The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

RB-Weld

Hwaseong-si, South Korea

A

11-50 Employees

-

Key takeaway

RBW specializes in cobot welding and metalworking, providing innovative solutions that enhance productivity and quality while reducing labor costs. Their automated MIG welding system and advanced fiber laser welding technology address the industry's growing need for efficient welding processes.

Reference

Core business

Home | RBW

Unirobotics

Gunpo-si, South Korea

A

- Employees

-

Key takeaway

Unirobotics offers advanced robotics technology that can significantly enhance manufacturing processes. Their Smart Manufacturing System emphasizes the importance of data analysis to improve efficiency and reliability in production.

Reference

Core business

Home | Unirobotics Inc.

KALMAN

Seoul, South Korea

A

1-10 Employees

2020

Key takeaway

KALMAN offers comprehensive robotic solutions that can enhance industrial processes, including automation and inspections. Their customized robotic systems are designed to improve safety, productivity, and cost-efficiency, making them relevant for industries seeking advanced technological integration.

Reference

Core business

Kalman Robot | Kalman Inc | 안양시

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

ROBOGATES Co. LTD

Gunpo-si, South Korea

A

1-10 Employees

2010

Key takeaway

ROBOGATES is a company specializing in robotics and AI technology-based solutions, focusing on smart factories and automation. Their AI Robotics Technology Research Institute develops and supplies collaborative robots and AGVs, emphasizing efficient robotic automation for various industrial applications.

Reference

Core business

로보게이트 | AI 로봇기술연구소 | 스마트공장 | 경기도

ROBOGATES: 로보게이트 AI로봇기술연구소는, 스마트공장 및 스마트팜 자동화 공급기업으로, 공정 자동화 개발/공급/기술지원/교육 수행 전문회사입니다. ROMES는 공장자동화 MES 솔루션이며, 협동로봇과 AGV를 공급하고 있습니다.

Robots and Design Co., Ltd

Seongnam-si, South Korea

A

101-250 Employees

1999

Key takeaway

RND specializes in advanced robots and automation equipment, having manufactured over 200 types of robots. With more than 20 years of experience, RND focuses on providing innovative solutions that enhance productivity across various industries, including semiconductor and biotechnology.

Reference

Core business

Home | Robotics | Robots and Design

Robots and Design, Co., Ltd., specialized in advanced robots and automation equipment, has manufactured more than 200 kinds of robots. RND aims to provide the best solution to optimize customers' satisfaction.

Hanwha Robotics

Seongnam-si, South Korea

A

51-100 Employees

2016

Key takeaway

Hanwha Corporation/Momentum addresses the challenges of modern manufacturing, including the need for flexible and safe production environments. They have introduced a range of collaborative robots designed to enhance process automation and improve production quality, which is particularly relevant for robotic welding applications.

Reference

Product

Hanwha Corporation/Momentum's

Neuromeka

Pyeongtaek-si, South Korea

A

11-50 Employees

2013

Key takeaway

Neuromeka focuses on enhancing manufacturing productivity and safety through the use of collaborative robots. Their easy-to-use and affordable robotic solutions are designed to automate processes, making them particularly beneficial for small and medium-sized enterprises.

Reference

Core business

Neuromeka | Collaborative robotic automation

뉴로메카는 협동로봇을 제조, 판매합니다. 뉴로메카의 협동로봇은 사용이 쉽고 저렴해 중소기업 제조라인의 자동화를 이끌고, 사람과 함께 작업할 수 있도록 안전하게 동작합니다. 또한 쉬운 프로그래밍을 통해 다양한 공정에 적용 가능합니다.

Macroact Inc.

Seoul, South Korea

A

1-10 Employees

2019

Key takeaway

Macroact focuses on developing advanced robotic systems that integrate AI, machine learning, and deep learning to enhance automation and productivity in various industries. Their adaptive solutions aim to create intelligent robots capable of autonomous control, addressing complex challenges and driving innovation in smart manufacturing and beyond.

Reference

Core business

Macroact - Make Robots Active & Smart

Make robots active and smart with autonomous control

fabWeaver

Seoul, South Korea

A

1001-5000 Employees

2021

Key takeaway

The company emphasizes its advanced technology and precision in 3D printing, which could be relevant to robotic welding by highlighting innovation and quality in manufacturing processes. Their commitment to providing comprehensive solutions for 3D printing suggests a focus on optimizing production efficiency and reducing costs.

Reference

Core business

fabWeaver Industrial 3D Printers, Professional 3D Printers, Prototyping 3D Printers | fabWeaver

ROAS Inc.

Bucheon-si, South Korea

A

11-50 Employees

-

Key takeaway

The company, ROAS Inc., specializes in total robotic solutions, including applications like machine tending and automated picking. Their focus on advanced robotics and 3D vision suggests expertise that could be relevant to robotic welding processes.

Reference

Core business

(주)로아스 | ROAS Inc. | Robotics On Advanced Solution | 3D Vision | 산업용 로봇 | AGV/AMR - Roas

TOTAL ROBOT SOLUTION LEARN MORE video gallery Mech-Mind Robotics-Application:Tightly Piled Sacks Picking Cable bin Picking Test 케이블 빈 피킹 테스트 Wafer Picking

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

SpeedGun

Go to product

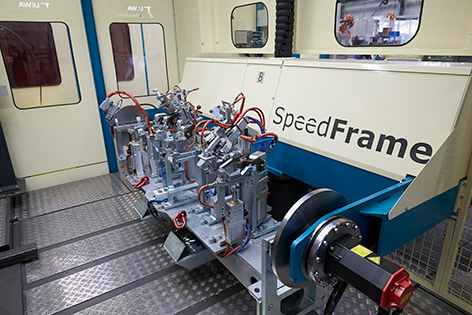

Product

SpeedFrame

Go to product

Service

Sheet Metal Parts and Components

Go to product

Service

Relocation Projects

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

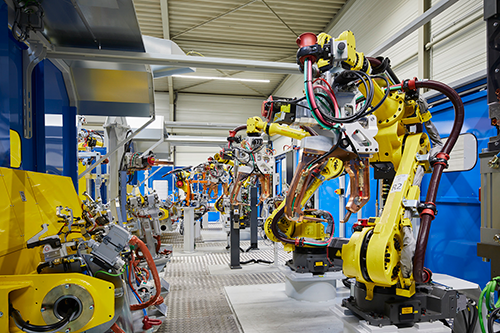

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

Use case

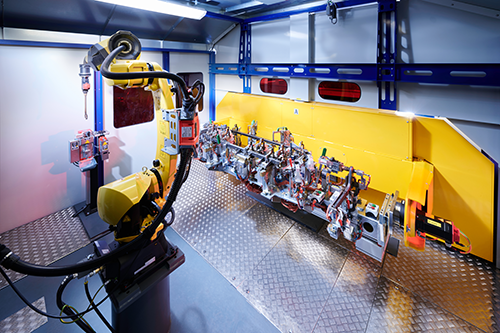

Production system for MIG welding of a seat assembly

automotive

esign of a production system for MIG welding of a complex, heavy duty vehicle seat assembly consisting of backrest (60% and 40%) and seat bench. The goal is 30,000 units per year in a maximum of 616 seconds per seat assembly. The production system is to be manned by one operator. We developed a flexible production concept, which ensures future expansion and integration of other products in the event of volume fluctuations or design modifications according to the ReUse principle.

Use case

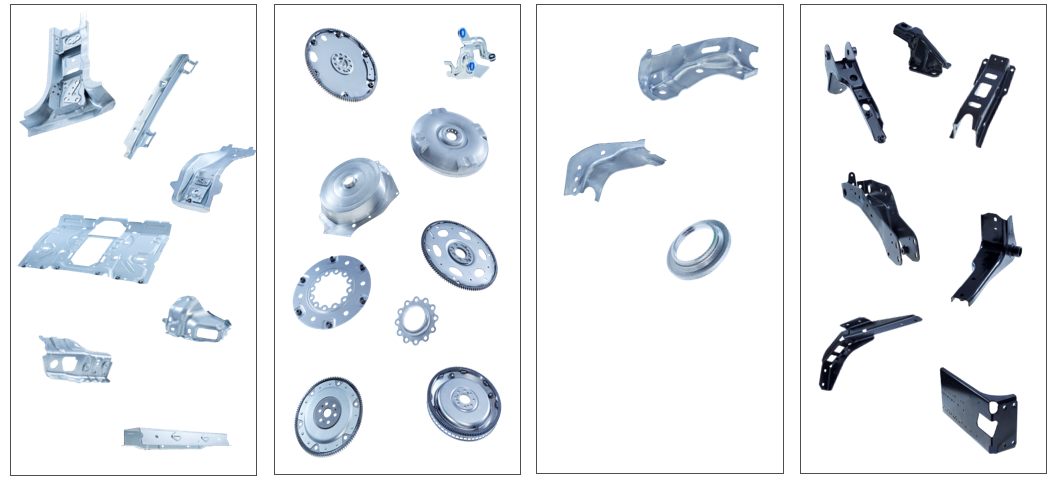

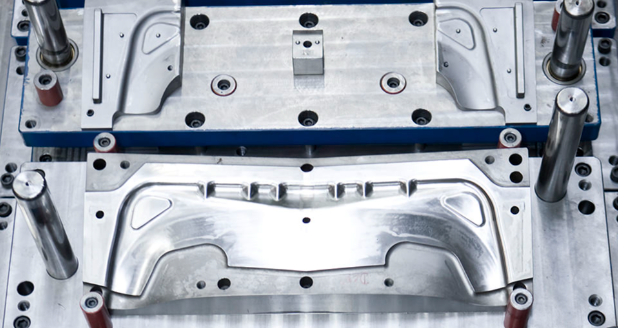

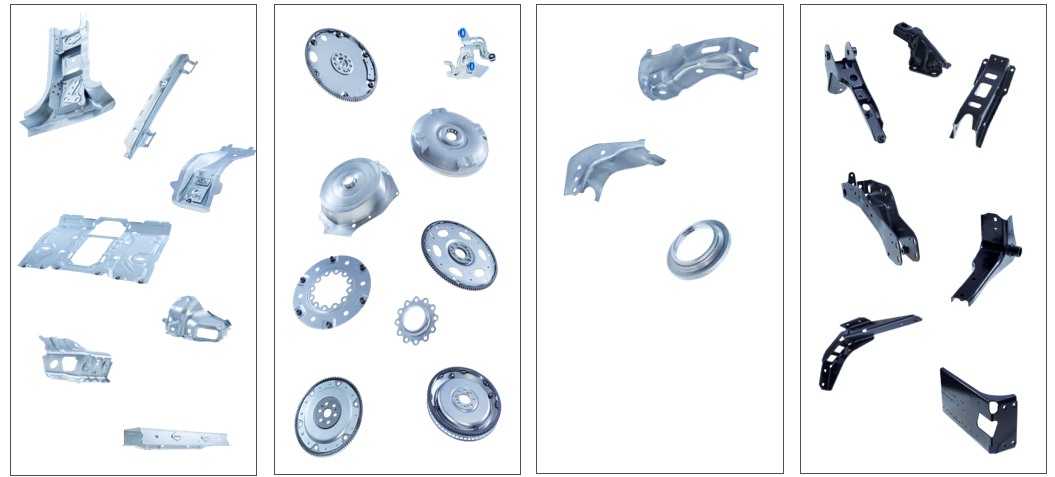

Car Body in White

Automotive, Industry

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

Use case

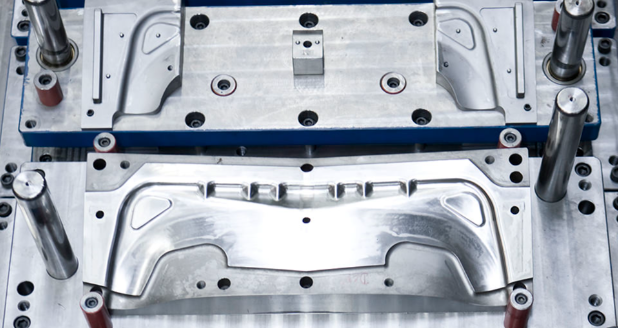

Relocation projects

Automotive, Industry

Seamless Relocation Projects in Forming and Joining Technology—Powered by Mühlhoff When it comes to relocating your production lines, Mühlhoff is your expert partner. We specialize in executing complex relocation projects in forming and joining technology, ensuring minimal downtime and maximum efficiency. With our comprehensive service, we handle everything—from planning and dismantling to reassembly and optimization at the new site. Our experienced team works closely with you, providing tailor-made solutions that meet your specific needs while ensuring that your production is up and running as quickly as possible. Why trust Mühlhoff with your relocation project? End-to-End Service: We manage every aspect of the relocation process, so you don’t have to. Expertise in Forming and Joining: Decades of experience in these specialized technologies mean your equipment is in safe hands. Minimal Downtime: Efficient planning and execution to reduce disruptions and keep your production moving. Customized Solutions: We tailor our approach to fit your unique production requirements and goals. Relocating doesn’t have to be a headache. With Mühlhoff’s proven expertise, your forming and joining equipment will be relocated smoothly, safely, and on schedule. Get in touch with us today, and let’s make your next relocation project a success!

Use case

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

When exploring the robotic welding industry in South Korea, several key considerations emerge. The country's advanced manufacturing sector, combined with a strong emphasis on automation and technology, presents significant opportunities for growth. South Korea is known for its high levels of investment in robotics, which is driven by the need for increased efficiency and productivity in industries such as automotive and shipbuilding. However, potential challenges include navigating regulatory frameworks that govern workplace safety and environmental standards. Compliance with these regulations is crucial for companies aiming to operate sustainably. Additionally, the competitive landscape is intense, with both local and international players vying for market share, making it essential for businesses to differentiate themselves through innovation and technology. Environmental concerns are also prevalent, as industries face increasing pressure to reduce carbon footprints and improve sustainability practices. Companies must be aware of the global market relevance of their operations, as South Korea serves as a significant hub for exports, particularly in the Asia-Pacific region. Understanding local market dynamics, technological advancements, and the evolving regulatory environment will be vital for anyone looking to succeed in the robotic welding sector in South Korea.

Some interesting numbers and facts about your company results for Robotic Welding

| Country with most fitting companies | South Korea |

| Amount of fitting manufacturers | 15 |

| Amount of suitable service providers | 6 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1999 |

| Youngest suiting company | 2021 |

Some interesting questions that has been asked about the results you have just received for Robotic Welding

What are related technologies to Robotic Welding?

Based on our calculations related technologies to Robotic Welding are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Robotic Welding?

The most represented industries which are working in Robotic Welding are Automation, IT, Software and Services, Electronics and Electrical engineering, Manufacturing, Other

How does ensun find these Robotic Welding Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.