The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

FORMET LIMITED

Montrose, United Kingdom

A

1-10 Employees

-

Key takeaway

Formet Fabrications offers subcontract services for custom sheet metalwork, emphasizing high-quality production and timely delivery, which can help reduce productivity costs in metal forming processes.

Reference

Service

Services - Formet Fabrications

Metal Forming Solutions

Tulsa, United States

B

51-100 Employees

2019

Key takeaway

Metal Forming Solutions specializes in manufacturing various metal products, including SA234 Butt Weld Fittings and providing cold and hot forming services. With over thirty years of experience, the company is recognized for its innovative solutions and high-quality metal works, making it a key player in the metal forming industry.

Reference

Core business

Cold Forming & Hot Forming Solution & Custom | Metal Forming Solutions

A leading provider of bending services & applications, foreign and domestic. Tight radius and large radius cold forming. Bending for Shell & Tube

Techniform Metal Curving

Mabank, United States

B

51-100 Employees

1992

Key takeaway

Techniform has been a leader in metal forming since 1989, specializing in various techniques such as roll forming, brake forming, and stretch forming for both ferrous and non-ferrous metals. The company serves multiple industries, including aerospace and transportation, and is known for its commitment to quality and customer satisfaction in fabrication and machining services.

Reference

Service

Techniform Stretchform | Metal & Alloy Bending Fabrication | Mabank, TX

Stretchforming, Rolling, Bending, Sheet Metal, Brake and Bump Forming, Joggle, Machining, Hot Forming, Check and Straighten, Fabrication, Steel, Aluminum

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Fabrication Services Incorporated

Central, United States

B

11-50 Employees

1970

Key takeaway

The company, Fabrication Services, Inc., specializes in metal forming, highlighting its ability to manufacture critical parts and components without compromising product integrity. Their in-house rolling and forming capabilities ensure high quality and timely delivery for various commercial metal forming processes.

Reference

Service

Metal Fabrication & Forming Services | Fabrication Services, Inc.

Learn how Fabrication Services, Inc. can meet your custom fabrication needs with rolling and forming services. Contact us today or visit our website.

Hill Engineering, Inc.

Carol Stream, United States

B

- Employees

1950

Key takeaway

Formtek specializes in roll forming solutions, offering a comprehensive range of tube and pipe mill solutions and coil processing systems. With over 100 years of experience, they provide tailored metal forming and fabrication solutions for various industries, focusing on both standard and custom applications.

Reference

Core business

Formtek - Formtek

Form Fabrications

United Kingdom

A

1-10 Employees

-

Key takeaway

Form Fabrications (Birmingham) Ltd specializes in a full range of bespoke fabrication services, including sheet metal work and coded welding, which are integral to the metal forming process. With a commitment to quality and customer satisfaction, the company has built a reputation for trust and expertise in various fabrication techniques since 1976.

Reference

Service

Our Services - Form Fabrications

Imperial Group Manufacturing, Inc.

United States

B

1001-5000 Employees

2013

Key takeaway

Ironform is a leading Tier 1 metal fabricator that specializes in various sectors, including transportation and construction. By applying Lean manufacturing principles, Ironform enhances metal forming processes, ensuring high quality and efficiency while accommodating fluctuations in volume and part variation.

Reference

Core business

Home | Ironform

Trusted Tier 1 metal fabricator, supplying market leaders in Class 8 transportation, construction, agriculture, mining, off-road, material handling, and industrial equipment. Applys Lean manufacturing principles to metal fabrication. Offers the shortest lead times at the lowest variable cost, with flexibility to accommodate volume fluctuations and part variation. Combines world-class dimensional control with a disciplined execution model to consistently deliver the lowest PPM in the business.

Metal Forms Engineering Ltd

Walsall, United Kingdom

A

1-10 Employees

-

Key takeaway

The company, MetalForms, specializes in quality precision sheet metal fabrication, making it well-suited for metal forming needs. With a strong reputation and state-of-the-art machinery, they cater to various manufacturing industries across the UK.

Reference

Core business

Metal Forms Engineering| CNC fabricator| bespoke| sheet| metal| products| Press Braking| Threaded Inserts| Welding| In-house Painting| Product Finishing| CNC Punching & Profiling

Formasters Corporation

Mentor, United States

B

11-50 Employees

1993

Key takeaway

ForMasters is a leading manufacturer specializing in roll forming and custom metal stamping, with over 25 years of experience in metal shaping processes. Their expertise in CNC machining and advanced design techniques ensures high-quality production of metal parts to exact specifications.

Reference

Core business

ForMaster's Roll Forming and Roll Form Manufacturing

Cleveland, OH based company with expertise in roll forming manufacturing. Able to manufacture all sizes of metal shape and parts.

MetalForming Magazine

Independence, United States

B

1-10 Employees

-

Key takeaway

The metal forming industry encompasses a wide range of activities, including contract and captive metal stamping, precision sheet metal fabrication, and tool and die production. MetalForming Magazine actively supports this sector by hosting webinars that connect equipment and technology providers with industry professionals, facilitating the exchange of knowledge and solutions relevant to metal forming and fabrication.

Reference

Core business

MetalForming Magazine

at MetalForming Magazine

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

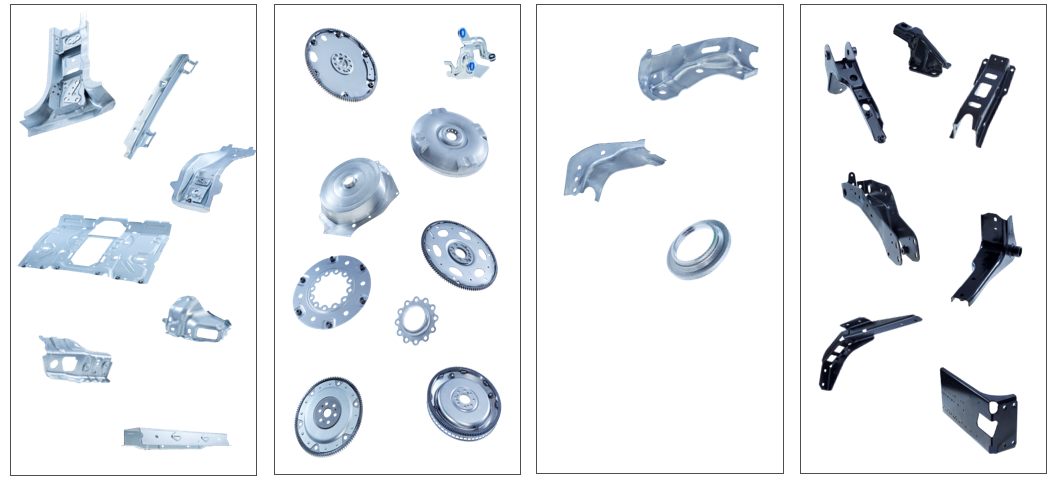

Service

Sheet Metal Parts and Components

Go to product

Service

Relocation Projects

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

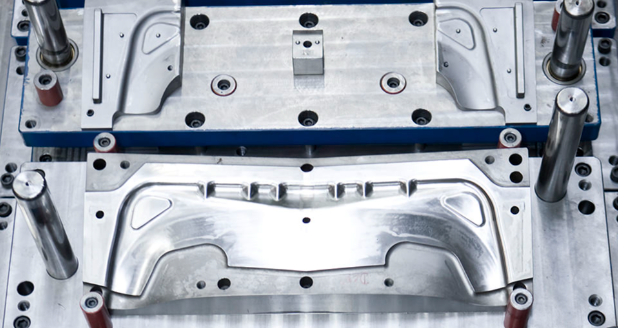

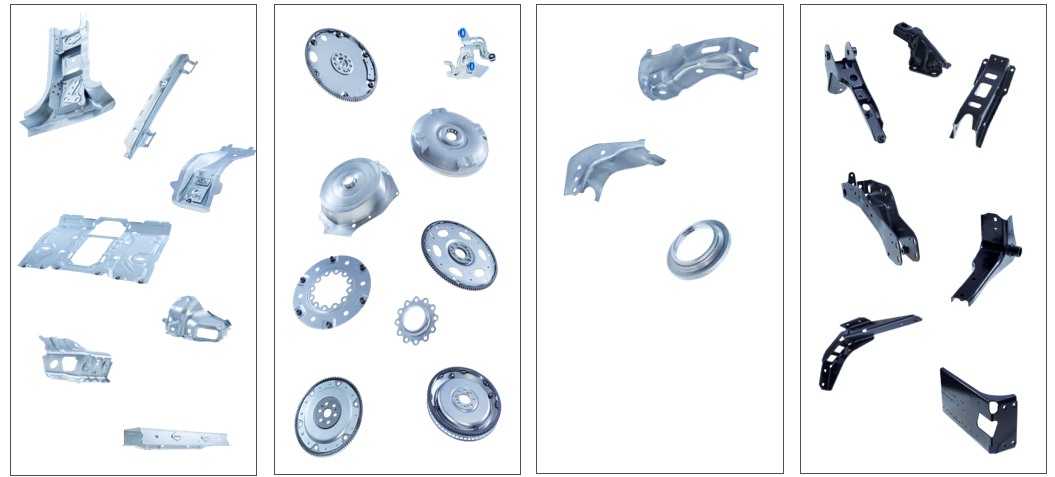

Use case

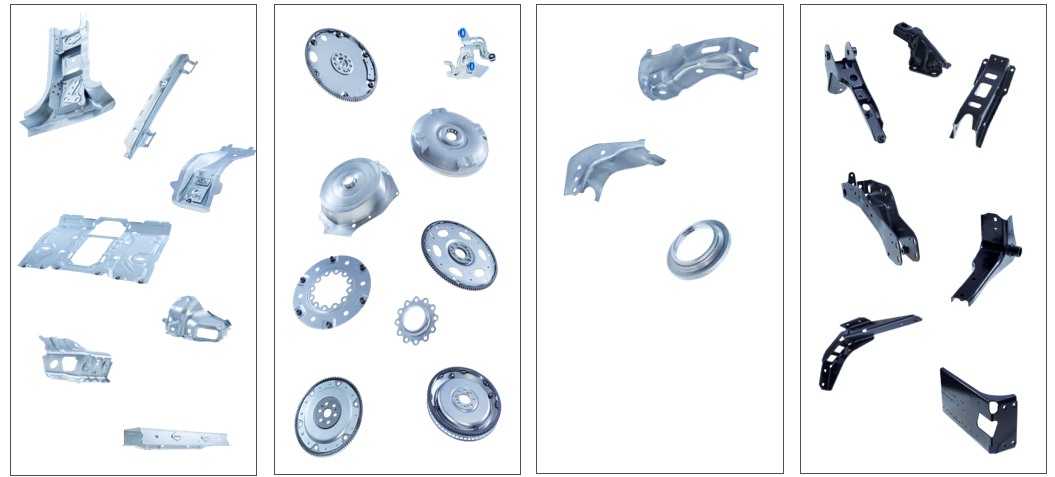

Car Body in White

Automotive, Industry

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

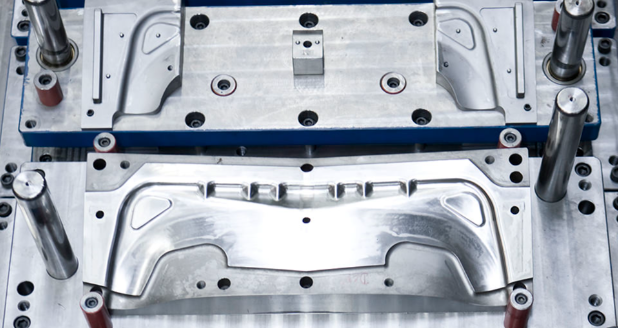

Use case

Relocation projects

Automotive, Industry

Seamless Relocation Projects in Forming and Joining Technology—Powered by Mühlhoff When it comes to relocating your production lines, Mühlhoff is your expert partner. We specialize in executing complex relocation projects in forming and joining technology, ensuring minimal downtime and maximum efficiency. With our comprehensive service, we handle everything—from planning and dismantling to reassembly and optimization at the new site. Our experienced team works closely with you, providing tailor-made solutions that meet your specific needs while ensuring that your production is up and running as quickly as possible. Why trust Mühlhoff with your relocation project? End-to-End Service: We manage every aspect of the relocation process, so you don’t have to. Expertise in Forming and Joining: Decades of experience in these specialized technologies mean your equipment is in safe hands. Minimal Downtime: Efficient planning and execution to reduce disruptions and keep your production moving. Customized Solutions: We tailor our approach to fit your unique production requirements and goals. Relocating doesn’t have to be a headache. With Mühlhoff’s proven expertise, your forming and joining equipment will be relocated smoothly, safely, and on schedule. Get in touch with us today, and let’s make your next relocation project a success!

Use case

Car Body in White

Automotive, Industry

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

Metal forming is a manufacturing process that involves shaping metal into desired forms through various techniques, such as bending, stretching, and compressing. This process can be achieved through methods like forging, stamping, rolling, and extrusion, which allow for the transformation of raw metal into parts and products with specific geometries and properties. The advantages of metal forming include improved strength, reduced material waste, and the ability to produce complex shapes with precision. By manipulating the physical properties of metals, manufacturers can create components that meet stringent specifications for various industries, including automotive, aerospace, and construction.

1. Forging

This process involves shaping metal using localized compressive forces. It enhances the strength of the metal and is commonly used for creating components like gears and shafts.

2. Rolling

In rolling, metal is passed through rollers to reduce thickness and create sheets or plates. This method is efficient for producing large quantities of metal products.

3. Extrusion

Extrusion involves pushing metal through a die to create long shapes with a constant cross-section, such as pipes and rods. It's ideal for creating complex profiles.

4. Bending

Bending permanently deforms metal sheets or bars to a desired angle. This technique is widely used in fabricating parts for various industries.

5. Stamping

Stamping utilizes dies and presses to shape metal sheets. It can create intricate designs and is often used for mass production of parts like brackets and enclosures.

6. Deep Drawing

This process transforms flat sheets into hollow shapes by pulling the metal into a die. It’s commonly used for manufacturing containers and automotive parts.

7. Hydroforming

Hydroforming uses high-pressure fluid to shape metals, allowing for complex geometries without the need for traditional dies. It's often utilized in the automotive and aerospace sectors.

Metal forming significantly alters the properties of materials through processes such as bending, stretching, and compressing. These techniques can enhance strength, ductility, and toughness by refining the microstructure of the metal. During forming, dislocations within the material are rearranged, which increases the yield strength due to work hardening. Additionally, the process can lead to improved surface finish and dimensional accuracy. The controlled deformation allows for better control over grain structure, which in turn influences mechanical characteristics. As a result, metal forming not only shapes materials but also optimizes their overall performance in various applications.

Various industries rely heavily on metal forming for their operations.

1. Automotive

The automotive industry utilizes metal forming to produce components such as body panels, frames, and structural parts, ensuring both safety and performance.

2. Aerospace

Aerospace companies employ metal forming techniques to create lightweight and strong components that meet stringent safety and regulatory standards.

3. Construction

In construction, metal forming is essential for fabricating structural elements, roofing, and fittings, contributing to the durability and safety of buildings.

4. Electronics

The electronics sector uses metal forming for the production of enclosures, connectors, and other components, enabling the efficient assembly of devices.

5. Appliances

Manufacturers of household appliances rely on metal forming to create durable and functional parts that enhance the longevity and performance of their products.

1. Improved Material Utilization

Metal forming minimizes waste by efficiently using raw materials. The processes often involve shaping metal without significant cutting, leading to a higher yield from each piece of material.

2. Enhanced Structural Integrity

Formed metals typically possess superior strength and durability. The processes align the grain structure of the metal, resulting in components that can withstand greater stress and strain compared to those made through other methods.

3. Reduced Production Costs

By streamlining manufacturing processes, metal forming reduces labor and material costs. Fewer operations are needed, which can lead to shorter production times and lower overall expenses.

4. Versatility in Design

Metal forming techniques allow for complex shapes and designs that might be difficult or impossible to achieve with other manufacturing methods. This versatility enables manufacturers to tailor components to specific applications.

5. Improved Surface Finish

Many forming processes enhance the surface quality of the metal. A better finish can reduce the need for additional machining, saving time and improving the final product's aesthetics.

Some interesting numbers and facts about your company results for Metal Forming

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 9857 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1950 |

| Youngest suiting company | 2019 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Metal Forming

What are related technologies to Metal Forming?

Based on our calculations related technologies to Metal Forming are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Metal Forming?

The most represented industries which are working in Metal Forming are Other, Manufacturing, Machinery Manufacturing, Mining, Construction

How does ensun find these Metal Forming Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.