The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Unirobotics

Gunpo-si, South Korea

A

- Employees

-

Key takeaway

Unirobotics leverages advanced robotics technology to enhance business efficiency through its Smart Manufacturing System. Their expertise in data analysis and seamless integration with existing ecosystems positions them as a key partner in the robotic integration landscape.

Reference

Product

Solutions | Unirobotics Inc.

RB-Weld

Hwaseong-si, South Korea

A

11-50 Employees

-

Key takeaway

RBW specializes in robotic integration through its advanced cobot welding and metalworking systems, which significantly enhance productivity, speed, and quality while reducing labor costs. Their innovative solutions, including automated MIG and fiber laser welding systems, address the industry's labor shortages and streamline project start-up times.

Reference

Core business

Home | RBW

Macroact Inc.

Seoul, South Korea

A

1-10 Employees

2019

Key takeaway

Macroact specializes in developing integrated robotic solutions that leverage AI, ML, and DL to enhance automation and productivity across various industries. Their adaptive technologies focus on creating smart, autonomous robots that improve operational control and address complex challenges, driving innovation in smart manufacturing and beyond.

Reference

Core business

Macroact - Make Robots Active & Smart

Make robots active and smart with autonomous control

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Neuromeka

Pyeongtaek-si, South Korea

A

11-50 Employees

2013

Key takeaway

Neuromeka is enhancing manufacturing productivity and safety through the use of collaborative robots, including cooperative and delta robots. Their focus on easy-to-use and affordable automation solutions positions them as key players in robotic integration for various industries.

Reference

Core business

Neuromeka | Collaborative robotic automation

뉴로메카는 협동로봇을 제조, 판매합니다. 뉴로메카의 협동로봇은 사용이 쉽고 저렴해 중소기업 제조라인의 자동화를 이끌고, 사람과 함께 작업할 수 있도록 안전하게 동작합니다. 또한 쉬운 프로그래밍을 통해 다양한 공정에 적용 가능합니다.

ROBOGATES Co. LTD

Gunpo-si, South Korea

A

1-10 Employees

2010

Key takeaway

ROBOGATES is a specialized company in robotics and AI technology that develops and supplies automation solutions for smart factories and smart farms. Their AI Robotics Technology Research Institute focuses on creating efficient robotic automation systems, integrating collaborative robots and AGVs with MES and WMS systems to provide optimized solutions for various industrial applications.

Reference

Core business

로보게이트 | AI 로봇기술연구소 | 스마트공장 | 경기도

ROBOGATES: 로보게이트 AI로봇기술연구소는, 스마트공장 및 스마트팜 자동화 공급기업으로, 공정 자동화 개발/공급/기술지원/교육 수행 전문회사입니다. ROMES는 공장자동화 MES 솔루션이며, 협동로봇과 AGV를 공급하고 있습니다.

KALMAN

Seoul, South Korea

A

1-10 Employees

2020

Key takeaway

KALMAN offers comprehensive robotic solutions that automate industrial inspections, ensuring a seamless integration from development to implementation. Their customizable and scalable approach, along with a dedicated engineering team, enhances workplace safety, maximizes productivity, and reduces costs through tailored robotic systems.

Reference

Core business

Kalman Robot | Kalman Inc | 안양시

Hanwha Robotics

Seongnam-si, South Korea

A

51-100 Employees

2016

Key takeaway

Hanwha Corporation/Momentum addresses the challenges of Industry 4.0 and factory automation by offering collaborative robots that enhance production environments through process automation and flexibility. Their commitment to improving safety and efficiency aligns with the growing demand for innovative robotic integration in manufacturing.

Reference

Core business

Hanwha Corporation/Momentum's

Robots and Design Co., Ltd

Seongnam-si, South Korea

A

101-250 Employees

1999

Key takeaway

RND has extensive experience in robotic integration, having manufactured 55 types of robots for various sectors, including semiconductor and biotechnology. Their commitment to research and development ensures high-quality, reliable robotic solutions that optimize customer satisfaction.

Reference

Core business

Company | About | Robotics | Robots and Design

Specialized in Advanced Robots and Automation Equipment, Robots and Design, Co., Ltd. has manufactured 55 kinds of robots and supplied them as OEM or ODM to the domestic as well as international market in the fields of semiconductor, display, nano-optics, biotechnology, education, service, etc.

Moroba

Osan-si, South Korea

A

1-10 Employees

-

Key takeaway

Moroba emphasizes the growing demand for automation in logistics centers, proposing enhanced efficiency through robotic integration and the use of the Robot Operating System (ROS). Their solutions aim to address challenges such as rising labor costs and the need for 24/7 operations in smart factories and logistics environments.

Reference

Core business

Moroba | 인휠모터 | 로봇 | 경기도

인휠모터 기술 기반 Undercarriage Robot Platform 전문기업 Moroba

ROAS Inc.

Bucheon-si, South Korea

A

11-50 Employees

-

Key takeaway

ROAS Inc. offers a comprehensive total robot solution, showcasing various applications of robotics such as tightly piled sacks picking, cable bin picking, and wafer picking, highlighting their expertise in robotic integration. Their focus on 3D vision and industrial robots positions them as a key player in advanced robotic solutions.

Reference

Core business

(주)로아스 | ROAS Inc. | Robotics On Advanced Solution | 3D Vision | 산업용 로봇 | AGV/AMR - Roas

TOTAL ROBOT SOLUTION LEARN MORE video gallery Mech-Mind Robotics-Application:Tightly Piled Sacks Picking Cable bin Picking Test 케이블 빈 피킹 테스트 Wafer Picking

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

ArtiMinds Robot Programming Suite

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

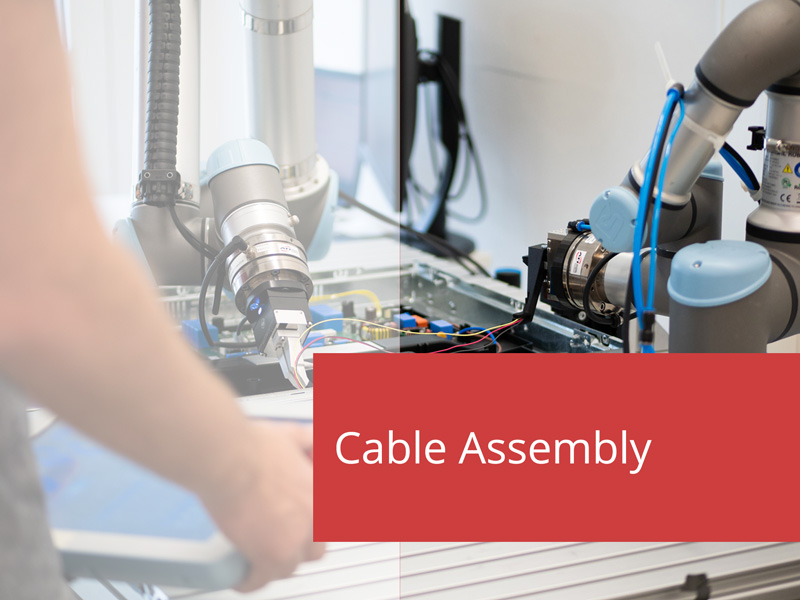

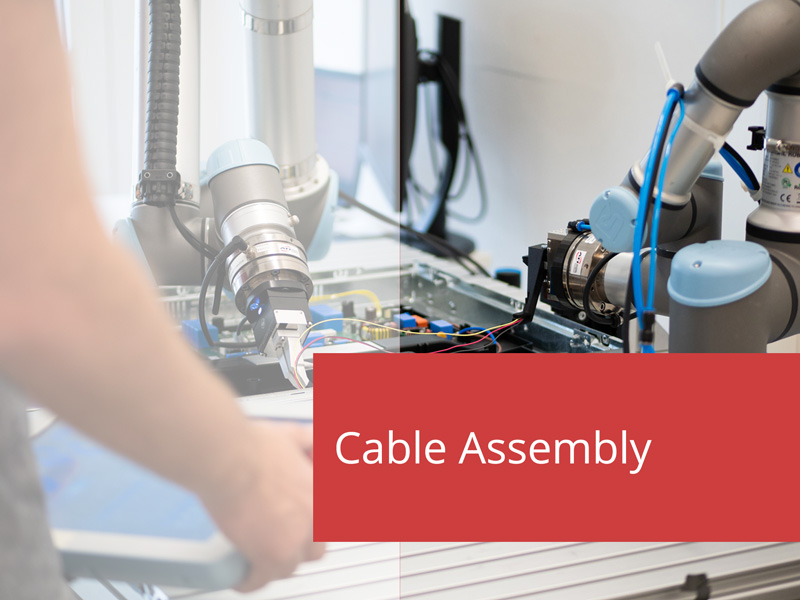

Cable Handling and Assembly

Automotive, Manufacturing, Electronics, Consumer Goods

Automated handling, manipulation, and assembly of flexible workpieces such as cables, wires, connectors or fabrics/coverings pose a number of challenges in production. Conventional robotic processes often lack the dexterity to handle these sensitive materials. Localizing the position and identifying the the shape of parts are a major challenge in classic robot programming. The liability and form instability of the material leads to constantly changing dynamics of the part tolerances, shape, and localization throughout the entire handling or assembly process. However, robot-based, precise cable assembly can be programmed and implemented robustly and efficiently, and therefore economically, using ArtiMinds RPS. The complexity of programming automation processes with tolerances becomes manageable with ArtiMinds.

Use case

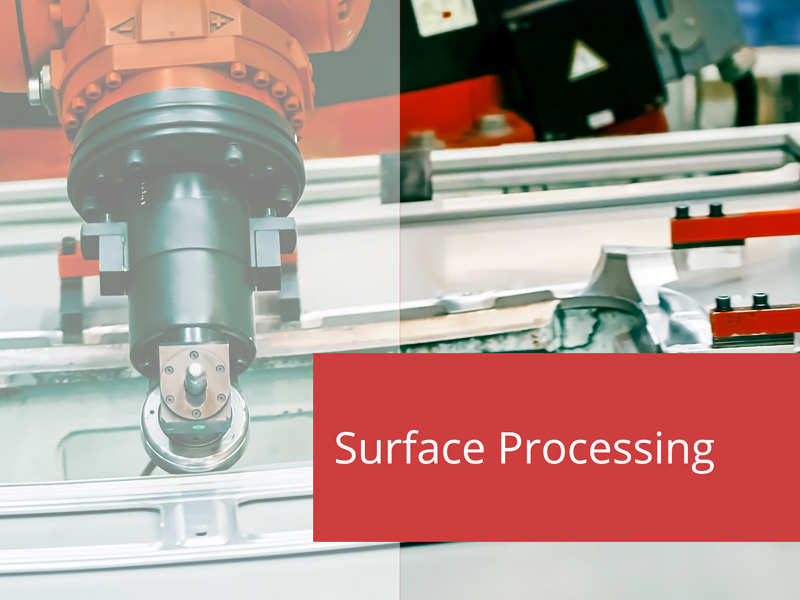

Surface Processing and Finishing

automotive, aerospace, polishing, grinding, metal

The software ArtiMinds RPS, combines offline and online programming in a unique way to solve applications requiring precise tool paths. Easily create tool paths based on the CAD geometry of your parts or import a tool path directly from your CAD file. Quickly check for collisions and reachability to figure out the best layout of your robot cell. Connect to the real robot to calibrate the robot program, teach key poses and optimize parameters. The challenges of robot-based surface processing, such as deburring, polishing or grinding, lie in the compensation of tolerances, the programming of sensor-adaptive processes and the handling of complex geometries. Furthermore the integration of force-torque sensors, camera systems or special tools and the interaction with the robot requires special programming skills. The innovative functionalities of the ArtiMinds RPS enable the most diverse forms of surface processing. For example, thanks to the easy import of CAD files, robot motion paths can be simulated and created automatically.

Use case

Cable Handling and Assembly

Automotive, Manufacturing, Electronics, Consumer Goods

Automated handling, manipulation, and assembly of flexible workpieces such as cables, wires, connectors or fabrics/coverings pose a number of challenges in production. Conventional robotic processes often lack the dexterity to handle these sensitive materials. Localizing the position and identifying the the shape of parts are a major challenge in classic robot programming. The liability and form instability of the material leads to constantly changing dynamics of the part tolerances, shape, and localization throughout the entire handling or assembly process. However, robot-based, precise cable assembly can be programmed and implemented robustly and efficiently, and therefore economically, using ArtiMinds RPS. The complexity of programming automation processes with tolerances becomes manageable with ArtiMinds.

When exploring the Robotic Integration industry in South Korea, several key considerations emerge. The country is recognized for its advanced technology landscape, which includes innovative robotics solutions in manufacturing, healthcare, and service sectors. It is crucial to understand the local regulatory environment, as South Korea has specific standards and guidelines governing robotics, particularly concerning safety and operational protocols. The competitive landscape is robust, with both established companies and startups vying for market share, making it essential to research the strengths and weaknesses of various players. Opportunities abound due to the government's commitment to promoting robotics as part of its broader economic strategy, which includes investment in R&D and infrastructure. However, challenges such as high labor costs and the need for skilled workers in robotics engineering can pose hurdles for new entrants. Environmental considerations are also vital, as sustainability practices are increasingly influencing industry operations and consumer preferences. Furthermore, South Korea's strategic position in global supply chains enhances its relevance in the international robotics market, providing avenues for collaboration and export. Understanding these factors will be crucial for anyone looking to engage with the robotic integration sector in this dynamic region.

Some interesting numbers and facts about your company results for Robotic Integration

| Country with most fitting companies | South Korea |

| Amount of fitting manufacturers | 16 |

| Amount of suitable service providers | 7 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1999 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Robotic Integration

What are related technologies to Robotic Integration?

Based on our calculations related technologies to Robotic Integration are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Robotic Integration?

The most represented industries which are working in Robotic Integration are IT, Software and Services, Automation, Other, Electronics and Electrical engineering, Manufacturing

How does ensun find these Robotic Integration Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.