The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Applied Robotics

Silverwater, Australia

A

11-50 Employees

1984

Key takeaway

Applied Robotics, led by Dr. Paul Wong, specializes in delivering innovative automation solutions, including advanced robotic integration that has transformed industries like food and beverage. Their notable projects, such as the world's largest assorted biscuit packing system, highlight their expertise in creating flexible and efficient robotic systems to meet complex industrial challenges.

Reference

Service

Services | Applied Robotics

Robotic Engineering Solutions

Sydney, Australia

A

1-10 Employees

2018

Key takeaway

Robotic Engineering Solutions is dedicated to innovative ideas and exceptional service, highlighting their expertise in the field of robotics which is relevant to robotic integration.

Reference

Core business

Home | Robotic Engineering Solutions

Robotic Automation

Sydney, Australia

A

11-50 Employees

1988

Key takeaway

The company specializes in automating repetitive tasks and processes to enhance productivity and efficiency, with a focus on robotic integration. They have experience in modernizing robotic systems, as demonstrated by their successful upgrade of the Automated Guided Vehicle system at the Royal Adelaide Hospital.

Reference

Product

Software - Robotic Automation

Robotic Automation supplies software supporting robotic automation, including application software, calibration tools, communication tools, development tools.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Priority Integrated Systems

Melbourne, Australia

A

1-10 Employees

2018

Key takeaway

Priority Robotics is dedicated to designing and developing advanced robotic systems that automate and optimize complex tasks across various industries, including manufacturing, healthcare, and eCommerce fulfillment. Their commitment to innovation and practicality positions them at the forefront of robotic integration, aiming to enhance productivity and efficiency for their clients.

Reference

Core business

Priority Robotics

Robofabrika Pty Ltd

Melbourne, Australia

A

1-10 Employees

-

Key takeaway

Robofabrika specializes in robotic integration for automating processes like de-burring, drilling, and precision finishing. Their custom-built robotic solutions enhance manufacturing efficiency, ensuring higher quality and faster production times while providing the flexibility to handle various shapes and sizes.

Reference

Core business

Robofabrika | Manufacturing Innovation

Robofabrika provides custom-built solutions to automate your manual processes. Enhance your business with Robofabrika's robotic systems!

The Robot People

Sydney, Australia

A

11-50 Employees

-

Key takeaway

The Robot People are specialists in robotic integration, offering a specialized range of collaborative robotic equipment and over 30 years of experience in process automation for Australian manufacturing. Their expertise ensures high-quality production at lower costs through effective robotic automation solutions.

Reference

Core business

The Robot People - Collaborative Robots Australia | Kingsgrove

With over 30 years of experience, The Robot People stock, distribute and integrate a specialised range of collaborative robotic equipment from Universal Robots, Microscan and OnRobot suited to Australian manufacturing.

Robonomics AI

Sydney, Australia

A

11-50 Employees

2016

Key takeaway

Robonomics AI specializes in integrating advanced technologies, including Robotics Process Automation, to support organizations in their AI-First digital transformation journey. Their approach enhances automation through a structured process, addressing specific client challenges and fostering innovation.

Reference

Core business

Robonomics AI – Applied Intelligence

M.A.P Services

Melbourne, Australia

A

1-10 Employees

2013

Key takeaway

The company specializes in providing robotic and vision system solutions that enhance industrial processes, offering a comprehensive service that includes integration of a wide range of industrial robots, such as the TH180 SCARA Robot, designed for applications like end-of-line packaging and assembly.

Reference

Product

TH180 - M.A.P Services

Product Features Heavy duty arm Rigid arm structure Highest payload in its class Up to 20kg payload Arm lengths from 180 to 1200mm Ideal for end of line packaging and assembly work

Future Concepts Technology

Adelaide, Australia

A

1-10 Employees

2020

Key takeaway

Future Concepts Tech specializes in autonomous robotic solutions that enhance operational efficiency in various industrial settings, including agriculture. Their use of the Robot Operating System (ROS) allows these intelligent systems to function effectively in dynamic environments.

Reference

Product

Autonomous Robotic Solutions

Solutions - Future Concepts Technology

Specialised Automation Systems

Sydney, Australia

A

- Employees

-

Key takeaway

Robycs Technology specializes in robotic integration and industrial automation, offering innovative solutions that enhance operational efficiency for Australian businesses. With a strong portfolio that includes projects for major companies, they provide comprehensive services in automation systems, utilizing advanced technologies from leading brands.

Reference

Core business

Industrial Automation and Robotics for Sydney businesses

Sydney expert service for Automation Controls, Robotic Automation and Industrial Electrics. Industrial Automation solutions for PLC, SCADA, HMI & more

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

ArtiMinds Robot Programming Suite

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

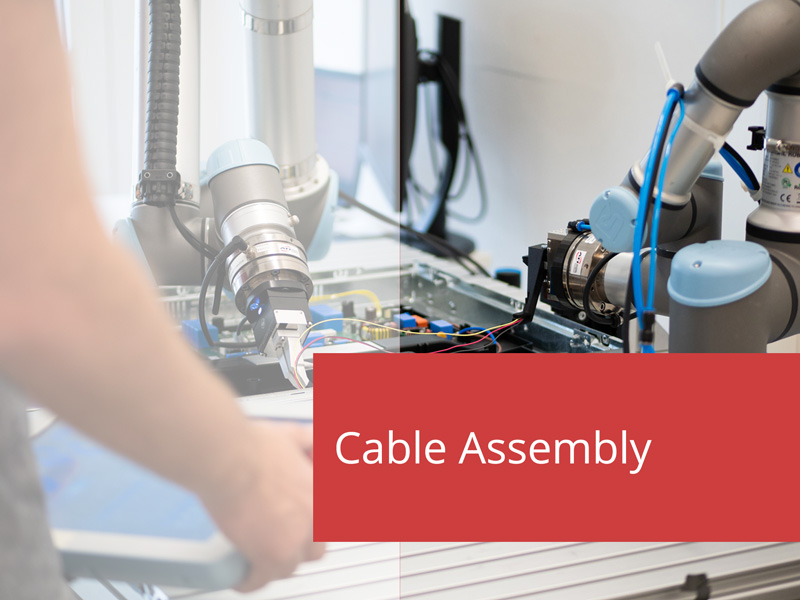

Use case

Cable Handling and Assembly

Automotive, Manufacturing, Electronics, Consumer Goods

Automated handling, manipulation, and assembly of flexible workpieces such as cables, wires, connectors or fabrics/coverings pose a number of challenges in production. Conventional robotic processes often lack the dexterity to handle these sensitive materials. Localizing the position and identifying the the shape of parts are a major challenge in classic robot programming. The liability and form instability of the material leads to constantly changing dynamics of the part tolerances, shape, and localization throughout the entire handling or assembly process. However, robot-based, precise cable assembly can be programmed and implemented robustly and efficiently, and therefore economically, using ArtiMinds RPS. The complexity of programming automation processes with tolerances becomes manageable with ArtiMinds.

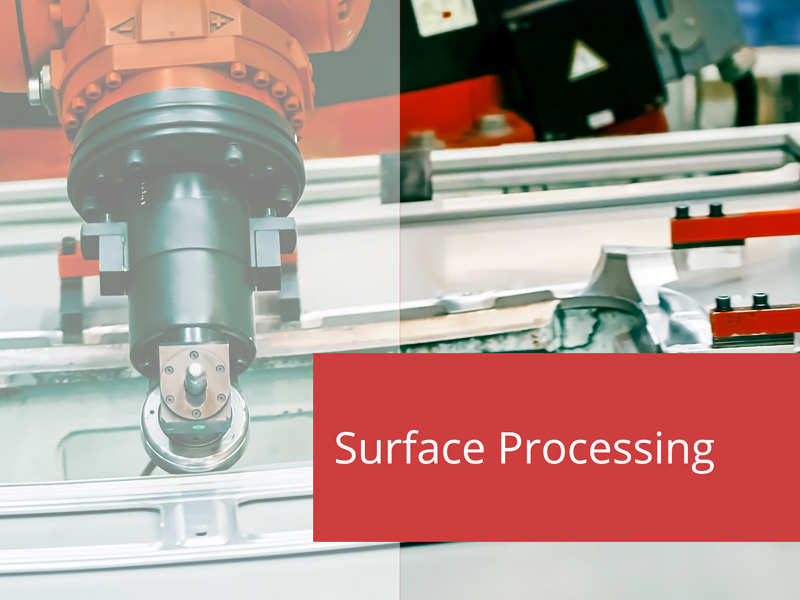

Use case

Surface Processing and Finishing

automotive, aerospace, polishing, grinding, metal

The software ArtiMinds RPS, combines offline and online programming in a unique way to solve applications requiring precise tool paths. Easily create tool paths based on the CAD geometry of your parts or import a tool path directly from your CAD file. Quickly check for collisions and reachability to figure out the best layout of your robot cell. Connect to the real robot to calibrate the robot program, teach key poses and optimize parameters. The challenges of robot-based surface processing, such as deburring, polishing or grinding, lie in the compensation of tolerances, the programming of sensor-adaptive processes and the handling of complex geometries. Furthermore the integration of force-torque sensors, camera systems or special tools and the interaction with the robot requires special programming skills. The innovative functionalities of the ArtiMinds RPS enable the most diverse forms of surface processing. For example, thanks to the easy import of CAD files, robot motion paths can be simulated and created automatically.

Use case

Cable Handling and Assembly

Automotive, Manufacturing, Electronics, Consumer Goods

Automated handling, manipulation, and assembly of flexible workpieces such as cables, wires, connectors or fabrics/coverings pose a number of challenges in production. Conventional robotic processes often lack the dexterity to handle these sensitive materials. Localizing the position and identifying the the shape of parts are a major challenge in classic robot programming. The liability and form instability of the material leads to constantly changing dynamics of the part tolerances, shape, and localization throughout the entire handling or assembly process. However, robot-based, precise cable assembly can be programmed and implemented robustly and efficiently, and therefore economically, using ArtiMinds RPS. The complexity of programming automation processes with tolerances becomes manageable with ArtiMinds.

When exploring the Robotic Integration industry in Australia, several key considerations come into play. The regulatory landscape is crucial, as compliance with safety standards and industry regulations is mandatory for all robotic systems. Understanding these regulations can prevent costly delays and ensure successful implementation. The industry faces challenges such as high initial costs and the need for skilled labor, which can limit accessibility for smaller businesses. However, opportunities abound, driven by advancements in technology and increasing demand for automation across sectors like manufacturing, healthcare, and logistics. The competitive landscape is robust, with both established companies and startups vying for market share, leading to continuous innovation and collaboration. Environmental concerns are increasingly significant, as businesses are urged to adopt sustainable practices in their operations. With the global market for robotic integration expanding, Australian companies have the chance to position themselves as leaders in this growing sector. Networking within industry associations and attending relevant trade shows can provide valuable insights and foster connections that enhance business prospects. Understanding these factors will empower individuals and organizations to make informed decisions in the dynamic field of robotic integration in Australia.

Some interesting numbers and facts about your company results for Robotic Integration

| Country with most fitting companies | Australia |

| Amount of fitting manufacturers | 325 |

| Amount of suitable service providers | 334 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1984 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Robotic Integration

What are related technologies to Robotic Integration?

Based on our calculations related technologies to Robotic Integration are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Robotic Integration?

The most represented industries which are working in Robotic Integration are IT, Software and Services, Automation, Manufacturing, Electronics and Electrical engineering, Other

How does ensun find these Robotic Integration Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.