The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Novarc Technologies

North Vancouver, Canada

A

11-50 Employees

2013

Key takeaway

Novarc Technologies specializes in robotic welding, offering innovative collaborative robotic systems that significantly enhance the efficiency and quality of pipe welding tasks. Their groundbreaking pipe welding machine, the world's first welding cobot, has the potential to triple productivity compared to manual welding.

Reference

Core business

Robotic Welding | Pipe Welding Machine | Novarc Technologies

Novarc is a leader in robotic welding innovation. Our pipe welding machine is the world's first welding cobot and will make you more competitive in your market.

Robot Welding Services Inc

Milton, Canada

A

1-10 Employees

2016

Key takeaway

The company specializes in high-quality robotic welding services, making it a key player in the automotive sub-assembly production and specialty metals sectors. Their commitment to quality and strategic location enhances their ability to meet the demands of competitive clients.

Reference

Product

Robot Welding Services Ontario - Robotic Welding Services

Robot Welding Services is a provider of high quality robotic welding job shop services. Your robotic welding department in Ontario Canada.

Vital Manufacturing Inc.

Port Coquitlam, Canada

A

251-500 Employees

2014

Key takeaway

The company offers a Vital 9000 Series Robotic Welder, highlighting their expertise in robotic welding solutions. With over 35 years of experience in stainless steel fabrication, they ensure seamless integration and high-quality design from concept to commissioning.

Reference

Product

Robotic Welder | Vital Manufacturing

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

AZ Robotics Inc

Canada

A

1-10 Employees

2016

Key takeaway

AZ Robotics specializes in robotic welding solutions, offering customized setups for MIG/ARC and spot welding projects. They provide comprehensive support from design to implementation, ensuring high-quality automation for various applications.

Reference

Core business

Robotics | PLC | Welding | Vision systems | Controls – Robotics – Welding – PLCs – Vision Systems

BeamMasterWeld

Trois-Rivières, Canada

A

51-100 Employees

-

Key takeaway

AGT Robotics specializes in the design and manufacturing of custom robotic welding equipment, enhancing the structural steel construction process through advanced precision-welding technologies. Their products, like the BeamMaster and LayoutMaster, make robotic welding more accessible to fabricators, ultimately increasing productivity and reducing labor costs.

Reference

Core business

Robotic Welding System - AGT Robotics - Structural Steel

AGT Robotique se spécialisée dans la conception et fabrication d'équipements de soudage industriels robotisé sur mesure.

Tecnar / Rotoweld

Saint-Bruno-de-Montarville, Canada

A

11-50 Employees

1980

Key takeaway

The Rotoweld 3.0 is an advanced automated welding solution designed to enhance productivity and quality in pipe prefabrication. Its PerfectPass-iQ™ technology allows for real-time adjustments to welding settings, optimizing the welding process and reducing the need for close operator proximity to the arc, thus minimizing UV exposure and associated risks.

Reference

Core business

The Ultimate Welding Solution for Pipe Prefabrication | Rotoweld

An automated welding work cell that will increase your productivity and exceed all your expectations in terms of pipe spool fabrication.

DIY Robotics

Sherbrooke, Canada

A

11-50 Employees

-

Key takeaway

The company offers a Robotic Welding Assistant kit designed to enhance the welding process, particularly on irregular metal parts. This kit includes essential components and programs that facilitate user-friendly operation, making robotic welding more accessible and efficient.

Reference

Product

Robotic Welding Assistant - Industrial Robotic Kit - DIY Robotics

The Robotic Welding Assistant works in symbiosis with the welder, therefore facilitating the process of welding on irregular metal parts.

Marcon Metalfab

Delta, Canada

A

51-100 Employees

1981

Key takeaway

The company specializes in robotic welding technology, which ensures consistent, high-quality welds and supports high-volume production. Their commitment to exceeding industry standards and rigorous quality assurance procedures underscores their capability to handle complex structural challenges effectively.

Reference

Service

Marcon Metal Fabrication | Robotic Services

Automation Alternatives

Vaughan, Canada

A

11-50 Employees

1998

Key takeaway

Automation Alternatives specializes in innovative and affordable technology, including industrial laser processing equipment integrated into automated production lines. With over 150 years of combined experience, the company's leadership ensures complete control over design and support, which is crucial for effective solutions in manufacturing.

Reference

Product

Welding | Automation Alternatives

Irco Automation Inc

Burlington, Canada

A

11-50 Employees

1963

Key takeaway

IRCO Automation has been specializing in designing and manufacturing automated welding systems and weld positioning equipment for heavy industry since 1963.

Reference

Core business

IRCO Automation: Automated Welding Systems & Weld Positioning

IRCO Automation designs, engineers, and manufactures welding positioning equipment and automated welding systems for heavy industry. Contact us today!

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

SpeedGun

Go to product

Product

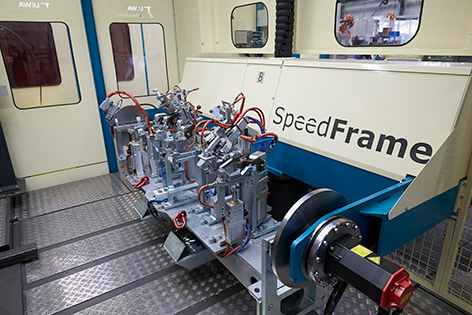

SpeedFrame

Go to product

Service

Sheet Metal Parts and Components

Go to product

Service

Relocation Projects

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

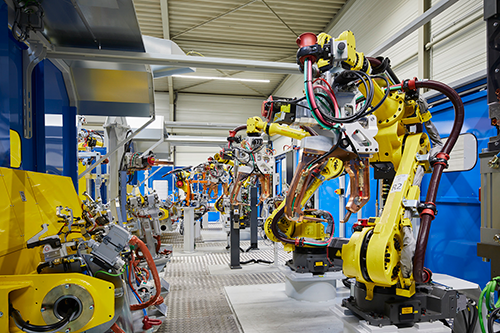

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

Use case

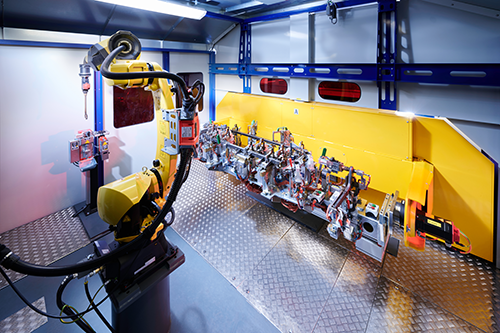

Production system for MIG welding of a seat assembly

automotive

esign of a production system for MIG welding of a complex, heavy duty vehicle seat assembly consisting of backrest (60% and 40%) and seat bench. The goal is 30,000 units per year in a maximum of 616 seconds per seat assembly. The production system is to be manned by one operator. We developed a flexible production concept, which ensures future expansion and integration of other products in the event of volume fluctuations or design modifications according to the ReUse principle.

Use case

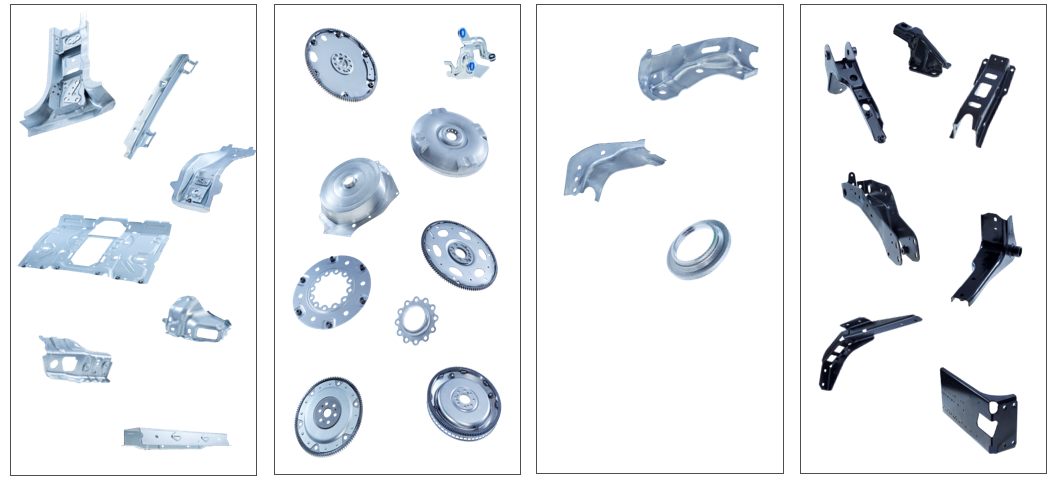

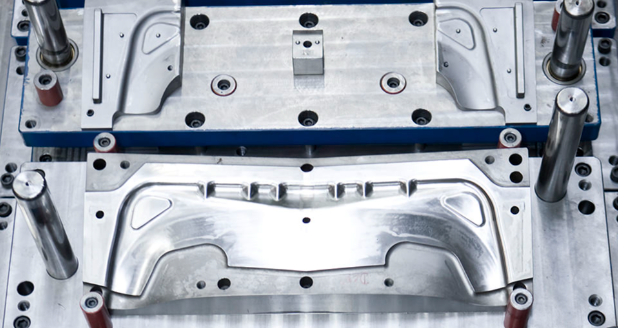

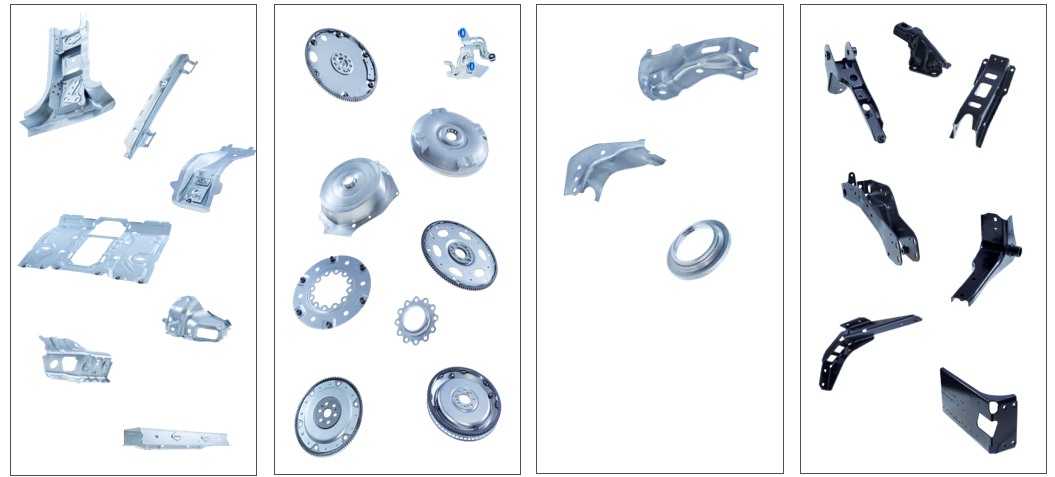

Car Body in White

Automotive, Industry

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

Use case

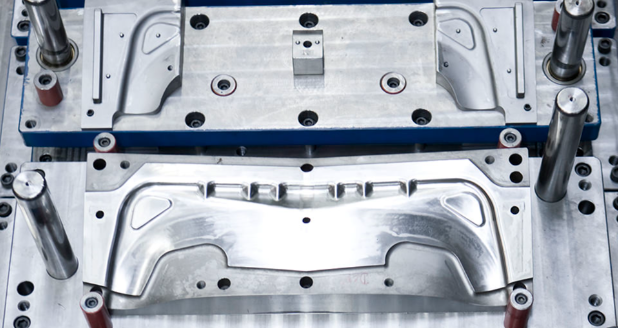

Relocation projects

Automotive, Industry

Seamless Relocation Projects in Forming and Joining Technology—Powered by Mühlhoff When it comes to relocating your production lines, Mühlhoff is your expert partner. We specialize in executing complex relocation projects in forming and joining technology, ensuring minimal downtime and maximum efficiency. With our comprehensive service, we handle everything—from planning and dismantling to reassembly and optimization at the new site. Our experienced team works closely with you, providing tailor-made solutions that meet your specific needs while ensuring that your production is up and running as quickly as possible. Why trust Mühlhoff with your relocation project? End-to-End Service: We manage every aspect of the relocation process, so you don’t have to. Expertise in Forming and Joining: Decades of experience in these specialized technologies mean your equipment is in safe hands. Minimal Downtime: Efficient planning and execution to reduce disruptions and keep your production moving. Customized Solutions: We tailor our approach to fit your unique production requirements and goals. Relocating doesn’t have to be a headache. With Mühlhoff’s proven expertise, your forming and joining equipment will be relocated smoothly, safely, and on schedule. Get in touch with us today, and let’s make your next relocation project a success!

Use case

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

When exploring the Robotic Welding industry in Canada, several key considerations come into play. Understanding the regulatory landscape is crucial, as the industry must comply with safety standards and environmental regulations set by agencies such as the Canadian Standards Association and Environment and Climate Change Canada. Challenges include the high initial investment costs and the need for skilled workers proficient in programming and maintaining robotic systems. However, opportunities abound due to the growing demand for automation across various sectors, including automotive, aerospace, and manufacturing, which can lead to increased productivity and reduced labor costs. The competitive landscape features both established companies and emerging startups, necessitating thorough research into potential partners or suppliers. Additionally, companies must stay attuned to global market trends, such as advancements in artificial intelligence and machine learning, which can enhance robotic welding capabilities. Environmental concerns, including waste reduction and energy efficiency, are also becoming more prominent, pushing businesses to adopt greener practices. Overall, a comprehensive understanding of these factors will empower individuals to make informed decisions when entering or investing in the Canadian robotic welding market.

Some interesting numbers and facts about your company results for Robotic Welding

| Country with most fitting companies | Canada |

| Amount of fitting manufacturers | 540 |

| Amount of suitable service providers | 651 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1963 |

| Youngest suiting company | 2016 |

Some interesting questions that has been asked about the results you have just received for Robotic Welding

What are related technologies to Robotic Welding?

Based on our calculations related technologies to Robotic Welding are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Robotic Welding?

The most represented industries which are working in Robotic Welding are Automation, Machinery Manufacturing, Other, Manufacturing, IT, Software and Services

How does ensun find these Robotic Welding Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.