The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

MITAKA CO. LTD.

Kumagaya, Japan

A

11-50 Employees

1991

Key takeaway

The company specializes in CNC machining, producing precision parts for medical equipment, semiconductors, and electronic devices with a cutting accuracy of ±5 microns. Their expertise includes working with various materials, ensuring high-quality manufacturing suitable for advanced technological applications.

Reference

Product

Machining – 株式会社ミタカ|医療機器・半導体・電子機器部材の製造

PrevNext Characteristics ±5 micron cutting accuracy 挽目優先加工 Special processing (bellows, etc.) Main usage Medical supplies Electronic components Others Corresponding specifications Material PEEK, tungsten, beryllium, other superalloys, etc. Max. processing wire diameter 4mm Max. processing length 150mm

ADVANCE CO., LTD.

Japan

A

11-50 Employees

1985

Key takeaway

The company has an extensive range of CNC machining equipment, including multiple machining centers and five-axis machines from leading manufacturers like FANUC and Mazak, which are essential for precision manufacturing and prototyping.

Reference

Core business

設備一覧 | 株式会社アドバンス

加工設備 設備名称 メーカー/型式 台数 合計 備考 マシニングセンター FANUC ROBODRILL 69 90 Mazak VCN510 3 MAKINO V33 2 MILLTAP 700 5 DMU-60 monoblock 2 5軸マシン DMU-85 monoblock 1 5軸マシン(6面パレットチェンジャー付) DMU-100 monoblock 2 5軸マシン FANUC ROBODRILL 6 5軸マシン 複合加工機 INTEGREXi‐200S 1 1 汎用フライス MAKINO、春日製作所、他 3 3 汎用旋盤 TATEYA 1 1 彫刻機 サカザキ精工 1 1 放電加工機 TATEYA 2

Cominix

Osaka, Japan

A

11-50 Employees

1950

Key takeaway

Cominix specializes in the sale of cutting tools and wear-resistant tools used in metal processing, boasting a product lineup that covers approximately 60% of the global cutting tool market. Their focus on maximizing efficiency through data-driven testing and collaboration with excellent manufacturers highlights their commitment to providing high-value solutions in the manufacturing process.

Reference

Product

切削工具|株式会社Cominix

切削工具|株式会社CominixのWebサイトです。製品情報、企業情報、IR情報等をご覧いただけます。

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

YASDA PRECISION TOOLS K.K.

Satosho, Japan

A

251-500 Employees

-

Key takeaway

YASDA is dedicated to achieving the highest level of precision in CNC machining, particularly through their advanced YASDA MICRO CENTER (YMC), which addresses the growing demand for ultra-precision and high surface quality milling. Their commitment to continuous development and innovative automation solutions ensures exceptional accuracy and stability in machining processes.

Reference

Core business

YASDA PRECISION TOOLS K.K.

At YASDA, our uncompromising will is to pursue the highest level of precision and services and to deliver the best CNC Machines.

SOMNIX.Co.Ltd

Tokyo, Japan

A

1-10 Employees

2011

Key takeaway

SOMNIX Co. Ltd offers comprehensive support for design and manufacturing, emphasizing their extensive knowledge of materials and manufacturing methods. They provide tailored solutions that include material selection and processing, which are essential for CNC machining projects.

Reference

Core business

Manufacturing in Japan, Business with Japanese companies | SOMNIX.Co.LTD | Tokyo

SOMNIX.Co.Ltd supports you at the design and manufacturing stages, and with the entire transaction with Japanese companies. We have extensive knowledge of materials and manufacturing methods and we select the most suitable methods for you. We handle Molybdenum, Tungsten, Tantalum, Aluminum, Stainless steel, Cupper, Plastics and so on.

Matsuura Machinery

Fukui, Japan

A

251-500 Employees

1935

Key takeaway

The company, Matsuura Machinery Ltd, is located in multiple regions, including England, Germany, and Japan.

Reference

Core business

Matsuura Machinery Corporation

TMT Machinery

Japan

A

501-1000 Employees

2002

Key takeaway

TMT MACHINERY, INC. is a leading global provider of advanced synthetic fiber machinery, which includes spinning, drawing, and winding systems designed to meet diverse needs. Their commitment to R&D and engineering ensures they support customers in embracing new technologies and innovations.

Reference

Core business

TMT Machinery, Inc

Kousei USA

Kariya, Japan

A

11-50 Employees

1985

Key takeaway

Kousei USA, Inc. specializes in precision machining and manufacturing high-quality prototype parts, jigs, and fixtures for the automotive and electronic industries. Their expertise in design and engineering solutions ensures timely delivery within budget.

Reference

Core business

Kousei USA, Inc. | Tooling Manufacturer Serving Automotive Electronic

Kousei USA, Inc. is a tooling manufacturer serving the automotive & electronic industries. We provide engineering solutions and precision machining. Our focus is on the prototype parts, jigs and fixtures, gauges and design, and special machines. We manufacture quality components. Contact us.

Orbital Engineering Co., Ltd.

Yokohama, Japan

A

- Employees

1998

Key takeaway

The company, ORBITAL Engineering Inc., is involved in manufacturing, which may encompass CNC machining processes.

Reference

Product

製造 | ORBITAL Engineering Inc.

TECHNOsolutions

Tokyo, Japan

A

51-100 Employees

2005

Key takeaway

The company offers a variety of software and solutions including SOLIDWORKS and Geomagic products that are integral to CNC machining processes.

Reference

Product

Markforged Desktop Series : Onyx One/Onyx Pro/Mark Two | 株式会社テクノソリューションズ

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

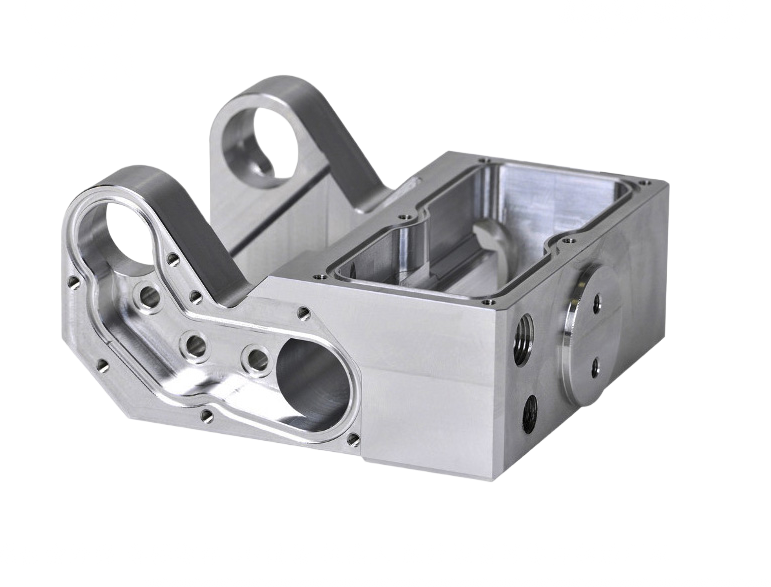

CNC Turning Parts

Go to product

Service

Machining

Go to product

Service

CNC Machining

Go to product

Service

CNC machining

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

CNC Turning Parts

Machinery, Shipbuilding, Energy, Automotive

Shafts: These are long, cylindrical pieces used to transmit power or motion. Pins: Precision pins are used in various applications, including as hinge pins, dowels, or locator pins in machinery and equipment. Bushings: These are cylindrical linings designed to reduce friction or provide a protective interface between two parts in mechanical systems. Spacers: Used to create a space between two components in an assembly to ensure proper positioning and alignment. Valves and Valve Components: Essential in controlling the flow of liquids or gases in systems. Pulleys: These parts support movement and change of direction of a belt in machines. Bolts and Screws: Precision threading can be produced with CNC turning. Hydraulic Components: Parts like pistons, cylinders, and connectors, used in hydraulic systems. Carbon Steels: Low carbon steels (like 1018) are more ductile and weldable, while high carbon steels (like 1045) are harder and wear-resistant but less ductile. Alloy Steels: These steels are often used for their strength, toughness, wear resistance, and hardness. Examples include 4140 and 4340 steels. Tool Steels: Tool steels are high-carbon steels .They are known for their hardness and resistance to abrasion. Examples are D2, A2, and O1. Stainless Steels: Common grades used in CNC turning include 304 and 316, known for their good formability and corrosion resistance.

Use case

HLH helps Swiss Smartflyer achieve 5X faster CNC lead times

Aerospace, Aviation, Electric Aircrafts

HLH helps Swiss Aviation Company, Smartflyer, build precision aircraft components via CNC Machining (4 and 5 axis) and CNC turning for their hybrid-electric aircraft. ✔ Precision milled and turned parts like actuator, bearings, push rods, bellcranks, fuselage mount, rudder mount, etc. ✔ Supplied 10+ different CNC parts within 1-week lead time. ✔ Smartflyer immediately saw an immediate improvement in lead times - 5 times faster than local suppliers.

Use case

Fast and precise: Parker Hannifin relies on state-of-the-art Online Manufacturing of turned and milled parts by FACTUREE

aerospace, motion technologies, control technologies, actuators, fittings, couplings

Fast and precise: Parker Hannifin relies on state-of-the-art Online Manufacturing of turned and milled parts by FACTUREE Berlin, March 25th 2020 In today’s world, a high level of precision and fast delivery times are crucial to the production of individual components. Online Manufacturer FACTUREE (www.facturee.de) is meeting these new requirements with its wide range of manufacturing services, quick response times and on-time delivery. To benefit from this cutting-edge procurement process, leading engineering company Parker Hannifin commissioned FACTUREE to produce special turned and milled parts for mounting devices in their engineering department. The move enables the company to efficiently drive its own digital transformation without being affected by capacity bottlenecks and disproportionate personnel involvement.

Use case

Custom CNC Machined Parts for Automotive Applications

Automotive, Electric Vehicles, Mobility Solutions, OEM Manufacturing

FutureParts delivers high-precision CNC machined components for the automotive industry, supporting both traditional and electric vehicle applications. From engine brackets and transmission housings to battery enclosures and interior fixtures, our CNC machining services ensure top-tier accuracy, repeatability, and strength. We work with a wide range of materials including aluminum, stainless steel, and engineering plastics to meet automotive-grade requirements for thermal resistance, strength, and dimensional precision. Whether you're developing prototypes or require low-to-mid volume production, FutureParts offers efficient lead times, tight tolerance machining, and reliable quality control for every part. Trusted by automotive OEMs and Tier 1 suppliers, we help drive innovation, performance, and production efficiency.

Use case

CNC Turning Parts

Machinery, Shipbuilding, Energy, Automotive

Shafts: These are long, cylindrical pieces used to transmit power or motion. Pins: Precision pins are used in various applications, including as hinge pins, dowels, or locator pins in machinery and equipment. Bushings: These are cylindrical linings designed to reduce friction or provide a protective interface between two parts in mechanical systems. Spacers: Used to create a space between two components in an assembly to ensure proper positioning and alignment. Valves and Valve Components: Essential in controlling the flow of liquids or gases in systems. Pulleys: These parts support movement and change of direction of a belt in machines. Bolts and Screws: Precision threading can be produced with CNC turning. Hydraulic Components: Parts like pistons, cylinders, and connectors, used in hydraulic systems. Carbon Steels: Low carbon steels (like 1018) are more ductile and weldable, while high carbon steels (like 1045) are harder and wear-resistant but less ductile. Alloy Steels: These steels are often used for their strength, toughness, wear resistance, and hardness. Examples include 4140 and 4340 steels. Tool Steels: Tool steels are high-carbon steels .They are known for their hardness and resistance to abrasion. Examples are D2, A2, and O1. Stainless Steels: Common grades used in CNC turning include 304 and 316, known for their good formability and corrosion resistance.

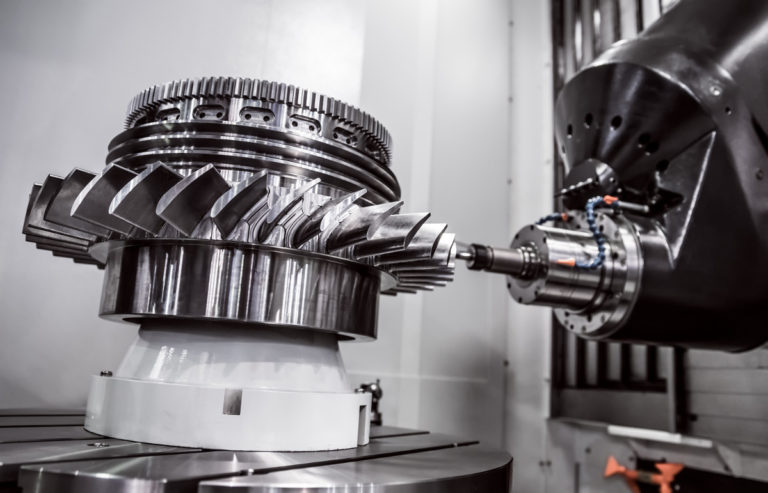

When exploring the CNC machining industry in Japan, several key considerations emerge. First, Japan is renowned for its advanced technology and precision engineering, making it a global leader in CNC machining. Companies must navigate strict regulations regarding quality control and safety standards, which are essential to maintaining Japan's reputation for high-quality manufacturing. Additionally, the competitive landscape is intense, with numerous domestic and international players vying for market share. Understanding the local market dynamics, including customer preferences and industry trends, is crucial for success. Environmental concerns also play a significant role, as Japan emphasizes sustainability and eco-friendly practices in manufacturing. Companies are increasingly expected to implement green technologies and waste reduction strategies. Moreover, potential challenges include labor shortages due to an aging workforce and the need for skilled technicians to operate advanced machinery. Opportunities exist for innovation in automation and smart manufacturing, as businesses adopt Industry 4.0 technologies to enhance efficiency. Lastly, the global relevance of Japan's CNC machining sector cannot be understated, as it supplies critical components to various industries, including automotive, aerospace, and electronics, making it an integral part of the global supply chain. Understanding these factors will provide valuable insights for anyone interested in entering or collaborating within this dynamic industry.

Some interesting numbers and facts about your company results for CNC Machining

| Country with most fitting companies | Japan |

| Amount of fitting manufacturers | 7 |

| Amount of suitable service providers | 3 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1935 |

| Youngest suiting company | 2011 |

Some interesting questions that has been asked about the results you have just received for CNC Machining

What are related technologies to CNC Machining?

Based on our calculations related technologies to CNC Machining are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on CNC Machining?

The most represented industries which are working in CNC Machining are Other, Machinery Manufacturing, Manufacturing, Electronics and Electrical engineering, Medical

How does ensun find these CNC Machining Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.