The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

WeWo

-

- Employees

-

Key takeaway

WEWO Techmotion specializes in automated guided vehicles (AGVs) that enhance logistics processes by optimizing the movement of materials and products. Their innovative, custom-made AGVs are designed to improve efficiency and productivity in various environments.

Reference

Product

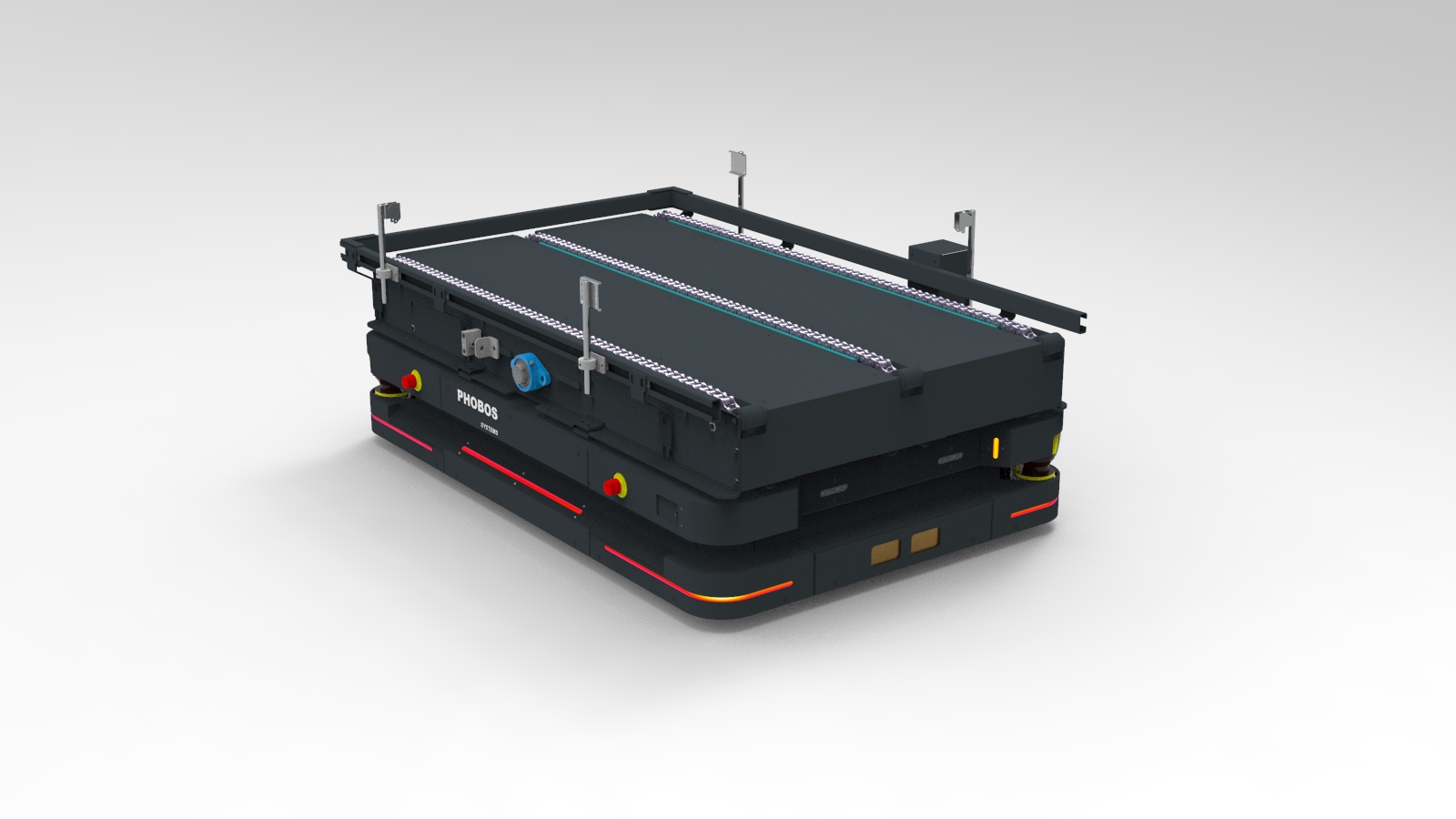

AGV | Automated Guided Vehicle | WEWO Techmotion

WEWO Techmotion specialises in automated guided vehicles (AGVs) that are used for moving materials and products in various environments.

WAKU Robotics

Berlin, Germany

A

1-10 Employees

2019

Key takeaway

WAKU Robotics GmbH specializes in providing software solutions for the maintenance and management of AGV and AMR fleets through their WAKU Care platform. This service enables efficient lifecycle digitization for mobile robots, offering expert advice on integrating these technologies into intralogistics processes.

Reference

Product

AGV & AMR Fleet Control & Management - WAKU Robotics

Shenzhen Casun Intellingent Robot Co. Ltd.

Shenzhen, China

D

251-500 Employees

-

Key takeaway

Casun is a prominent player in the AGV (Automated Guided Vehicle) sector, specializing in industrial mobile robots and intelligent logistics systems. Their F8 Unidirectional Latent Traction AGV is designed for efficient operations in automotive manufacturing, showcasing advanced capabilities like 90-degree turns and 180-degree rotations.

Reference

Product

AGV Automotive Manufacturer, F8 Unidirectional Latent Traction | CASUN

Grab a great deal on AGV automotive! F8 AGV automotive is a mini pallet mover AGV and can do challenging jobs like 90-degree turning a corner or 180-degree in-situ rotation & turning around. Lower AGV automotive cost, better quality. Make an order now!

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

AGV Commercial & Technical Services Ltd.

Piraeus, Greece

B

1-10 Employees

2007

Key takeaway

AGV is a company that provides high-quality commercial and technical services, specializing in innovative products and solutions for the marine and industrial sectors. Their commitment to customized proposals and efficient after-sales service highlights their focus on meeting market needs.

Reference

Core business

AGV | AGV Commercial & Technical Services P.C.

Myzer Sp. z o.o.

Wrocław, Poland

B

11-50 Employees

2016

Key takeaway

The company, Myzer, specializes in AGV/AMR robots that can autonomously transport loads or tow wheeled carts, providing effective solutions for automating logistics processes. With over 18 years of experience, they design and deliver innovative milkrun systems and AGV/AMR forklifts tailored to optimize material handling in various organizational settings.

Reference

Core business

Myzer_PL - Innowacyjne Rozwiązania w Intralogistyce | Grupa Myzer

Z Grupą Myzer odkryj zaawansowane rozwiązania AGV/AMR dla efektywnej intralogistyki. Specjalizujemy się w systemach transportu surowca, ciągnikach AGV/AMR i innowacyjnych systemach milkrun.

Almacenes AGV

Quart de Poblet, Spain

A

1-10 Employees

-

Key takeaway

AGV is a logistics company that specializes in warehousing and distribution services, with a focus on both national and international operations. They offer a range of services, including special transport management and efficient stock control.

Reference

Core business

Almacenes AGV

Almacenaje, manipulación y distribución de mercancías. En AGV ponemos todos nuestros medios y experiencia a tu disposición para que puedas conseguirlo.

AGV Environment Sdn Bhd

Petaling Jaya, Malaysia

C

11-50 Employees

2015

Key takeaway

AGV Environment specializes in environmental, health, and safety consultancy, providing expert services throughout the project lifecycle in both traditional and renewable energy sectors. With over 20 years of experience, their team collaborates with global firms to deliver customized solutions for sustainability and climate change adaptation.

Reference

Core business

wrap resources logo | AGV Environment Malaysia, Singapore & ASEAN

Advantabuy LLC

Lake Forest, United States

B

11-50 Employees

2019

Key takeaway

Advantabuy LLC specializes in providing sensor products for the automotive industry, including a universal chassis designed for AGV (autonomous guided vehicles). Their AMB Series Unmanned Chassis offers features like map editing and localization navigation, making it a key solution for AGV applications.

Reference

Product

Auto Mobile Base Series – AdvantaBuy LLC

AMB Series Unmanned Chassis AMB (Auto Mobile Base) for AGV autonomous vehicle, a universal chassis designed for AGV autonomous guided vehicles, provides features such as map editing and localization navigation. This unmanned chassis for AGV cart provides abundant interfaces such as I/O and CAN to mount various upper mo

AGV Plumbing

Mid Devon, United Kingdom

A

1-10 Employees

-

Key takeaway

AGV Plumbing specializes in plumbing and heating services, including the installation and maintenance of various systems like gas, oil, and biomass. They offer a comprehensive range of services to meet domestic plumbing needs, including the installation of back boilers for efficient hot water and heating.

Reference

Core business

ABOUT US - AGV Plumbing, Heating & Boiler Services

About us - Cullompton's leading provider of plumbing & heating for your needs! Call us on 01884 798335 for your plumbing services in Devon.

AGV Riesa

Riesa, Germany

A

51-100 Employees

-

Key takeaway

The Allgemeine Grundstücks- und Verwaltungsgesellschaft mbH (AGV) is a municipal service provider that offers essential city services, including janitorial and cleaning services, as well as street and open space maintenance.

Reference

Core business

Partner | AGV Riesa

Die AGV versteht sich als städtischer Dienstleister im Bereich Hausmeister- und Reinigungsservice sowie der Straßen- und Freiflächenpflege.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

PX Mover 100

Go to product

Product

PX Mover 500

Go to product

Product

PX Mover 1500

Go to product

Service

AGV Basic Check

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Transportation of small bins and boxes

E-Commerce, Logistics, 3PL, Automotive, Food and Beverage, Chemical, Pharmaceutical, Consumer Electronics, White Appliances

With a carrying capacity of 100 kg and compact size, it is suitable for use in small spaces. It particularly facilitates material handling in tight areas and congested zones, leading to labor and time savings. Its fully automatic operation minimizes human errors and enhances workplace safety. Configurable for different industry needs with a diverse set of top modules.

Use case

Transportation of Palletized Loads

Logistics, Automotive, E-Commerce, White Appliances, Food and Beverage, Chemical, Pharmaceutical, Consumer Electronics

Designed specifically for handling large payloads, this robot features high speed movement and precise positioning capabilities. It is particularly suitable for logistics operations, enabling safe and efficient transportation of palletized loads. It is well suited for use in high volume warehouses and manufacturing facilities. Additionally with its lifting and conveyor attachments, it provides a versatile solution for transporting different types of loads. It is designed to enhance operational efficiency while ensuring the safety of workers.

Use case

Transportation of Heavy Palletized Loads

Logistics, Automotive, E-Commerce, White Appliances, Food and Beverage, Chemical, Pharmaceutical, Consumer Electronics

The high payload capacity of this robot provides a significant advantage in industrial settings where heavy loads are extensively handled. Designed to lift, convey and transport palletized loads, it can efficiently perform these operations with its high capacity. Its customizable structure can be adapted to provide the necessary strength and durability for handling even higher payloads. These features make it an ideal solution for customers seeking to carry out high volume material transportation tasks in industrial facilities.

Use case

MillPart extends production time 7 hours with Global AGV

Metal

Extended production time by 6-7 hours MillPart provides hydraulic components to global companies and boasts one of Denmark's most advanced machine facilities. Prioritising quality without compromise, MillPart places a strong emphasis on leveraging automation in both production processes and enhancing the working environment. Their recent investment in a new robot cell presented the perfect opportunity to incorporate Global AGV to automate numerous heavy pallet transfers to and from these robot cells.

Use case

Welltec leverages employee resources better with Global AGV

Metal

Welltec leverages employee resources better with Global AGV With Global AGV, Welltec can enhance production by efficiently transporting raw materials from saw to manufacturing, optimising employee resource utilisation, achieving smoother production, and ensuring a future-proof production environment.

Use case

Transportation of small bins and boxes

E-Commerce, Logistics, 3PL, Automotive, Food and Beverage, Chemical, Pharmaceutical, Consumer Electronics, White Appliances

With a carrying capacity of 100 kg and compact size, it is suitable for use in small spaces. It particularly facilitates material handling in tight areas and congested zones, leading to labor and time savings. Its fully automatic operation minimizes human errors and enhances workplace safety. Configurable for different industry needs with a diverse set of top modules.

Automated Guided Vehicles (AGVs) are mobile robots used to transport materials within a facility without human intervention. These vehicles navigate through predefined paths using various technologies, such as lasers, magnetic strips, or vision systems. AGVs improve operational efficiency by automating the movement of goods, reducing labor costs, and minimizing the risk of accidents in industrial environments. Their applications range from warehouses and manufacturing plants to distribution centers, making them essential in modern supply chain and logistics operations.

AGV technology operates through a combination of sensors, software, and navigation systems. These automated guided vehicles utilize a variety of guidance methods, such as magnetic strips, laser navigation, and vision systems, to move efficiently along predetermined paths. Once the AGV receives a task, its onboard computer processes the information and plans the optimal route. The vehicle's sensors detect obstacles, allowing it to navigate safely within its environment. Real-time data processing ensures that AGVs can adapt to changes in their surroundings, making them effective for material handling and warehouse operations.

1. Increased Efficiency

Utilizing AGV systems significantly boosts operational efficiency by streamlining material handling processes. These automated vehicles can transport goods without human intervention, reducing the time taken for repetitive tasks and minimizing delays in production lines.

2. Enhanced Safety

AGVs are equipped with advanced sensors and navigation systems that promote a safer working environment. By minimizing human error, these systems help prevent workplace accidents and injuries, ensuring a more secure atmosphere for employees.

3. Cost Reduction

Implementing AGV systems can lead to considerable cost savings for businesses. With reduced labor costs and minimized product damage due to precise navigation, companies can improve their overall profitability while maintaining high productivity levels.

4. Flexibility and Scalability

AGV systems offer flexibility in operations, allowing organizations to adapt to changing demands easily. As businesses grow, these systems can be scaled up or modified to accommodate increasing workloads without significant capital investment.

Various industries benefit from the implementation of automated guided vehicles (AGVs). In the manufacturing sector, AGVs streamline material handling processes, enhancing efficiency on production lines. These vehicles are also prevalent in warehousing and logistics, where they assist in transporting goods and optimizing inventory management. Another significant area is the healthcare industry, where AGVs are used to deliver medications, linens, and other essential supplies within hospitals. Additionally, the automotive industry utilizes AGVs for transporting parts and assemblies, improving workflow and safety in assembly plants. Each of these sectors showcases the versatility and effectiveness of AGVs in modern operations.

An AGV system consists of several key components that work together to ensure efficient material handling.

1. Navigation System

This includes sensors, cameras, and software that help the AGV determine its location and path within the environment.

2. Control System

The control system manages the AGV's operations, coordinating movement, task execution, and communication with other systems.

3. Power Source

AGVs are powered by various sources such as batteries or fuel cells, providing the necessary energy for operation.

4. Drive Mechanism

This component includes the wheels or tracks that allow the AGV to move, often utilizing electric motors for propulsion.

5. Safety Features

Safety systems, including emergency stop buttons, obstacle detection sensors, and safety lights, ensure safe operation in dynamic environments.

6. Load Handling Equipment

Depending on the application, AGVs may be equipped with forks, conveyors, or other tools to facilitate the movement of goods.

Some interesting numbers and facts about your company results for AGV

| Country with most fitting companies | Germany |

| Amount of fitting manufacturers | 7 |

| Amount of suitable service providers | 9 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 2007 |

| Youngest suiting company | 2019 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for AGV

What are related technologies to AGV?

Based on our calculations related technologies to AGV are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on AGV?

The most represented industries which are working in AGV are Automation, IT, Software and Services, Logistics, Supply Chain and Transportation, Other, Automotive

How does ensun find these AGV Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.