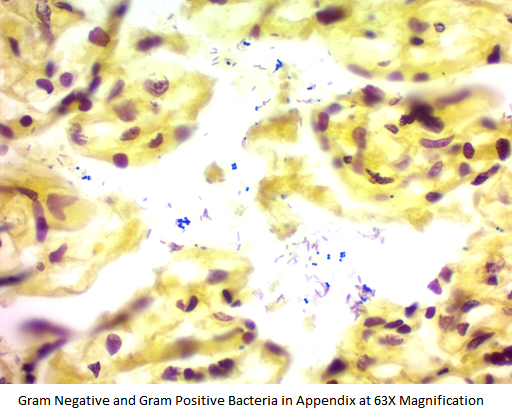

Gram Stain Kit

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Gram Stain Kit

Healthcare, Medical, Biotechnology, Antibodies

Gram Stain Kit - The Gram Stain Kit is intended for the demonstration and differentiation of Gram-positive and Gram-negative bacteria. Gram Positive Bacteria: Blue Gram Negative Bacteria: Red Other Tissue: Yellow Nuclei: Red https://www.scytek.com/products/44.07-BBS-2-Gram-Stain-Kit-(Modified-Brown-and-Brenn).asp Scytek Laboratories Inc- #1 diagnostic reagents: Special Stains, Antibodies, Microbiology ScyTek Biotech Life Sciences manufactures diagnostic reagents, Special Stains, Antibodies, Hematology, Immunohistochemistry, buffers, Microbiology, Hematoxlyn, Gram Stain kit, Methylene Blue Solution, Giemsa Stain kit etc https://www.scytek.com

Use case

Gram Stain Kit

Healthcare, Medical, Biotechnology, Antibodies

Gram Stain Kit - The Gram Stain Kit is intended for the demonstration and differentiation of Gram-positive and Gram-negative bacteria. Gram Positive Bacteria: Blue Gram Negative Bacteria: Red Other Tissue: Yellow Nuclei: Red https://www.scytek.com/products/44.07-BBS-2-Gram-Stain-Kit-(Modified-Brown-and-Brenn).asp Scytek Laboratories Inc- #1 diagnostic reagents: Special Stains, Antibodies, Microbiology ScyTek Biotech Life Sciences manufactures diagnostic reagents, Special Stains, Antibodies, Hematology, Immunohistochemistry, buffers, Microbiology, Hematoxlyn, Gram Stain kit, Methylene Blue Solution, Giemsa Stain kit etc https://www.scytek.com

Materials testing refers to the process of evaluating the physical, mechanical, and chemical properties of materials to ensure they meet specific standards and requirements for various applications. This testing is crucial in industries such as construction, manufacturing, and aerospace, where material performance can significantly impact safety and functionality. Through various techniques such as tensile testing, hardness testing, and fatigue testing, professionals assess how materials respond under different conditions. The results inform engineers and designers about the suitability and durability of materials for specific uses, thereby enabling informed decision-making and enhancing product quality.

Materials Testing plays a crucial role in product development by ensuring that materials meet specific performance criteria and safety standards. It helps identify the mechanical properties, chemical composition, and durability of materials, which is essential for predicting how a product will perform under various conditions. By conducting thorough testing, developers can make informed decisions about material selection, reduce the risk of product failure, and improve overall quality. This process enhances reliability, meets regulatory requirements, and ultimately contributes to customer satisfaction by delivering safer and more effective products.

1. Tensile Testing

This method measures the strength and ductility of materials by applying a uniaxial force until the material deforms or breaks. It helps in determining the yield strength, ultimate tensile strength, and elongation of the material.

2. Hardness Testing

Hardness testing evaluates a material's resistance to deformation. Common techniques include Rockwell, Brinell, and Vickers hardness tests, each providing insights into the material's durability and wear resistance.

3. Impact Testing

Impact testing assesses a material's toughness by measuring its ability to absorb energy during fracture. Charpy and Izod tests are widely used to evaluate the material's performance under sudden loads.

4. Fatigue Testing

This method examines a material's behavior under cyclic loading conditions. It helps identify the fatigue limit and the number of cycles a material can endure before failure, crucial for components subjected to repetitive stress.

5. Metallographic Testing

Metallographic testing involves microscopic examination of materials to assess their microstructure. This includes examining grain size, phase distribution, and any defects, providing valuable information on the material's properties and performance.

Materials testing plays a crucial role in maintaining quality control within the manufacturing sector. By evaluating the properties of materials used in production, it ensures that they meet specified standards and performance criteria. Testing methods, such as tensile, compressive, and fatigue tests, provide data on strength, durability, and flexibility, which are essential for determining whether materials are suitable for their intended applications. Furthermore, consistent materials testing identifies defects or inconsistencies early in the manufacturing process. This proactive approach allows manufacturers to adjust their processes or materials before producing final products, ultimately reducing waste and improving overall product quality. Regular testing also helps in compliance with industry regulations and standards, affirming that the materials used are safe and effective for consumer use.

1. Construction

The construction industry relies heavily on materials testing to ensure the strength and durability of various building materials. Testing concrete, steel, and other components helps prevent structural failures and ensures compliance with safety regulations.

2. Aerospace

Aerospace manufacturers benefit from materials testing to assess the performance and reliability of materials used in aircraft and spacecraft. Rigorous testing ensures that components can withstand extreme conditions, enhancing safety and performance.

3. Automotive

In the automotive sector, materials testing is crucial for evaluating the durability, safety, and performance of vehicle components. This testing helps manufacturers meet stringent regulatory requirements and improve vehicle design.

4. Manufacturing

Manufacturers across various sectors utilize materials testing to optimize production processes and improve product quality. Understanding material properties can lead to enhanced efficiency and reduced waste.

5. Electronics

The electronics industry benefits from materials testing to ensure that components can withstand thermal and mechanical stresses. This testing is vital for the reliability and longevity of electronic devices.

Some interesting numbers and facts about your company results for Materials Testing

| Country with most fitting companies | United Kingdom |

| Amount of fitting manufacturers | 8312 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1948 |

| Youngest suiting company | 2020 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Materials Testing

What are related technologies to Materials Testing?

Based on our calculations related technologies to Materials Testing are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Materials Testing?

The most represented industries which are working in Materials Testing are Other, Manufacturing, Construction, IT, Software and Services, Oil, Energy and Gas

How does ensun find these Materials Testing Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.