The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Fulfilmatica

Barcelona, Spain

A

11-50 Employees

2020

Key takeaway

The company offers an industrial robotic hardware and software productivity platform specifically designed for warehouses, emphasizing the transformative impact of robotics on fulfillment processes. Their solutions include warehouse robots and smart picking devices, highlighting their focus on enhancing logistics operations.

Reference

Core business

Fulfilmatica - Warehouse Robots and Smart Picking Devices

Unbox Robotics

Bengaluru, India

D

11-50 Employees

2019

Key takeaway

Unbox Robotics is a pioneering supply chain robotics technology company that specializes in robotics-based fulfillment and distribution solutions for various logistics enterprises. Their advanced robotic systems significantly enhance order fulfillment efficiency, boosting productivity by over 3X and improving the overall customer experience.

Reference

Product

Leading Supply Chain Robotics Technology - Unbox Robotics

Unbox Robotic's cutting edge technology solutions accelerate parcel sortation and order fulfillment to facilitate efficient express logistics operations!

Lowpad - Autonomous Mobile Robots

Bleskensgraaf ca, Netherlands

A

51-100 Employees

2017

Key takeaway

Lowpad is revolutionizing logistics through the integration of Autonomous Mobile Robots (AMRs), enhancing the efficiency of warehouse operations and product delivery. Their scalable solutions, demonstrated in facilities like GXO in the Netherlands and TJ Morris, optimize various intralogistics processes, including cross-docking and dynamic zone picking.

Reference

Core business

Lowpad

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Robogistics

Beaumont, United States

B

51-100 Employees

-

Key takeaway

Robogistics specializes in intelligent robotic gantry automation and innovative software technology, providing comprehensive material handling and distribution center solutions that enhance logistics chain management. Their expertise in designing and integrating automated systems directly addresses the material-handling and logistical automation challenges faced by various industries.

Reference

Core business

Gantry | Robogistics | United States

Robogistics designs, manufacturers, and integrates intelligent robotic gantry automation software & equipment for the material handling and logistics industries.

RUIBOTICS

Lisbon, Portugal

A

1-10 Employees

2020

Key takeaway

RUIBOTICS specializes in providing technical resources and solutions for the deployment of supply chain technologies, including automation systems and AMR technology. Their dedicated team works closely with developers and end-users to ensure reliable installation and maintenance, making them a key player in the logistics robotics sector.

Reference

Core business

Robotics Logistics | Ruibotics

RUIBOTICS Provides OEMs, integrators and end-users with technical resources and solutions to perfectly deploy their supply chain technologies. robotics logistics We install, update and maintain all AMR technology

Bleum

Huangpu District, China

D

1001-5000 Employees

2001

Key takeaway

Prime Robotics specializes in providing tailored robotic automation solutions for warehouses, e-commerce, and material handling. Their expertise in logistics operations allows them to develop customized systems that enhance efficiency and reduce costs, making them a key player in the logistics robotics sector.

Reference

Core business

Warehouse Robotic Automation Solutions

Prime Robotics automation solutions allow Warehouse, E-Commerce and Factory facilities to accelerate operations for efficiency and cost savings.

Dextrous Robotics

Memphis, United States

B

1-10 Employees

2019

Key takeaway

Dextrous Robotics is a logistics robotics startup that offers advanced robots designed to unload trailers up to four times faster, enhancing efficiency while ensuring accuracy and safety. Their latest product, DX-1, is now available for pre-order, promising to significantly improve operational capabilities.

Reference

Core business

Dextrous Robotics | Logistics Robotics Startup

IQ Robotics

Dubai, United Arab Emirates

C

51-100 Employees

-

Key takeaway

IQ Robotics, founded in Dubai in 2019, specializes in innovative logistics solutions powered by robotics and AI. Their offerings include a range of automated products such as picking and sorting robots, which can significantly reduce labor and enhance operational efficiency across various industries like eCommerce, retail, and pharmaceuticals.

Reference

Product

Rethink Warehousing - IQ Robotics

Fully automated, intelligent and efficient Robots for varied application across multiple industries by IQ Robotics

Vecna Robotics

Waltham, United States

B

251-500 Employees

2018

Key takeaway

The company specializes in intelligent industrial workforce solutions that enhance efficiency through autonomous material handling. With a focus on robotics innovation, they offer flexible warehousing automation that addresses key challenges like labor shortages and operational backlogs.

Reference

Product

Warehousing Automation - Vecna Robotics

Vecna Robotics makes warehousing go! Rise above labor shortages, backlogs, and turnaround times with flexible warehousing automation.

VisionNav Robotics

Houston, United States

B

251-500 Employees

2016

Key takeaway

VisionNav Robotics is a prominent supplier of autonomous forklifts and intralogistics automation solutions, utilizing advanced technologies like machine learning and environment perception to enable reliable, human-free operations. Their autonomous vehicles are deployed in numerous facilities worldwide, optimizing logistics processes across various industries, including e-commerce and manufacturing.

Reference

Core business

About Us

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Palletizing

Go to product

Service

AMR Controller SRC-3000FS

Go to product

Service

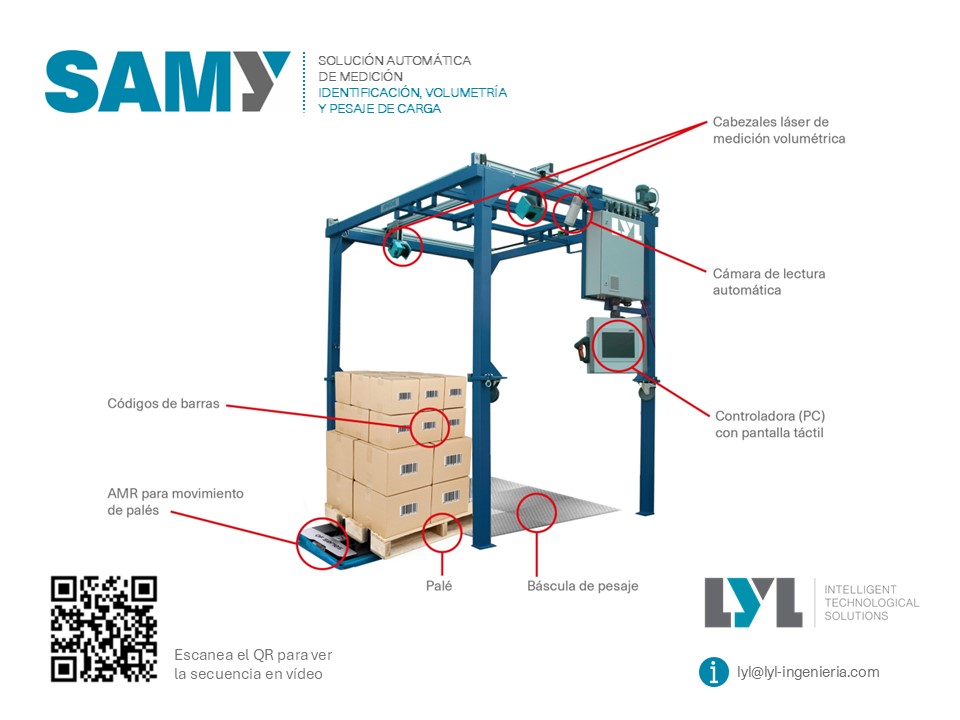

SAMY

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Griffins

Food, Beverage, material handling

PHS Innovate was the automation supplier selected to supply the new palletizer solution for Griffin’s factory. We designed a SAP-compatible system utilising four ABB robots and integrated stretch wrapping and labelling. Our proposal also included an upgrade to Griffins’ conveyor systems, to help with back pressure and product line control. The new palletizer system was installed while the old system was still running, to enable a staged changeover. Our robots were equipped with standard mechanical gripping heads, which have the versatility required for Griffins’ diverse product range. Compared to Griffins’ old system, this method of holding cases was a significant improvement. The final installation was achieved over two weekends, to ensure minimal impact to production at the factory. Initially, half the production line was directed to the new palletizer system. After a few weeks, when it was clear that everything was running smoothly, total production was directed to the new solution and the old palletiser was decommissioned.

Use case

Griffins

Food, Beverage, material handling

PHS Innovate was the automation supplier selected to supply the new palletizer solution for Griffin’s factory. We designed a SAP-compatible system utilising four ABB robots and integrated stretch wrapping and labelling. Our proposal also included an upgrade to Griffins’ conveyor systems, to help with back pressure and product line control. The new palletizer system was installed while the old system was still running, to enable a staged changeover. Our robots were equipped with standard mechanical gripping heads, which have the versatility required for Griffins’ diverse product range. Compared to Griffins’ old system, this method of holding cases was a significant improvement. The final installation was achieved over two weekends, to ensure minimal impact to production at the factory. Initially, half the production line was directed to the new palletizer system. After a few weeks, when it was clear that everything was running smoothly, total production was directed to the new solution and the old palletiser was decommissioned.

Logistics robotics refers to the application of robotic technology to streamline and automate logistics operations. This technology encompasses various robotic systems, including autonomous mobile robots (AMRs), robotic arms, and drones, which are designed to perform tasks such as inventory management, order picking, and transportation within warehouses and distribution centers. By leveraging logistics robotics, businesses can enhance efficiency, reduce labor costs, and improve accuracy in their supply chain processes. These robotic solutions enable faster processing times and can operate continuously, thus optimizing the overall workflow in logistics environments.

Logistics robotics significantly enhance supply chain efficiency through automation and precision. By utilizing robotic systems for tasks such as picking, packing, and sorting, warehouses can experience increased speed and accuracy in operations, minimizing human error. Additionally, these robots can operate continuously, optimizing workflows and reducing downtime. They are also equipped with advanced sensors and AI, allowing for real-time data processing and decision-making, which leads to better inventory management and reduced operational costs. Overall, the integration of logistics robotics creates a more streamlined and responsive supply chain.

Key technologies in logistics robotics include advanced sensors and computer vision systems. These components enable robots to navigate complex environments, detect obstacles, and optimize their paths in real-time. Additionally, machine learning algorithms play a crucial role in enhancing the decision-making capabilities of logistics robots. They allow for adaptive learning from operational data, improving efficiency and accuracy in tasks such as inventory management and order fulfillment. Integration of Internet of Things (IoT) technology also facilitates seamless communication between robots and warehouse management systems, streamlining operations further.

Logistics robotics can significantly lower operational costs through increased efficiency and accuracy in warehouse operations. By automating tasks such as picking, packing, and sorting, these systems reduce the need for manual labor, which can be a substantial expense. Moreover, robotics systems optimize inventory management and reduce errors, leading to less waste and improved resource allocation. Additionally, logistics robotics enable faster processing times, allowing companies to handle larger volumes of orders without increasing overhead costs. This scalability is crucial for businesses looking to expand while maintaining profitability. Overall, the integration of robotics in logistics creates a more streamlined operation, driving down costs and enhancing competitiveness in the market.

Implementing logistics robotics presents several challenges that organizations must navigate. One significant hurdle is the integration of robotic systems with existing infrastructure and software. This often requires substantial modifications to current processes, which can lead to operational disruptions. Additionally, cost considerations play a crucial role. The initial investment for robotics technology can be high, and organizations need to assess the return on investment carefully. Workforce adaptation is another challenge, as employees may require training to work alongside robotic systems effectively. Resistance to change among staff can impede the successful adoption of robotics in logistics operations. Lastly, technology reliability is essential, as any malfunction can significantly disrupt supply chain processes. Ensuring that robotic solutions are robust and dependable is vital for a smooth implementation.

Some interesting numbers and facts about your company results for Logistics Robotics

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 9715 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 2001 |

| Youngest suiting company | 2020 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Logistics Robotics

What are related technologies to Logistics Robotics?

Based on our calculations related technologies to Logistics Robotics are Water/Ocean Cleaning Technologies, Waste Management, Renewable Energy, Sustainable Fashion, Smart Grid

Which industries are mostly working on Logistics Robotics?

The most represented industries which are working in Logistics Robotics are Logistics, Supply Chain and Transportation, IT, Software and Services, Other, Automation, Manufacturing

How does ensun find these Logistics Robotics Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.