The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Trans Form Plastics Corp.

Danvers, United States

B

11-50 Employees

1976

Key takeaway

Trans Form Plastics is a leading supplier of custom pressure formed parts, catering to various industries including medical devices and electronics. They offer services such as new product design consultation and material selection, ensuring efficient production and timely delivery.

Reference

Service

Services - Trans Form Plastics Corp.

Trans Form Plastics in Danvers, MA: Supplier of custom pressure and vacuum formed parts. Pressure Forming, Thermoforming, Sheet Fabrication MA

Gregstrom Corporation

Woburn, United States

B

51-100 Employees

1946

Key takeaway

Gregstrom Corporation specializes in pressure forming, offering services that create plastic parts with textured surfaces and fine details. With nearly 70 years of experience, the company demonstrates its technical skill and industry knowledge in thermoforming.

Reference

Service

Pressure Forming Services | Plastic Thermoforming | Gregstrom

Pressure forming from Gregstrom create plastic parts with textured surfaces and fine details. Choose Made in the USA pressure forming from us.

POST FORMED SYSTEMS LTD

Newport, United Kingdom

A

11-50 Employees

-

Key takeaway

Post Formed Systems Ltd is a prominent supplier of washroom suites, offering products like plumbing ducts, cubicles, and vanity units, and has developed a process that ensures high-quality results.

Reference

Core business

Post Formed System Ltd

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

prothermoform.com

Burlington, Canada

A

1-10 Employees

2008

Key takeaway

Prothermoform specializes in thermoforming, utilizing advanced rotary and shuttle machines to create complex shapes from various materials. With capabilities for large parts and thick sheets, they continuously enhance their processes and techniques, making them well-equipped for high-quality production.

Reference

Service

Prothermoform - Vacuum Forming

Best Formed Plastics, LLC

United States

B

11-50 Employees

2006

Key takeaway

Best Formed Plastics specializes in engineered vacuum-formed products, offering custom-designed thermoformed components that meet various performance requirements such as strength and flexibility. Their commitment to quality and continuous improvement positions them as a leading provider of both thin and thick gauge thermoformed products in the U.S.

Reference

Core business

Home - Best Formed Plastics

Custom Plastic Forming

Salisbury, United States

B

51-100 Employees

1997

Key takeaway

Custom Plastic Forming specializes in both heavy- and thin-gauge thermoforming services, making them a capable provider for custom plastic forming projects. Their extensive experience and in-house capabilities ensure that they can effectively bring unique visions to life, emphasizing a partnership that supports long-term production.

Reference

Core business

Custom Plastic Forming

Custom Plastic Forming offers all the plastic manufacturing solutions businesses need to succeed. Contact our plastic forming pros today!

Formaflo

Shelbyville, United States

B

11-50 Employees

-

Key takeaway

FormaFlo is a specialized supplier of flooring system solutions for food processing facilities, known for its fast and effective processes that enhance food safety. They offer a range of customized flooring systems utilizing innovative materials, which may relate to the concept of pressure forming in terms of advanced manufacturing techniques.

Reference

Service

Services | FormaFlo

DuraTech Industries

La Crosse, United States

B

251-500 Employees

1977

Key takeaway

DuraTech Industries specializes in high pressure forming, utilizing advanced techniques that ensure tight placement tolerance. Their expertise in various forming processes, including vacuum and thermo forming, positions them as a reliable source for custom solutions.

Reference

Service

Vacuum Forming, Thermo Forming, High Pressure Forming

Vacuum forming, hydro, & thermo forming come together with our high pressure forming process. Utilizing high pressure forming brings tight placement tolerance.

Forming Technologies LLC

United States

B

51-100 Employees

2004

Key takeaway

Forming Technologies specializes in heavy gauge thermoformed products, emphasizing their commitment to service, quality, and timely delivery. Their strategic location in Muskegon, Michigan, enhances their ability to serve customers effectively.

Reference

Core business

About Forming Tech - Muskegon MI

Forming Technologies is a leader in heavy gauge thermoformed products by providing unequaled service, quality, and timing to our customers.

ACB

Nantes, France

A

101-250 Employees

1999

Key takeaway

The company, ACB, specializes in advanced manufacturing techniques, including Superplastic Forming (SPF), which is relevant to pressure forming. They offer a range of presses designed for high productivity and flexibility, making them well-suited for small and medium series production.

Reference

Product

Superplastic Forming | ACB - An Aries Alliance company

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Relocation Projects

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Relocation projects

Automotive, Industry

Seamless Relocation Projects in Forming and Joining Technology—Powered by Mühlhoff When it comes to relocating your production lines, Mühlhoff is your expert partner. We specialize in executing complex relocation projects in forming and joining technology, ensuring minimal downtime and maximum efficiency. With our comprehensive service, we handle everything—from planning and dismantling to reassembly and optimization at the new site. Our experienced team works closely with you, providing tailor-made solutions that meet your specific needs while ensuring that your production is up and running as quickly as possible. Why trust Mühlhoff with your relocation project? End-to-End Service: We manage every aspect of the relocation process, so you don’t have to. Expertise in Forming and Joining: Decades of experience in these specialized technologies mean your equipment is in safe hands. Minimal Downtime: Efficient planning and execution to reduce disruptions and keep your production moving. Customized Solutions: We tailor our approach to fit your unique production requirements and goals. Relocating doesn’t have to be a headache. With Mühlhoff’s proven expertise, your forming and joining equipment will be relocated smoothly, safely, and on schedule. Get in touch with us today, and let’s make your next relocation project a success!

Use case

Relocation projects

Automotive, Industry

Seamless Relocation Projects in Forming and Joining Technology—Powered by Mühlhoff When it comes to relocating your production lines, Mühlhoff is your expert partner. We specialize in executing complex relocation projects in forming and joining technology, ensuring minimal downtime and maximum efficiency. With our comprehensive service, we handle everything—from planning and dismantling to reassembly and optimization at the new site. Our experienced team works closely with you, providing tailor-made solutions that meet your specific needs while ensuring that your production is up and running as quickly as possible. Why trust Mühlhoff with your relocation project? End-to-End Service: We manage every aspect of the relocation process, so you don’t have to. Expertise in Forming and Joining: Decades of experience in these specialized technologies mean your equipment is in safe hands. Minimal Downtime: Efficient planning and execution to reduce disruptions and keep your production moving. Customized Solutions: We tailor our approach to fit your unique production requirements and goals. Relocating doesn’t have to be a headache. With Mühlhoff’s proven expertise, your forming and joining equipment will be relocated smoothly, safely, and on schedule. Get in touch with us today, and let’s make your next relocation project a success!

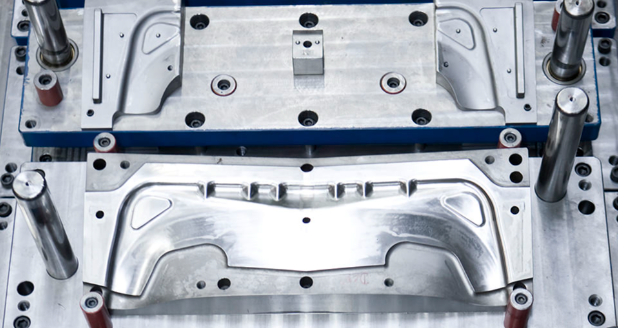

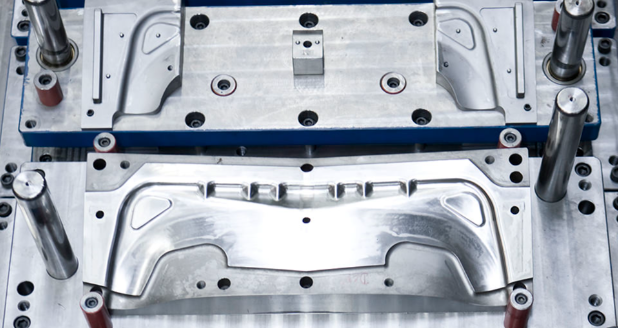

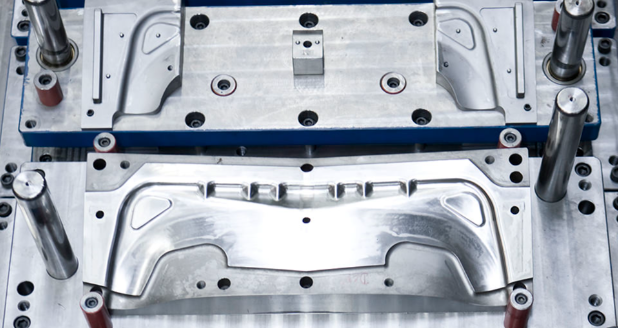

Pressure forming is a manufacturing process that utilizes high-pressure air or fluids to shape materials, primarily thermoplastics. This technique allows for the creation of complex geometries and detailed features in the final product. During pressure forming, a heated sheet of plastic is draped over a mold, and then air pressure is applied to push the material into the mold's contours. This method is particularly advantageous for producing lightweight components with excellent surface finishes, making it popular in industries such as automotive, aerospace, and consumer goods. The ability to work with various materials and achieve precise shapes enhances the versatility of pressure forming in modern manufacturing.

Pressure forming and vacuum forming are both techniques used to shape thermoplastic materials, but they differ significantly in their processes and applications. In pressure forming, a sheet of plastic is heated and then forced against a mold using a combination of air pressure and mechanical force. This method allows for more intricate designs and deeper draws, resulting in higher precision and better surface detail. In contrast, vacuum forming relies solely on atmospheric pressure to pull the heated plastic against the mold. While this method is simpler and often more cost-effective, it typically produces less detailed parts compared to pressure forming. Additionally, pressure forming is better suited for applications requiring greater strength and durability, making it ideal for more complex and demanding projects.

Various materials are suitable for pressure forming, particularly those that can withstand the high pressures and temperatures involved in the process. Thermoplastics such as ABS, polycarbonate, and PVC are commonly used due to their flexibility and ability to be reshaped when heated. Additionally, thermosetting plastics like epoxy resins can also be utilized, providing excellent dimensional stability and strength. Other materials include certain types of composite materials that benefit from the pressure forming process, allowing for the production of lightweight yet durable components.

The process of pressure forming is widely utilized across several industries due to its efficiency in creating complex shapes from various materials.

1. Aerospace

In the aerospace sector, pressure forming is essential for producing lightweight, durable components that meet stringent safety and performance standards.

2. Automotive

The automotive industry frequently employs pressure forming for manufacturing parts such as dashboards, interior panels, and other components that require precision and durability.

3. Medical Devices

Medical device manufacturing relies on pressure forming for creating custom components that demand high levels of accuracy and biocompatibility.

4. Consumer Electronics

Consumer electronics benefit from pressure forming, particularly in producing housings and casings that require intricate designs and robust materials.

5. Packaging

In packaging, pressure forming is used to create protective and functional packaging solutions that can withstand handling and transportation.

1. Enhanced Detail and Precision

Pressure forming allows for high levels of detail and accuracy in the finished product. The method utilizes both heat and pressure, which enables complex shapes and fine features to be formed without compromising material integrity.

2. Improved Material Properties

This technique often results in superior mechanical properties compared to traditional forming methods. The application of pressure during the forming process can enhance the strength and durability of the material, making it more suitable for demanding applications.

3. Greater Design Flexibility

Pressure forming offers designers more flexibility in creating parts with varied thicknesses and intricate designs. This adaptability allows for innovative solutions and the ability to meet specific project requirements more effectively than other forming methods.

4. Reduced Waste and Cost Efficiency

Because pressure forming utilizes materials more efficiently, it can lead to reduced waste during production. This efficiency not only cuts costs but also contributes to more sustainable manufacturing practices.

Some interesting numbers and facts about your company results for Pressure Forming

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 8168 |

| Amount of suitable service providers | 8611 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1946 |

| Youngest suiting company | 2008 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Pressure Forming

What are related technologies to Pressure Forming?

Based on our calculations related technologies to Pressure Forming are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Pressure Forming?

The most represented industries which are working in Pressure Forming are Other, Manufacturing, Plastics, Packaging, Construction

How does ensun find these Pressure Forming Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.