The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

WinRoad RTS

Tokyo, Japan

A

1-10 Employees

2019

Key takeaway

The company, WinRoad RTS, specializes in providing Japanese robot technology to the Middle East and Africa, and offers support for developing custom robotic systems and starting robotic businesses.

Reference

Core business

Robot Technology Provider | WinRoad RTS | Japan

A robotic company specializes in providing Japanese robot technology to the Middle East and Africa.

Rapyuta Robotics

Tokyo, Japan

A

101-250 Employees

2014

Key takeaway

Rapyuta Robotics specializes in robotic integration, offering the Rapyuta PA-AMR, a cutting-edge solution that enhances work efficiency and productivity in picking operations. Their platform simplifies the development, deployment, and management of robotic applications, addressing labor shortages and improving operational effectiveness.

Reference

Product

Products | Rapyuta Robotics

rapyuta.io is the world’s first all-in-one DevOps platform for cloud connected robots that empower robotics teams to take full control of the complete application life cycle – development, deployment & operations.

TELEXISTENCE Inc.

Tokyo, Japan

A

11-50 Employees

2017

Key takeaway

The company focuses on expanding robotic integration beyond traditional factory settings, developing remote-controlled robots with artificial intelligence. Their innovative approach includes advanced technologies such as ultra-low latency streaming and hybrid intelligent control, positioning their solutions for various applications, including retail.

Reference

Product

Technology – TELEXISTENCE inc.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Coarobo

Kyoto, Japan

A

1-10 Employees

2019

Key takeaway

Coarobo GK plays a significant role in robotic integration by developing containerized Software Development Environments (SDE) that facilitate the integration of robotic systems, as highlighted in their published research. Additionally, they enhance practical skills in advanced motion planning through tutorials and support, directly benefiting researchers and developers in service robotics and artificial intelligence.

Reference

Core business

Coarobo GK - 企業情報

Coarobo GK provides consulting services for innovative robotics solutions powered by state-of-the-art artificial intelligence.

(株)ハイボット

Tokyo, Japan

A

11-50 Employees

2004

Key takeaway

HiBox integrates hibot’s autonomous Smart Tools with advanced data management and real-time visualization, enhancing robotic inspection capabilities. Their robots provide exceptional mobility for autonomous inspections in challenging environments, making them ideal for critical tasks like predicting infrastructure failures.

Reference

Product

Products | Hibot

Hibot Website

Mujin, Inc.

Tokyo, Japan

A

101-250 Employees

2011

Key takeaway

Mujin specializes in robotic integration, offering advanced automation platforms that enhance robotic capabilities for applications like automated storage and order fulfillment. Their MujinController enables robots to operate with perception and autonomous decision-making, making it suitable for a wide range of uses in production environments.

Reference

Core business

Intelligent robotics | Mujin Corp

At Mujin, we design automation platforms to enhance any robot, enable advanced capabilities and lower operating costs.

LexxPluss

Kawasaki, Japan

A

11-50 Employees

2020

Key takeaway

LexxPluss is developing a new autonomous mobile robot aimed at enhancing manufacturing and logistics operations. Their robotics automation technology promises to bring sustainability and agility to production environments.

Reference

Core business

株式会社LexxPluss | Sustainable Industry Sustainable Life

株式会社LexxPlussは、自動搬送ロボットをはじめとするロボティクスオートメーション技術で物流センターや製造工場へ持続可能性を提供するテクノロジーカンパニーです。法人向け設計図公開プログラムを実施しています。

Synapse Innovation Inc.

Tokyo, Japan

A

251-500 Employees

1984

Key takeaway

Synapse Innovation specializes in seamlessly connecting information systems and devices through advanced software and control system development. Their Ultimate Manufacturing Platform leverages technologies like data analysis and IoT to address critical manufacturing challenges.

Reference

Core business

Synapse Innovation Inc. Ultimate Manufacturing solutions using technology

Solutions for the Manufacturing and Industry Sector. The Manufacturing Platform using technologies such as data analysis, integration, IoT.

INTERPOLATION

Tokyo, Japan

A

1-10 Employees

2015

Key takeaway

Interpolation specializes in providing Internet of Things (IoT) solutions that enhance operational efficiency and streamline energy management for businesses across Asia. Their expertise in industrial IoT technology and data analysis, combined with end-to-end services, positions them as a valuable partner for companies looking to integrate innovative solutions into their operations.

Reference

Core business

Services | Interpolation

IoT devices Production/Import/Export IoT Custom System Integration IoT Deployment/Support/Maintenance

Kudan

Tokyo, Japan

A

11-50 Employees

2011

Key takeaway

Kudan is a key player in robotic integration, providing essential computer software algorithms for artificial perception, particularly through their SLAM (Simultaneous Localization and Mapping) technology. This innovation enables machines to effectively perceive their surroundings, which is crucial for autonomous decision-making in robotics and other applications.

Reference

Product

Consumer Robotics | Kudan global

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

ArtiMinds Robot Programming Suite

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

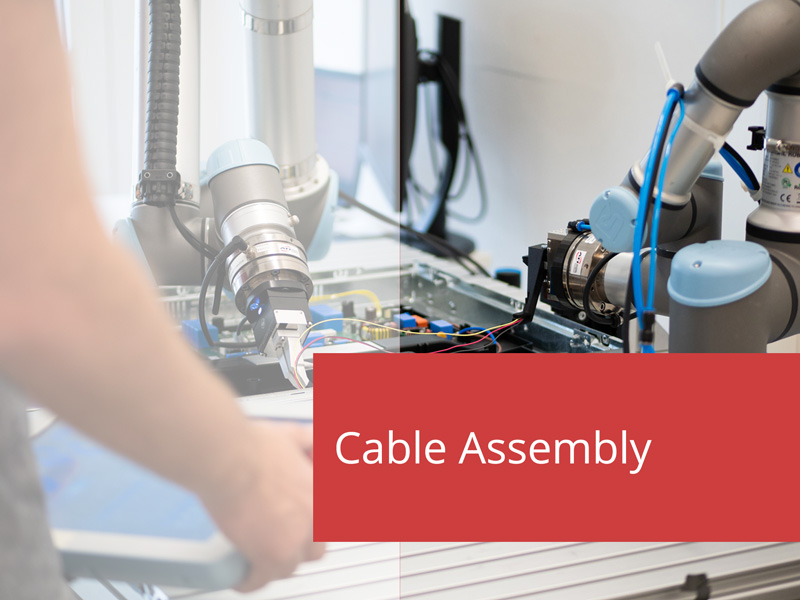

Cable Handling and Assembly

Automotive, Manufacturing, Electronics, Consumer Goods

Automated handling, manipulation, and assembly of flexible workpieces such as cables, wires, connectors or fabrics/coverings pose a number of challenges in production. Conventional robotic processes often lack the dexterity to handle these sensitive materials. Localizing the position and identifying the the shape of parts are a major challenge in classic robot programming. The liability and form instability of the material leads to constantly changing dynamics of the part tolerances, shape, and localization throughout the entire handling or assembly process. However, robot-based, precise cable assembly can be programmed and implemented robustly and efficiently, and therefore economically, using ArtiMinds RPS. The complexity of programming automation processes with tolerances becomes manageable with ArtiMinds.

Use case

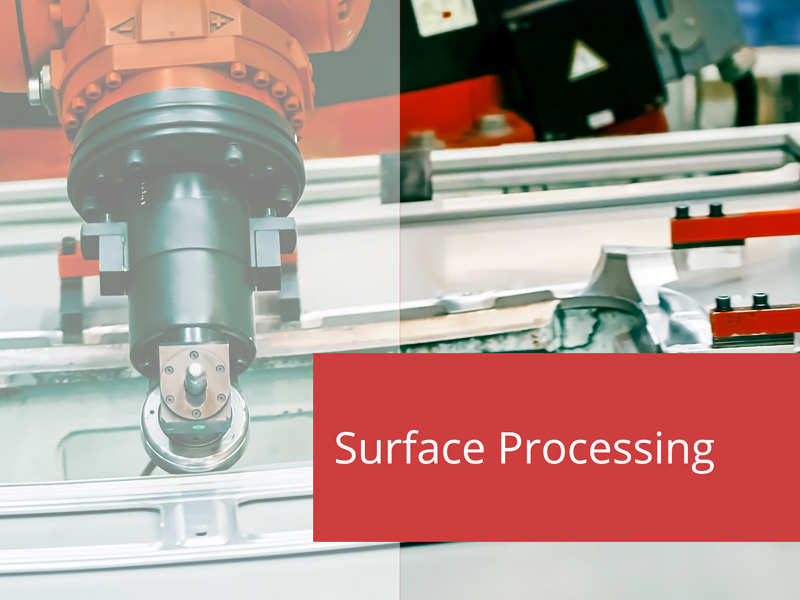

Surface Processing and Finishing

automotive, aerospace, polishing, grinding, metal

The software ArtiMinds RPS, combines offline and online programming in a unique way to solve applications requiring precise tool paths. Easily create tool paths based on the CAD geometry of your parts or import a tool path directly from your CAD file. Quickly check for collisions and reachability to figure out the best layout of your robot cell. Connect to the real robot to calibrate the robot program, teach key poses and optimize parameters. The challenges of robot-based surface processing, such as deburring, polishing or grinding, lie in the compensation of tolerances, the programming of sensor-adaptive processes and the handling of complex geometries. Furthermore the integration of force-torque sensors, camera systems or special tools and the interaction with the robot requires special programming skills. The innovative functionalities of the ArtiMinds RPS enable the most diverse forms of surface processing. For example, thanks to the easy import of CAD files, robot motion paths can be simulated and created automatically.

Use case

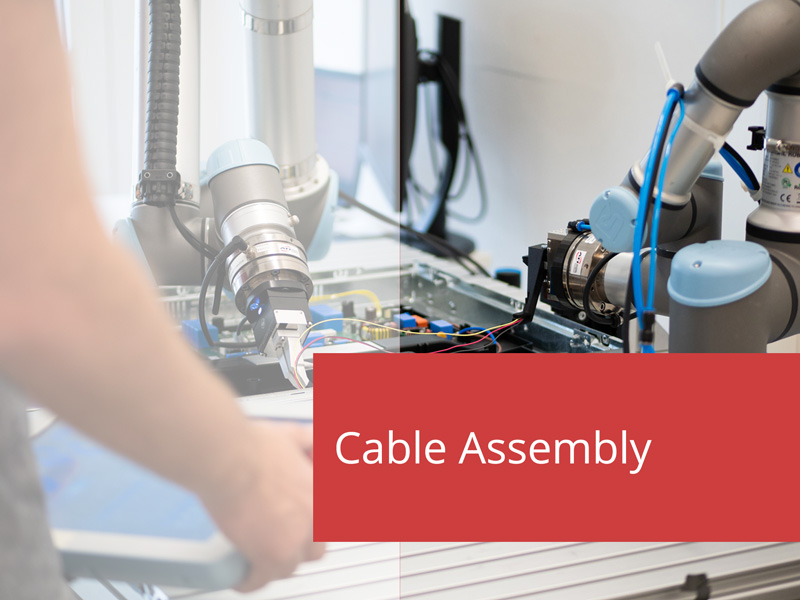

Cable Handling and Assembly

Automotive, Manufacturing, Electronics, Consumer Goods

Automated handling, manipulation, and assembly of flexible workpieces such as cables, wires, connectors or fabrics/coverings pose a number of challenges in production. Conventional robotic processes often lack the dexterity to handle these sensitive materials. Localizing the position and identifying the the shape of parts are a major challenge in classic robot programming. The liability and form instability of the material leads to constantly changing dynamics of the part tolerances, shape, and localization throughout the entire handling or assembly process. However, robot-based, precise cable assembly can be programmed and implemented robustly and efficiently, and therefore economically, using ArtiMinds RPS. The complexity of programming automation processes with tolerances becomes manageable with ArtiMinds.

When exploring the robotic integration industry in Japan, several critical factors warrant attention. First, Japan is renowned for its advanced technology and innovation, making it a global leader in robotics. Understanding local regulations is essential, as Japan has specific laws governing robotics, particularly concerning safety and labor. The industry faces challenges such as a shrinking workforce and the need for skilled technicians to manage and maintain robotic systems. However, these challenges also present opportunities for growth, especially in sectors like manufacturing, healthcare, and logistics, where automation can enhance efficiency. Environmental concerns are increasingly relevant, as companies aim to develop sustainable technologies. The competitive landscape is intense, with established players and startups vying for market share, necessitating thorough research on potential partners or competitors. Additionally, the global market relevance of Japanese robotics cannot be understated, as innovations often set trends worldwide. Understanding the cultural context and business practices in Japan also plays a vital role in successful engagement within the industry. Networking and building relationships are crucial, as business interactions often prioritize trust and long-term partnerships. Overall, thorough research on these aspects will provide valuable insights for anyone interested in the robotic integration sector in Japan.

Some interesting numbers and facts about your company results for Robotic Integration

| Country with most fitting companies | Japan |

| Amount of fitting manufacturers | 14 |

| Amount of suitable service providers | 8 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1984 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Robotic Integration

What are related technologies to Robotic Integration?

Based on our calculations related technologies to Robotic Integration are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Robotic Integration?

The most represented industries which are working in Robotic Integration are IT, Software and Services, Automation, Electronics and Electrical engineering, Other, Plastics

How does ensun find these Robotic Integration Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.