The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

FSW-Friction Stir Welding

Santa Maria di Sala, Italy

B

251-500 Employees

-

Key takeaway

The company offers StirRob, a 6-axis welding robot specifically designed for friction stir welding (FSW), providing flexible and cost-effective solutions for various industrial applications. Their expertise spans from feasibility analysis to production, ensuring that businesses can effectively manage FSW technology.

Reference

Product

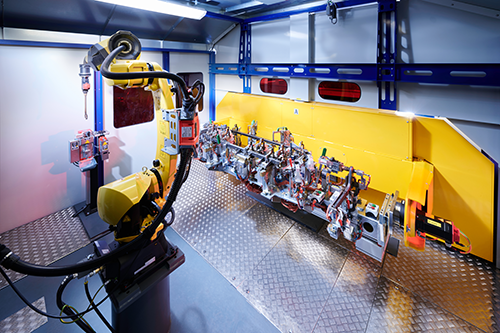

Born for Friction Stir Welding: StirRob, 6-axis welding robot | FSW

StirRob is a robot specially designed for friction welding: a machine that offers flexible and cost-effective FSW solutions for various industrial applications.

ROBOSURF

Italy

B

11-50 Employees

2018

Key takeaway

At Robosurf, innovative robotic solutions like their "Wizard" robot painter are designed to automate labor-intensive tasks, enhancing efficiency and quality in operations such as surface finishing and spray painting. Their focus on autonomous mobile robot technology and artificial intelligence positions them as leaders in addressing industry challenges.

Reference

Core business

Robo Tech for Surface Work & Spray Painting

Company Information Data Protection Privacy Policy Quality Policy Company Information Data Protection Privacy

TEKNO PROGETTI

Cassino, Italy

B

51-100 Employees

1982

Key takeaway

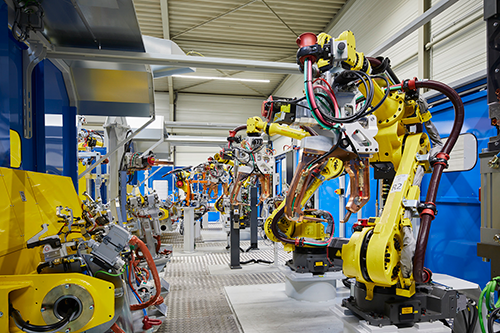

Tekno Progetti is a technology company that specializes in the design and implementation of advanced robotic welding systems. Their robotic systems perform various welding techniques, including spot, arc, laser, and resistance welding, on a wide range of metals, integrating advanced technologies for enhanced production efficiency.

Reference

Product

Technology Archivi - Tekno Progetti

In Tekno Progetti the robotic systems carry out all the different types of welding – spot, arc, laser, resistance – on all the most common metals. We also integrate advanced technologies such as marking, vision and glue coating into our “turnkey” lines.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Mac Welding

Milan, Italy

B

11-50 Employees

1985

Key takeaway

MacWelding offers robotic welding solutions that enhance productivity and improve the quality of welded joints, making them ideal for replacing or supplementing manual welding. Their technology ensures the well-being of operators while delivering efficient and high-quality results.

Reference

Product

Robot di saldatura - MacWelding

Ideale per sostituire o integrare la saldatura manuale, per aumentarne la produttività e la qualità del giunto saldato nel rispetto della salute e del benessere degli operatori: la massima testimonianza dell’efficienza della tecnologia TAWERS di Panasonic

PromeK - Welding Robotics and automation

Rosta, Italy

B

11-50 Employees

2001

Key takeaway

PromeK specializes in designing and manufacturing automation lines, including robotic welding systems, tailored to meet diverse customer needs. Their expertise extends from simple welding solutions to complex turnkey projects with automatic cells and industrial equipment.

Reference

Service

Consulting - Promek - Welding, Robotic and Automation

Do you have a Project in Mind that you want to tell us about? Contact Us Consulting “Which method to use? The best for you" With decades of experience in

REA Robotics Srl - Industrial Automation

Veggiano, Italy

B

51-100 Employees

1985

Key takeaway

REA Robotics is a leading Italian company specializing in robotic automation, focusing on creating robotic islands and industrial automation projects, particularly in the sheet metal and foundry sectors.

Reference

Core business

REA Robotics - Automazione Industriale settore lamiere, revamping e retrofit

REA Robotics realizza isole robotizzate, progetti di automazione industriale settore lamiere e fonderia, revamping e retofit, lavorazioni meccaniche.

YK-Robotics

Pontedera, Italy

B

1-10 Employees

2020

Key takeaway

YK-Robotics specializes in designing and deploying advanced robotic systems, which can enhance robotic cell management for applications like assembly and quality control.

Reference

Service

Our Services - YK-Robotics

YK-Robotics studies, designs, develops and deploys advanced robotic systems to solve general industry processes needs.

Intec Robotics

Travagliato, Italy

B

11-50 Employees

1999

Key takeaway

Intec Robotics specializes in robotic machines for surface finishing, offering solutions that facilitate the transition from manual processes to automation. Their comprehensive after-sales services, including support, programming, training, and retrofitting, are designed to enhance flexibility and scalability for customers dealing with complex processes.

Reference

Core business

Intec Robotics – The ultimate Manufacturer of Robotic Machines for Surface Finishing

The ultimate Manufacturer of Robotic Machines for Surface Finishing

SIDERGAS SPA

Sant'Ambrogio di Valpolicella, Italy

B

51-100 Employees

-

Key takeaway

Sidergas is dedicated to developing innovative welding consumables that meet the increasing demand for reliability in robotic welding and automation. With over 50 years of experience, Sidergas produces premium quality wires, emphasizing continuous product development and adherence to stringent safety standards.

Reference

Core business

Company - SIDERGAS - Robotic Welding Wires

Tiesse Robot S.p.a.

Visano, Italy

B

51-100 Employees

1976

Key takeaway

KAWASAKI ROBOTICS ITALIA offers a range of robotic solutions, including anthropomorphic and SCARA robots, designed for industrial automation across various sectors. Tiesse Robot specializes in designing and implementing robotic systems for all industrial automation processes, leveraging innovative strategies to meet evolving market trends.

Reference

Core business

Robotic industrial automation | Tiesse Robot

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

SpeedGun

Go to product

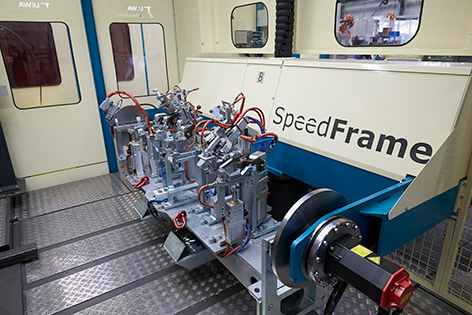

Product

SpeedFrame

Go to product

Service

Sheet Metal Parts and Components

Go to product

Service

Relocation Projects

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

Use case

Production system for MIG welding of a seat assembly

automotive

esign of a production system for MIG welding of a complex, heavy duty vehicle seat assembly consisting of backrest (60% and 40%) and seat bench. The goal is 30,000 units per year in a maximum of 616 seconds per seat assembly. The production system is to be manned by one operator. We developed a flexible production concept, which ensures future expansion and integration of other products in the event of volume fluctuations or design modifications according to the ReUse principle.

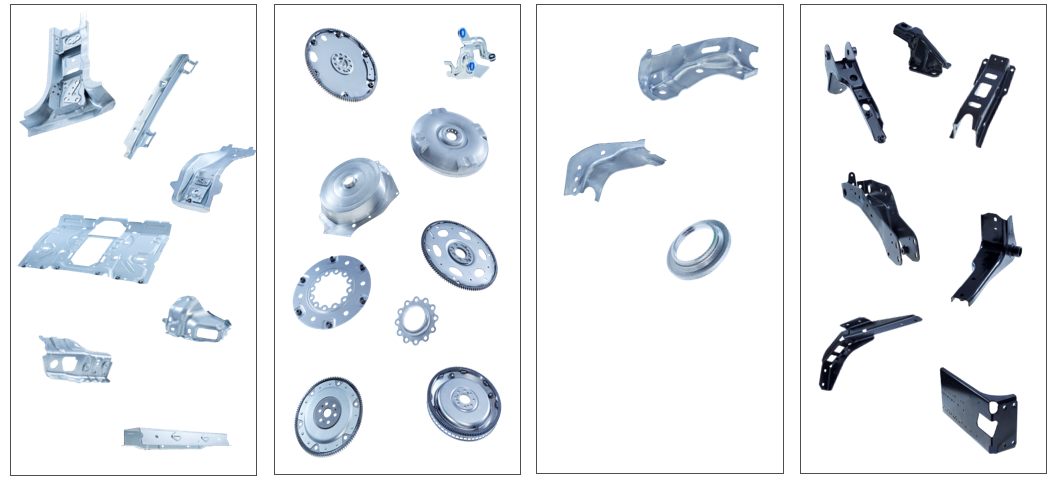

Use case

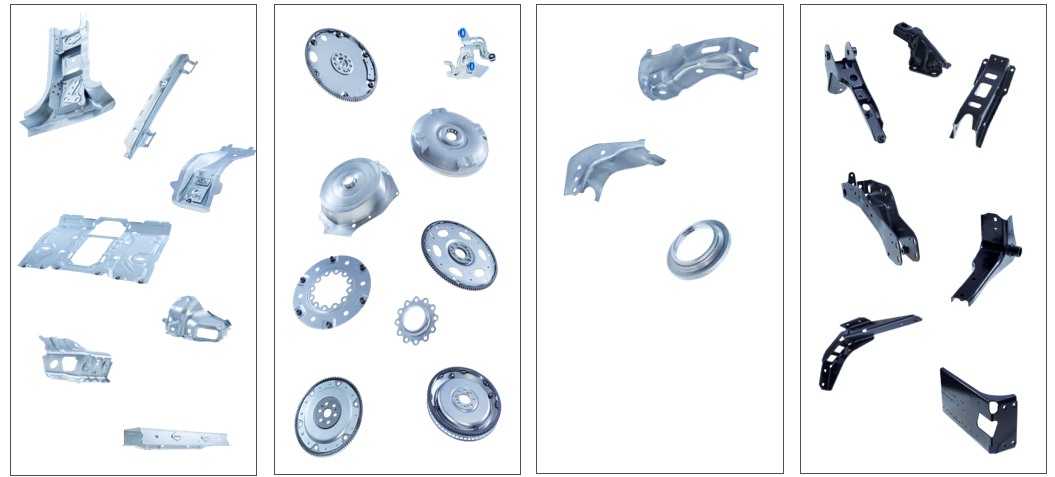

Car Body in White

Automotive, Industry

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

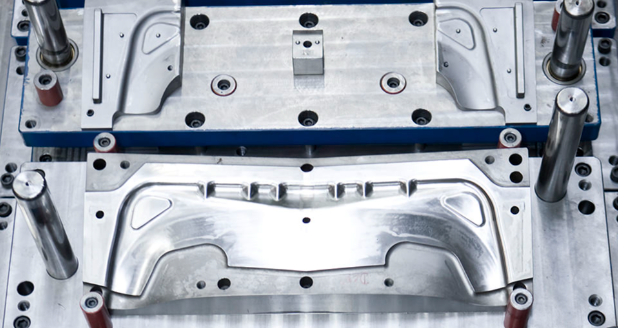

Use case

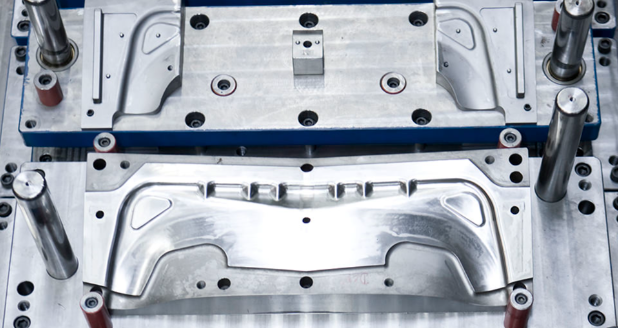

Relocation projects

Automotive, Industry

Seamless Relocation Projects in Forming and Joining Technology—Powered by Mühlhoff When it comes to relocating your production lines, Mühlhoff is your expert partner. We specialize in executing complex relocation projects in forming and joining technology, ensuring minimal downtime and maximum efficiency. With our comprehensive service, we handle everything—from planning and dismantling to reassembly and optimization at the new site. Our experienced team works closely with you, providing tailor-made solutions that meet your specific needs while ensuring that your production is up and running as quickly as possible. Why trust Mühlhoff with your relocation project? End-to-End Service: We manage every aspect of the relocation process, so you don’t have to. Expertise in Forming and Joining: Decades of experience in these specialized technologies mean your equipment is in safe hands. Minimal Downtime: Efficient planning and execution to reduce disruptions and keep your production moving. Customized Solutions: We tailor our approach to fit your unique production requirements and goals. Relocating doesn’t have to be a headache. With Mühlhoff’s proven expertise, your forming and joining equipment will be relocated smoothly, safely, and on schedule. Get in touch with us today, and let’s make your next relocation project a success!

Use case

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

When exploring the robotic welding industry in Italy, several key factors demand attention. Italy is known for its strong manufacturing base, particularly in sectors like automotive and aerospace, which increasingly utilize robotic welding technologies to enhance precision and efficiency. Understanding local regulations is crucial, as compliance with safety standards and environmental laws can impact operations. The European Union's directives on emissions and waste management also apply, necessitating that companies adopt sustainable practices. Challenges in the industry include the high initial investment for advanced robotic systems and the need for skilled personnel to operate and maintain these technologies. However, there are significant opportunities, especially with the ongoing digital transformation and the integration of Industry 4.0 principles, which promote automation and data exchange in manufacturing environments. The competitive landscape is marked by both established players and innovative startups that are pushing the boundaries of robotic applications. Additionally, Italy's position in the global market allows for potential collaboration with international firms, enhancing technological exchange and market access. Overall, thorough research into these aspects will provide valuable insights for anyone considering entering the robotic welding sector in Italy.

Some interesting numbers and facts about your company results for Robotic Welding

| Country with most fitting companies | Italy |

| Amount of fitting manufacturers | 181 |

| Amount of suitable service providers | 105 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1976 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Robotic Welding

What are related technologies to Robotic Welding?

Based on our calculations related technologies to Robotic Welding are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Robotic Welding?

The most represented industries which are working in Robotic Welding are Automation, Machinery Manufacturing, Manufacturing, Other, IT, Software and Services

How does ensun find these Robotic Welding Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.