The challenges

The search for innovative solutions in production is a constant companion of R+W Antriebselemente. "Many projects lack the resources of the employees who are essential for research," reported Mr Markert, Team Leader in the Research & Development department.

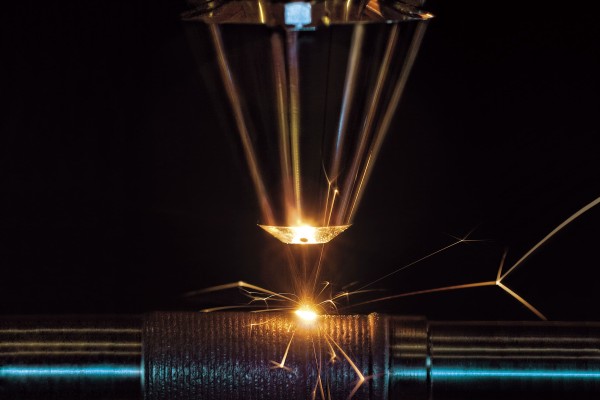

The first challenge that was tackled with the help of ensun dealt with a process that had previously been outsourced to another company. In this step, stainless steel sheet was processed using lasers for further processing. "The dependency on a single supplier often creates problems in planning and budgeting, as, for example, prices are sometimes increased unexpectedly," Mr Markert told us. The employees of R+W Antriebselemente only had limited time to search for and qualify new suppliers due to tasks from their daily business. Can ensun now solve this task in an uncomplicated and, above all, resource-saving way?

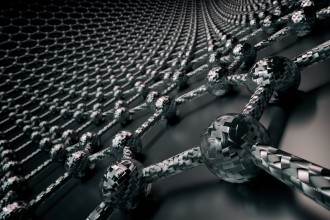

The second challenge that the company has been facing for some time is the semi-automated straightening of pipes. The pipes did not quite meet the desired quality requirements upon delivery and were to be upgraded by means of a complete solution. "Until now, it was not possible to organise a suitable solution by doing our own research," explained Mr Markert. Here, ensun's AI is now to be qualitatively put to the test by finding compatible solutions and providers for such an extraordinary problem.

The result

"ensun has managed to meet all our expectations and even exceed them in some cases. After the initial project advertisement, suitable solutions and providers were found for the respective projects in a very short time. These were not only available, but also met the quality requirements," said Mr Markert. The first benefit was quickly noticed: the pressure from individual suppliers was no longer there. For the machining of the pipes (project 2), a supplier was found who specialised in exactly this task. This company could not be found before via conventional search engines such as Google. Through the first discussions with potential solution providers, which were suggested by ensun for this project, R+W Antriebselemente got the first ideas for concrete solutions. In the next step, a complete solution was then found, which is now to be used. The machine is used in a production process for manufacturing cardan shafts. It increases the quality of the tubes used as an intermediate step. The qualitative optimisation of this production step ensures an upgrading of the overall product in the end.

The conclusion

„Die Nutzung von ensun haben wir als sehr intuitiv und einfach empfunden. Es ist sehr hilfreich, dass so eine Plattform existiert. Viele versuchen KIMethoden, Algorithmen oder Ähnliches überall einzusetzen, kriegen es aber nicht richtig hin diese wirklich sinnvoll anzuwenden. Hierbei bietet ensun eine große Chance und auch Hilfe. Es ist ein sehr guter Fortschritt, dass nicht mehr nur die Digitalisierung im Fokus der Projekte steht, sondern auch viele weitere Bereiche. Gerade in Sachen Fertigungstechnik ist für uns viel Potenzial für weitere Challenges. Natürlich gibt es auch andere Plattformen, die einem angeblich mit Hilfe von ein paar Suchbegriffen den passenden Anbieter finden wollen. Diese Ergebnisse sind jedoch einfach zu ungenau. ensun hat bei beiden Projekten genau das geliefert was wir brauchten, ohne dass wir immer wieder andere Begriffe oder verschiedene Plattformen ausprobieren mussten. In Zukunft werden wir mal schauen, wie wir das Potenzial von ensun weiter nutzen und auch innerhalb der Fima weitertragen können.“- Sascha Markert, Team Leader Research & Development.