The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Associated Spot Welders, Inc.

El Monte, United States

B

1-10 Employees

1943

Key takeaway

Associated Spot Welders is certified by Nadcap in advanced spot welding techniques and is an authorized vendor for the Boeing Company, underscoring their expertise and reliability in the field. They offer a range of spot welding services for various metals, equipped to handle both high-volume production and smaller jobs.

Reference

Core business

Nadcap Certified Welding Los Angeles & Orange County CA: Spot, Stud, Projection & Production Welding

HYBROCO SALES INC.

Stockbridge, United States

B

11-50 Employees

1986

Key takeaway

The company has over 30 years of experience in providing stud welding equipment and has grown to serve various industries. Their dedication to service and extensive inventory suggests they are well-equipped to meet diverse welding and fastening needs.

Reference

Core business

Stud Welding Experts

Dahching Electric Industrial Co., Ltd.

Tainan, Taiwan

11-50 Employees

1979

Key takeaway

Dahching Electric specializes in various welding machines, including spot welders that join sheet metal by electric current, forming weld nuggets through dome-shaped electrodes. Their technology effectively utilizes resistance to heat and forge metal parts, making it ideal for creating strong, air or liquid-proof joints.

Reference

Core business

Dahching Electric - Spot Welder, Seam Welder Manufacturer

Machine type we provide : spot welding machine/ seam welding machine/ projection welding machine/ grating welding machine/ flash butt welding machine...

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Welding & Welder

Plymouth, United Kingdom

A

1-10 Employees

2010

Key takeaway

Welding and Welder offers a variety of spot welders, including handheld and pedestal models, designed for precision resistance welding of nails, washers, screws, and rivets. Their products are tailored for both professionals and hobbyists, ensuring quality and efficiency in welding applications.

Reference

Product

Auto Spotter c/w Puller 230V - Welding & Welder

Used for the resistance welding of nails and washers for sheet straightening, screws and rivets and localized heating of sheets. Reduces the cost of body repairs by eliminating the need to remove interior trims and fitments and easily repairing double skin areas Comes complete with handle (item 20002) and electrodes (7602-7603-7604).

WeldComputer

City of Troy, United States

B

11-50 Employees

1987

Key takeaway

WeldComputer specializes in addressing resistance welding challenges, ensuring high-quality and consistent welds across various industries. Their expertise and technology have made them leaders in the field, particularly noted for their Adaptive Control for seam welding applications.

Reference

Service

Resistance Welding Services | Consulting Services | Welding

Spot Welding Products, Inc.

Franklin Park, United States

B

1-10 Employees

1959

Key takeaway

Spotwelding Products, Inc. is a leading provider of resistance welding solutions, including spot welding, seam welding, projection welding, and flash welding. With over 65 years of experience, the company is committed to delivering high-quality welding services and workmanship.

Reference

Core business

test - Spotwelding Products, Inc.

full name Email Create Account Get Your Free Thingy Here

Resistance Welding Solutions Inc Lors Machinery

United States

B

1-10 Employees

2019

Key takeaway

Resistance Spot Welding Sales and Consulting LLC specializes in the distribution of spot welding machines, parts, and accessories, essential for industries that manufacture metal products. Their commitment extends to providing consulting services to enhance welding operations and train personnel.

Reference

Core business

Resistance Spot Welding Sales and Consulting LLC – Equipment, Parts, Accessories, Consulting and Training

Resistance Spot Welding Sales and Consulting LLC is dedicated to serving the industry by selling spot welding machines, parts, accessories and consumables.

Electroweld Industries

Mumbai, India

D

51-100 Employees

1974

Key takeaway

Electroweld Industries is a prominent manufacturer of welding machines, offering a diverse range of products in the Resistance Welding category, including spot welders. Their extensive portfolio features over 50 welding machines, showcasing their expertise and commitment to high quality and customer satisfaction.

Reference

Product

Electroweld Projection Welder for Weld Nuts, Weld Bolts and Weld Studs – Electroweld Industries

Listing Template Visit Store Butt Welders Spot Welders Seam Welders Special Purpose Machines Brazing Machines Electroweld Press Type Projection/Spot Welder 50KVA (SP-50PR) Categories Rod Butt Welder Upset Butt Welder Wire Butt Welder Micro Wire Butt Welder Bandsaw Blade Butt Welder Foot Rocker Arm Spot Welder Pneumatic

WeldiT Mobile Welding & Fabrication

Houston, United States

B

251-500 Employees

2018

Key takeaway

WELDIT is a prominent provider of welding and fabrication services, offering customized solutions that cater to various industries, including construction. Their commitment to high-quality work and outstanding service positions them as a valuable resource for spot welding and related needs.

Reference

Service

WeldIt

Airfoil Services Sdn Bhd

Petaling Jaya, Malaysia

C

501-1000 Employees

1991

Key takeaway

Airfoil Services Sdn Bhd (ASSB) specializes in comprehensive repair solutions for airfoils, particularly for high-pressure compressors and low-pressure turbines. They utilize advanced auto welding technology, which may be relevant for applications like spot welding in their repair processes.

Reference

Product

Auto Welding Technology

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

SpeedCell

Go to product

Product

SpeedGun

Go to product

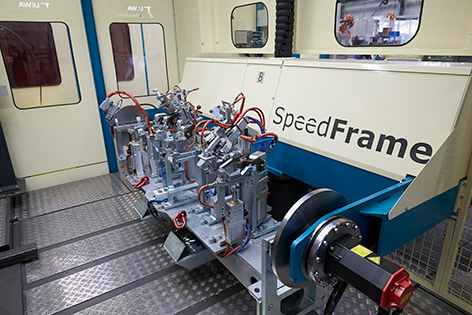

Product

SpeedFrame

Go to product

Service

Sheet Metal Parts and Components

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

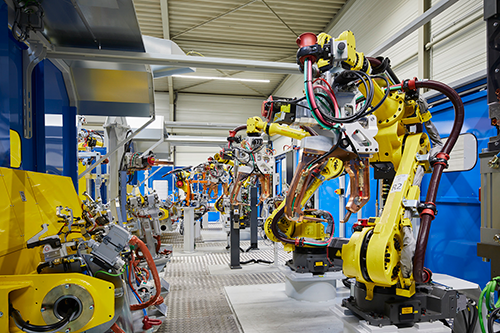

Minimum footprint with maximum productivity in spot welding

automotive, e-mobility, manufacturing

We explain how the LEWA Attendorn guarantees minimum footprint with maximum productivity in spot welding. With the SpeedCell SPOT 2.0, our developers have succeeded in making the super-fast SpeedLine components run even faster - in a very small space. Maximum flexibility for production through high standardization and stringent modularization Maximum flexibility through easy internal and external relocation of compact production systems ... and much more!

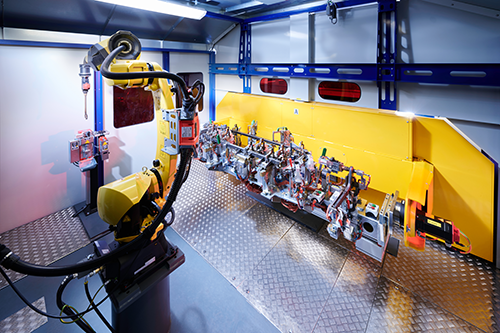

Use case

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

Use case

Production system for MIG welding of a seat assembly

automotive

esign of a production system for MIG welding of a complex, heavy duty vehicle seat assembly consisting of backrest (60% and 40%) and seat bench. The goal is 30,000 units per year in a maximum of 616 seconds per seat assembly. The production system is to be manned by one operator. We developed a flexible production concept, which ensures future expansion and integration of other products in the event of volume fluctuations or design modifications according to the ReUse principle.

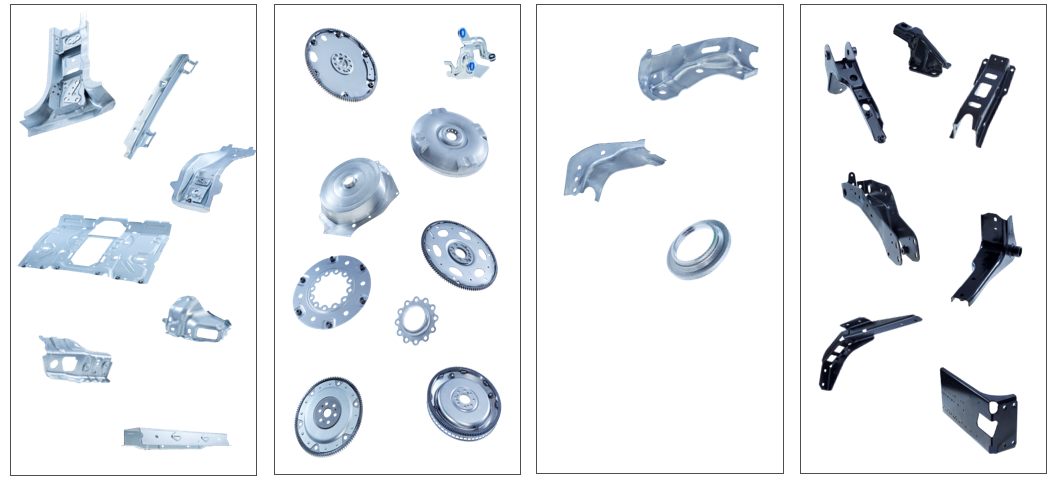

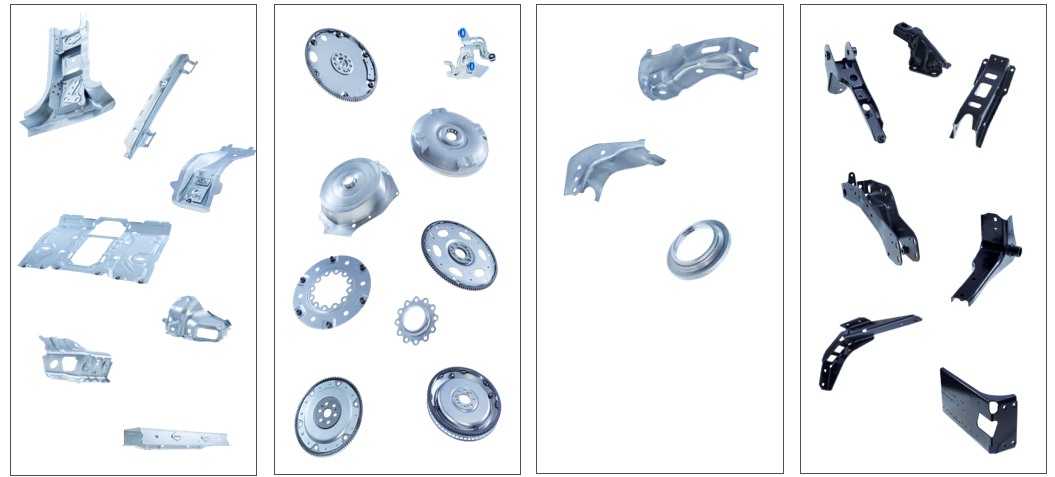

Use case

Car Body in White

Automotive, Industry

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

Use case

Relocation projects

Automotive, Industry

Seamless Relocation Projects in Forming and Joining Technology—Powered by Mühlhoff When it comes to relocating your production lines, Mühlhoff is your expert partner. We specialize in executing complex relocation projects in forming and joining technology, ensuring minimal downtime and maximum efficiency. With our comprehensive service, we handle everything—from planning and dismantling to reassembly and optimization at the new site. Our experienced team works closely with you, providing tailor-made solutions that meet your specific needs while ensuring that your production is up and running as quickly as possible. Why trust Mühlhoff with your relocation project? End-to-End Service: We manage every aspect of the relocation process, so you don’t have to. Expertise in Forming and Joining: Decades of experience in these specialized technologies mean your equipment is in safe hands. Minimal Downtime: Efficient planning and execution to reduce disruptions and keep your production moving. Customized Solutions: We tailor our approach to fit your unique production requirements and goals. Relocating doesn’t have to be a headache. With Mühlhoff’s proven expertise, your forming and joining equipment will be relocated smoothly, safely, and on schedule. Get in touch with us today, and let’s make your next relocation project a success!

Use case

Minimum footprint with maximum productivity in spot welding

automotive, e-mobility, manufacturing

We explain how the LEWA Attendorn guarantees minimum footprint with maximum productivity in spot welding. With the SpeedCell SPOT 2.0, our developers have succeeded in making the super-fast SpeedLine components run even faster - in a very small space. Maximum flexibility for production through high standardization and stringent modularization Maximum flexibility through easy internal and external relocation of compact production systems ... and much more!

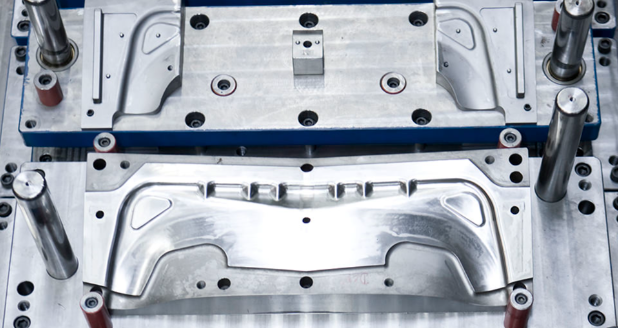

Spot welding is a process used to join two or more metal pieces together by applying heat and pressure to a small area. This method involves the use of electric current to generate heat at the interface of the materials, causing them to melt and fuse together. The process is typically performed using specialized equipment, such as spot welding machines, which apply pressure through electrodes that contact the metal surfaces. This technique is widely utilized in various industries, including automotive and manufacturing, due to its efficiency and ability to produce strong, permanent joints. Spot welding is particularly effective for thin materials and is favored for its speed and low energy consumption compared to other welding methods.

Spot welding is a process that uses heat generated from electrical resistance to join two or more metal sheets together. It involves applying pressure to the overlapping parts of the sheets while passing a high electric current through them. As the current flows, it encounters resistance at the contact points, generating heat. This heat causes the metal to melt and form a small, localized weld nugget. During the process, electrodes press down on the metal sheets, ensuring a tight connection. The combination of pressure and heat allows the molten metal to fuse together, creating a strong bond. Once the current is stopped, the heat dissipates quickly, solidifying the weld. This method is widely used in manufacturing, especially in the automotive industry, due to its efficiency and ability to create strong, reliable joints.

Spot welding is primarily used for joining metals, especially those that are conductive. Common materials include mild steel, which is widely used in automotive and manufacturing applications due to its strength and weldability. Stainless steel is another material that can be spot welded, often utilized in applications requiring corrosion resistance. Additionally, aluminum is also suitable for spot welding, though it requires specific techniques due to its thermal conductivity and oxide layer. Copper and its alloys can be joined through spot welding as well, making it a versatile method for various metallic materials.

1. Speed

Spot welding is a rapid process, allowing for quick assembly of components. This efficiency is particularly beneficial in high-volume production environments, significantly reducing manufacturing time.

2. Strength

This method creates strong and durable joints, ensuring the structural integrity of the welded materials. The localized heat generation results in a robust bond that can withstand various stresses.

3. Minimal Material Distortion

Due to the concentrated heat applied only at the joint area, spot welding causes less thermal distortion in the surrounding materials. This precision helps maintain the dimensions and appearance of the components being joined.

4. Cost-Effectiveness

Spot welding requires less energy and fewer materials compared to other welding methods. This reduction in resource consumption translates to lower operational costs, making it an economical choice for manufacturers.

5. Automation Compatibility

The spot welding process can easily be automated, facilitating integration into robotic systems. This capability enhances consistency in production and reduces human error, leading to improved quality control.

Various industries rely on spot welding due to its efficiency and effectiveness in joining materials. The automotive industry is one of the primary users, as it requires strong, durable connections for assembling vehicle bodies. Manufacturers in the electronics sector also utilize spot welding for creating reliable connections in devices such as circuit boards and battery packs. Additionally, the aerospace industry benefits from spot welding for assembling lightweight components while maintaining structural integrity. Other sectors, including appliance manufacturing and metal fabrication, frequently employ spot welding to produce products with high strength and precision.

Some interesting numbers and facts about your company results for Spot Welding

| Country with most fitting companies | United Kingdom |

| Amount of fitting manufacturers | 5569 |

| Amount of suitable service providers | 6660 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1943 |

| Youngest suiting company | 2019 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Spot Welding

What are related technologies to Spot Welding?

Based on our calculations related technologies to Spot Welding are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Spot Welding?

The most represented industries which are working in Spot Welding are Other, Manufacturing, Machinery Manufacturing, Construction, Mining

How does ensun find these Spot Welding Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.