The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Iom Technology Co., Ltd.

Shizuoka, Japan

A

11-50 Employees

2001

Key takeaway

The company, iO MOLD TECHNOLOGY, specializes in the comprehensive technology of plastic mold development and manufacturing, which includes expertise in blow molding processes. They offer a unified management approach that ensures high quality, cost reduction, and stable production for both Japan-made and global products.

Reference

Core business

iO MOLD TECHNOLOGY アイオー モールド テクノロジー

iO MOLD TECHNOLOGY / アイオー モールド テクノロジーです。「射出成形プラスチック金型の総合技術事業」です。◎金型設計・製作一式 ◎設計関連(製品生技性検討生産設計(製品DR)、型設計の単独の設計関連、CAE流動詳細解析等) ◎型改造・型修正(メンテ)・単品部品加工等、金型関連開発の上流から下流まで全般的にて技術的に対応可能です。

甲賀高分子(株)

Konan, Japan

A

51-100 Employees

-

Key takeaway

Koka Polymer Co., Ltd. is a manufacturer of hard and soft polymer materials.

Reference

Core business

BCP | 甲賀高分子株式会社

NAGASE PLASTICS CO., LTD.

Hirakata, Japan

A

51-100 Employees

1975

Key takeaway

The company, Nagase Plastics Corporation, likely engages in the plastics industry, which may include processes like blow molding.

Reference

Core business

主な仕入先 | 企業情報 | ナガセプラスチックス株式会社

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

micro-AMS

Kawasaki, Japan

A

- Employees

2018

Key takeaway

micro-AMS Inc. is focused on revolutionizing thermoplastic resin molding through innovative techniques like "Photon Molding."

Reference

Core business

樹脂成形の光成形機器開発販売|株式会社micro-AMS

JSP

Tokyo, Japan

A

- Employees

-

Key takeaway

The company, JSP, produces ARPRO material, a leading expanded polypropylene (EPP) foam that can be molded into various shapes, making it suitable for blow molding applications. With its unique properties, including energy absorption, structural strength, and recyclability, ARPRO is ideal for innovative prototyping in sectors like construction and packaging.

Reference

Product

Moulding for industrial parts, packaging & more - ARPRO

Wavelock Advanced Technology Co.Ltd.

Osaka, Japan

A

1-10 Employees

-

Key takeaway

The company, Wavelock Advanced Technology, highlights its expertise in shaping composite materials, which is relevant to blow molding processes.

Reference

Product

成形 - 株式会社ウェーブロック・アドバンスト・テクノロジー

当社の金属調フィルムを使用した代表的な成形方法はこちらです フィルムインサート フィルムインサート工法説明 O

GREENMAX RECYCLING

Tokyo, Japan

A

51-100 Employees

2010

Key takeaway

INTCO Recycling提供しました。

Reference

Core business

発泡スチロール減容溶解機の製造企業の会社概要|Greenmax溶融減容機器

MARU HACHI Corporation

Sakai, Japan

A

11-50 Employees

1936

Key takeaway

MaruHachi Group, a developer and manufacturer of composite materials, has diversified into the thermoplastic composites sector, offering products that can be utilized in advanced manufacturing processes. Their expertise in high-performance materials positions them as a key player in the innovative landscape of thermoplastic applications.

Reference

Core business

MaruHachi – Thermoplastic Composite Material Systems

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Full electric type Extrusion Blow Molding Manchine JD Series

Go to product

Product

Automatic type Extrusion Blow Molding Manchine JN Series

Go to product

Product

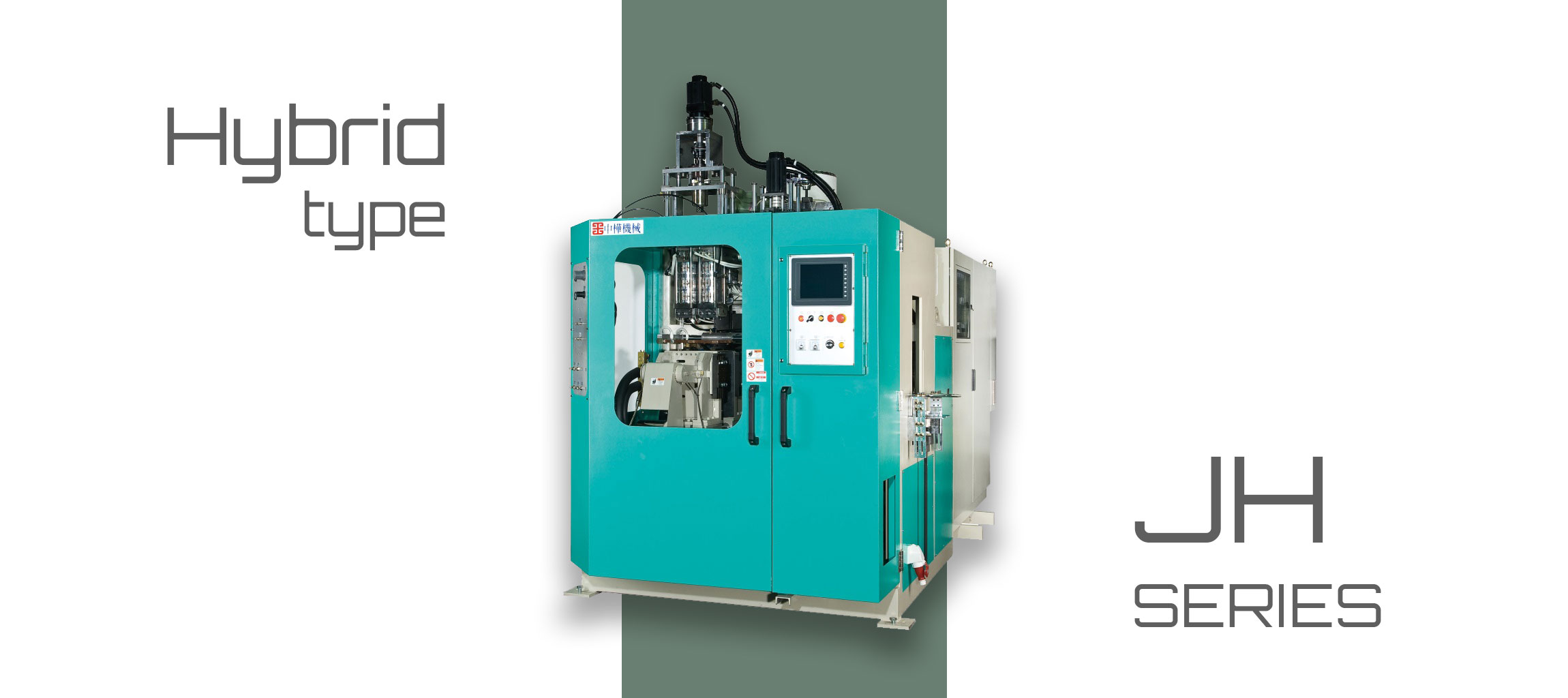

Hybrid type Extrusion Blow Molding Manchine

Go to product

Product

Basic type Extrusion Blow Molding Manchine - JS Series

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Bottles

Automobile, Cosmetic, Medical products, Daily cleanser, Beverage, Food, Industry, Automotive

In the beginning, the customer came to Jonh Huah referred by a other company. This customer is a multinational corporation who is supplying the bellow/dust cover and its serial products to a variety brands of automobile makers in Korea, Japan, India and US who impose critical request for the products based on endurable and safety concern. Regarding this project, the challenges including below: TPE melting index is very fast, not easy to control the precision of parison / wall thickness. (CPK) of the long product. The CPK requirements on product thickness in every area of product body is very strict. Auto deflash Top and bottom scrap auto deflash. To meet the all above high quality request, we make new design by modifying JS-550E and integration of drying system and gravimetric dosing system for the TPE material which requires special treatment in process. It is accumulator type and very high speed and high precision injection design is adopted to assure the quick injection for the parison. Eventually, Jonh Huah has built up a new Extrusion Blow Molding Machine design which is completely meet the customer’s requirements. And now the machines are promoting to North America (US, Canada and Mexico) and India.

Use case

Peru - Engine oil / Lubrication oil bottle

Automotive, oil, Engine oil , Lubrication oil, Cosmetic, Medical, cleanser, Food, Beverage, Industry, automotive

The customer has great reputation in engine oil industry of Peru who wants to make a new serial bottle family and the customer requests fully automated production. As such, we propose the blow molding machine integrated the needful accessories which including material feeding and conveying, crushing, material recycle, take out robot, finished bottle collection and conveying and Leak Detector…etc. The features of blow molding machine with automated integration system include. Labor cost less Product quality assurance Power saving Eventually, the customer is satisfied with the performance of Jonh Huah machine which is completely meet the their’s requirements. Both the automation and power saving design could make the customer’s quick payback on the investment, a strong competitive edge for the customer to keep its leading position in Peru county. With the success of this project, customer continues to buy two more similar automation systems in three consecutive years.

Use case

Taiwan - High value-added food packaging

Food, Medical products, Cosmetic, Daily cleanser, Automotive, Industry, Beverage

The customer is the large-scale packaging film manufacturer in the south of Taiwan specializes in a variety of high value-added food packaging. Since 2012, they have developed a close partnership with JOHN HUAH. JOHN HUAH has won the appreciation and recognition of Taiwan's index packaging film manufacturers for our solid and powerful machine appearance structure design, simple and flexible humanized control interface and energy-efficient integration of core units. Through close technical exchanges and positive interaction between the two parties, JOHN HUAH has built a number of simple and efficient Extrusion Blow Molding Machine for this customer, which has been well received with continuous and stable mass production. Our automation design bring the customer a full automatic production from blowing process to leak testing and labeling process. “It is just like the fully automatic money printing machine” said the customer. JONH HUAH will continue to focus on the concept of “Made Simple”, listening to customers' needs, aiming at providing customers with the most efficient solutions and integrating the most advanced technology to satisfy customers. The value of the brand “JONH HUAH” will be deeply rooted in every customer.

Use case

Korea - Automobile dust cover - Specialized

Automobile, Cosmetic, cleanser, Food , Beverage, Medical , Industry

In the beginning, the customer came to Jonh Huah referred by a other company. This customer is a multinational corporation who is supplying the bellow/dust cover and its serial products to a variety brands of automobile makers in Korea, Japan, India and US who impose critical request for the products based on endurable and safety concern. Regarding this project, the challenges including below: TPE melting index is very fast, not easy to control the precision of parison / wall thickness. (CPK) of the long product. The CPK requirements on product thickness in every area of product body is very strict. Auto deflash Top and bottom scrap auto deflash. To meet the all above high quality request, we make new design by modifying JS-550E and integration of drying system and gravimetric dosing system for the TPE material which requires special treatment in process. It is accumulator type and very high speed and high precision injection design is adopted to assure the quick injection for the parison. Eventually, Jonh Huah has built up a new Extrusion Blow Molding Machine design which is completely meet the customer’s requirements. And now the machines are promoting to North America (US, Canada and Mexico) and India.

Use case

Madagascar - 20L Jerrycan for Cooking oil

Industry, Automotive, Beverage, tank, jerrycan

Owning up to 10 set of Jonh Huah’s accumulator type Extrusion Blow Molding Machine, the customer produces and supplies the necessities of cooking oil over the Madagascar in Africa. With business booming year by year, the customer consistently purchase machine from Jonh Huah and gives high credit to Jonh Huah’s outstanding machine on its quality, durability, and the after sales service Jonh Huah provide. ‘’Thanks to Jonh Huah’s blow molding solution, the container stay firm without damage or leaking during the long-distance delivery.’’ The distance between customer’s factory to the dealer sometimes last more than thousands of miles, by passing curvy mountain road with bad traffic condition, and most of the time it damage half amount of the container during the delivery, not until they have met Jonh Huah, Jonh Huah have changed their container design as well as the artistic of blow molding. It is always happy to see customer booming business after using Jonh Huah’s Extrusion Blow Molding Machine.

Use case

Madagascar - 20L Jerrycan for Cooking oil

Food packaging , Industry, Automotive, Beverage

Owning up to 10 set of Jonh Huah’s accumulator type Extrusion Blow Molding Machine, the customer produces and supplies the necessities of cooking oil over the Madagascar in Africa. With business booming year by year, the customer consistently purchase machine from Jonh Huah and gives high credit to Jonh Huah’s outstanding machine on its quality, durability, and the after sales service Jonh Huah provide. ‘’Thanks to Jonh Huah’s blow molding solution, the container stay firm without damage or leaking during the long-distance delivery.’’ The distance between customer’s factory to the dealer sometimes last more than thousands of miles, by passing curvy mountain road with bad traffic condition, and most of the time it damage half amount of the container during the delivery, not until they have met Jonh Huah, Jonh Huah have changed their container design as well as the artistic of blow molding. It is always happy to see customer booming business after using Jonh Huah’s Extrusion Blow Molding Machine.

Use case

Bottles

Automobile, Cosmetic, Medical products, Daily cleanser, Beverage, Food, Industry, Automotive

In the beginning, the customer came to Jonh Huah referred by a other company. This customer is a multinational corporation who is supplying the bellow/dust cover and its serial products to a variety brands of automobile makers in Korea, Japan, India and US who impose critical request for the products based on endurable and safety concern. Regarding this project, the challenges including below: TPE melting index is very fast, not easy to control the precision of parison / wall thickness. (CPK) of the long product. The CPK requirements on product thickness in every area of product body is very strict. Auto deflash Top and bottom scrap auto deflash. To meet the all above high quality request, we make new design by modifying JS-550E and integration of drying system and gravimetric dosing system for the TPE material which requires special treatment in process. It is accumulator type and very high speed and high precision injection design is adopted to assure the quick injection for the parison. Eventually, Jonh Huah has built up a new Extrusion Blow Molding Machine design which is completely meet the customer’s requirements. And now the machines are promoting to North America (US, Canada and Mexico) and India.

When exploring the blow molding industry in Japan, several critical factors should be considered. The regulatory environment is stringent, with regulations focusing on product safety and environmental standards. Companies must comply with local laws pertaining to waste management and recycling, reflecting Japan's strong commitment to sustainability. The competitive landscape is robust, featuring both established local players and international firms, which creates both challenges and opportunities for new entrants. Japan's technological advancements in manufacturing processes often lead to higher quality products, but competition can be fierce due to the high standards expected by consumers. The market is influenced by global trends, especially with the rise in demand for lightweight and sustainable packaging solutions. Environmental concerns also drive innovation in the industry, with a significant push towards eco-friendly materials and production methods. Additionally, understanding the supply chain dynamics is crucial, as Japan's geographical location impacts logistics and sourcing of raw materials. Networking within industry associations can provide valuable insights and connections. Overall, those interested in the blow molding sector in Japan should be aware of these multifaceted challenges and opportunities to navigate the market effectively.

Some interesting numbers and facts about your company results for Blow Molding

| Country with most fitting companies | Japan |

| Amount of fitting manufacturers | 5 |

| Amount of suitable service providers | 1 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1936 |

| Youngest suiting company | 2018 |

Some interesting questions that has been asked about the results you have just received for Blow Molding

What are related technologies to Blow Molding?

Based on our calculations related technologies to Blow Molding are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Blow Molding?

The most represented industries which are working in Blow Molding are Other, Plastics, Electronics and Electrical engineering, Environment, Disposal and Recycling

How does ensun find these Blow Molding Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.