The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

cellgo.io

Paderborn, Germany

A

11-50 Employees

2020

Key takeaway

Cellgo revolutionizes warehouse automation by providing a straightforward and adaptable automated storage system specifically designed for small and medium-sized businesses. Their innovative technology and customizable software enhance efficiency and scalability, making it an ideal solution for evolving storage needs.

Reference

Product

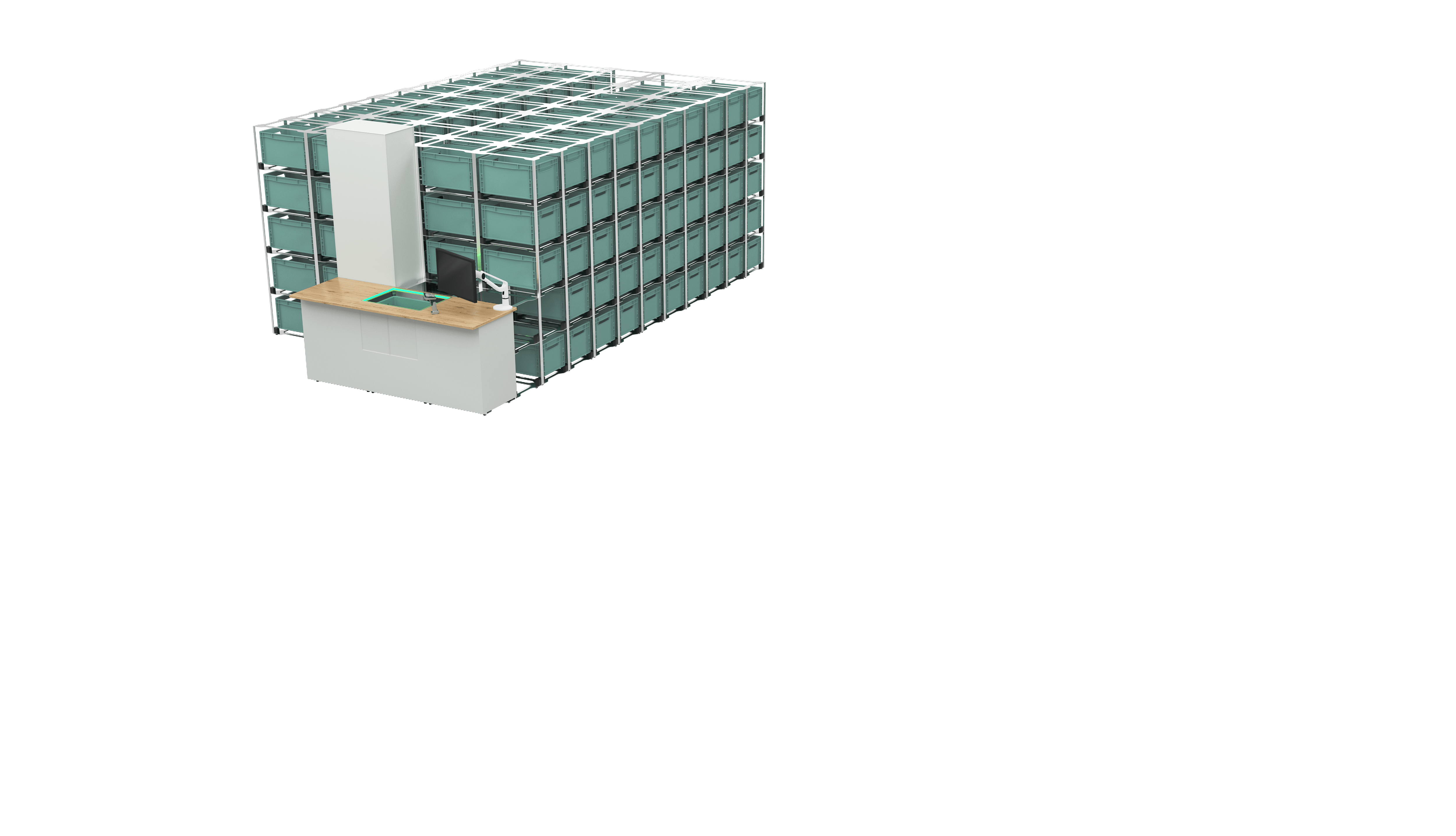

Cellgo automated warehouse

Modular automated warehouse - efficient warehouse automation Cellgo's modular automated storage system offers all-in-one technology for the automated storage of small parts. The intelligent miniload system enables a profitable, scalable solution - from small applications to large sites with individual requirements. Small and medium-sized companies in particular benefit from Cellgo's automation solution. Designed for Euronorm containers, intelligent underride robots transport the goods efficiently to the station. The compact design enables a storage density of up to 50 containers per m², even with low ceiling heights. The integrated plug & play solution enables seamless connection to online stores and marketplaces, allowing direct sales to be set up quickly. The warehouse management system can also be easily integrated into existing systems. The multi-order picking process increases picking efficiency. The low initial investment enables decentralized warehousing in city centres. Warehouse service providers and production companies benefit from the simple scalability: expansions, seasonal increases in throughput or adjustments to the production layout can be implemented in just a few days. Our software provides real-time analyses to optimize workflows, inventory monitoring and material flow control - for maximum efficiency and reduced operating costs.

Boxtronic GmbH

Putzbrunn, Germany

A

1-10 Employees

-

Key takeaway

Boxtronic offers innovative solutions to automate self-storage businesses, including online booking, sensor technology, and digital locks, enabling facilities to operate with little to no staffing. Their products and automation software are designed to streamline processes and enhance security.

Reference

Core business

Make Self Storage Smart | Boxtronic

Boxtronic makes products for Self Storage operators. Electronic locks, sensors, branch automation, online booking and automated access technology.

WAKU Robotics

Berlin, Germany

A

1-10 Employees

2019

Key takeaway

WAKU Robotics GmbH offers a specialized software solution, WAKU Care, that enhances the maintenance and management of AGV and AMR fleets, making it highly relevant for warehouse automation. Their expertise in integrating mobile robots into intralogistics processes, along with capabilities for ROI and productivity calculations, supports businesses in optimizing their robotic operations.

Reference

Product

AGV, AMR integrated with WCS, WMS, ERP - WAKU Robotics

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Fori Automation GmbH

Merzig, Germany

A

11-50 Employees

2005

Key takeaway

The company specializes in automated material handling systems, including Automated Guided Vehicles and Carts, which are essential for efficient warehouse automation. Their expertise extends to turnkey assembly and automation solutions for both the automotive and non-automotive industries.

Reference

Product

Automated Material Handling

HandlingTech Automations-Systeme GmbH

Steinenbronn, Germany

A

51-100 Employees

1994

Key takeaway

HandlingTech specializes in developing and implementing modular automation systems around industrial robots, enhancing warehouse efficiency and reducing costs. Their unique design approach and commitment to innovation ensure tailored solutions that boost output and relieve employee workloads.

Reference

Product

leanZ

LeanZ makes automation easy for you. The aim is to combine broad applicability and intuitive handling in an economical way. To achieve this, we rely on many innovative technologies and approaches - from the offer to operation and service. Despite the compact format of a Euro pallet, the leanZ has a lot to offer. In addition to the modular hardware, which can be expanded in many ways without adjusting the solid base, the cell is particularly impressive due to its simple operating concept. With the wireless touch panel and the intuitive hand guidance of the robot, you can quickly create your own processes for a wide variety of applications.

vorausrobotik.com

Hanover, Germany

A

11-50 Employees

2022

Key takeaway

The company specializes in enabling autonomous automation through the integration of advanced technologies like robots and AI, which is highly relevant to warehouse automation. Their middleware software enhances operational efficiency in a vendor-neutral environment, making it easier for companies to adopt innovative automation solutions.

Reference

Product

voraus.core

With the voraus.core manufacturers, integrators, and end users can easily create and execute solutions for all applications and optimize their entire automation. Operate effortlessly with a nocode interface and no restrictions. The voraus.core is the middleware that enables building a modern automation stack. Through its open API (OPC UA and Python) it ensures flexible expansion of devices and functionality from driver level to the top interface level. The latter allows the voraus.core to be connected to higher-level platforms such as graphical user interfaces like the voraus.operator, ERP, or cloud services. This unique, hardware agnostic platform facilitates modern software development, testing and deployment, and fast software update cycles. The voraus.core provides all the necessary resources to future-proof your automation solution with a high level of efficiency.

ProLog Automation GmbH & Co. KG

Freiberg am Neckar, Germany

A

51-100 Employees

2015

Key takeaway

ProLog Automation provides independent expertise in mobile robotics, offering services that include logistics concept validation and project planning for automated guided vehicles (AGVs). Their comprehensive support ensures both users and manufacturers can effectively implement and maintain warehouse automation solutions.

Reference

Service

AGV Maintenance/UVV-Inspection

You are an AGV manufacturer and have ongoing service contracts with your customers in Germany or worldwide? You want to deliver the best possible support to your customers, but you lack capacity? Or are you an operator of your own plant and need support with service issues at short notice? Then you will find the necessary capacities and know-how with us! ProLog Automation keeps your plant highly available and safe.

WITRON Group

Parkstein, Germany

A

1001-5000 Employees

1971

Key takeaway

WITRON specializes in the control and production of conveyor and warehousing systems, ensuring the efficient flow of goods and improving the availability of essential groceries. This focus on automated logistics highlights their commitment to enhancing supply chain operations.

Reference

Core business

WITRON: Your career in automated logistics

Solid 3D

Gelsenkirchen, Germany

A

11-50 Employees

-

Key takeaway

Solid-3D is dedicated to accelerating the transition to automated warehouses and manufacturing facilities through its advanced robotic solutions. Their flagship product, the Mark.One Robotic platform, enhances warehouse automation with high-precision positioning and AI-driven operations.

Reference

Core business

SOLID 3D – ACCELERATING THE TRANSITION TO AUTOMATED WAREHOUSES

inconso

Bad Nauheim, Germany

A

501-1000 Employees

-

Key takeaway

Inconso provides innovative software solutions designed to optimize supply chain and warehouse management processes. Their cloud solutions and system integration services enhance the efficiency and scalability of logistics operations.

Reference

Product

Warehouse Management

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Cellgo automated warehouse

Go to product

Product

Cellgo warehouse lift

Go to product

Product

Automated Warehouse

Go to product

Product

Pallet Shuttle

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Talleys

Food, Beverage

Working with our Italian partner Automha and local Racking Partner StorePro, PHS Innovate’s scope included all the racking, automation equipment and conveyors in and surrounding the Cool store. The system scans wrapped and labelled pallets and communicates with Talley’s inventory system to retrieve details for the pallet. The system then stores the pallets in rack locations based on Batch and date for optimised future retrieval. When a truck or container load is needed, Talley’s inventory system communicates with our automated handling system to request specific pallets. Our solution then retrieves and delivers the requested pallets to a designated area for the forklift driver to load into the truck or container.

Use case

Talleys

Food, Beverage

Working with our Italian partner Automha and local Racking Partner StorePro, PHS Innovate’s scope included all the racking, automation equipment and conveyors in and surrounding the Cool store. The system scans wrapped and labelled pallets and communicates with Talley’s inventory system to retrieve details for the pallet. The system then stores the pallets in rack locations based on Batch and date for optimised future retrieval. When a truck or container load is needed, Talley’s inventory system communicates with our automated handling system to request specific pallets. Our solution then retrieves and delivers the requested pallets to a designated area for the forklift driver to load into the truck or container.

When exploring the Warehouse Automation industry in Germany, several key factors are important to consider. Germany is a leader in logistics and automation technology, driven by its robust manufacturing sector and strong emphasis on efficiency. Regulatory compliance is essential, as companies must adhere to strict EU standards on safety, labor, and environmental impact. The challenges faced in this sector include high initial investments and the need for continuous technological upgrades to keep pace with rapid advancements. Nevertheless, there are significant opportunities, particularly with the increasing demand for e-commerce and the shift toward Industry 4.0, which prioritizes smart automation solutions. Environmental concerns are also pivotal, as companies are increasingly focusing on sustainability and reducing carbon footprints in their operations. In terms of the competitive landscape, Germany hosts numerous established players, which can make market entry challenging for newcomers. However, the global relevance of the German market cannot be overlooked, as it serves as a gateway to the European market and is influential in shaping automation trends worldwide. Understanding these dynamics is crucial for anyone interested in investing or working in warehouse automation in Germany, ensuring informed decision-making and strategic planning.

Some interesting numbers and facts about your company results for Warehouse Automation

| Country with most fitting companies | Germany |

| Amount of fitting manufacturers | 952 |

| Amount of suitable service providers | 915 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1971 |

| Youngest suiting company | 2022 |

Some interesting questions that has been asked about the results you have just received for Warehouse Automation

What are related technologies to Warehouse Automation?

Based on our calculations related technologies to Warehouse Automation are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Who are Start-Ups in the field of Warehouse Automation?

Start-Ups who are working in Warehouse Automation are vorausrobotik.com

Which industries are mostly working on Warehouse Automation?

The most represented industries which are working in Warehouse Automation are Other, IT, Software and Services, Logistics, Supply Chain and Transportation, Automation, Machinery Manufacturing

How does ensun find these Warehouse Automation Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.