The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Metal Forming Solutions

Tulsa, United States

B

51-100 Employees

2019

Key takeaway

Metal Forming Solutions specializes in cold forming, offering a range of products and services, including the cold bending of tubing and piping for various applications. With over thirty years of experience, the company is recognized for its innovative solutions and high-quality metal works, making it a key player in the cold forming industry.

Reference

Core business

Cold Forming & Hot Forming Solution & Custom | Metal Forming Solutions

A leading provider of bending services & applications, foreign and domestic. Tight radius and large radius cold forming. Bending for Shell & Tube

COLD FORMED PRODUCTS LIMITED

London, United Kingdom

A

1-10 Employees

-

Key takeaway

Cold Formed Products specializes in aluminum impact extrusions and forging, utilizing advanced impact extrusion technology to produce high integrity engineering components. Their extensive experience and in-house tooling capabilities ensure high quality and precision, making them a key supplier across various sectors, including automotive and aerospace.

Reference

Core business

Aluminium Impact Extrusions | Forging of Parts | Lean Manufacturing

Cold Formed Products are leaders in aluminium impact extrusions and forging of parts for world wide markets. Over 50 years of lean component manufacturing.

SACMA GROUP

Limbiate, Italy

B

251-500 Employees

1939

Key takeaway

The company emphasizes its commitment to excellence and innovative solutions in cold forming technologies, highlighting its expertise in cold forming machines.

Reference

Product

Transfer

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Formit Ltd

Sandwell, United Kingdom

A

1-10 Employees

1998

Key takeaway

Formit specializes in supplying complete roll forming and coil processing lines, making them a key player in the cold forming industry. They offer a comprehensive range of equipment and services, including design, installation, and maintenance, ensuring efficient production from coil through to finished products.

Reference

Product

Custom Requirement - Formit

Specials can be made utilising pre-pierce, post-pierce, bending, welding, etc. Let us help you design your product for efficient production, submit proposals with line layouts and follow the project through from start to finish. Production line from coil with pre-pierce, shear, conveyor, rollform and stacking. As well as COPRA® our engineers and designers use […]

Daver Steels Ltd

Sheffield, United Kingdom

A

11-50 Employees

1996

Key takeaway

Daver Steels specializes in cold forming, a process that shapes metal without heating, allowing for precise fabrication of various products including equal and unequal angles, Zed sections, and channels. This technique, combined with their skilled team and advanced technology, enables them to meet diverse customer specifications in the construction industry.

Reference

Service

Cold Forming - Daver Steels

Cold Forming is a manufacturing process used to shape metal without having to heat up the material. This is usually accomplished by pressing the material within various top and bottom tooling…

Cold Forming Technology

Sterling Heights, United States

B

11-50 Employees

-

Key takeaway

Cold Forming Technology, Inc. specializes in production spline and thread rolling services, emphasizing their capability to assist customers with emergency rolling during machine downtimes or unexpected increases in volume. Their expertise in manufacturing high-quality tools aligns with the needs of customers requiring effective cold forming solutions.

Reference

Core business

About Us | Cold Forming Technology, Inc. | Spline Rolling

Production Spline and Thread Rolling Services since 1992. Highest quality spline and thread rolling tools, prototypes and emergency rolling services. Partnered with West Michigan Spline, Inc.

Form Cut Industries

Newark, United States

B

- Employees

1961

Key takeaway

Form Cut specializes in the manufacture of precision wire forms, including connector pins and terminal pins, highlighting their expertise in creating intricate and detailed parts through processes like cold forming. With a long history and a commitment to high quality, they produce hundreds of millions of parts annually at their US manufacturing facility.

Reference

Service

Manufacturing Processes - Form Cut Industries - Wire Forming Services

Form Cut manufactures precision connector pins, terminal pins, and wire form parts. All parts made in the USA. Fast quote turnaround, highest quality.

PrecisionForm Inc.

Lititz, United States

B

51-100 Employees

1986

Key takeaway

PrecisionForm specializes in cold forming and has integrated Statistical Process Controls to ensure high productivity and dimensional integrity. With a diverse range of manufacturing equipment, they are equipped to meet the rigorous demands of various industries while minimizing costs and waste.

Reference

Service

Capabilities | Precision Form Inc

FORMET LIMITED

Montrose, United Kingdom

A

1-10 Employees

-

Key takeaway

Formet Fabrications offers subcontract services for custom sheet metalwork, emphasizing their ability to reduce productivity costs while ensuring high-quality products are delivered on time and within budget.

Reference

Service

Services - Formet Fabrications

MN Kaltformteile

Altena, Germany

A

1-10 Employees

-

Key takeaway

MN Kaltformteile specializes in cold forming, where they develop customized solutions for series production. Their expertise in cold mass forming ensures high product quality through a well-equipped quality assurance process.

Reference

Product

What is coldforming? - MN-Kaltform

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Sheet Metal Parts and Components

Go to product

Service

Relocation Projects

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

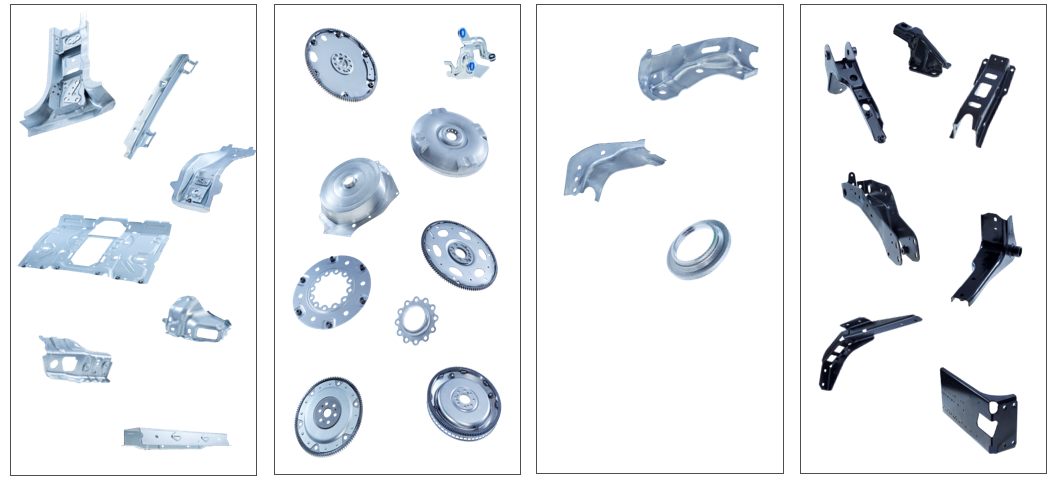

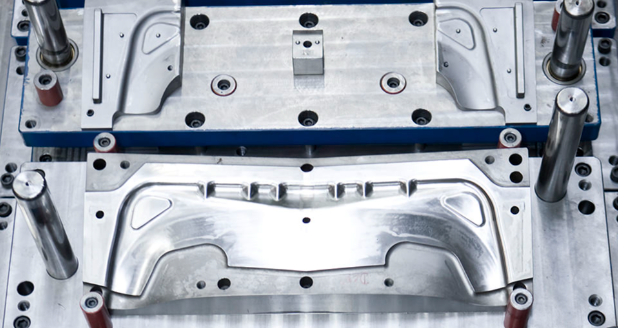

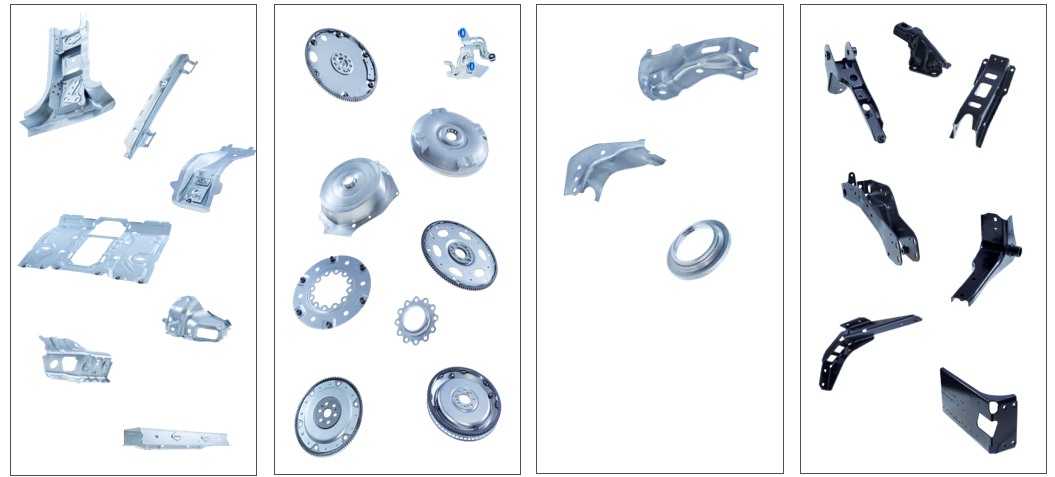

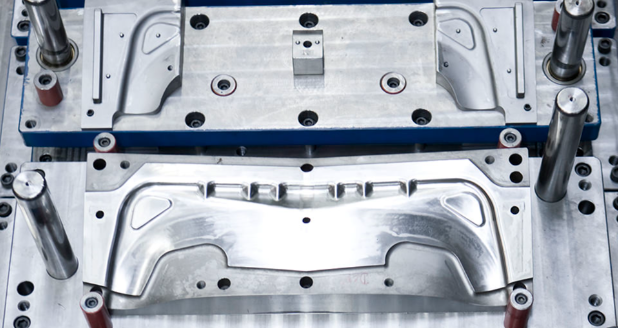

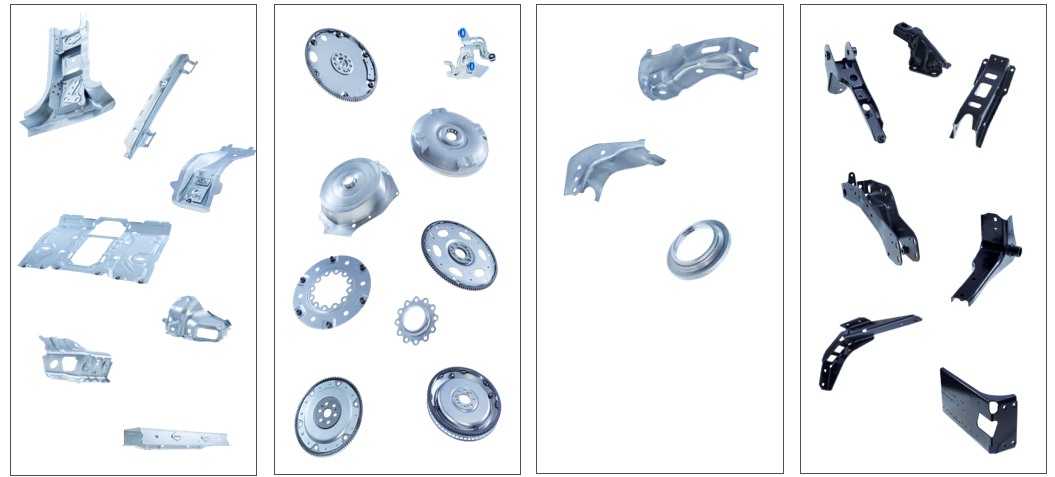

Car Body in White

Automotive, Industry

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

Use case

Relocation projects

Automotive, Industry

Seamless Relocation Projects in Forming and Joining Technology—Powered by Mühlhoff When it comes to relocating your production lines, Mühlhoff is your expert partner. We specialize in executing complex relocation projects in forming and joining technology, ensuring minimal downtime and maximum efficiency. With our comprehensive service, we handle everything—from planning and dismantling to reassembly and optimization at the new site. Our experienced team works closely with you, providing tailor-made solutions that meet your specific needs while ensuring that your production is up and running as quickly as possible. Why trust Mühlhoff with your relocation project? End-to-End Service: We manage every aspect of the relocation process, so you don’t have to. Expertise in Forming and Joining: Decades of experience in these specialized technologies mean your equipment is in safe hands. Minimal Downtime: Efficient planning and execution to reduce disruptions and keep your production moving. Customized Solutions: We tailor our approach to fit your unique production requirements and goals. Relocating doesn’t have to be a headache. With Mühlhoff’s proven expertise, your forming and joining equipment will be relocated smoothly, safely, and on schedule. Get in touch with us today, and let’s make your next relocation project a success!

Use case

Car Body in White

Automotive, Industry

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

Cold forming is a manufacturing process that shapes metal at room temperature without heating it, utilizing mechanical force to deform the material. This technique leads to improved mechanical properties, such as greater strength and hardness, because the metal's grain structure is altered during the process. Industries often favor cold forming for producing precision components, as it allows for tight tolerances and reduces waste, making it a cost-effective solution for high-volume production. Additionally, this method can enhance surface finish and eliminate the need for secondary machining in many applications.

Cold forming and hot forming are distinct processes used in manufacturing metals. In cold forming, materials are shaped at or near room temperature, which enhances the material's strength due to strain hardening. This method allows for precise tolerances and a superior surface finish, making it ideal for intricate shapes. In contrast, hot forming involves heating the material above its recrystallization temperature, making it malleable and easier to shape. This process can lead to larger, more complex geometries but may result in a rougher surface finish and lower strength compared to cold-formed parts. Each method has unique applications depending on the desired properties and specifications of the final product.

In cold forming, various materials are commonly utilized, with metals being predominant. Steel is frequently used due to its strength and versatility, making it ideal for a range of applications. Aluminum is also popular, known for its lightweight properties and resistance to corrosion. Additionally, brass and copper are often employed for their excellent conductivity and machinability. Stainless steel is another choice, prized for its durability and resistance to rust, making it suitable for environments where corrosion is a concern. These materials allow for precise and efficient production of components through cold forming techniques.

1. Material Efficiency

Cold forming processes utilize raw materials more effectively than traditional machining. By shaping metal at room temperature, less waste is produced, leading to cost savings and reduced material costs.

2. Enhanced Mechanical Properties

This technique can improve the tensile strength and hardness of the material due to strain hardening. As the metal is deformed, its internal structure is altered, resulting in stronger components.

3. Dimensional Accuracy

Cold forming allows for tighter tolerances and improved dimensional accuracy. The process produces parts that require minimal finishing, reducing the need for extensive machining after forming.

4. Lower Energy Consumption

Since the process occurs at room temperature, it typically requires less energy than hot forming methods. This can contribute to lower production costs and a reduced carbon footprint.

5. Increased Production Rates

Cold forming is often faster than other manufacturing methods. High-speed production capabilities enable manufacturers to produce large quantities of components in a shorter timeframe.

Cold forming processes are widely used across various industries due to their efficiency and precision.

1. Automotive Industry

The automotive sector frequently employs cold forming to create components such as fasteners, brackets, and structural parts, ensuring high strength and durability.

2. Aerospace Industry

In aerospace, cold forming is crucial for producing lightweight yet strong parts, including fittings, brackets, and structural components that meet stringent safety standards.

3. Electronics Industry

The electronics industry utilizes cold forming for manufacturing connectors, terminals, and other components that require precise dimensions and minimal material waste.

4. Construction Industry

Cold forming is also prevalent in construction, where it is used to produce steel studs, frames, and other structural elements that benefit from enhanced strength and stability.

5. Medical Device Manufacturing

Medical devices often require highly precise and reliable components, making cold forming a valuable process for producing parts like surgical instruments and implants.

Some interesting numbers and facts about your company results for Cold Forming

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 8646 |

| Amount of suitable service providers | 9750 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1939 |

| Youngest suiting company | 2019 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Cold Forming

What are related technologies to Cold Forming?

Based on our calculations related technologies to Cold Forming are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Cold Forming?

The most represented industries which are working in Cold Forming are Other, Manufacturing, Machinery Manufacturing, Construction, Mining

How does ensun find these Cold Forming Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.