The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Warehouse Automation AI

Los Angeles, United States

B

11-50 Employees

2010

Key takeaway

Warehouse Automation AI specializes in helping clients navigate their digital transformation by integrating industrial robots and automation systems into their warehousing processes. Their expertise in real-time inventory management and innovative robotic solutions positions them as key players in the evolving landscape of warehouse automation.

Reference

Core business

Warehouse Automation

Warehouse Automation is an independent supply chain consulting and advisory firm with a focus in assisting clients through their digital transformation in the integration of industrial robots and warehouse automation systems. We further advise clients in procuring the most suitable software solution

PHS Innovate

Waitematā, New Zealand

A

11-50 Employees

1955

Key takeaway

PHS Innovate specializes in advanced warehouse automation technologies, offering solutions such as robotic palletizing and automated warehousing. Their dedicated engineering team ensures that all systems are meticulously designed and tested before being installed at customer sites.

Reference

Product

Automated Warehouse

For any pallet-based warehouse environment – from -30°C to +45°C – a fully-automatic pallet storage system supports better use of space, around-the-clock availability, goods control with full traceability, error reduction and improved safety for workers. Employing Autosatmovers, Rushmovers and ASRS cranes by Automha, our fully-automated warehousing solutions are tailormade for your industry and warehouse/factory space. Our warehouse automation solutions are produced in partnership with AutoMHA Italy. By working with us, you get the benefit of world-leading componentry, including warehouse robotics, as well as the reassurance of industry knowledge, training and ongoing service.

cellgo.io

Paderborn, Germany

A

11-50 Employees

2020

Key takeaway

Cellgo revolutionizes warehouse automation by providing a straightforward and adaptable automated storage system specifically designed for small and medium-sized businesses. Their innovative technology and customizable software enhance efficiency and scalability, making it an ideal solution for evolving storage needs.

Reference

Product

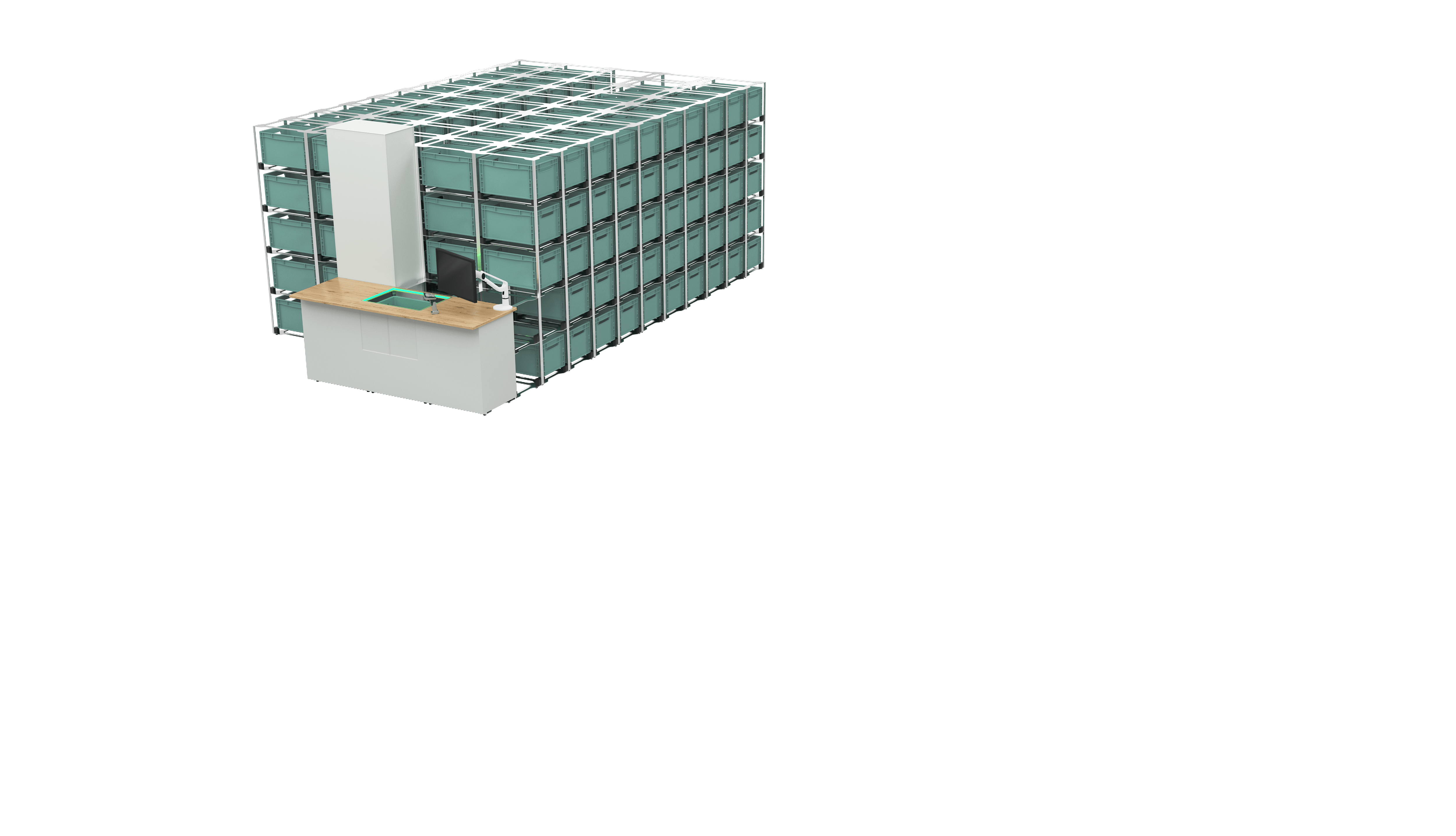

Cellgo automated warehouse

Modular automated warehouse - efficient warehouse automation Cellgo's modular automated storage system offers all-in-one technology for the automated storage of small parts. The intelligent miniload system enables a profitable, scalable solution - from small applications to large sites with individual requirements. Small and medium-sized companies in particular benefit from Cellgo's automation solution. Designed for Euronorm containers, intelligent underride robots transport the goods efficiently to the station. The compact design enables a storage density of up to 50 containers per m², even with low ceiling heights. The integrated plug & play solution enables seamless connection to online stores and marketplaces, allowing direct sales to be set up quickly. The warehouse management system can also be easily integrated into existing systems. The multi-order picking process increases picking efficiency. The low initial investment enables decentralized warehousing in city centres. Warehouse service providers and production companies benefit from the simple scalability: expansions, seasonal increases in throughput or adjustments to the production layout can be implemented in just a few days. Our software provides real-time analyses to optimize workflows, inventory monitoring and material flow control - for maximum efficiency and reduced operating costs.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Fulfilmatica

Barcelona, Spain

A

11-50 Employees

2020

Key takeaway

Fulfilmatica offers a productivity platform that integrates industrial robotic hardware and software specifically designed for warehouse automation, transforming fulfillment processes even in small spaces.

Reference

Core business

Fulfilmatica - Warehouse Robots and Smart Picking Devices

The Rubic

Calgary, Canada

A

1-10 Employees

2020

Key takeaway

The company highlights its warehouse-agnostic, autonomous robotic system that enhances warehouse automation by integrating seamlessly into existing facilities. With features like a patented stabilization system and the ability to maximize space and efficiency, their solution aims to optimize operational effectiveness and return on investment.

Reference

Core business

Unlock Warehouse Automation | The Rubic

Unlock the potential of automation with a warehouse-agnostic, autonomous robotic system, designed to operate seamlessly within your existing facilities, exactly as they are.

Peak Porter AD

Bulgaria

B

1-10 Employees

2021

Key takeaway

Peak Porter specializes in warehouse automation, offering tailored solutions such as automated storage and retrieval systems, conveyor systems, and mobile solutions. Their comprehensive services, from consulting to training, ensure clients can streamline operations and enhance productivity through innovative technologies.

Reference

Core business

Peak Porter – Optimize Your Warehouse

6 River Systems

Waltham, United States

B

51-100 Employees

2015

Key takeaway

6 River Systems offers an industry-leading warehouse automation system that integrates software and autonomous mobile robots (AMRs) to enhance productivity and reduce operational costs. Their patented algorithms optimize task allocation and path planning, enabling warehouses to achieve higher throughput and efficiency.

Reference

Core business

Fulfillment Solutions & Warehouse Automation | 6 River Systems

At 6 River Systems, we build fulfillment solutions that power the winning warehouses of the future. Improve efficiency, optimize labor, scale quickly & easily.

StreamTech Engineering

St. Louis, United States

B

11-50 Employees

2007

Key takeaway

The company specializes in providing tailored warehouse automation solutions that enhance operational efficiency and support growth. With over 13 years of experience, their integration of advanced fulfillment automation technologies, including shipping and packing automation, helps businesses optimize their processes and stay competitive in the eCommerce landscape.

Reference

Product

Fulfillment Automation Technologies | StreamTech Engineering

Fulfillment automation technologies designed and engineered to solve your specific material handling requirements.

Falcon Autotech

Greater Noida, India

D

501-1000 Employees

2004

Key takeaway

The company specializes in designing and implementing advanced warehouse automation systems, particularly for e-commerce logistics. Their product lineup includes various sorting and scanning systems, highlighting their commitment to innovation in warehouse operations.

Reference

Core business

Warehouse Automation Systems for E-commerce Logistics Companies

We are a leading company that designs, manufactures, supplies, implements and maintains world class warehouse automation systems globally.

Bleum

Huangpu District, China

D

1001-5000 Employees

2001

Key takeaway

Prime Robotics specializes in providing tailored automation solutions for warehouses, e-commerce, and material handling industries, making it a key player in warehouse automation. Their expertise allows them to develop customized systems that enhance operational efficiency and reduce costs through advanced robotic automation and software integration.

Reference

Core business

Warehouse Robotic Automation Solutions

Prime Robotics automation solutions allow Warehouse, E-Commerce and Factory facilities to accelerate operations for efficiency and cost savings.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Cellgo automated warehouse

Go to product

Product

Cellgo warehouse lift

Go to product

Product

Automated Warehouse

Go to product

Product

Pallet Shuttle

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Talleys

Food, Beverage

Working with our Italian partner Automha and local Racking Partner StorePro, PHS Innovate’s scope included all the racking, automation equipment and conveyors in and surrounding the Cool store. The system scans wrapped and labelled pallets and communicates with Talley’s inventory system to retrieve details for the pallet. The system then stores the pallets in rack locations based on Batch and date for optimised future retrieval. When a truck or container load is needed, Talley’s inventory system communicates with our automated handling system to request specific pallets. Our solution then retrieves and delivers the requested pallets to a designated area for the forklift driver to load into the truck or container.

Use case

Talleys

Food, Beverage

Working with our Italian partner Automha and local Racking Partner StorePro, PHS Innovate’s scope included all the racking, automation equipment and conveyors in and surrounding the Cool store. The system scans wrapped and labelled pallets and communicates with Talley’s inventory system to retrieve details for the pallet. The system then stores the pallets in rack locations based on Batch and date for optimised future retrieval. When a truck or container load is needed, Talley’s inventory system communicates with our automated handling system to request specific pallets. Our solution then retrieves and delivers the requested pallets to a designated area for the forklift driver to load into the truck or container.

Warehouse automation refers to the use of technology and systems to optimize and streamline warehouse operations. This includes the implementation of automated machinery, software solutions, and robotics to enhance efficiency in tasks such as inventory management, order fulfillment, and shipping. By integrating various technologies like conveyor systems, automated guided vehicles (AGVs), and warehouse management systems (WMS), businesses can reduce manual labor, minimize errors, and improve overall productivity. As a result, warehouse automation plays a crucial role in meeting the demands of modern supply chains while reducing operational costs.

Warehouse automation significantly enhances efficiency by streamlining operations and reducing manual labor. Automated systems minimize human error, leading to more accurate inventory management and order fulfillment. Additionally, these systems can operate continuously, handling repetitive tasks such as sorting and packing at a faster rate than manual processes. Another key benefit is the optimization of space and resources. Automated storage and retrieval systems maximize storage capacity and ensure that products are easily accessible, reducing the time spent locating items. This leads to quicker turnaround times and improved productivity across the warehouse. Overall, the integration of advanced technologies fosters a more agile and responsive supply chain.

Warehouse automation utilizes a variety of advanced technologies to enhance efficiency and streamline operations. Robotics play a crucial role, with automated guided vehicles (AGVs) and robotic arms handling tasks such as picking, sorting, and transporting goods. Additionally, artificial intelligence (AI) and machine learning algorithms are employed to optimize inventory management, predict demand, and improve decision-making processes. Other important technologies include warehouse management systems (WMS) that facilitate real-time tracking and reporting, as well as Internet of Things (IoT) devices that provide data on equipment performance and environmental conditions. Together, these technologies significantly improve operational productivity and accuracy in warehouse settings.

1. Increased Efficiency

Implementing warehouse automation significantly enhances operational efficiency. Automated systems streamline processes such as inventory management, order picking, and shipping. This results in faster turnaround times and reduced labor costs, allowing businesses to allocate resources more effectively.

2. Improved Accuracy

Automation reduces human errors in tasks like order fulfillment and inventory tracking. With precise data handling, companies can expect fewer mistakes, leading to higher customer satisfaction and fewer returns. Accurate inventory levels also help in better stock management, preventing overstocking or stockouts.

3. Enhanced Safety

Automated systems can handle hazardous tasks, reducing the risk of workplace injuries. By minimizing manual labor, workers are less exposed to dangerous situations, promoting a safer working environment. This focus on safety can also lead to lower insurance costs for businesses.

4. Scalability

Warehouse automation solutions are designed to grow with a business. As demand fluctuates, automated systems can be adjusted or expanded to meet changing needs without significant disruptions. This scalability ensures that businesses can remain competitive in a dynamic market.

5. Data-Driven Insights

Automated systems generate valuable data on warehouse operations. Analyzing this data helps companies identify trends, optimize processes, and make informed decisions. With real-time analytics, businesses can respond quickly to changes and improve overall performance.

Warehouse automation significantly influences labor requirements by streamlining operations and enhancing productivity. By integrating advanced technologies, such as robotics and automated storage systems, businesses can reduce the need for manual labor in repetitive and physically demanding tasks. This shift allows human workers to focus on more complex responsibilities that require critical thinking and problem-solving skills. Moreover, automation can lead to a more efficient workforce by minimizing errors and increasing throughput, which may result in a smaller but more skilled labor force. Companies often invest in training programs to equip employees with the necessary skills to work alongside automated systems, ensuring they can adapt to the evolving technological landscape. As a result, while overall labor needs may decrease, the demand for skilled workers capable of managing and maintaining these technologies increases.

Some interesting numbers and facts about your company results for Warehouse Automation

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1955 |

| Youngest suiting company | 2021 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Warehouse Automation

What are related technologies to Warehouse Automation?

Based on our calculations related technologies to Warehouse Automation are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Who are Start-Ups in the field of Warehouse Automation?

Start-Ups who are working in Warehouse Automation are Peak Porter AD

Which industries are mostly working on Warehouse Automation?

The most represented industries which are working in Warehouse Automation are IT, Software and Services, Logistics, Supply Chain and Transportation, Automation, Other, Machinery Manufacturing

How does ensun find these Warehouse Automation Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.