The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

BRH2 PLASTICOS

Hermosillo, Mexico

D

11-50 Employees

-

Key takeaway

BRH2 Plastics specializes in the development and manufacturing of consumer plastic products through innovative injection molding techniques. With a commitment to quality and efficiency, they aim to meet the diverse needs of their clients in the plastic manufacturing industry.

Reference

Core business

Custom Plastics Manufacturer | Injection Molding - BRH2 Plastics

For innovation and better quality, turn to BRH2 Plastics, an injection molding company, for the development & manufacturing of consumer plastic products.

Providence Plastics

Mexico

D

- Employees

-

Key takeaway

The company, Providence Plastics, specializes in custom injection molding and has over 35 years of experience in the field. Their expertise in plastics manufacturing and commitment to sustainable practices positions them as a key player in the industry.

Reference

Core business

Custom Plastic Injection Molding, plastic components monterrey, plastic injection molding

Custom Plastic Injection Molding, plastic components, monterrey mexico, plastic injection molding, injection molding, plastic injection molding company, Custom Plastic Injection Molding in Monterrey, providence

Western Tool & Mold

San Nicolás de los Garza, Mexico

D

51-100 Employees

-

Key takeaway

Western Tool & Mold specializes in providing comprehensive plastic solutions, including tooling and molding, for industries such as aviation, medical, and electronics. Their expertise in injection molding and commitment to quality make them a key player in delivering innovative solutions to clients.

Reference

Core business

About – Western Tool & Mold Limited

Tooling, Molding, CNC, 3D Printing, Painting Start from Design & Engineering, we provide one stop solution. We are specialised for Aviation, Medical and Electronic appliances. Get a free quote When The East Meets The West Western Tool & Mold is

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

AKOPET MACHINES

Mexico

D

1-10 Employees

-

Key takeaway

The company specializes in providing a variety of plastic processing machinery, including automatic and semi-automatic PET blow molding machines, and extrusion blow molding equipment. With over 30 years of experience, they emphasize efficiency and productivity in the manufacturing of containers through advanced blow molding technologies.

Reference

Core business

Akopet, Maquinaria para la Industria del Plástico | Equipos de Inyección de Alto Rendimiento

Akopet, Maquinaria para la Industria del Plástico, Equipos de Inyección de Alto Rendimiento. Orientados siempre a nuestros clientes creamos y comercializamos maquinaria que sea: simple, de máxima eficiencia, de bajo consumo energético y a precios competitivos.

TAI-MEX Máquinas de inyección de plástico

Zapopan, Mexico

D

11-50 Employees

-

Key takeaway

The company specializes in plastic molding solutions, offering a variety of machines including blow molding machines. With over 40 years of experience, they provide expertise in both horizontal and vertical injection molding, as well as related automation equipment.

Reference

Core business

Inyección de Plástico - TAI-MEX

Expertos en Maquinaria de Inyección de Plástico en México. Servicio en toda la República.

laminados tecnicos extruidos sa de cv (LAMITEX)

Mexico

D

11-50 Employees

1998

Key takeaway

LAMITEX México is a 100% Mexican company with over 25 years of experience in plastic transformation processes, including extrusion and thermoforming.

Reference

Core business

Fabrica De Estireno | Lamitex | Ciudad de México

fábrica de estireno lamina hoja extrusión poliestireno termoformado impresión cdmx lamina de estireno tratamiento corona lamitex

Multi Plastic

Mexico

D

11-50 Employees

1997

Key takeaway

The company, Multi Plastic, specializes in the design and development of plastic packaging, including blow-molded containers made from HDPE, PET, and PP. Their product range includes various bottle caps and cylindrical containers, highlighting their expertise in creating functional and secure packaging solutions.

Reference

Core business

Multi Plastic | Design and Development of Packaging HDPE, PET, PP

Mecanoplástica Industrial

Guadalajara, Mexico

D

51-100 Employees

2010

Key takeaway

The company, Mecanoplástica, emphasizes its expertise in custom mold design and high-quality plastic molding solutions, making it a key player in the industry. Their comprehensive approach, from mold design to product manufacturing, positions them as a valuable partner for clients seeking innovative plastic injection solutions.

Reference

Core business

Inicio | Mecanoplástica

Desde el diseño del molde hasta la fabricación de tu producto, Mecanoplástica es tu opción en inyección de plástico.

Nicholas Plastics de México

Mexico

D

51-100 Employees

2003

Key takeaway

Nicholas Plastics de México is a specialized company in the plastic industry, handling extrusion, injection, and die cutting of plastics, which are relevant processes in blow molding applications. They focus on high-volume projects and the development and manufacturing of tooling and plastic components.

Reference

Core business

Nicholas Plastics - Fabricante de Perfiles Especializados de Plástico

Empresa especializada en la industria del plástico, Proyectos de EXTRUSIÓN, INYECCIÓN y TROQUELADO de alto volumen. Componentes y Perfiles.

HISMAQ

Ciudad Juárez, Mexico

D

1-10 Employees

2018

Key takeaway

The company, HISMAQ PLASTICS, specializes in plastic injection molding and has over 25 years of experience in designing and repairing molds, which enhances their production capabilities. They collaborate with Tier 1 and 2 companies to streamline processes and reduce costs in the manufacturing of plastic parts for various industries, including automotive.

Reference

Core business

Inyección de Piezas Plásticas

Gestionamos la Fabricación de Piezas Plásticas a través de Procesos y metodologías Inteligentes para diferentes sectores de la Industria del Plástico.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Full electric type Extrusion Blow Molding Manchine JD Series

Go to product

Product

Automatic type Extrusion Blow Molding Manchine JN Series

Go to product

Product

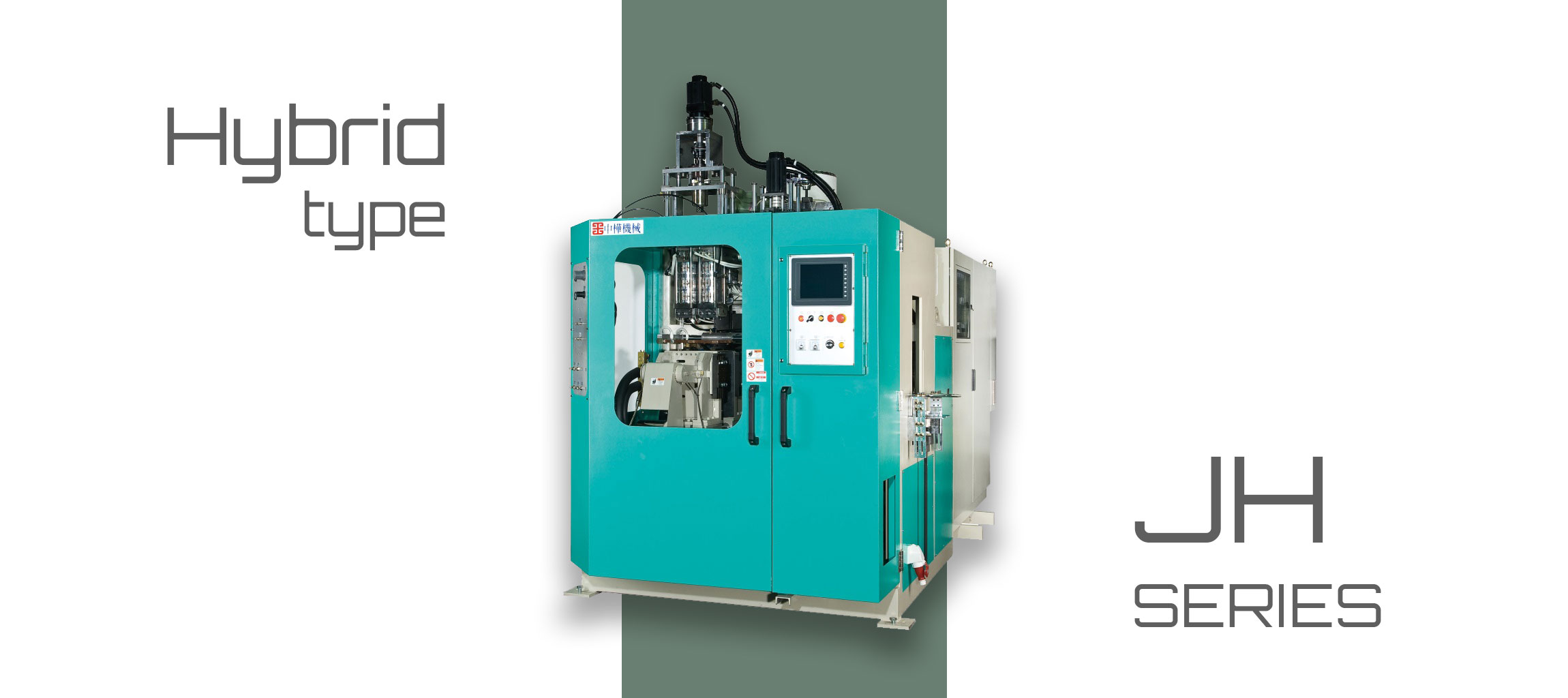

Hybrid type Extrusion Blow Molding Manchine

Go to product

Product

Basic type Extrusion Blow Molding Manchine - JS Series

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Bottles

Automobile, Cosmetic, Medical products, Daily cleanser, Beverage, Food, Industry, Automotive

In the beginning, the customer came to Jonh Huah referred by a other company. This customer is a multinational corporation who is supplying the bellow/dust cover and its serial products to a variety brands of automobile makers in Korea, Japan, India and US who impose critical request for the products based on endurable and safety concern. Regarding this project, the challenges including below: TPE melting index is very fast, not easy to control the precision of parison / wall thickness. (CPK) of the long product. The CPK requirements on product thickness in every area of product body is very strict. Auto deflash Top and bottom scrap auto deflash. To meet the all above high quality request, we make new design by modifying JS-550E and integration of drying system and gravimetric dosing system for the TPE material which requires special treatment in process. It is accumulator type and very high speed and high precision injection design is adopted to assure the quick injection for the parison. Eventually, Jonh Huah has built up a new Extrusion Blow Molding Machine design which is completely meet the customer’s requirements. And now the machines are promoting to North America (US, Canada and Mexico) and India.

Use case

Peru - Engine oil / Lubrication oil bottle

Automotive, oil, Engine oil , Lubrication oil, Cosmetic, Medical, cleanser, Food, Beverage, Industry, automotive

The customer has great reputation in engine oil industry of Peru who wants to make a new serial bottle family and the customer requests fully automated production. As such, we propose the blow molding machine integrated the needful accessories which including material feeding and conveying, crushing, material recycle, take out robot, finished bottle collection and conveying and Leak Detector…etc. The features of blow molding machine with automated integration system include. Labor cost less Product quality assurance Power saving Eventually, the customer is satisfied with the performance of Jonh Huah machine which is completely meet the their’s requirements. Both the automation and power saving design could make the customer’s quick payback on the investment, a strong competitive edge for the customer to keep its leading position in Peru county. With the success of this project, customer continues to buy two more similar automation systems in three consecutive years.

Use case

Taiwan - High value-added food packaging

Food, Medical products, Cosmetic, Daily cleanser, Automotive, Industry, Beverage

The customer is the large-scale packaging film manufacturer in the south of Taiwan specializes in a variety of high value-added food packaging. Since 2012, they have developed a close partnership with JOHN HUAH. JOHN HUAH has won the appreciation and recognition of Taiwan's index packaging film manufacturers for our solid and powerful machine appearance structure design, simple and flexible humanized control interface and energy-efficient integration of core units. Through close technical exchanges and positive interaction between the two parties, JOHN HUAH has built a number of simple and efficient Extrusion Blow Molding Machine for this customer, which has been well received with continuous and stable mass production. Our automation design bring the customer a full automatic production from blowing process to leak testing and labeling process. “It is just like the fully automatic money printing machine” said the customer. JONH HUAH will continue to focus on the concept of “Made Simple”, listening to customers' needs, aiming at providing customers with the most efficient solutions and integrating the most advanced technology to satisfy customers. The value of the brand “JONH HUAH” will be deeply rooted in every customer.

Use case

Korea - Automobile dust cover - Specialized

Automobile, Cosmetic, cleanser, Food , Beverage, Medical , Industry

In the beginning, the customer came to Jonh Huah referred by a other company. This customer is a multinational corporation who is supplying the bellow/dust cover and its serial products to a variety brands of automobile makers in Korea, Japan, India and US who impose critical request for the products based on endurable and safety concern. Regarding this project, the challenges including below: TPE melting index is very fast, not easy to control the precision of parison / wall thickness. (CPK) of the long product. The CPK requirements on product thickness in every area of product body is very strict. Auto deflash Top and bottom scrap auto deflash. To meet the all above high quality request, we make new design by modifying JS-550E and integration of drying system and gravimetric dosing system for the TPE material which requires special treatment in process. It is accumulator type and very high speed and high precision injection design is adopted to assure the quick injection for the parison. Eventually, Jonh Huah has built up a new Extrusion Blow Molding Machine design which is completely meet the customer’s requirements. And now the machines are promoting to North America (US, Canada and Mexico) and India.

Use case

Madagascar - 20L Jerrycan for Cooking oil

Industry, Automotive, Beverage, tank, jerrycan

Owning up to 10 set of Jonh Huah’s accumulator type Extrusion Blow Molding Machine, the customer produces and supplies the necessities of cooking oil over the Madagascar in Africa. With business booming year by year, the customer consistently purchase machine from Jonh Huah and gives high credit to Jonh Huah’s outstanding machine on its quality, durability, and the after sales service Jonh Huah provide. ‘’Thanks to Jonh Huah’s blow molding solution, the container stay firm without damage or leaking during the long-distance delivery.’’ The distance between customer’s factory to the dealer sometimes last more than thousands of miles, by passing curvy mountain road with bad traffic condition, and most of the time it damage half amount of the container during the delivery, not until they have met Jonh Huah, Jonh Huah have changed their container design as well as the artistic of blow molding. It is always happy to see customer booming business after using Jonh Huah’s Extrusion Blow Molding Machine.

Use case

Madagascar - 20L Jerrycan for Cooking oil

Food packaging , Industry, Automotive, Beverage

Owning up to 10 set of Jonh Huah’s accumulator type Extrusion Blow Molding Machine, the customer produces and supplies the necessities of cooking oil over the Madagascar in Africa. With business booming year by year, the customer consistently purchase machine from Jonh Huah and gives high credit to Jonh Huah’s outstanding machine on its quality, durability, and the after sales service Jonh Huah provide. ‘’Thanks to Jonh Huah’s blow molding solution, the container stay firm without damage or leaking during the long-distance delivery.’’ The distance between customer’s factory to the dealer sometimes last more than thousands of miles, by passing curvy mountain road with bad traffic condition, and most of the time it damage half amount of the container during the delivery, not until they have met Jonh Huah, Jonh Huah have changed their container design as well as the artistic of blow molding. It is always happy to see customer booming business after using Jonh Huah’s Extrusion Blow Molding Machine.

Use case

Bottles

Automobile, Cosmetic, Medical products, Daily cleanser, Beverage, Food, Industry, Automotive

In the beginning, the customer came to Jonh Huah referred by a other company. This customer is a multinational corporation who is supplying the bellow/dust cover and its serial products to a variety brands of automobile makers in Korea, Japan, India and US who impose critical request for the products based on endurable and safety concern. Regarding this project, the challenges including below: TPE melting index is very fast, not easy to control the precision of parison / wall thickness. (CPK) of the long product. The CPK requirements on product thickness in every area of product body is very strict. Auto deflash Top and bottom scrap auto deflash. To meet the all above high quality request, we make new design by modifying JS-550E and integration of drying system and gravimetric dosing system for the TPE material which requires special treatment in process. It is accumulator type and very high speed and high precision injection design is adopted to assure the quick injection for the parison. Eventually, Jonh Huah has built up a new Extrusion Blow Molding Machine design which is completely meet the customer’s requirements. And now the machines are promoting to North America (US, Canada and Mexico) and India.

When exploring the blow molding industry in Mexico, several key considerations come into play. The country has become a significant player in manufacturing due to its strategic location, an extensive trade network, and competitive labor costs. However, navigating the regulatory landscape is essential, as businesses must comply with local environmental laws and international trade agreements. Additionally, understanding the challenges of supply chain logistics and sourcing raw materials is crucial, especially given fluctuations in global markets. Opportunities in the Mexican blow molding sector are growing, driven by demand in various industries such as automotive, packaging, and consumer goods. Companies should also be aware of environmental concerns, as sustainability practices are increasingly prioritized by consumers and regulations, leading to a shift towards eco-friendly materials and processes. The competitive landscape includes both local players and international corporations, necessitating a focus on innovation and quality to stand out. Furthermore, global market relevance is significant, as Mexico serves as a hub for exports to North America and beyond. This interconnectedness can offer businesses a robust platform for growth while requiring a keen awareness of international market trends and consumer preferences. Engaging with local industry associations and attending trade shows can also provide valuable insights and networking opportunities in this dynamic sector.

Some interesting numbers and facts about your company results for Blow Molding

| Country with most fitting companies | Mexico |

| Amount of fitting manufacturers | 11 |

| Amount of suitable service providers | 9 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1997 |

| Youngest suiting company | 2018 |

Some interesting questions that has been asked about the results you have just received for Blow Molding

What are related technologies to Blow Molding?

Based on our calculations related technologies to Blow Molding are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Blow Molding?

The most represented industries which are working in Blow Molding are Plastics, Manufacturing, Packaging, Machinery Manufacturing, Other

How does ensun find these Blow Molding Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.