The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Rapyuta Robotics

Tokyo, Japan

A

101-250 Employees

2014

Key takeaway

The company offers advanced robotics solutions, specifically the Rapyuta PA-AMR, which enhances logistics operations by improving productivity in picking tasks, reducing workers’ workload, and addressing labor shortages through automation. This system features easy integration and key functionalities that optimize workflow efficiency.

Reference

Product

Technology

We come from the school of thought that it is more pragmatic and scalable to build simple heterogeneous robots that focus on a smaller subset of tasks and coordinate these robots to achieve larger objectives, instead of building all-in-one complex robots. We focus on the following technologies to create value for our customers.

WinRoad RTS

Tokyo, Japan

A

1-10 Employees

2019

Key takeaway

The company, WinRoad RTS, is a robotic technology provider specializing in Japanese robot technology for the Middle East and Africa. They offer support for developing custom robot systems and starting robotic businesses, which may be relevant for logistics robotics applications.

Reference

Core business

Robot Technology Provider | WinRoad RTS | Japan

A robotic company specializes in providing Japanese robot technology to the Middle East and Africa.

LexxPluss

Kawasaki, Japan

A

11-50 Employees

2020

Key takeaway

LexxPluss is a technology company that provides sustainable solutions for logistics and manufacturing through its autonomous mobile robots. Their innovative robotics automation technology is designed to enhance efficiency in logistics centers and manufacturing plants.

Reference

Core business

株式会社LexxPluss | Sustainable Industry Sustainable Life

株式会社LexxPlussは、自動搬送ロボットをはじめとするロボティクスオートメーション技術で物流センターや製造工場へ持続可能性を提供するテクノロジーカンパニーです。法人向け設計図公開プログラムを実施しています。

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

SITMA JAPAN, K.K.

Tokyo, Japan

A

1-10 Employees

1999

Key takeaway

Sitma Machinery S.p.A. is focused on elogistics as a key area of investment, developing scalable solutions specifically for the e-commerce industry. The company specializes in machinery for e-commerce packaging, offering innovative inline packaging systems.

Reference

Product

Elogistics | Ecommerce Packaging - Sitma Machinery S.p.A.

Sitma is specialized in machinery for ecommerce packaging. Discover our solutions for inline packaging systems.

Mujin, Inc.

Tokyo, Japan

A

101-250 Employees

2011

Key takeaway

Mujin specializes in logistics robotics, offering automated solutions for storage and order fulfillment that ensure zero damage and efficient packing. Their MujinController platform empowers robots with advanced perception and autonomous decision-making, while their TruckBot provides an innovative, autonomous method for unloading trailers and shipping containers.

Reference

Core business

News | Mujin Corp

Get the latest news at Mujin Corp - a warehouse robotic company taking automation to the next level through groundbreaking innovation.

Smart Vision Logistics

Tokyo, Japan

A

51-100 Employees

2019

Key takeaway

The company, SVL, emphasizes its commitment to transforming logistics through sustainable supply chain practices and a focus on customer needs. They believe that extraordinary efficiency and a strong workforce are key to enhancing logistics and delivery services.

Reference

Service

サービス概要 - Smart Vision Logistics

Nittsu Research Institute and Consulting

Tokyo, Japan

A

51-100 Employees

1958

Key takeaway

The NX Logistics Research Institute and Consulting, Inc. offers a lineup of tools, including the "Rojitan Series," designed to enhance various aspects of logistics, such as warehouse operations analysis and driver management. Their focus on IoT utilization and digitalization aims to promote the development of next-generation logistics systems.

Reference

Service

ろじたんシリーズ | NX総研

倉庫作業の分析、ドライバーの運行管理の把握、オフィスワークにおける業務時間のデータ化など物流に関わる様々なシーンで活躍できるラインナップとなっております。 NX総研の業務改善ツールで IoT活用、デジタル化を促進させ次世代の物流体制を構築してみませんか。

TELEXISTENCE Inc.

Tokyo, Japan

A

11-50 Employees

2017

Key takeaway

The company focuses on expanding the role of robots beyond traditional settings, developing advanced robotics solutions that integrate artificial intelligence and teleoperation technologies. Their innovative approach aims to revolutionize labor through robotics, with a specific solution designed for retail.

Reference

Product

Technology – TELEXISTENCE inc.

Coarobo

Kyoto, Japan

A

1-10 Employees

2019

Key takeaway

Coarobo GK focuses on enhancing service robotics and artificial intelligence through innovative software development environments. They provide consulting services and have published research that supports robotic system integration, which is critical for logistics robotics applications.

Reference

Core business

Coarobo GK - 企業情報

Coarobo GK provides consulting services for innovative robotics solutions powered by state-of-the-art artificial intelligence.

(株)ハイボット

Tokyo, Japan

A

11-50 Employees

2004

Key takeaway

Hibot provides advanced robotic solutions that enhance logistics through autonomous inspection and maintenance, particularly in hazardous or confined spaces. Their integration of smart tools with data management and AI-driven defect detection is crucial for predicting failures in aging infrastructures.

Reference

Core business

Home | Hibot

Hibot Website

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Palletizing

Go to product

Service

AMR Controller SRC-3000FS

Go to product

Service

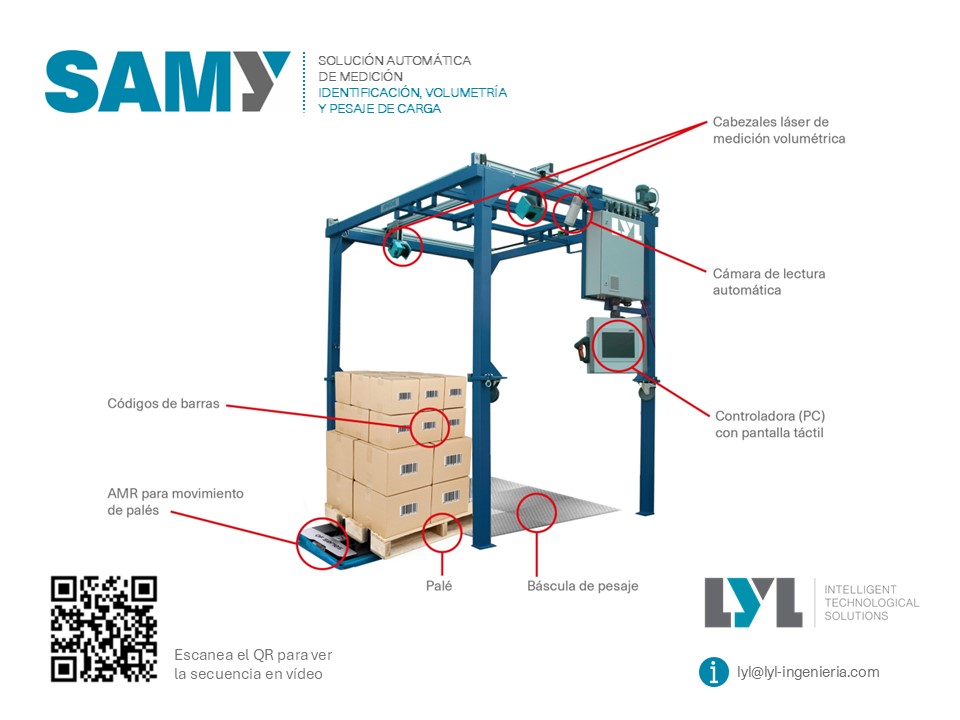

SAMY

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Griffins

Food, Beverage, material handling

PHS Innovate was the automation supplier selected to supply the new palletizer solution for Griffin’s factory. We designed a SAP-compatible system utilising four ABB robots and integrated stretch wrapping and labelling. Our proposal also included an upgrade to Griffins’ conveyor systems, to help with back pressure and product line control. The new palletizer system was installed while the old system was still running, to enable a staged changeover. Our robots were equipped with standard mechanical gripping heads, which have the versatility required for Griffins’ diverse product range. Compared to Griffins’ old system, this method of holding cases was a significant improvement. The final installation was achieved over two weekends, to ensure minimal impact to production at the factory. Initially, half the production line was directed to the new palletizer system. After a few weeks, when it was clear that everything was running smoothly, total production was directed to the new solution and the old palletiser was decommissioned.

Use case

Griffins

Food, Beverage, material handling

PHS Innovate was the automation supplier selected to supply the new palletizer solution for Griffin’s factory. We designed a SAP-compatible system utilising four ABB robots and integrated stretch wrapping and labelling. Our proposal also included an upgrade to Griffins’ conveyor systems, to help with back pressure and product line control. The new palletizer system was installed while the old system was still running, to enable a staged changeover. Our robots were equipped with standard mechanical gripping heads, which have the versatility required for Griffins’ diverse product range. Compared to Griffins’ old system, this method of holding cases was a significant improvement. The final installation was achieved over two weekends, to ensure minimal impact to production at the factory. Initially, half the production line was directed to the new palletizer system. After a few weeks, when it was clear that everything was running smoothly, total production was directed to the new solution and the old palletiser was decommissioned.

The Logistics Robotics industry in Japan presents unique opportunities and challenges that are crucial for potential investors and stakeholders to consider. Japan's aging population and shrinking workforce create a pressing need for automation, positioning logistics robotics as a viable solution to enhance efficiency and reduce labor costs. Regulatory frameworks in Japan are generally supportive of technological advancements, but navigating local laws, safety standards, and labor regulations is essential for compliance. Challenges such as high initial investment costs and the complexity of integrating robotics into existing logistics systems must also be addressed. Environmental sustainability is becoming increasingly important, with companies focusing on reducing carbon footprints and implementing eco-friendly practices in their operations. Furthermore, the competitive landscape is marked by both established firms and innovative startups, which can provide a diverse range of solutions and partnerships. The global market relevance of Japanese logistics robotics is significant, as advancements in this sector can influence trends and innovations worldwide. Understanding these factors will enable informed decision-making and strategic planning for those interested in engaging with the logistics robotics sector in Japan.

Some interesting numbers and facts about your company results for Logistics Robotics

| Country with most fitting companies | Japan |

| Amount of fitting manufacturers | 9 |

| Amount of suitable service providers | 5 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1958 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Logistics Robotics

What are related technologies to Logistics Robotics?

Based on our calculations related technologies to Logistics Robotics are Water/Ocean Cleaning Technologies, Waste Management, Renewable Energy, Sustainable Fashion, Smart Grid

Which industries are mostly working on Logistics Robotics?

The most represented industries which are working in Logistics Robotics are Automation, Other, Logistics, Supply Chain and Transportation, IT, Software and Services, Wholesale

How does ensun find these Logistics Robotics Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.