The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Priority Integrated Systems

Melbourne, Australia

A

1-10 Employees

2018

Key takeaway

Priority Robotics is dedicated to revolutionizing industries across Australia through advanced robotic systems that automate and optimize complex tasks, particularly in logistics, eCommerce fulfillment, and third-party logistics. Their innovative solutions aim to increase productivity, reduce costs, and enhance safety in various sectors.

Reference

Core business

Priority Robotics

Fuzzy LogX

Sydney, Australia

A

11-50 Employees

2015

Key takeaway

Fuzzy LogX is a leader in automation within intralogistics, offering comprehensive support services that enhance the efficiency of logistics operations. Their expertise in warehouse automation and integration positions them as key players in transforming supply chain processes.

Reference

Core business

Independent Logistics & Warehouse Engineering Xperts | Fuzzy LogX

THE WAREHOUSE AUTOMATION EXPERTS. Working together with you to achieve your business case. From project management to consulting and integration support.

LYRO Robotics

Greater Brisbane, Australia

A

11-50 Employees

2019

Key takeaway

LYRO provides robotic picking and packing solutions that enhance the efficiency and reliability of food supply chains. Their expertise in robotic vision and deep learning, highlighted by their success at the International Amazon Robotics Challenge, underscores their innovative approach to logistics robotics, particularly for fruits and vegetables.

Reference

Product

Innovation – LYRO Robotics

A robotic packing solution for fruits and vegetables

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Logistics Cloud Co.

Sydney, Australia

A

1-10 Employees

2021

Key takeaway

The company specializes in warehouse management system (WMS) implementation and addresses productivity issues caused by poor warehouse design, making it particularly relevant for those interested in logistics robotics. Their focus on optimizing warehouse operations through technology and expert support can significantly enhance efficiency in logistics processes.

Reference

Product

Technology – Logistics Cloud Co.

Orbit Logistics Pty Ltd

Melbourne, Australia

A

11-50 Employees

2003

Key takeaway

Orbit Logistics is a highly credentialed international freight forwarder that leverages customized technology and a global network of partners to deliver comprehensive logistics solutions. Their services include full track and trace capabilities and superior last mile management, ensuring efficient and transparent supply chain operations.

Reference

Product

Orbit Logistics

ThreeSixty Supply Chain Group

Melbourne, Australia

A

11-50 Employees

2018

Key takeaway

The company specializes in transforming and optimizing supply chains through innovative intralogistics solutions, offering manual, semi-automated, and fully automated warehouse designs tailored to business needs. Their experience includes delivering an advanced automated distribution center for a major fashion retailer, highlighting their capability to enhance operational efficiency and flexibility.

Reference

Service

Warehouse Design and Intralogistics Solutions | ThreeSixty

Our team’s dedicated approach ensures delivery of a warehouse design that provides your business with operational excellence, efficiency and flexibility. We are experienced in: Manual warehousing – large property footprint with high manning levels to meet year-on-year volume increases; Semi-automated warehousing – reduced property footprint with sufficient technology to meet volumes, reduce manning and allow for operational flexibility and improved safety; Fully-automated warehousing – optimised property footprint with a high level of warehouse automation and extensive use of technology to significantly reduce labour, improve safety and provide a major improvement in service levels.

Quantum Robotics

Melbourne, Australia

A

1-10 Employees

2017

Key takeaway

Quantum Robotics specializes in logistics robotics, offering automated storage and goods-to-person solutions that enhance order fulfillment efficiency. Their range of collaborative and autonomous robots, including mobile delivery robots and automated forklifts, aims to make advanced automation accessible to Australian businesses.

Reference

Core business

Quantum Robotics: Australia’s Collaborative Robot Experts

Robot System Integrators Melbourne, Australia - Collaborative Autonomous Robots, Cobots Universal Robots Omron LD Lynx Adept Robotics, MiR

FMH Group

Melbourne, Australia

A

501-1000 Employees

-

Key takeaway

Logistics Holdings Australia is focused on creating a superior logistics ecosystem that enhances supply chain efficiency through advanced technology and integrated services. Their commitment to safety and customer-centric solutions positions them as leaders in the logistics industry.

Reference

Core business

Home | FMH Group | Innovative Integrated Logistics Services

Discover a new, fully-integrated digital logistics ecosystem that enables true supply chain efficiency and sustainability.

Get Logistics Australia

Melbourne, Australia

A

1-10 Employees

-

Key takeaway

Get Logistics Australia is a prominent provider of logistics services, offering flexible warehousing and delivery options tailored to the needs of their customers. Their experience and commitment to flexibility make them a trusted partner for efficient logistics solutions.

Reference

Core business

About Us | Get Logistics

Future Concepts Technology

Adelaide, Australia

A

1-10 Employees

2020

Key takeaway

Future Concepts Tech specializes in autonomous robotics, offering innovative solutions that assist in automating operational and logistics activities, particularly for farmers. Their use of the Robot Operating System (ROS) enables intelligent robotic systems to operate effectively in dynamic environments, revolutionizing last-mile delivery processes.

Reference

Core business

Autonomous Robotics | Next gen Mobility solutions Future Concepts Tech

Future Concepts Tech is Australia's leading Autonomous robotics company providing next generation smart mobility solutions. Our Autonomous delivery robots will revolutionise and transform the way last mile deliveries are performed.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Palletizing

Go to product

Service

AMR Controller SRC-3000FS

Go to product

Service

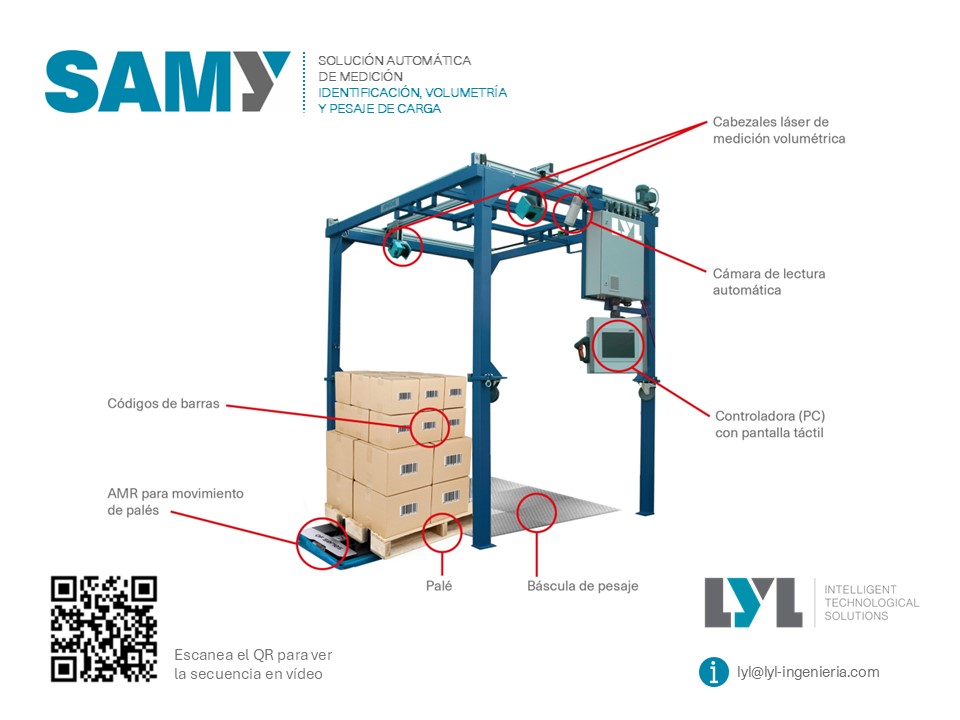

SAMY

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Griffins

Food, Beverage, material handling

PHS Innovate was the automation supplier selected to supply the new palletizer solution for Griffin’s factory. We designed a SAP-compatible system utilising four ABB robots and integrated stretch wrapping and labelling. Our proposal also included an upgrade to Griffins’ conveyor systems, to help with back pressure and product line control. The new palletizer system was installed while the old system was still running, to enable a staged changeover. Our robots were equipped with standard mechanical gripping heads, which have the versatility required for Griffins’ diverse product range. Compared to Griffins’ old system, this method of holding cases was a significant improvement. The final installation was achieved over two weekends, to ensure minimal impact to production at the factory. Initially, half the production line was directed to the new palletizer system. After a few weeks, when it was clear that everything was running smoothly, total production was directed to the new solution and the old palletiser was decommissioned.

Use case

Griffins

Food, Beverage, material handling

PHS Innovate was the automation supplier selected to supply the new palletizer solution for Griffin’s factory. We designed a SAP-compatible system utilising four ABB robots and integrated stretch wrapping and labelling. Our proposal also included an upgrade to Griffins’ conveyor systems, to help with back pressure and product line control. The new palletizer system was installed while the old system was still running, to enable a staged changeover. Our robots were equipped with standard mechanical gripping heads, which have the versatility required for Griffins’ diverse product range. Compared to Griffins’ old system, this method of holding cases was a significant improvement. The final installation was achieved over two weekends, to ensure minimal impact to production at the factory. Initially, half the production line was directed to the new palletizer system. After a few weeks, when it was clear that everything was running smoothly, total production was directed to the new solution and the old palletiser was decommissioned.

The Logistics Robotics industry in Australia is influenced by several key considerations. Firstly, regulatory compliance is crucial, as businesses must adhere to safety standards and labor laws governing automated systems. Understanding these regulations can help companies avoid legal pitfalls and operate efficiently. The competitive landscape features both established players and innovative startups, which fosters a dynamic environment but also heightens competition. This industry presents significant opportunities, particularly in enhancing supply chain efficiency and reducing operational costs through automation. Environmental concerns are increasingly relevant, as companies face pressure to adopt sustainable practices, such as reducing carbon footprints and minimizing waste through robotic solutions. Additionally, the global market relevance of logistics robotics is significant, with Australia being a part of a rapidly growing sector that is witnessing advancements in AI and machine learning. Companies in this field must stay abreast of technological innovations and market trends to remain competitive. Challenges such as workforce displacement and the initial investment costs for robotics technology also need to be addressed. Overall, a thorough understanding of these factors can guide potential entrants and stakeholders in making informed decisions in the logistics robotics landscape in Australia.

Some interesting numbers and facts about your company results for Logistics Robotics

| Country with most fitting companies | Australia |

| Amount of fitting manufacturers | 303 |

| Amount of suitable service providers | 380 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 2003 |

| Youngest suiting company | 2021 |

Some interesting questions that has been asked about the results you have just received for Logistics Robotics

What are related technologies to Logistics Robotics?

Based on our calculations related technologies to Logistics Robotics are Water/Ocean Cleaning Technologies, Waste Management, Renewable Energy, Sustainable Fashion, Smart Grid

Who are Start-Ups in the field of Logistics Robotics?

Start-Ups who are working in Logistics Robotics are Logistics Cloud Co.

Which industries are mostly working on Logistics Robotics?

The most represented industries which are working in Logistics Robotics are Logistics, Supply Chain and Transportation, IT, Software and Services, Other, Automation, Manufacturing

How does ensun find these Logistics Robotics Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.