The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

WeldObot

Israel

B

11-50 Employees

2012

Key takeaway

Weldobot offers advanced robotic welding solutions with its patented SuperMIG® technology, which combines two popular welding processes into a single, efficient system, enabling high-performance and cost-effective welding without the need for bevels.

Reference

Core business

WELDOBOT - Introducing the SuperMIG ® Single Pass, no bevel welds

Weldobot’s patented welding technology (SuperMIG®) successfully unites two widely-used welding processes into a single, high-performance, cost-effective system.

Robologics

Binyamina - Givat Ada, Israel

B

- Employees

2011

Key takeaway

RoboLogics specializes in advanced technologies for quality control, providing cutting-edge visual inspection software that enhances production efficiency and integrity. Their comprehensive data analytics and tailored solutions help industries identify trends and make informed decisions, ensuring exceptional accuracy and reliability in defect detection.

Reference

Core business

Home | RoboLogics

ANV Laser Industry Ltd.

Petah Tikva, Israel

B

11-50 Employees

2012

Key takeaway

ANV Laser Industries Ltd. specializes in laser welding and cutting of metal tubes and plates, utilizing advanced automated manufacturing processes for high precision. Their expertise in laser welding is particularly relevant for applications requiring intricate and precise joins.

Reference

Service

laser-welding - ANV Laser

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

G.B.M. AUTOMATION & ROBOTICS LTD

Kfar Saba, Israel

B

11-50 Employees

1979

Key takeaway

GBIM specializes in industrial automation and robotics, providing comprehensive solutions for the development and integration of high-speed mechanical assembly machines and robotics layouts. Their expertise in robotic systems enhances production capabilities across various industries.

Reference

Core business

GBIM | Specializing in industrial robotics

RoboTiCan

Israel

B

1-10 Employees

2011

Key takeaway

Robotican is an Israeli company that specializes in developing intelligent autonomous robotic solutions, including unmanned aerial and ground vehicles. Their focus on fully autonomous capabilities enhances mission performance and reduces manpower, making their technology relevant for advanced applications like robotic welding.

Reference

Core business

Robotican - Autonomous Robotic Solutions

The team at robotican specializes at smart autonomous robotic solutions, Including HLS ,ISR ,Search & Rescue ,C-UAS and more.

I-Scan Robotics

Kadima - Zoran, Israel

B

1-10 Employees

1997

Key takeaway

I-Scan Robotics specializes in providing innovative automation systems for the glass industry, focusing on enhancing production yield and reducing costs. Their solutions emphasize flexibility, safety, and quality, making them a valuable partner for manufacturers looking to optimize their processes.

Reference

Core business

I-Scan Robotics – Automation systems for the glass industry

General Robotics

Beit Shemesh, Israel

B

11-50 Employees

2009

Key takeaway

The company, General Robotics, specializes in providing fully integrated border-security solutions that incorporate advanced technologies, including unique operational systems designed to enhance situational awareness. They emphasize the importance of training and support for long-term success.

Reference

Core business

About Us - Generel Robotics

SkillReal - Digital Twins for Industrial Manufacturing

Ramat Gan, Israel

B

11-50 Employees

2020

Key takeaway

SkillReal is focused on enhancing manufacturing processes through advanced Digital Twin technologies, which can significantly improve the quality and productivity of robotic welding. Their next-generation AR inspection technology allows for real-time monitoring and alignment of digital and physical systems, ensuring high standards in welding and manufacturing quality.

Reference

Product

Integrated AR & inspection app for manufacturing and training

Learn about SkillReal AssistAR inspection, assembly, maintenance and training technology | All you need in one product

Deep Learning Robotics

Ashdod, Israel

B

1-10 Employees

2015

Key takeaway

DLRob is an innovative software solution that simplifies the integration of robotics into operations, making it particularly beneficial for companies with high mix operations. Its advanced visual technology allows robots to learn and replicate tasks by observing human demonstrations, which can significantly enhance robotic welding processes.

Reference

Core business

Home | DeepLearningRobotics

Aquabot Automation LTD.

Emek Izrael Regional Council, Israel

B

11-50 Employees

-

Key takeaway

Aquabot Automation specializes in innovative robotic solutions that enhance order fulfillment, utilizing state-of-the-art technology to increase efficiency and accuracy. Their expertise in automation could be relevant for applications in robotic welding and similar processes.

Reference

Core business

Home - Aquabot Automation

BOOST YOUR ORDER FULFILLMENT CAPABILITIES INTRODUCING THE MOST INNOVATIVE AUTOMATIC ORDER FULFILLMENT, PICKING AND SORTING SOLUTIONS ON THE MARKET TODAY INCREASE YOUR REVENUE REDUCE YOUR FOOTPRINT, LABOR AND MAINTENANCE COSTS WORK FASTER & SMARTER TO WIN IN TODAY’S MARKET Speed up your high-volume order fulfillment and delivery process, while keeping 100% accuracy https://aquabot-automation.com/wp-content/uploads/2022/07/Orange_WORK-_FASTER_4_features_444.mp4 – Patents […]

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

SpeedGun

Go to product

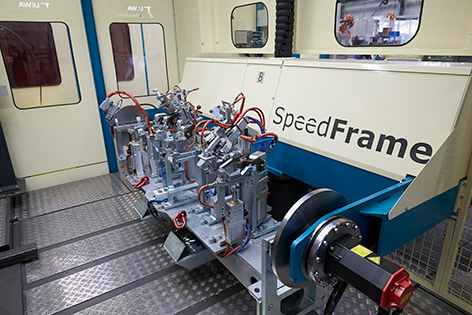

Product

SpeedFrame

Go to product

Service

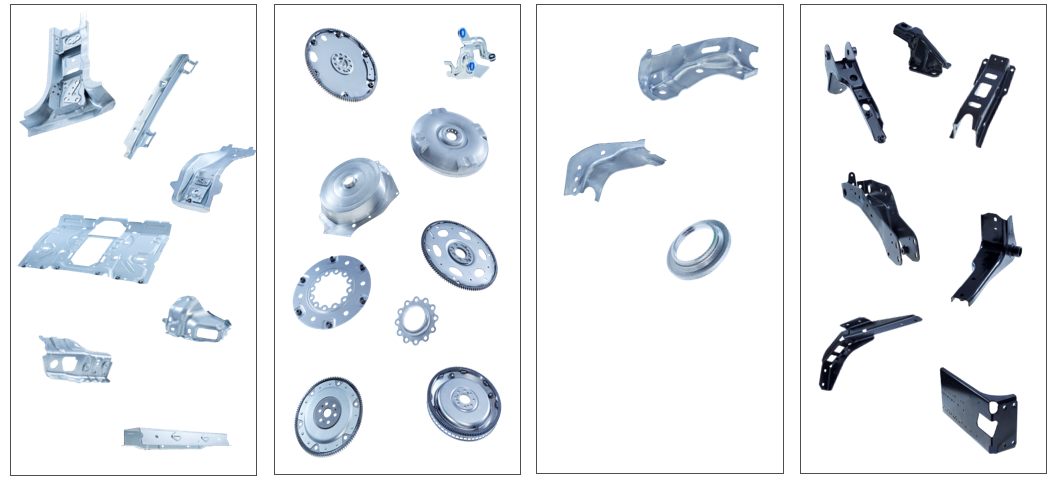

Sheet Metal Parts and Components

Go to product

Service

Relocation Projects

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

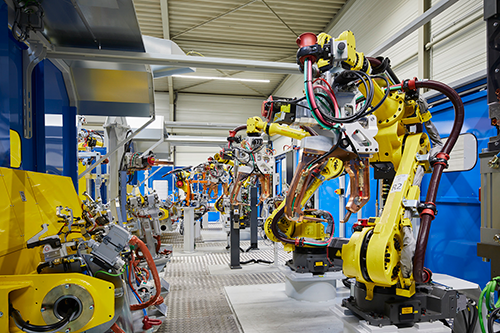

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

Use case

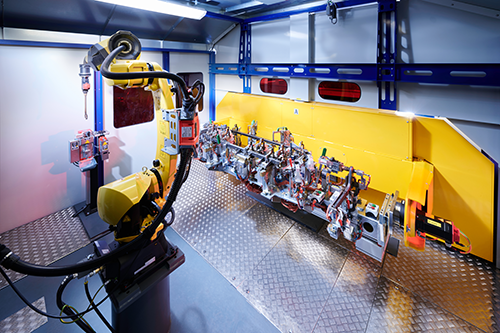

Production system for MIG welding of a seat assembly

automotive

esign of a production system for MIG welding of a complex, heavy duty vehicle seat assembly consisting of backrest (60% and 40%) and seat bench. The goal is 30,000 units per year in a maximum of 616 seconds per seat assembly. The production system is to be manned by one operator. We developed a flexible production concept, which ensures future expansion and integration of other products in the event of volume fluctuations or design modifications according to the ReUse principle.

Use case

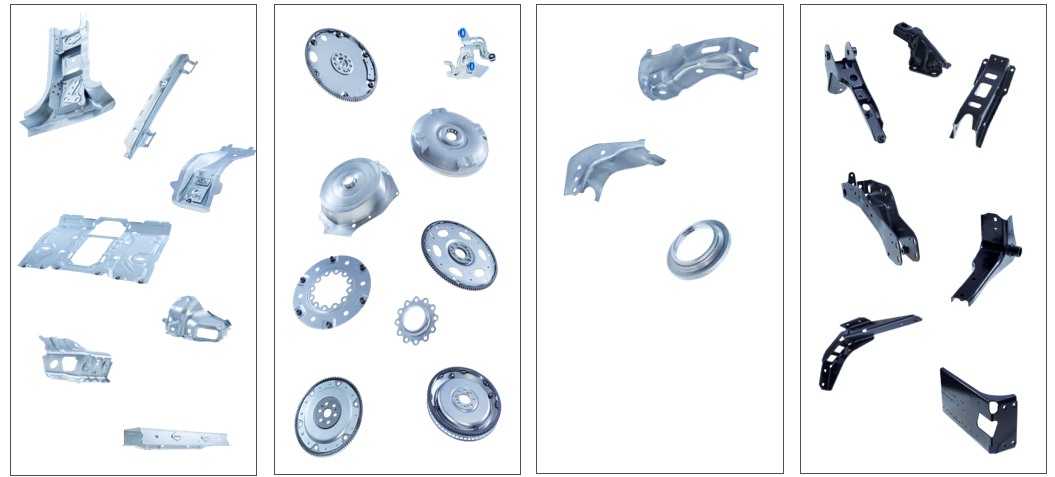

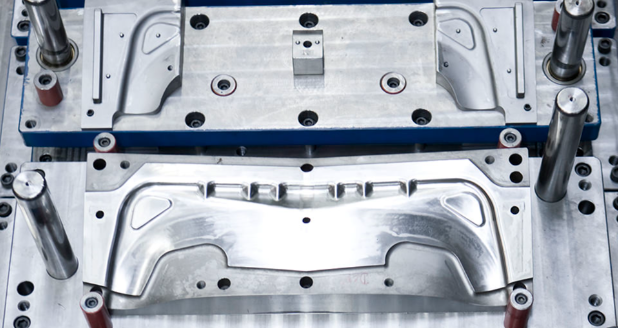

Car Body in White

Automotive, Industry

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

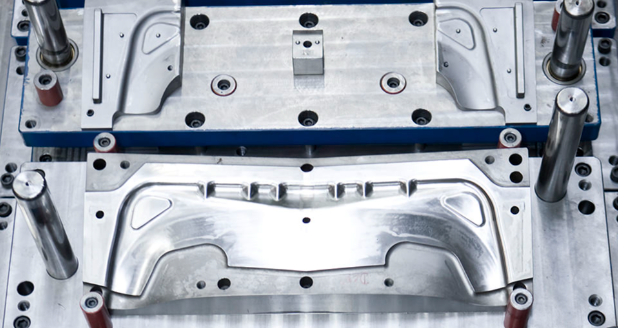

Use case

Relocation projects

Automotive, Industry

Seamless Relocation Projects in Forming and Joining Technology—Powered by Mühlhoff When it comes to relocating your production lines, Mühlhoff is your expert partner. We specialize in executing complex relocation projects in forming and joining technology, ensuring minimal downtime and maximum efficiency. With our comprehensive service, we handle everything—from planning and dismantling to reassembly and optimization at the new site. Our experienced team works closely with you, providing tailor-made solutions that meet your specific needs while ensuring that your production is up and running as quickly as possible. Why trust Mühlhoff with your relocation project? End-to-End Service: We manage every aspect of the relocation process, so you don’t have to. Expertise in Forming and Joining: Decades of experience in these specialized technologies mean your equipment is in safe hands. Minimal Downtime: Efficient planning and execution to reduce disruptions and keep your production moving. Customized Solutions: We tailor our approach to fit your unique production requirements and goals. Relocating doesn’t have to be a headache. With Mühlhoff’s proven expertise, your forming and joining equipment will be relocated smoothly, safely, and on schedule. Get in touch with us today, and let’s make your next relocation project a success!

Use case

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

When exploring the robotic welding industry in Israel, several key considerations come into play. The region is known for its advanced technology and innovation, which benefits the robotic welding sector through a strong emphasis on research and development. Companies must navigate local regulations, including safety standards and environmental laws, which can impact operational practices and investment decisions. The competitive landscape is dynamic, with both established players and startups vying for market share, necessitating a focus on unique selling propositions and technological advancements. Challenges such as skilled labor shortages and the high cost of advanced machinery may also affect the industry's growth potential. However, opportunities abound, particularly with the increasing demand for automation in manufacturing processes and the emphasis on precision welding in sectors like automotive and aerospace. Additionally, the global market relevance of robotic welding continues to rise, driven by trends in Industry 4.0 and the push for more efficient production methods. Environmental concerns related to waste and emissions are also critical, prompting companies to adopt cleaner technologies. Overall, understanding these factors is crucial for anyone interested in entering or investing in the robotic welding industry in Israel, as they can significantly influence business strategies and outcomes.

Some interesting numbers and facts about your company results for Robotic Welding

| Country with most fitting companies | Israel |

| Amount of fitting manufacturers | 48 |

| Amount of suitable service providers | 24 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1979 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Robotic Welding

What are related technologies to Robotic Welding?

Based on our calculations related technologies to Robotic Welding are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Robotic Welding?

The most represented industries which are working in Robotic Welding are Other, Automation, IT, Software and Services, Manufacturing, Aviation and Aerospace

How does ensun find these Robotic Welding Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.