The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Robogistics

Beaumont, United States

B

51-100 Employees

-

Key takeaway

Robogistics specializes in intelligent robotic gantry automation and innovative software technology, providing comprehensive material handling and distribution center solutions that enhance logistics chain management. Their expertise in designing and integrating automated systems directly addresses the material-handling and logistical automation challenges faced by various industries.

Reference

Core business

Gantry | Robogistics | United States

Robogistics designs, manufacturers, and integrates intelligent robotic gantry automation software & equipment for the material handling and logistics industries.

Dextrous Robotics

Memphis, United States

B

1-10 Employees

2019

Key takeaway

Dextrous Robotics is a logistics robotics startup that offers advanced robots designed to unload trailers up to four times faster, enhancing efficiency while ensuring accuracy and safety. Their latest product, DX-1, is now available for pre-order, promising to significantly improve operational capabilities.

Reference

Core business

Dextrous Robotics | Logistics Robotics Startup

Vecna Robotics

Waltham, United States

B

251-500 Employees

2018

Key takeaway

The company specializes in intelligent industrial workforce solutions that enhance efficiency through autonomous material handling. With a focus on robotics innovation, they offer flexible warehousing automation that addresses key challenges like labor shortages and operational backlogs.

Reference

Product

Warehousing Automation - Vecna Robotics

Vecna Robotics makes warehousing go! Rise above labor shortages, backlogs, and turnaround times with flexible warehousing automation.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

VisionNav Robotics

Houston, United States

B

251-500 Employees

2016

Key takeaway

VisionNav Robotics is a prominent supplier of autonomous forklifts and intralogistics automation solutions, utilizing advanced technologies like machine learning and environment perception to enable reliable, human-free operations. Their autonomous vehicles are deployed in numerous facilities worldwide, optimizing logistics processes across various industries, including e-commerce and manufacturing.

Reference

Core business

About Us

LogisticsFlow

Denver, United States

B

11-50 Employees

2021

Key takeaway

LogisticsFlow is an enterprise software provider that specializes in creating products designed for distribution, addressing the need for efficient logistics technology. Their focus on streamlining the distribution process helps companies reduce costs and improve turnaround times.

Reference

Core business

LogisticsFlow: About Us

Nimble Robotics

San Francisco, United States

B

11-50 Employees

2017

Key takeaway

The company, Nimble, specializes in logistics robotics, offering free 2-day or less delivery through its AI-powered robotic fulfillment system. This innovative approach allows for efficient order fulfillment and optimized inventory placement, enabling brands to compete effectively in the e-commerce space.

Reference

Core business

Nimble - Fully Autonomous Fulfillment

Offer free 2-day or less delivery using Nimble — the robotic 3PL.

6 River Systems

Waltham, United States

B

51-100 Employees

2015

Key takeaway

6 River Systems offers an advanced warehouse automation system that integrates software and autonomous mobile robots (AMRs) to enhance logistics operations. Their solution improves efficiency and productivity while reducing costs and risks, making it ideal for optimizing logistics processes.

Reference

Core business

Fulfillment Solutions & Warehouse Automation | 6 River Systems

At 6 River Systems, we build fulfillment solutions that power the winning warehouses of the future. Improve efficiency, optimize labor, scale quickly & easily.

Supply Chain Ventures

Boston, United States

B

1-10 Employees

2001

Key takeaway

Descartes is a key player in logistics, offering on-demand software solutions that enhance the productivity and security of logistics-intensive businesses. Additionally, the company provides a comprehensive range of e-commerce order fulfillment services.

Reference

Product

nextshift-robotics - supplychainventure.com

Warehouse Automation AI

Los Angeles, United States

B

11-50 Employees

2010

Key takeaway

Warehouse Automation AI specializes in logistics solutions that integrate automation and robotics to enhance inventory management and reduce operational costs. Their expertise in digital transformation and warehouse automation positions them as key players in the evolving landscape of logistics robotics.

Reference

Core business

Warehouse Automation

Warehouse Automation is an independent supply chain consulting and advisory firm with a focus in assisting clients through their digital transformation in the integration of industrial robots and warehouse automation systems. We further advise clients in procuring the most suitable software solution

Robotica Inc

Cypress, United States

B

11-50 Employees

2000

Key takeaway

Robotica™ offers innovative fulfillment automation solutions, particularly in logistics robotics, with a focus on scalable and flexible systems for labor-intensive operations. Their modular parcel sorting technology and autonomous robotic systems significantly reduce the need for human intervention, enhancing efficiency in the automated material handling market.

Reference

Core business

About | Robotica Inc | Autonomous Automated Parcel Sorting

Following a path in robotic development begun in 1980, Robotica founder set out to provide robot solutions for high demand applications where none existed.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Palletizing

Go to product

Service

AMR Controller SRC-3000FS

Go to product

Service

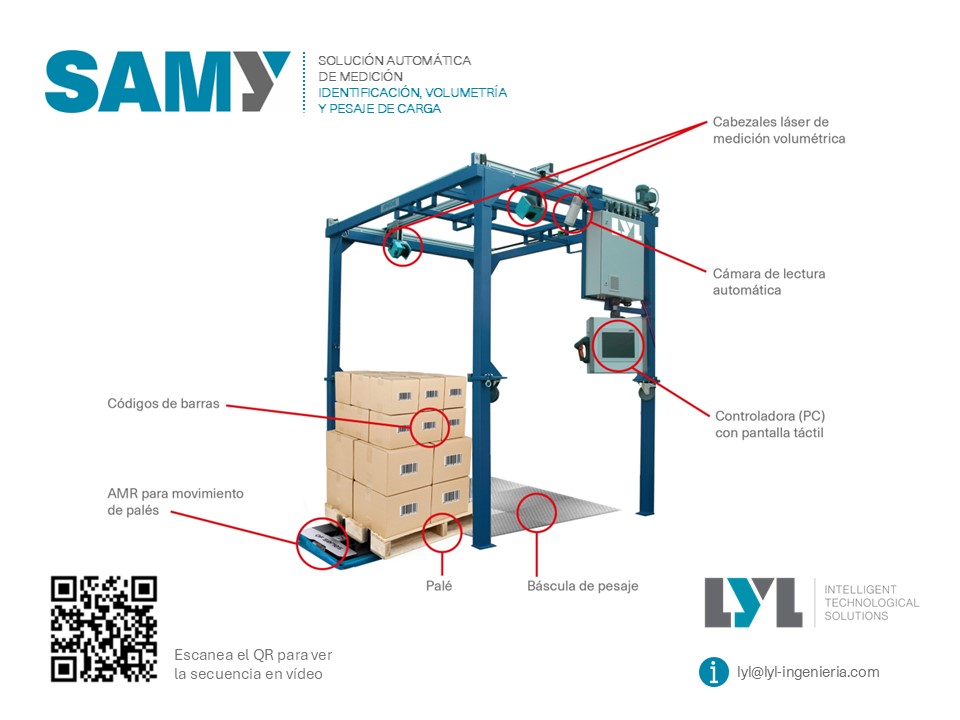

SAMY

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Griffins

Food, Beverage, material handling

PHS Innovate was the automation supplier selected to supply the new palletizer solution for Griffin’s factory. We designed a SAP-compatible system utilising four ABB robots and integrated stretch wrapping and labelling. Our proposal also included an upgrade to Griffins’ conveyor systems, to help with back pressure and product line control. The new palletizer system was installed while the old system was still running, to enable a staged changeover. Our robots were equipped with standard mechanical gripping heads, which have the versatility required for Griffins’ diverse product range. Compared to Griffins’ old system, this method of holding cases was a significant improvement. The final installation was achieved over two weekends, to ensure minimal impact to production at the factory. Initially, half the production line was directed to the new palletizer system. After a few weeks, when it was clear that everything was running smoothly, total production was directed to the new solution and the old palletiser was decommissioned.

Use case

Griffins

Food, Beverage, material handling

PHS Innovate was the automation supplier selected to supply the new palletizer solution for Griffin’s factory. We designed a SAP-compatible system utilising four ABB robots and integrated stretch wrapping and labelling. Our proposal also included an upgrade to Griffins’ conveyor systems, to help with back pressure and product line control. The new palletizer system was installed while the old system was still running, to enable a staged changeover. Our robots were equipped with standard mechanical gripping heads, which have the versatility required for Griffins’ diverse product range. Compared to Griffins’ old system, this method of holding cases was a significant improvement. The final installation was achieved over two weekends, to ensure minimal impact to production at the factory. Initially, half the production line was directed to the new palletizer system. After a few weeks, when it was clear that everything was running smoothly, total production was directed to the new solution and the old palletiser was decommissioned.

When exploring the Logistics Robotics industry in the United States, several key considerations come into play. First, understanding the regulatory landscape is crucial, as this sector is subject to safety and operational regulations that vary by state and federal guidelines. The challenges faced by companies include high initial investment costs, the technical complexity of implementing robotic systems, and the need for skilled labor to operate and maintain these technologies. Opportunities abound in this rapidly growing field, with advancements in artificial intelligence and machine learning enhancing the capabilities of logistics robots, leading to improved efficiency and reduced operational costs. Environmental concerns are also becoming increasingly significant, as companies look to integrate sustainable practices and reduce their carbon footprint through automation. The competitive landscape is dynamic, with both established players and startups vying for market share, making it important to analyze the strengths and weaknesses of different companies. Furthermore, the global market relevance cannot be overlooked; as the demand for logistics automation rises worldwide, U.S. companies can leverage their technological advancements to expand internationally. Overall, a comprehensive understanding of these factors will provide valuable insights for anyone interested in the logistics robotics sector in the United States.

Some interesting numbers and facts about your company results for Logistics Robotics

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 2704 |

| Amount of suitable service providers | 2928 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 2000 |

| Youngest suiting company | 2021 |

Some interesting questions that has been asked about the results you have just received for Logistics Robotics

What are related technologies to Logistics Robotics?

Based on our calculations related technologies to Logistics Robotics are Water/Ocean Cleaning Technologies, Waste Management, Renewable Energy, Sustainable Fashion, Smart Grid

Who are Start-Ups in the field of Logistics Robotics?

Start-Ups who are working in Logistics Robotics are LogisticsFlow

Which industries are mostly working on Logistics Robotics?

The most represented industries which are working in Logistics Robotics are Logistics, Supply Chain and Transportation, IT, Software and Services, Other, Automation, Machinery Manufacturing

How does ensun find these Logistics Robotics Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.