The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

OmniMod

Trondheim, Norway

A

1-10 Employees

2020

Key takeaway

The company focuses on developing intelligent solutions that enhance the efficiency and automation of logistics operations. Their innovative approach combines self-learning software with modular hardware, aiming to simplify and improve logistics processes.

Reference

Core business

Home | OmniMod

Blue Robot Company

Tønsberg, Norway

A

1-10 Employees

-

Key takeaway

Blue Robot AS specializes in automating small and medium-sized warehouses with their innovative automated storage and retrieval system (ASRS), designed to enhance operational efficiency and optimize picking speed. Their energy-efficient technology addresses key challenges in warehouse logistics, such as inventory accuracy and space utilization.

Reference

Core business

Automated storage and retrieval system | Blue Robot Company | Norway

Blue Robot is the worlds most innovative automated storage and retrieval system (ASRS). Blue Robot is cost effective and can be installed in your current warehouse. All Blue Robot need is 3 meter ceiling space, a leveled floor, power and internet access.

Optilift AS

Kristiansand, Norway

A

1-10 Employees

2010

Key takeaway

The company provides innovative solutions for digitalization and autonomous cargo handling, emphasizing the use of artificial intelligence to enhance the efficiency and safety of logistics operations.

Reference

Product

Digital Logistics – Optilift | Artificial intelligence for more efficient and safer cargo handling.

The brain behind.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

AutoStore

Vatne, Norway

A

101-250 Employees

1997

Key takeaway

The company specializes in logistics robotics with its AutoStore™ Robots, which automate the process of driving, collecting, and delivering Bins for efficient order fulfillment. This system not only enhances data visibility and reduces labor costs but also ensures timely delivery, particularly important for sectors like healthcare.

Reference

Core business

World's Fastest AS/RS | 4x Space and 97% Uptime | AutoStore

AutoStore is an automated storage and retrieval system (ASRS) that uses the power of warehouse robots for 24/7 order fulfillment within a cubic layout.

Driw AS

Ålesund, Norway

A

51-100 Employees

1982

Key takeaway

Solwr specializes in logistics robotics, offering innovative solutions like their picking robot Grab and sorting robot Sort, which enhance efficiency in warehouse operations. With a team of experts in automation and robotics, Solwr is committed to continuous product development and integration of advanced technologies in logistics.

Reference

Product

Solwr - Robotics

Our warehouse robots Sort and Grab ensures great efficiency and HSE gains. Grab picks'n places the goods, while Sort is our pallet sorting expert.

Element Logic

Kløfta, Norway

A

51-100 Employees

1985

Key takeaway

Element Logic is a leading AutoStore™ partner that specializes in designing and installing automated storage and retrieval systems, enhancing warehouse performance and efficiency. Their expertise in tailored solutions directly addresses the needs of logistics operations, streamlining workflows for improved productivity.

Reference

Product

Design and Consulting - Element Logic

Our team of AutoStore, and intralogistics experts map out your specific needs and preferences to design a tailored, automated warehouse solution.

Pickr.AI

Stavanger, Norway

A

1-10 Employees

-

Key takeaway

Pickr is revolutionizing order picking with its innovative robotic solutions, including the PickrMate, which enhances efficiency and enables faster delivery. Their autonomous order-picking cell has been successfully utilized since early 2021, providing a reliable robotic workforce that operates continuously to fulfill orders.

Reference

Core business

Home | PICKR.AI

VOCA AS

Spangereid, Norway

A

1-10 Employees

2006

Key takeaway

VOCA specializes in developing solutions that enhance logistics planning, execution, tracking, and reporting. Their subsidiaries, Optilift AS and Digital Logistics AS, focus on improving lifting and cargo handling operations through innovative technologies.

Reference

Product

Digital Logistics – VOCA | AI technology for industrial digitalization and automony.

The brain behind.

Spacelab

Tromsø, Norway

A

1-10 Employees

-

Key takeaway

The company focuses on creating software solutions that enhance the efficiency of logistics operations, aiming to optimize cargo capacity and reduce CO2 emissions in the supply chain industry. Their vision includes utilizing innovative approaches to improve the overall workflow and effectiveness of transportation.

Reference

Core business

Spacelab

Logistics Software Solutions

MixMove

Bærum, Norway

A

11-50 Employees

2017

Key takeaway

MIXMOVE® is at the forefront of logistics innovation, offering advanced software solutions that enhance fulfillment and streamline logistics processes. Their focus on data-driven strategies and connected supply chain software positions them as a key player in creating efficient and sustainable logistics operations.

Reference

Core business

MIXMOVE | Data-driven logistics | Visibility

It's time for data driven logistic! MIXMOVE is an award winning collaborative cloud platform enlightening logistics data to give multi-enterprise teams worldwide a new product level superpower. All with the aim of making logistics processes connected, efficient, and sustainable.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Palletizing

Go to product

Service

AMR Controller SRC-3000FS

Go to product

Service

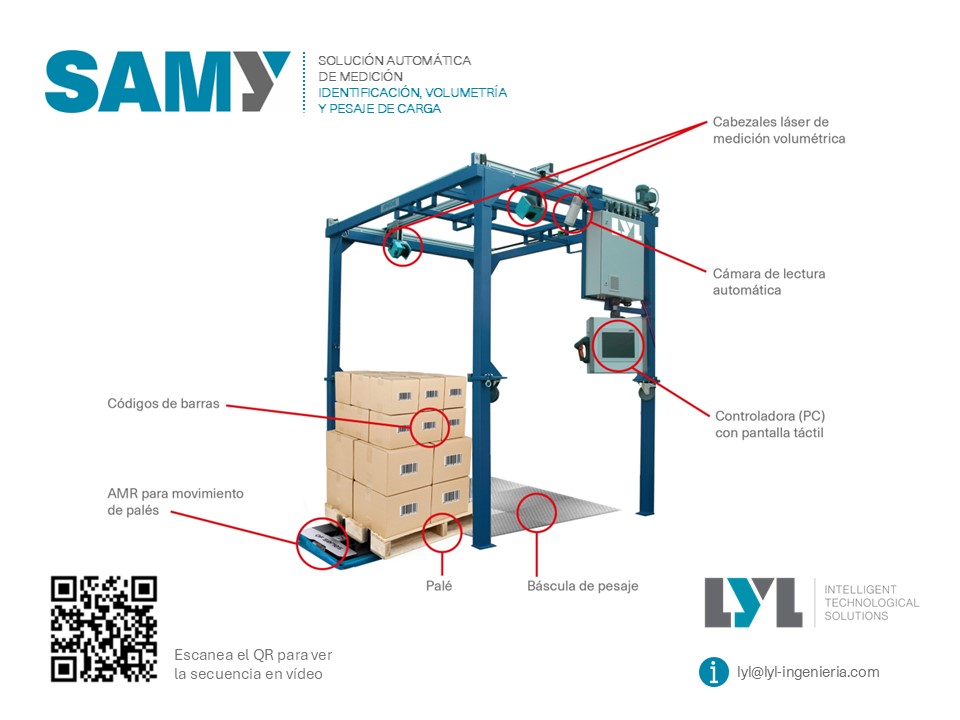

SAMY

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Griffins

Food, Beverage, material handling

PHS Innovate was the automation supplier selected to supply the new palletizer solution for Griffin’s factory. We designed a SAP-compatible system utilising four ABB robots and integrated stretch wrapping and labelling. Our proposal also included an upgrade to Griffins’ conveyor systems, to help with back pressure and product line control. The new palletizer system was installed while the old system was still running, to enable a staged changeover. Our robots were equipped with standard mechanical gripping heads, which have the versatility required for Griffins’ diverse product range. Compared to Griffins’ old system, this method of holding cases was a significant improvement. The final installation was achieved over two weekends, to ensure minimal impact to production at the factory. Initially, half the production line was directed to the new palletizer system. After a few weeks, when it was clear that everything was running smoothly, total production was directed to the new solution and the old palletiser was decommissioned.

Use case

Griffins

Food, Beverage, material handling

PHS Innovate was the automation supplier selected to supply the new palletizer solution for Griffin’s factory. We designed a SAP-compatible system utilising four ABB robots and integrated stretch wrapping and labelling. Our proposal also included an upgrade to Griffins’ conveyor systems, to help with back pressure and product line control. The new palletizer system was installed while the old system was still running, to enable a staged changeover. Our robots were equipped with standard mechanical gripping heads, which have the versatility required for Griffins’ diverse product range. Compared to Griffins’ old system, this method of holding cases was a significant improvement. The final installation was achieved over two weekends, to ensure minimal impact to production at the factory. Initially, half the production line was directed to the new palletizer system. After a few weeks, when it was clear that everything was running smoothly, total production was directed to the new solution and the old palletiser was decommissioned.

When exploring the logistics robotics industry in Norway, several key considerations come into play. The country's robust technological infrastructure and commitment to innovation create a fertile environment for companies in this sector. Regulations concerning automation and robotics are evolving, with a focus on ensuring safety and compliance with European standards. Understanding these regulations is crucial for companies looking to enter the market. The competitive landscape features both established players and emerging startups, making it important to analyze market positioning and technological advancements. Challenges include adapting to the unique geographical conditions of Norway, which can impact logistics operations and the deployment of robotics solutions. Additionally, environmental concerns are paramount, with a strong emphasis on sustainability and reducing carbon footprints. Opportunities exist in sectors such as e-commerce and warehousing, where automation can enhance efficiency and reduce operational costs. Furthermore, the global market relevance of logistics robotics is increasing, with Norway positioned as a significant player in the Nordic region. Collaborations with research institutions and government initiatives can provide further support for innovation. As companies assess their strategies, staying informed about market trends and technological advancements will be essential for success in this dynamic industry.

Some interesting numbers and facts about your company results for Logistics Robotics

| Country with most fitting companies | Norway |

| Amount of fitting manufacturers | 46 |

| Amount of suitable service providers | 32 |

| Average amount of employees | 1-10 |

| Oldest suiting company | 1982 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Logistics Robotics

What are related technologies to Logistics Robotics?

Based on our calculations related technologies to Logistics Robotics are Water/Ocean Cleaning Technologies, Waste Management, Renewable Energy, Sustainable Fashion, Smart Grid

Which industries are mostly working on Logistics Robotics?

The most represented industries which are working in Logistics Robotics are Logistics, Supply Chain and Transportation, IT, Software and Services, Other, Automation, Aviation and Aerospace

How does ensun find these Logistics Robotics Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.