The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Inrovo

Singapore

C

- Employees

2017

Key takeaway

Inrovo specializes in large-scale systems integration for robotics and automation, offering customized software and hardware solutions that enhance productivity and reduce costs. Their expertise in Robotics, Artificial Intelligence, and IoT positions them as a key player in advancing robotic integration for enterprise businesses across various sectors.

Reference

Core business

Robotics | Systems Integration | Inrovo Pte Ltd | Singapore

Inrovo builds customised AI+robots software and hardware solutions to get your business ready for a smart 4.0 revolution.

Regrello

San Francisco, United States

B

11-50 Employees

2021

Key takeaway

Dell enhances its supply chain efficiency and achieves real-time visibility through Regrello's orchestration platform, which includes features for robotic integrations and prebuilt third-party integrations. This focus on integration is crucial for streamlining manufacturing operations.

Reference

Product

Platform | Robotic Integrations | Regrello

Shape Process Automation

Auburn Hills, United States

B

101-250 Employees

1980

Key takeaway

Shape Process Automation (SPA) specializes in robotic integration, offering advanced automation solutions that enhance manufacturing efficiency and productivity. With over 12,000 installations worldwide, they provide comprehensive robotic systems integration, including machine vision and programming, to optimize processes in various industries.

Reference

Product

Robotic Systems Integration | Shape Process Automation

Complete factory robotic integration systems to boost manufacturing production. Machine vision, robot programming, and more.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Automation & Control Services Inc.

Schererville, United States

B

11-50 Employees

1994

Key takeaway

Automation & Control Services, Inc. is a factory authorized robotic system integrator, offering comprehensive robotic integration solutions and supporting major robot brands. Their commitment to innovative and well-designed control systems ensures customers receive effective automation solutions.

Reference

Service

Robotic Integration - Automation & Control Services, Inc.

Automation & Control Services is a factory authorized robotic system integrator representing and supporting most major robot brands

Terzago Robotics

Italy

B

11-50 Employees

2020

Key takeaway

Terzago Robotics specializes in providing tailor-made robotic solutions for various production needs, from small-scale fab-labs to large-scale automated lines featuring numerous anthropomorphic robots. They focus on integrating robotics across multiple industrial sectors, emphasizing full automation as the future of production.

Reference

Core business

Terzago Robotics S.r.l.

DesignPro Ltd

Limerick, Ireland

A

51-100 Employees

2004

Key takeaway

DesignPro Automation is an award-winning company that specializes in robotic integration, showcasing their expertise in creating advanced automation solutions. Their extensive experience and commitment to innovation make them a key player in enhancing manufacturing environments through robotics.

Reference

Product

Robotic Integration - DesignPro Automation

Crown ESA

Portage, United States

B

51-100 Employees

1992

Key takeaway

The company specializes in robotic integration solutions that enhance efficiency and profitability in manufacturing processes. By leveraging advanced technology, they automate and streamline operations, addressing labor shortages and increasing production volume.

Reference

Service

Adaptive Robotics Integration Across Manufacturing Industries

Migrate your skilled labor to critical roles with E Tech Group’s robotic integration solutions, using the latest technology to optimize efficiency and profitability.

CNC Robotics

Liverpool, United Kingdom

A

1-10 Employees

2010

Key takeaway

CNC Robotics is a leading robotic integrator that specializes in advanced machining and large format additive manufacturing solutions, effectively using industrial robots to enhance productivity in manufacturing. Their expertise in robotic system integration positions them as a key player in the field of robotic integration.

Reference

Core business

Robotic Integrators | Robotic System Integration | CNC Robotics

Robotic Integrators - CNC Robotics are a UK robotic integration company providing automated solutions and robotic system integration UK.

MVB Improvements

Three Rivers, United States

B

11-50 Employees

2010

Key takeaway

MVB Improvements emphasizes its expertise in robotic integration, showcasing a team of mechanical and automation engineers dedicated to optimizing the manufacturing process and minimizing downtime. Their professional custom machining services and responsive support enhance production efficiency, making them a valuable partner for manufacturing companies.

Reference

Service

Robotics Integrations – MVB

RoboMation

Village of Germantown, United States

B

1-10 Employees

2018

Key takeaway

RoboMation specializes in robotic integration and automation solutions, offering services like robotic system design, assembly, and custom fixturing to address complex manufacturing challenges. Their expertise in advanced technologies ensures effective integration of robotics into various processes.

Reference

Core business

RoboMation | Robomation Solutions

Robomation is an advanced Manufacturing solutions company focused on robotics and automations solutions. We are focused on the use of cutting edge technology to provide our clients with the optimal solutions to there most complex problems.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

ArtiMinds Robot Programming Suite

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

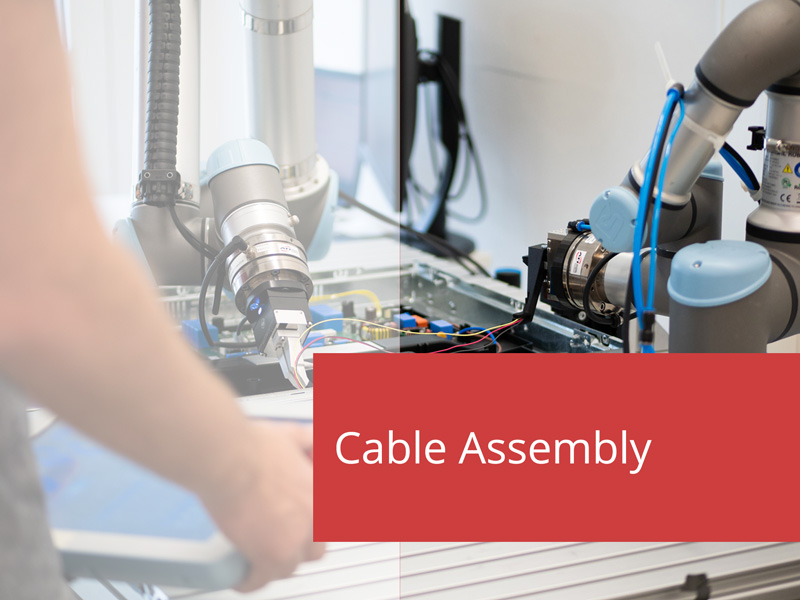

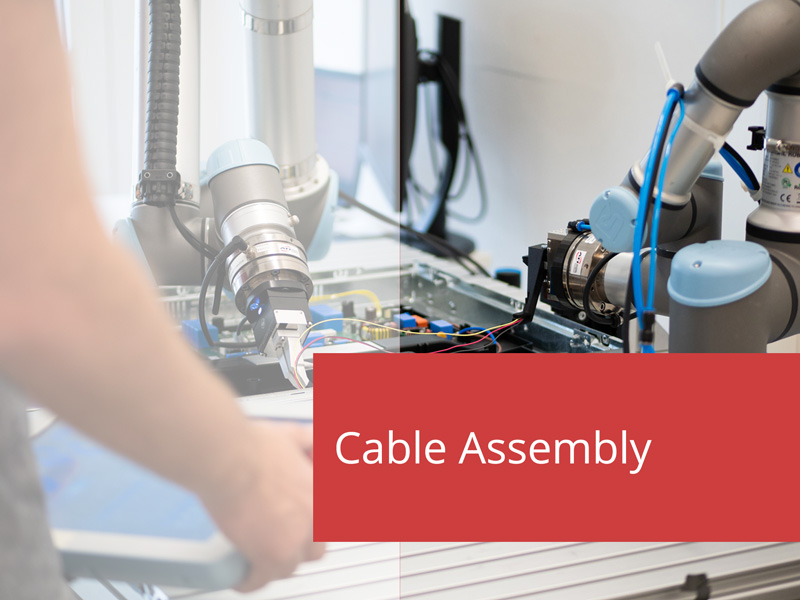

Use case

Cable Handling and Assembly

Automotive, Manufacturing, Electronics, Consumer Goods

Automated handling, manipulation, and assembly of flexible workpieces such as cables, wires, connectors or fabrics/coverings pose a number of challenges in production. Conventional robotic processes often lack the dexterity to handle these sensitive materials. Localizing the position and identifying the the shape of parts are a major challenge in classic robot programming. The liability and form instability of the material leads to constantly changing dynamics of the part tolerances, shape, and localization throughout the entire handling or assembly process. However, robot-based, precise cable assembly can be programmed and implemented robustly and efficiently, and therefore economically, using ArtiMinds RPS. The complexity of programming automation processes with tolerances becomes manageable with ArtiMinds.

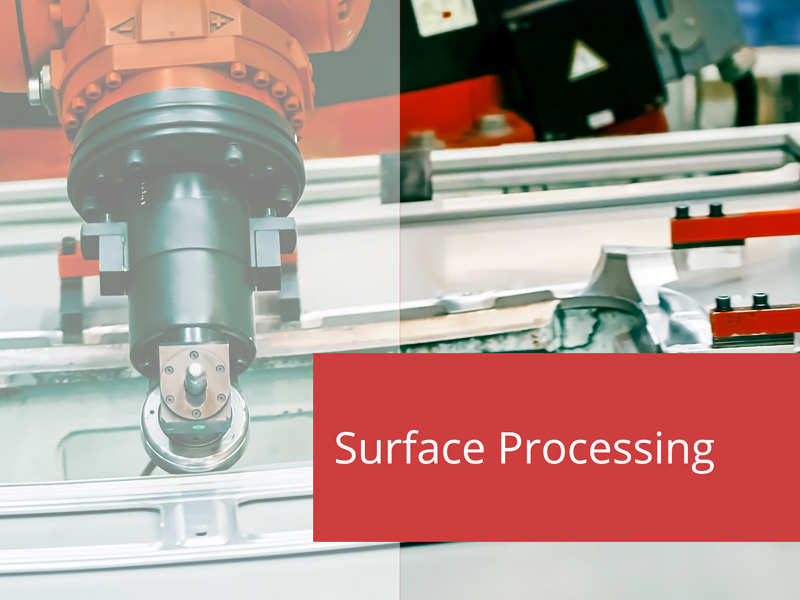

Use case

Surface Processing and Finishing

automotive, aerospace, polishing, grinding, metal

The software ArtiMinds RPS, combines offline and online programming in a unique way to solve applications requiring precise tool paths. Easily create tool paths based on the CAD geometry of your parts or import a tool path directly from your CAD file. Quickly check for collisions and reachability to figure out the best layout of your robot cell. Connect to the real robot to calibrate the robot program, teach key poses and optimize parameters. The challenges of robot-based surface processing, such as deburring, polishing or grinding, lie in the compensation of tolerances, the programming of sensor-adaptive processes and the handling of complex geometries. Furthermore the integration of force-torque sensors, camera systems or special tools and the interaction with the robot requires special programming skills. The innovative functionalities of the ArtiMinds RPS enable the most diverse forms of surface processing. For example, thanks to the easy import of CAD files, robot motion paths can be simulated and created automatically.

Use case

Cable Handling and Assembly

Automotive, Manufacturing, Electronics, Consumer Goods

Automated handling, manipulation, and assembly of flexible workpieces such as cables, wires, connectors or fabrics/coverings pose a number of challenges in production. Conventional robotic processes often lack the dexterity to handle these sensitive materials. Localizing the position and identifying the the shape of parts are a major challenge in classic robot programming. The liability and form instability of the material leads to constantly changing dynamics of the part tolerances, shape, and localization throughout the entire handling or assembly process. However, robot-based, precise cable assembly can be programmed and implemented robustly and efficiently, and therefore economically, using ArtiMinds RPS. The complexity of programming automation processes with tolerances becomes manageable with ArtiMinds.

Robotic integration involves combining robotic systems with existing infrastructure and processes to enhance automation and efficiency in various industries. This integration allows for seamless communication between robots and other machinery, enabling tasks such as material handling, assembly, and quality control to be performed with precision and speed. By implementing robotic integration, businesses can optimize workflows, reduce human error, and increase productivity. The use of advanced software and sensors ensures that robots can adapt to changes in their environment, making them versatile tools for modern manufacturing and logistics operations.

Robotic integration significantly enhances manufacturing efficiency by automating repetitive tasks, which reduces human error and increases productivity. When robots take over monotonous operations, they can work tirelessly around the clock, leading to higher output levels. Additionally, the precision of robotic systems ensures consistent quality in production processes, minimizing defects and waste. This integration allows for better allocation of human resources, enabling workers to focus on more complex tasks that require critical thinking and creativity, thus further boosting overall operational efficiency.

1. Manufacturing

The manufacturing industry greatly benefits from robotic integration, as robots can automate repetitive tasks, enhance precision, and increase production efficiency. This leads to reduced labor costs and minimized human error, allowing businesses to scale operations effectively.

2. Logistics

In logistics, robotic integration streamlines processes such as warehousing, sorting, and packing. Automated systems can handle large volumes of goods swiftly, improving accuracy and reducing delivery times, which is crucial for meeting customer demands in today's fast-paced market.

3. Healthcare

Healthcare providers utilize robotic integration for surgical procedures, patient monitoring, and even in pharmaceutical dispensing. These technologies enhance surgical precision, reduce recovery times, and improve patient care, thereby transforming the healthcare landscape.

4. Agriculture

Agriculture is experiencing significant advancements through robotic integration in tasks like planting, harvesting, and monitoring crops. Robots assist in improving yield and efficiency while reducing the need for manual labor, making farming operations more sustainable.

5. Food and Beverage

The food and beverage industry benefits from robotic integration in tasks such as packaging, sorting, and quality control. Automation ensures consistency and safety in food production, while also speeding up processes to meet high consumer demand.

1. Planning and Design

Successful robotic integration begins with thorough planning and design. This involves assessing the specific needs of the operation, determining the suitable robotic systems, and designing workflows that seamlessly incorporate these technologies. Engaging stakeholders early in the process ensures that the integration aligns with business goals and operational requirements.

2. Technology Compatibility

Ensuring compatibility between existing systems and new robotic technologies is crucial. This includes evaluating software and hardware interfaces to facilitate smooth communication and data exchange. A robust integration framework minimizes disruptions and enhances overall efficiency, allowing for a more streamlined operation.

3. Training and Support

Training personnel to operate and maintain robotic systems is vital for successful integration. Providing ongoing support and resources helps staff adapt to new technologies. This investment in human capital not only boosts productivity but also fosters a culture of innovation within the organization.

To assess the ROI of robotic integration, companies should first evaluate the initial investment costs associated with the technology. This includes the purchase price of robots, installation expenses, and any necessary training for staff. Next, businesses should analyze the productivity gains achieved through automation by measuring output before and after implementation. These metrics can include production speed, error rates, and labor costs. Furthermore, companies must consider the long-term savings associated with reduced manual labor and increased efficiency. Monitoring operational costs, maintenance expenses, and any downtime can provide valuable insights into the overall financial impact of robotic integration. By compiling this data, organizations can calculate the ROI and make informed decisions about future investments in automation technologies.

Some interesting numbers and facts about your company results for Robotic Integration

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 24 |

| Amount of suitable service providers | 26 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1980 |

| Youngest suiting company | 2021 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Robotic Integration

What are related technologies to Robotic Integration?

Based on our calculations related technologies to Robotic Integration are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Who are Start-Ups in the field of Robotic Integration?

Start-Ups who are working in Robotic Integration are Regrello

Which industries are mostly working on Robotic Integration?

The most represented industries which are working in Robotic Integration are Automation, Other, IT, Software and Services, Machinery Manufacturing, Manufacturing

How does ensun find these Robotic Integration Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.