The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

FLOW COMPUTING TECHNOLOGIES LTD

Arun, United Kingdom

A

1-10 Employees

2012

Key takeaway

CFD Engineering UK specializes in fluid dynamics simulation services, addressing fluid flow and heat transfer challenges across various sectors, including manufacturing and aerospace. Their expertise in CFD consulting helps solve complex problems in industrial processes and electronic designs.

Reference

Product

CFD Engineering UK | CFD Consultant | 10_rc7_orig_cn01_1_EN

Simulitica Ltd

London, United Kingdom

A

1-10 Employees

2023

Key takeaway

Simulitica specializes in providing advanced Computational Fluid Dynamics (CFD) solutions across various industries, including aerospace, automotive, and energy. Their expert team utilizes the latest CFD technologies to deliver innovative and cost-effective methodologies tailored to meet the specific needs of their clients.

Reference

Core business

Simulitica — CFD Solutions

Simulitica is a provider of Computational Fluid Dynamics (CFD) solutions for a wide range of industries. Our team of experts leverages the latest advancements in CFD technology to deliver innovative solutions that meet the unique needs of each of our clients. We pride ourselves on our commitment to high standards and excellence in everything we do, and our expertise in CFD allows us to provide unparalleled results to our customers. Whether you're in the aerospace, automotive, or energy industries, our team is dedicated to delivering top-quality CFD solutions that meet your specific requirements and help you achieve your goals. With Simulitica, you can expect exceptional service and cutting-edge solutions every time.

CFD ENGINEERING LIMITED

United Kingdom

A

1-10 Employees

-

Key takeaway

The company specializes in providing CFD (Computational Fluid Dynamics) simulations and design services, catering to a diverse range of projects from quick assessments to extensive design optimizations, utilizing advanced technologies and professional expertise.

Reference

Service

Capabilities - EngineeringCFD

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Hi-Tech CFD

Ahmedabad, India

D

501-1000 Employees

1992

Key takeaway

Hi-Tech Digital Solutions LLP specializes in CFD consulting, offering simulation solutions that optimize design processes for manufacturing and engineering organizations. Their experienced team utilizes advanced CFD software and hardware to deliver comprehensive analysis and insights across various industrial applications, ensuring effective support from concept to realization.

Reference

Core business

CFD Analysis Services By Simulation & Modeling | HiTechCFD.com

CFD Technologies Ltd

Sheffield, United Kingdom

A

1-10 Employees

2001

Key takeaway

CFD Technologies is a leading provider of expert CFD software, including POINTWISE for mesh generation and the ICFD++ solver, designed to enhance productivity and accuracy for engineers. With over three decades of experience in Computational Fluid Dynamics, the company also offers comprehensive training and support to ensure users can effectively utilize their tools.

Reference

Core business

Home - CFD Technologies

Staghoj

Børkop, Denmark

A

1-10 Employees

2020

Key takeaway

Staghoj specializes in Computational Fluid Dynamics (CFD), offering advanced simulation-driven product design that enhances fluid structure interaction and parametric CAD design.

Reference

Service

Computational Fluid Dynamics (CFD) – Staghoj

LIKUA

Heidelberg, Germany

A

1-10 Employees

-

Key takeaway

LIKUA has 20 years of experience in the development and application of CFD codes across various industries, including complex projects related to missile systems, mineral processing, and nuclear reactor thermal hydraulics. Their expertise is highlighted by their advanced hydrocode, Hydro, and the unique CMPS solver, which offers strongly coupled CFD multi-physics capabilities.

Reference

Service

CFD - Services

Simulation

CFD Freelancing - Simulation Services

Munich, Germany

A

1-10 Employees

2016

Key takeaway

Attila Felföldi, with his extensive expertise and a master's degree in Fluid Dynamics, offers affordable Computational Fluid Dynamics (CFD) simulation services through his consultancy, AF Consulting. His experience spans various applications, including tank sloshing, valve simulation, drone aerodynamics, and more, making him a valuable resource for solving complex fluid dynamics and thermodynamics challenges.

Reference

Core business

CFD Consulting | Cost-effective CFD Simulation Service from an Expert

Cost effective on-demand CFD consulting services worldwide. Outsource your aerodynamics, thermodynamics and aeroacoustics simulations to a CFD Expert!

Engineering CFD LTD

Sheffield, United Kingdom

A

1-10 Employees

2015

Key takeaway

The company specializes in CFD simulations, particularly for fire and smoke ventilation, using OpenFOAM and FDS software. Their analysis predicts heat and smoke movement, supporting the design of effective smoke ventilation systems in buildings.

Reference

Core business

Engineering CFD

CFDWAYS Engineering

Hà Nội, Vietnam

D

1-10 Employees

2018

Key takeaway

CFDWAYS offers technical solutions and services based on numerical simulation to address energy and environmental challenges. They provide access to industrial simulation software from Siemens, including Simcenter STAR-CCM+, which is relevant for CFD simulation.

Reference

Product

Simcenter Amesim | CFDWAYS LLC

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

CFD services

Go to product

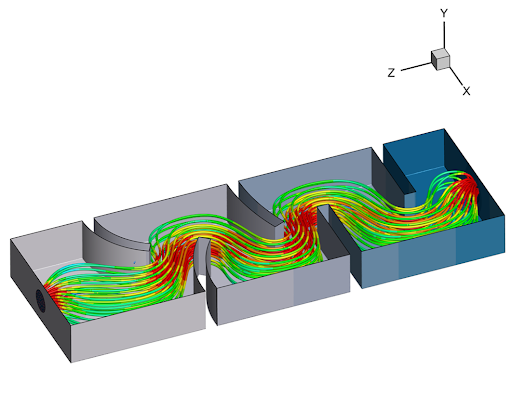

CFD simulation refers to the use of computational fluid dynamics to analyze and predict fluid flow, heat transfer, and associated phenomena. This technology employs numerical methods and algorithms to solve complex equations governing fluid motion, making it a vital tool in various industries such as aerospace, automotive, and energy. By simulating real-world conditions, CFD allows engineers to visualize fluid behavior, optimize designs, and improve performance without the need for costly physical prototypes. As a result, organizations can save time and resources while enhancing product efficiency and reliability.

CFD simulation operates by using numerical methods and algorithms to analyze fluid flow and heat transfer in various systems. Initially, the physical problem is divided into a grid or mesh, allowing for the approximation of complex geometries. The governing equations of fluid dynamics, including the Navier-Stokes equations, are then discretized and solved iteratively over the mesh. Each iteration calculates the properties of the fluid, such as velocity, pressure, and temperature, at each grid point. As the simulation progresses, the computational model converges to provide accurate predictions of how the fluid behaves under specific conditions. This technique is widely used in engineering, aerospace, and automotive industries to optimize designs and improve performance.

1. Enhanced Design Optimization

Utilizing CFD simulation allows engineers to visualize and analyze fluid flow and thermal characteristics within their designs. This capability leads to improved product performance and efficiency by enabling the optimization of shapes and materials before physical prototypes are created.

2. Cost and Time Efficiency

CFD simulations significantly reduce the time and costs associated with physical testing. By identifying potential issues early in the design process, engineers can avoid expensive modifications and iterations, leading to faster project completion and lower overall expenses.

Numerous industries leverage CFD simulation to optimize their processes and products.

1. Aerospace

CFD is crucial in the aerospace sector for analyzing airflow over wings and fuselage, ensuring designs meet aerodynamic efficiency and safety standards.

2. Automotive

In the automotive industry, CFD simulation aids in improving vehicle aerodynamics, cooling systems, and overall performance, contributing to fuel efficiency and handling.

3. Chemical Processing

Chemical manufacturers utilize CFD to model and optimize mixing processes, heat transfer, and reaction kinetics, enhancing production efficiency and safety.

4. HVAC

Heating, ventilation, and air conditioning systems benefit from CFD simulations, enabling engineers to design efficient airflow systems for improved indoor climate control.

5. Marine

The marine industry employs CFD to study fluid dynamics around ship hulls, optimizing design for reduced drag and better fuel efficiency.

6. Renewable Energy

In renewable energy, CFD is used to analyze wind patterns and optimize turbine designs for maximum energy capture and efficiency.

7. Electronics

CFD simulations help in the electronics sector to assess heat dissipation in components, ensuring reliability and performance in devices.

Several software solutions are available for conducting CFD simulation, each tailored to specific applications and industries. Popular options include Ansys Fluent, recognized for its comprehensive capabilities in fluid dynamics, and COMSOL Multiphysics, which integrates CFD with other physics simulations. Another notable software is OpenFOAM, an open-source tool that offers flexibility and customization for advanced users. Additionally, Autodesk CFD is favored for its user-friendly interface and integration with CAD software, making it accessible for a wide range of engineering professionals. Each of these platforms provides unique features that cater to diverse simulation needs in various fields.

Some interesting numbers and facts about your company results for CFD Simulation

| Country with most fitting companies | United Kingdom |

| Amount of fitting manufacturers | 9943 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 1-10 |

| Oldest suiting company | 1992 |

| Youngest suiting company | 2023 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for CFD Simulation

What are related technologies to CFD Simulation?

Based on our calculations related technologies to CFD Simulation are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Who are Start-Ups in the field of CFD Simulation?

Start-Ups who are working in CFD Simulation are Simulitica Ltd

Which industries are mostly working on CFD Simulation?

The most represented industries which are working in CFD Simulation are IT, Software and Services, Other, Manufacturing, Oil, Energy and Gas, Finance and Insurance

How does ensun find these CFD Simulation Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.