The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Metal Cutting

Cedar Grove, United States

B

11-50 Employees

1967

Key takeaway

The company specializes in precision metal cutting, highlighting its expertise in burr-free abrasive cut-off and related processes. With a focus on meeting tight tolerance requirements, they serve various industries, ensuring high-speed and high-volume cutting capabilities.

Reference

Service

Precision Metal Cutting Services

Metal Cutting provides unmatched abrasive and EDM precision metal cutting services with high speed capability, high volume capacity and burr-free results.

Laser Cutting Services

Houston, United States

B

51-100 Employees

1985

Key takeaway

The company specializes in high-quality metal cutting services, including flame cutting, high definition plasma cutting, laser cutting, and waterjet cutting.

Reference

Service

Services - Source Metals

Cutting Services Value Added Services

Messer Cutting Systems GmbH

-

251-500 Employees

1993

Key takeaway

Messer Cutting Systems is a global supplier of advanced cutting solutions for the metal-working industry, offering a range of technologies including oxyfuel, plasma, and laser cutting systems. Their commitment to innovation and collaboration with technology partners ensures they provide reliable and efficient cutting solutions tailored to specific needs.

Reference

Product

Cutting Processes

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Allset Engineering Pty Ltd

Sydney, Australia

A

51-100 Employees

-

Key takeaway

Allset Engineering offers a comprehensive range of services, including metal cutting, machining, and fabrication, supported by a fully equipped workshop capable of various cutting techniques. With 25 years of experience in the manufacturing and food production industry, Allset is well-equipped to meet diverse client needs.

Reference

Service

Metal Cutting – Allset Engineering

Metal Cutting Specialists

Houston, United States

B

11-50 Employees

1979

Key takeaway

Metal Cutting Specialists is a custom saw shop that specializes in the parting and sectioning of large and complex machined forgings and parts. They have expanded their services to include a full beam line for structural processing and pipe and tube profiling, emphasizing high volume and close tolerances.

Reference

Core business

MCS – Metal Cutting Specialists

Centro-Metalcut a Quantum Design product line

Caledonia, United States

B

11-50 Employees

-

Key takeaway

Centro-Metalcut is a globally recognized leader in the design and manufacturing of high-quality cutting and grinding equipment, making it highly relevant to the metal cutting industry. Their innovative machines are widely used in steel mills around the world, enhancing productivity and ensuring worker safety through advanced programming and remote operation capabilities.

Reference

Service

services | Centro Metalcut

Recognized internationally, Centro-Metalcut is an industry innovator in the design and manufacturing of the highest quality cutting and grinding equipment.

Cutorama

Waynesboro, United States

B

1-10 Employees

2021

Key takeaway

Cutorama specializes in material cutting services, utilizing advanced CNC machinery to offer a variety of cutting methods including routing, 2D and 3D milling, engraving, and rotational cutting. Their IIoT-enabled custom-built machinery also provides valuable metrics for enhanced milling processes.

Reference

Core business

Cutorama - Industry 4.0 / Manufacturing 4.0 CNC Cutting Services - Milling + Data

Quality Laser Inc.

Woburn, United States

B

11-50 Employees

-

Key takeaway

The company offers advanced metal cutting services, including laser cutting with a high-powered Amada Laser cutter and water jet cutting, ensuring precision and quality for various materials. They cater to diverse needs, from custom parts to full-scale production.

Reference

Core business

Quality Laser Cutting - Metal Laser Cutting - Water Jet Cutting

We provide both metal laser cutting and water jet cutting along with full metal fabrication and welding services to all customers.

Clear Cut Metal Works Inc

Calgary, Canada

A

1-10 Employees

2007

Key takeaway

Clear Cut Metal Works Inc specializes in precision metal cutting, offering custom waterjet and CNC cutting services for a variety of materials.

Reference

Core business

Custom Waterjet Metal Cutting | Clear Cut Metal Works Inc | Calgary

Clear Cut Metal Works Inc - Custom Waterjet Cutting in Calgary. Industrial and creative metal CNC cutting and fabrication. Your design, on time. Mild steel, aluminum, stainless steel, titanium, granite, marble, tile, glass, composites, rubber, plastic, mirror.

Cutters Fabrication Solutions

Tempe, United States

B

11-50 Employees

-

Key takeaway

Cutters Fab specializes in the design and production of high-quality metal products, offering services such as laser cutting and metal fabrication, which are essential for metal cutting projects. Their experienced team is equipped to handle both simple repairs and large orders, ensuring precision and innovation in every project.

Reference

Core business

HOME | Cutters Fabrication

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

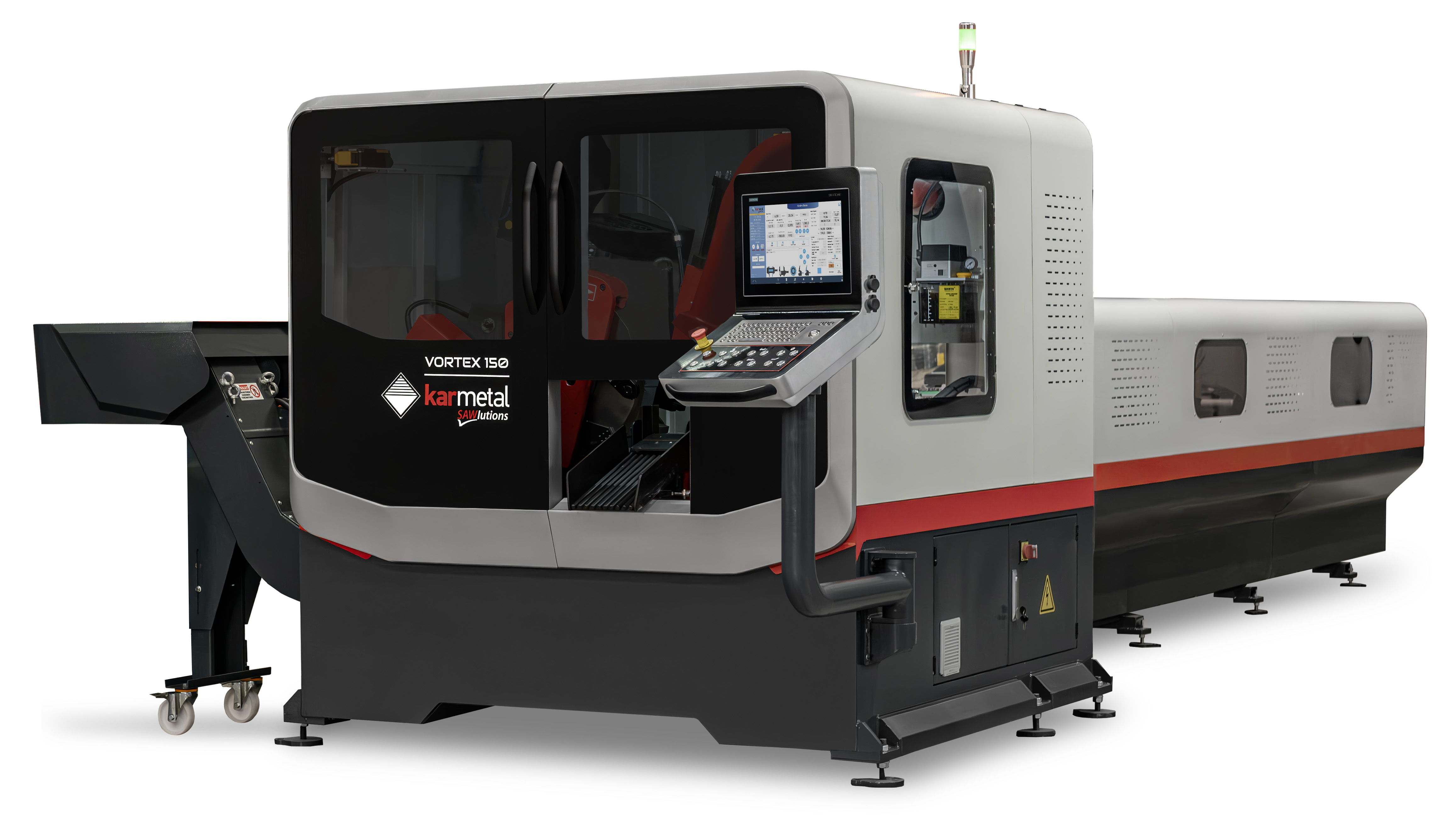

VORTEX 150

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Autonomous Circular Saw Machine

Automative, Steel, Metal, Cutting, Steel Trader, Forging

VORTEX 150 is a high-performance autonomous circular sawing machine. Considering user safety and comfort, it has been designed with ergonomic details and technical solutions. Its dynamic and innovative design represents high speed and flawless cutting technology. VORTEX 150 has an industrial computer with a 15,6” display that can be connected via LAN and Wi-Fi. Thanks to the Intelligent Sawing System (IPS), sawing can be performed in 6 different performance modes (Normal, Ultra, High Performance, Blade Saving, Turtle and Custom). VORTEX 150 can be operated in manual, automatic and intelligent sawing modes. The intelligent sawing system has a library consisting of 13.000 different material types categorized in 6 different standards. Vortex 150 is capable of adjusting all the parameters automatically by itself according to the material type-size, heat treatment, blade type and TPI. Linear guides ensure precise cutting capability. In addition, minimizing the vibration, the body with the special mineral casting provides perfect cutting. High torque main motor prevents torque loss under low or high frequency. VORTEX 150 provides a unique speed experience to its users.

Use case

Autonomous Circular Saw Machine

Automative, Steel, Metal, Cutting, Steel Trader, Forging

VORTEX 150 is a high-performance autonomous circular sawing machine. Considering user safety and comfort, it has been designed with ergonomic details and technical solutions. Its dynamic and innovative design represents high speed and flawless cutting technology. VORTEX 150 has an industrial computer with a 15,6” display that can be connected via LAN and Wi-Fi. Thanks to the Intelligent Sawing System (IPS), sawing can be performed in 6 different performance modes (Normal, Ultra, High Performance, Blade Saving, Turtle and Custom). VORTEX 150 can be operated in manual, automatic and intelligent sawing modes. The intelligent sawing system has a library consisting of 13.000 different material types categorized in 6 different standards. Vortex 150 is capable of adjusting all the parameters automatically by itself according to the material type-size, heat treatment, blade type and TPI. Linear guides ensure precise cutting capability. In addition, minimizing the vibration, the body with the special mineral casting provides perfect cutting. High torque main motor prevents torque loss under low or high frequency. VORTEX 150 provides a unique speed experience to its users.

Metal cutting refers to the process of removing material from a metal workpiece to achieve desired shapes and dimensions. This process is essential in manufacturing and fabrication industries, where precision and accuracy are critical. Various techniques are employed in metal cutting, including turning, milling, drilling, and grinding. These methods utilize specialized tools and machinery, such as lathes and CNC machines, to ensure efficient and effective material removal. The choice of technique often depends on the type of metal, the complexity of the part, and the required tolerances. Proper selection of cutting tools and parameters can significantly influence the quality of the finished product.

1. Mechanical Cutting

This method involves using tools such as saws, lathes, and milling machines to physically remove material from the metal. It is widely used due to its versatility and precision, making it suitable for various shapes and sizes.

2. Thermal Cutting

Thermal cutting utilizes heat to melt or burn through metal. Techniques like laser cutting, plasma cutting, and oxy-fuel cutting fall under this category. These methods are effective for intricate designs and thicker materials.

3. Abrasive Cutting

This approach employs abrasive materials, such as grinding wheels, to remove metal. It is particularly useful for achieving fine finishes and is often used in situations where precision is paramount.

4. Chemical Cutting

Chemical methods involve using corrosive substances to dissolve metal. This technique is less common but can be advantageous for specific applications where traditional cutting methods are not feasible.

5. Electrical Discharge Cutting

Also known as EDM (Electrical Discharge Machining), this method uses electrical discharges to remove material. It is ideal for hard metals and complex shapes, offering high precision and control.

Metal cutting technology significantly enhances production efficiency by optimizing the machining process. Advanced methods, such as laser cutting and CNC machining, allow for precise and rapid material removal, which reduces waste and minimizes production time. Moreover, the integration of automation and computer-aided design (CAD) systems streamlines workflows, ensuring that components are produced with high accuracy and consistency. This not only leads to faster turnaround times but also improves overall product quality, reducing the need for rework and increasing throughput in manufacturing environments.

In metal cutting processes, various materials are commonly utilized to achieve effective and precise results. High-Speed Steel (HSS) is frequently used due to its excellent wear resistance and ability to retain hardness at elevated temperatures, making it ideal for cutting tools. Another prevalent material is Carbide, known for its hardness and durability. Carbide tools can withstand high cutting speeds and temperatures, which significantly enhances their performance in metal cutting applications. Additionally, Cermet, a composite of ceramic and metal, is also employed for its superior wear resistance and ability to maintain cutting edge integrity. These materials contribute to the efficiency and effectiveness of metal cutting operations across various industries.

In metal cutting operations, safety considerations are paramount to prevent injuries and ensure a safe working environment. First, personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection should always be worn to safeguard against flying debris and loud machinery. Additionally, machine maintenance and inspections are crucial. Regular checks help identify any potential hazards, such as worn parts or improper alignment, that could lead to accidents. It's also essential to maintain a clean workspace to minimize tripping hazards and ensure that emergency exits are accessible. Proper training for operators on the correct use of cutting tools and machinery is vital to promote safety and reduce the risk of accidents.

Some interesting numbers and facts about your company results for Metal Cutting

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 7122 |

| Amount of suitable service providers | 9621 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1967 |

| Youngest suiting company | 2021 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Metal Cutting

What are related technologies to Metal Cutting?

Based on our calculations related technologies to Metal Cutting are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Who are Start-Ups in the field of Metal Cutting?

Start-Ups who are working in Metal Cutting are Cutorama

Which industries are mostly working on Metal Cutting?

The most represented industries which are working in Metal Cutting are Machinery Manufacturing, Other, Manufacturing, Mining, Construction

How does ensun find these Metal Cutting Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.