The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Bleum

Huangpu District, China

D

1001-5000 Employees

2001

Key takeaway

Prime Robotics specializes in providing tailored robotic automation solutions for warehouses, e-commerce, and material handling. Their expertise in logistics operations allows them to develop customized systems that enhance efficiency and reduce costs, making them a key player in the logistics robotics sector.

Reference

Core business

Warehouse Robotic Automation Solutions

Prime Robotics automation solutions allow Warehouse, E-Commerce and Factory facilities to accelerate operations for efficiency and cost savings.

Multiway Robotics

Shenzhen, China

D

251-500 Employees

2019

Key takeaway

Multiway Robotics specializes in intelligent intralogistics solutions, focusing on advanced robotics and AI technology to enhance efficiency and reduce operational costs. They offer a range of automated forklifts and integrated software systems, making them a key player in the logistics robotics sector.

Reference

Core business

Multiway Robotics | Automated AGV Forklifts Provider

ForwardX Robotics

Dongcheng District, China

D

251-500 Employees

2016

Key takeaway

ForwardX Robotics is a leading provider of autonomous mobile robot (AMR) solutions, significantly enhancing logistics operations through advanced technologies like RFID. Their systems increase picking productivity and achieve a remarkable 99.99% picking accuracy, offering a substantial return on investment in a short timeframe.

Reference

Core business

AMR Autonomous Mobile Robots & Solutions Provider - ForwardX Robotics

ForwardX Robotics, is one of the world's leading AMR manufacturers, providing the types of autonomous mobile robots and AMR solutions for enterprises in various industries.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

HAI ROBOTICS

Shenzhen, China

D

501-1000 Employees

2016

Key takeaway

Hai Robotics specializes in logistics robotics, offering the HaiPick solution, the world's first Autonomous Case-handling Mobile Robot (ACR) system. Their innovative approach enhances efficiency and flexibility in warehousing and distribution, addressing challenges like rising labor costs and the need for order-driven production.

Reference

Product

Automotive Warehousing, Auto Logistics Robotics Solution | Hai Robotics

The diversification of order-driven production and rising labor costs are posing significant challenges to the traditional mode of warehousing logistics. In response, a robotics-based automotive warehousing solution has emerged at the case handling level. Hai Robotics has disrupted the traditional manual operation mode by achieving significant advancements in efficiency, cost, and flexibility. This breakthrough is leading the logistics mode of the automotive industry to enter a revolution of automation, intelligence, and digitization.

Dorabot

Shenzhen, China

D

101-250 Employees

2015

Key takeaway

Dorabot is a technology leader in robotic fulfillment solutions, specializing in smart warehouse solutions that enhance logistics, e-commerce, and supply chain operations. Their AI-powered robotic systems streamline processes and improve efficiency, making them a key player in the logistics robotics sector.

Reference

Core business

Home - Dorabot

AI-powered robotic solutions for warehouses, DCs, supply chain operations, fulfillment centers and omnichannel.

Robotics Automation Solutions

Huangpu District, China

D

251-500 Employees

2001

Key takeaway

Strength Robotics specializes in designing and manufacturing compact and precise industrial robots, which are integral to optimizing automated logistics systems. Their focus on intelligent logistics solutions directly aligns with the need for advanced robotics in enhancing production efficiency.

Reference

Product

Intelligent Logistics, Robotics Automation Solutions | STRENGTH

Youibot

Shenzhen, China

D

1-10 Employees

2017

Key takeaway

YOUIBOT Robotics is a leading provider of mobile robot solutions, having deployed over 5,000 autonomous mobile robots (AMRs) for major clients like Apple and DHL, significantly enhancing logistics automation and productivity. Their innovative technologies and versatile systems are transforming supply chain operations across various industries.

Reference

Product

Automatic Trolley Robotic Solutions | Automatic Trolley Robot - Youibot

Introducing Fast, Flexible Fulfillment With Up To 3X Pick Productivity

Geek+

Dongcheng District, China

D

251-500 Employees

2015

Key takeaway

Geek+ is a global leader in logistics automation, specializing in smart autonomous mobile robots (AMRs) that enhance picking, sorting, and material handling in warehouses. With a focus on innovative robotic systems, they have been driving supply chain advancements for over 1,000 industry leaders since their inception in 2015.

Reference

Core business

Geek+ Robotics | Mobile Robots & Solutions for Logistics Automation

Geek+ builds smart autonomous mobile robots (AMRs) that handle picking, sorting and industrial material handling for logistics and warehouse automation

Hong Kong Centre for Logistics Robotics

Hong Kong Island, China

D

51-100 Employees

2020

Key takeaway

The Hong Kong Centre for Logistics Robotics, established in 2020, focuses on advancing robotics and AI technologies to address key challenges in the logistics industry. Through collaboration with leading academic and industrial partners, the Centre aims to enhance the competitiveness of the local logistics sector in the Greater Bay Area and beyond.

Reference

Core business

Hong Kong Centre For Logistics Robotics

上海天巍国际货物运输代理有限公司

Huangpu District, China

D

1-10 Employees

-

Key takeaway

The company has established itself as a leader in the international trade business, offering intelligent transportation solutions that cater to specific customer needs. Their strategically positioned distribution centers enhance inventory management and provide real-time visibility, ensuring efficient transportation of products.

Reference

Service

Logistics

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Palletizing

Go to product

Service

AMR Controller SRC-3000FS

Go to product

Service

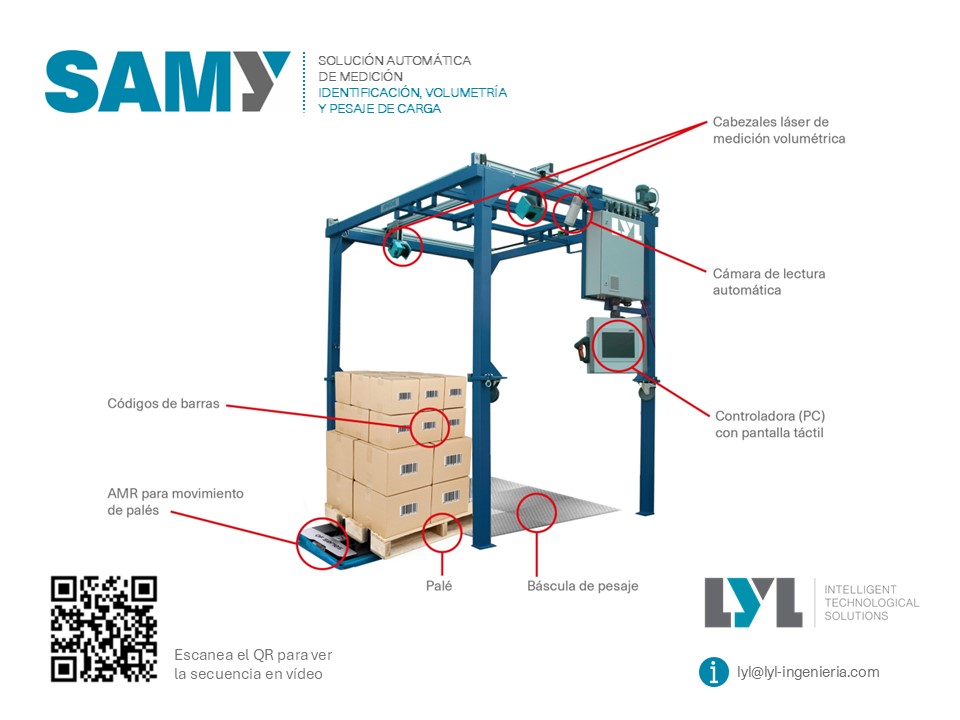

SAMY

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Griffins

Food, Beverage, material handling

PHS Innovate was the automation supplier selected to supply the new palletizer solution for Griffin’s factory. We designed a SAP-compatible system utilising four ABB robots and integrated stretch wrapping and labelling. Our proposal also included an upgrade to Griffins’ conveyor systems, to help with back pressure and product line control. The new palletizer system was installed while the old system was still running, to enable a staged changeover. Our robots were equipped with standard mechanical gripping heads, which have the versatility required for Griffins’ diverse product range. Compared to Griffins’ old system, this method of holding cases was a significant improvement. The final installation was achieved over two weekends, to ensure minimal impact to production at the factory. Initially, half the production line was directed to the new palletizer system. After a few weeks, when it was clear that everything was running smoothly, total production was directed to the new solution and the old palletiser was decommissioned.

Use case

Griffins

Food, Beverage, material handling

PHS Innovate was the automation supplier selected to supply the new palletizer solution for Griffin’s factory. We designed a SAP-compatible system utilising four ABB robots and integrated stretch wrapping and labelling. Our proposal also included an upgrade to Griffins’ conveyor systems, to help with back pressure and product line control. The new palletizer system was installed while the old system was still running, to enable a staged changeover. Our robots were equipped with standard mechanical gripping heads, which have the versatility required for Griffins’ diverse product range. Compared to Griffins’ old system, this method of holding cases was a significant improvement. The final installation was achieved over two weekends, to ensure minimal impact to production at the factory. Initially, half the production line was directed to the new palletizer system. After a few weeks, when it was clear that everything was running smoothly, total production was directed to the new solution and the old palletiser was decommissioned.

When exploring the Logistics Robotics industry in China, several key considerations come into play. The regulatory environment is evolving, with the government actively promoting automation and robotics through policies that encourage innovation while also enforcing safety standards. Companies must navigate complex regulations that may vary by region, impacting operational capabilities. The competitive landscape is intense, featuring both domestic firms and international players, which drives innovation and price competitiveness. Challenges such as talent shortages in robotics engineering and high initial investment costs can impede growth. However, opportunities abound in the booming e-commerce sector, where demand for automated logistics solutions is rising rapidly. Environmental concerns are also increasingly relevant, as companies face pressure to adopt sustainable practices, such as energy-efficient operations and reduced carbon footprints. Moreover, the global market relevance of China's Logistics Robotics industry cannot be overstated, as the nation is positioned as a leader in automation technology. Understanding local market dynamics, consumer preferences, and technological advancements is crucial for anyone looking to invest or engage in this sector. As the industry continues to develop, staying informed about trends and potential disruptions is essential for success.

Some interesting numbers and facts about your company results for Logistics Robotics

| Country with most fitting companies | China |

| Amount of fitting manufacturers | 158 |

| Amount of suitable service providers | 144 |

| Average amount of employees | 251-500 |

| Oldest suiting company | 2001 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Logistics Robotics

What are related technologies to Logistics Robotics?

Based on our calculations related technologies to Logistics Robotics are Water/Ocean Cleaning Technologies, Waste Management, Renewable Energy, Sustainable Fashion, Smart Grid

Which industries are mostly working on Logistics Robotics?

The most represented industries which are working in Logistics Robotics are Logistics, Supply Chain and Transportation, IT, Software and Services, Automation, Other, Electronics and Electrical engineering

How does ensun find these Logistics Robotics Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.