The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Neware Technology

Shenzhen, China

D

501-1000 Employees

1998

Key takeaway

Neware specializes in battery testing systems, offering a range of solutions for various applications, from small current cell testing to high precision testing for large packs. With over 24 years of experience, Neware provides flexible and accurate testing equipment, making it a trusted choice for battery manufacturers and R&D institutes.

Reference

Core business

Battery Testing System | NEWARE

MEWOI Electronics

Guangzhou City, China

D

51-100 Employees

2006

Key takeaway

The company offers a battery tester, which is essential for assessing battery performance and ensuring reliability.

Reference

Product

Battery Tester

PPST Solutions

Irvine, United States

B

51-100 Employees

2003

Key takeaway

PPST Solutions specializes in power test equipment, including a range of battery testing systems. They offer programmable power sources and regenerative loads, making them a key resource for battery testing needs.

Reference

Product

Battery TestSystems – PPST Solutions

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Greenlight Innovation

Burnaby, Canada

A

101-250 Employees

1992

Key takeaway

The company offers battery testing solutions through its software, specifically designed for the alternative energy industry.

Reference

Product

Battery Testing with Software from Greenlight Innovation

ITECH Electronics

Macau, China

D

251-500 Employees

-

Key takeaway

ITECH offers innovative testing solutions specifically for batteries, among other applications like EV and energy storage. Their focus on power regenerative products aligns with efforts to enhance battery performance and sustainability.

Reference

Product

Battery Test-Welcome to ITECH

React Labs

Bethesda, United States

B

11-50 Employees

-

Key takeaway

React Laboratories offers specialized battery performance testing services, ensuring compliance with regulatory requirements for electrical and electronic products. They are recognized by the Bureau of Indian Standards and designated as Conformity Assessment Bodies, highlighting their credibility in product safety compliance.

Reference

Service

Battery Performance Testing | React Laboratories

MBTS GmbH - High precision isothermal and isobaric battery testing

Graz, Austria

A

1-10 Employees

2022

Key takeaway

The company is a technical leader in battery testing, offering advanced testbenches that provide precise isothermal and isobaric conditions during electrical cycling. Their comprehensive testing portfolio includes various analyses such as swelling and breathing, aging studies, and mechanical characterization.

Reference

Core business

Products – MBTS GmbH

Intepro Systems America, LLC

Tustin, United States

B

11-50 Employees

2006

Key takeaway

The company specializes in production testing and characterization of power components, making it well-equipped for battery testing. Their expertise includes high power bi-directional racks and customizable test systems, ideal for efficient battery evaluation.

Reference

Product

Battery Testing - Intepro Systems

Rotronics Battery Management Solutions

Walsall, United Kingdom

A

11-50 Employees

-

Key takeaway

The company specializes in battery management solutions and offers comprehensive battery testing processes that integrate seamlessly into everyday workshop practices. Their service and repair center is equipped to handle all battery tester and charger servicing needs, helping to extend battery performance and reduce costs for fleet owners and independent workshops.

Reference

Product

Battery Testing Equipment | Battery System Testers

George W Cox & Sons Inc

San Antonio, United States

B

11-50 Employees

1965

Key takeaway

Autotest Company has nearly 50 years of experience providing customized power and power supply testers, making them well-equipped for efficient battery testing and ensuring reliability in mission-critical applications. Their expertise in developing innovative test methods and hardware adapts to the evolving landscape of power supply testing.

Reference

Core business

Autotest

Automated Test Equipment

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

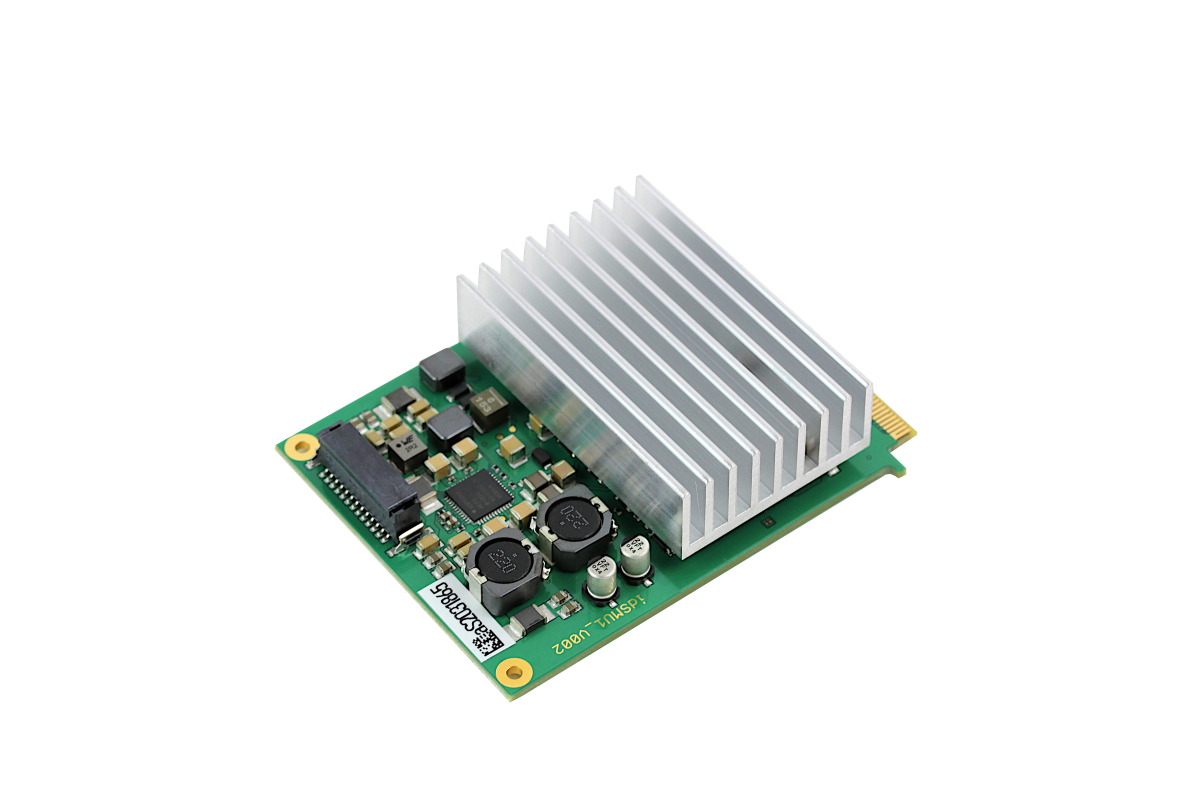

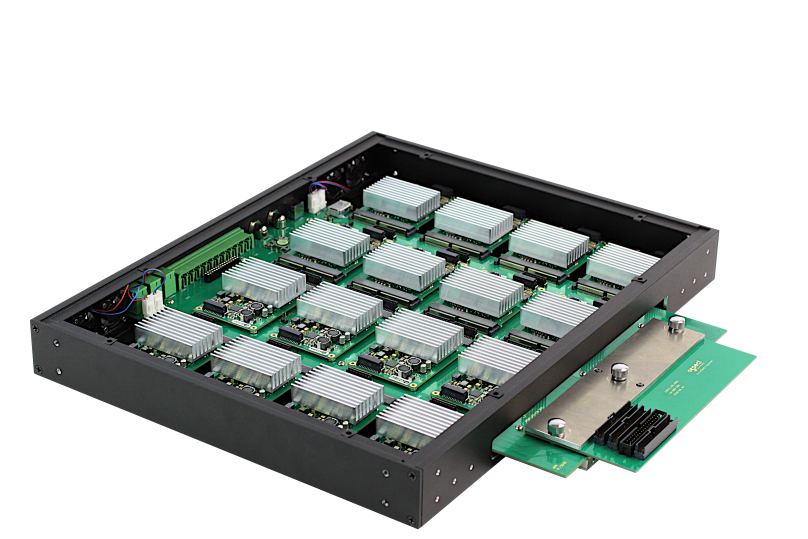

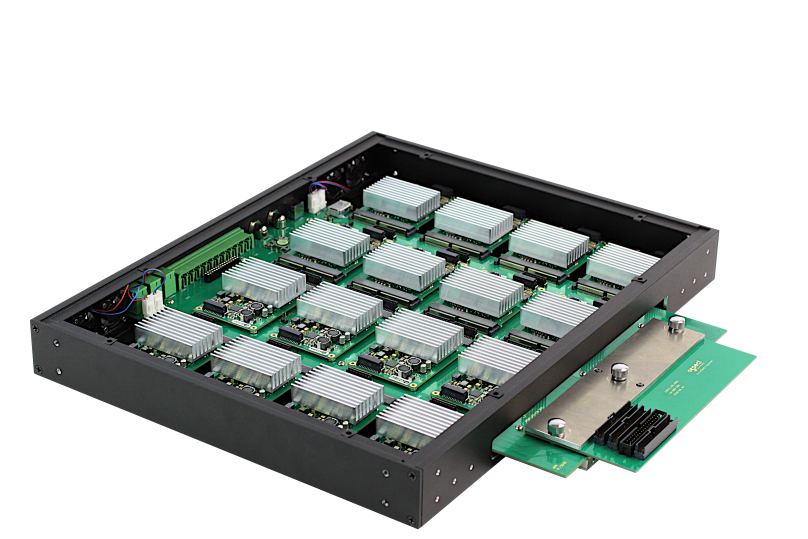

Product

idSMU1

Go to product

Product

leagend Battery Tester BA550

Go to product

Product

leagend Battery Tester BA510

Go to product

Product

leagend 12V/24V Lead-acid Battery Tester BA1000

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Test & Measurement

Semiconductor Test, Device Characterization, Material Science, Renewable Energy, Battery and Energy Storage, Research and Development

The 16 Slot Main Board supports up to 64 idSMU Ch, each Ch with 4 wire interfaces, also 512 digital pins, some utility PWR supplies and GND pins. This huge number of pins requires a compact connector type with 1300 pins. This is realized with Samtec Interposers which allow to connect Test Application Boards in a Board-to-Board style. In some application cases it is beneficial to connect with cable interfaces. Therfore aSpect supports some universal interface boards which are based on flat ribbon cables. These existing interface boards do not support all available resources of the 16 Slot Main Board but they can be seen as easy off-the-shelf interfaces and they act as reference design for custom interface boards.

Use case

Test & Measurement

Semiconductor Test, Device Characterization, Material Science, Renewable Energy, Battery and Energy Storage, Research and Development

The 16 Slot Main Board supports up to 64 idSMU Ch, each Ch with 4 wire interfaces, also 512 digital pins, some utility PWR supplies and GND pins. This huge number of pins requires a compact connector type with 1300 pins. This is realized with Samtec Interposers which allow to connect Test Application Boards in a Board-to-Board style. In some application cases it is beneficial to connect with cable interfaces. Therfore aSpect supports some universal interface boards which are based on flat ribbon cables. These existing interface boards do not support all available resources of the 16 Slot Main Board but they can be seen as easy off-the-shelf interfaces and they act as reference design for custom interface boards.

Battery testing is a critical process that evaluates the performance and safety of batteries in various applications. This procedure involves assessing several parameters such as capacity, voltage, internal resistance, and cycle life to ensure that batteries meet the required standards for reliability and efficiency. Testing can occur at different stages, including manufacturing, during product development, and after deployment in devices. Advanced techniques like thermal imaging and impedance spectroscopy are often employed to identify potential issues and enhance battery longevity, ultimately contributing to improved safety and performance in consumer electronics, electric vehicles, and renewable energy systems.

Battery testing plays a crucial role in ensuring safety by identifying potential hazards associated with battery usage. Through rigorous testing, manufacturers can evaluate the performance and reliability of batteries under various conditions. This process helps in detecting issues such as overheating, short circuits, or capacity failures that could lead to dangerous situations, including fires or explosions. Furthermore, comprehensive battery testing assesses compliance with industry standards and regulations. By adhering to these standards, manufacturers can guarantee that their products are safe for consumer use, thus protecting both users and the environment. Ultimately, effective battery testing is essential for reducing risks and enhancing the overall safety of battery-operated devices.

Battery testing for performance evaluation is conducted through a series of standardized procedures designed to assess various parameters of the battery. Typically, these tests include measuring voltage, capacity, and discharge rates under specific load conditions. During testing, batteries are subjected to controlled charging and discharging cycles to evaluate their efficiency and longevity. Environmental factors such as temperature and humidity are also monitored, as they can significantly affect performance. Advanced techniques like impedance spectroscopy and thermal imaging may be utilized to gain deeper insights into the battery's health and performance characteristics.

1. Performance Testing

This type assesses the battery's ability to deliver power under various conditions. It evaluates capacity, voltage levels, and discharge rates to ensure the battery meets its specifications.

2. Safety Testing

Safety testing involves evaluating the battery's resistance to hazards such as short circuits, overcharging, and thermal runaway. This ensures that the battery operates safely in real-world applications.

3. Life Cycle Testing

This testing examines how a battery performs over time, including charge and discharge cycles. It helps predict the battery's lifespan and efficiency as it undergoes repeated use.

4. Environmental Testing

Environmental conditions can greatly affect battery performance. This type of testing evaluates how temperature, humidity, and altitude impact battery function and stability.

5. Chemical Testing

Chemical composition analysis is crucial for understanding the materials used in battery production. This ensures compliance with regulations and helps identify any harmful substances.

Battery testing is governed by several established standards to ensure safety, performance, and reliability. The International Electrotechnical Commission (IEC) provides guidelines, particularly the IEC 62133 standard, which focuses on the safety requirements for portable sealed secondary cells. Additionally, the Underwriters Laboratories (UL) standards, such as UL 2054, address the safety of battery systems and their components. Testing often follows the Society of Automotive Engineers (SAE) standards, especially for electric vehicle batteries, to assess performance under various conditions. The American National Standards Institute (ANSI) also plays a role in creating guidelines for battery testing, ensuring consistency and reliability across different manufacturers. These standards collectively help in evaluating key parameters like capacity, cycle life, thermal stability, and overall safety of battery systems.

Some interesting numbers and facts about your company results for Battery Testing

| Country with most fitting companies | United Kingdom |

| Amount of fitting manufacturers | 7041 |

| Amount of suitable service providers | 7036 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1965 |

| Youngest suiting company | 2022 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Battery Testing

What are related technologies to Battery Testing?

Based on our calculations related technologies to Battery Testing are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Who are Start-Ups in the field of Battery Testing?

Start-Ups who are working in Battery Testing are MBTS GmbH - High precision isothermal and isobaric battery testing

Which industries are mostly working on Battery Testing?

The most represented industries which are working in Battery Testing are Electronics and Electrical engineering, Other, IT, Software and Services, Oil, Energy and Gas, Construction

How does ensun find these Battery Testing Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.