The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Precognize

Tirat HaCarmel, Israel

B

11-50 Employees

2011

Key takeaway

Precognize offers a predictive monitoring solution that significantly reduces the number of anomalies, providing up to five actionable alerts a day. This approach combines expert knowledge with machine learning, enhancing predictive maintenance for the process industry.

Reference

Core business

Predictive Maintenance for the Process Industry | Precognize

Precognize is a leading predictive maintenance solution for the process industry, lowering maintenance cost and increasing availability

EMiS-CON

Ramat HaSharon, Israel

B

1-10 Employees

2014

Key takeaway

The company offers consulting and integration services for electronic monitoring systems, which can enhance condition monitoring for community supervision agencies. Their expertise helps these agencies effectively manage technology, allowing them to focus on their core mission.

Reference

Core business

Electronic monitoring integration & consulting services

Galooli

Nes Ziona, Israel

B

101-250 Employees

2009

Key takeaway

Galooli specializes in providing innovative remote monitoring and management solutions that offer actionable insights into the performance of energy assets, including generators. Their approach enables clients to enhance energy efficiency, reduce operational costs, and monitor performance effectively, making it a key player in condition monitoring for sustainable energy management.

Reference

Product

Generator Monitoring - Galooli

Generator Monitoring Data-driven insights for peak generator performance get a quote D3A41193-D828-42B8-98F7-3C6C199157CB About the Product Generators – diesel or hybrid – are heavily relied upon in a variety of industrial use cases because they provide immediate power to remote sites and facilities. Our Generator Monitoring Module ensures that all your generators are properly installed, use […]

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Greazly

Nes Ziona, Israel

B

1-10 Employees

2021

Key takeaway

Greazly offers a real-time machine monitoring system that ensures proper greasing, effectively preventing unplanned downtime caused by poor lubrication. By utilizing Greazly's system, manufacturers can significantly reduce their unplanned downtime, leading to substantial cost savings.

Reference

Core business

Monitor Machines To Ensure Proper Greasing | Greazly

Greazly monitor machines to ensure proper greasing

IronComm

Petah Tikva, Israel

B

1-10 Employees

2019

Key takeaway

IronComm offers advanced incident management software that effectively minimizes unplanned downtime in production environments. By leveraging AI and continuous learning, their solution helps organizations manage incidents and enhance operational efficiency, directly addressing the challenges of downtime in manufacturing.

Reference

Core business

HOME | IronComm

Razor Labs

Tel-Aviv, Israel

B

101-250 Employees

2016

Key takeaway

Razor Labs offers a comprehensive predictive maintenance platform that enhances condition monitoring through 24/7 site coverage and advanced sensor technology. Their solutions focus on optimizing maintenance strategies to prevent failures and reduce unplanned downtime, ultimately boosting productivity and improving safety.

Reference

Core business

Making Machines Smarter - Razor Labs

Making Machines Smarter Reimagine Predictive Maintenance with Sensor Fusionfor Superb Failure Coverage and Root Cause Analysis. Request a Demo Why Razor Labs Razor Labs is revolutionizing the mining industry with its cutting-edge all-in-one predictive maintenance solutions that reduce unplanned shutdowns, boost productivity, and improve staff safety. Sensors A comprehensive hardware offering for a full 24/7 site […]

CartaSense

Drom HaSharon Regional Council, Israel

B

1-10 Employees

2007

Key takeaway

CartaSense is a dedicated team focused on innovation and technology for the cold chain industry, offering powerful condition monitoring services. Their self-contained sensors provide real-time information, enabling proactive management of international shipments and helping to avoid failures before they occur.

Reference

Product

Monitoring Products Overview

AutoMonX Ltd

Jerusalem, Israel

B

1-10 Employees

2019

Key takeaway

AutoMonX specializes in providing automated performance monitoring and observability solutions for both cloud and on-premises IT infrastructure, enabling IT engineers to efficiently manage the entire monitoring life-cycle of their assets. With a strong focus on integrating with popular monitoring services, AutoMonX leverages years of experience to enhance network management and performance oversight.

Reference

Core business

Monitoring of Cloud and On-Prem IT assets |Microsoft Azure, CiscoACI | AutoMonX Ltd

AutoMonX via its Monitoring Automation helps IT engineers to automatically handle the entire monitoring life-cycle of IT assets such as HPE 3PAR, Microsoft Azure, Cisco and Juniper devices and more

Sensorz

Kfar Saba, Israel

B

1-10 Employees

2021

Key takeaway

Sensorz provides continuous and persistent monitoring that identifies interferences and potential bottlenecks, ensuring reliable and high-performance 5G networks. Their advanced AI-powered solutions not only detect but also predict malicious activities, enhancing threat detection and response times.

Reference

Core business

Sensorz

Wireless Observability Platform by Sensorz - Continuous spectrum monitoring, AI-based detection, and classification of wireless threats.

Upstream Security

Herzliya, Israel

B

51-100 Employees

2017

Key takeaway

Upstream's cloud-based data platform offers predictive maintenance solutions for connected vehicles, enabling stakeholders to proactively manage vehicle upkeep and prevent breakdowns. By leveraging telematics data, Upstream helps reduce maintenance costs and increase vehicle uptime.

Reference

Product

Automotive Predictive Maintenance | Upstream

Upstream's cloud-based platform leverages telematics data collected from connected vehicles to empower smart mobility stakeholders to proactively manage vehicle maintenance, prevent breakdowns, reduce downtime, and reinforce brand perceptions.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

OndoSense apex radar sensor (E)

Go to product

Product

edbic

Go to product

Product

edpem

Go to product

Service

OperAID

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

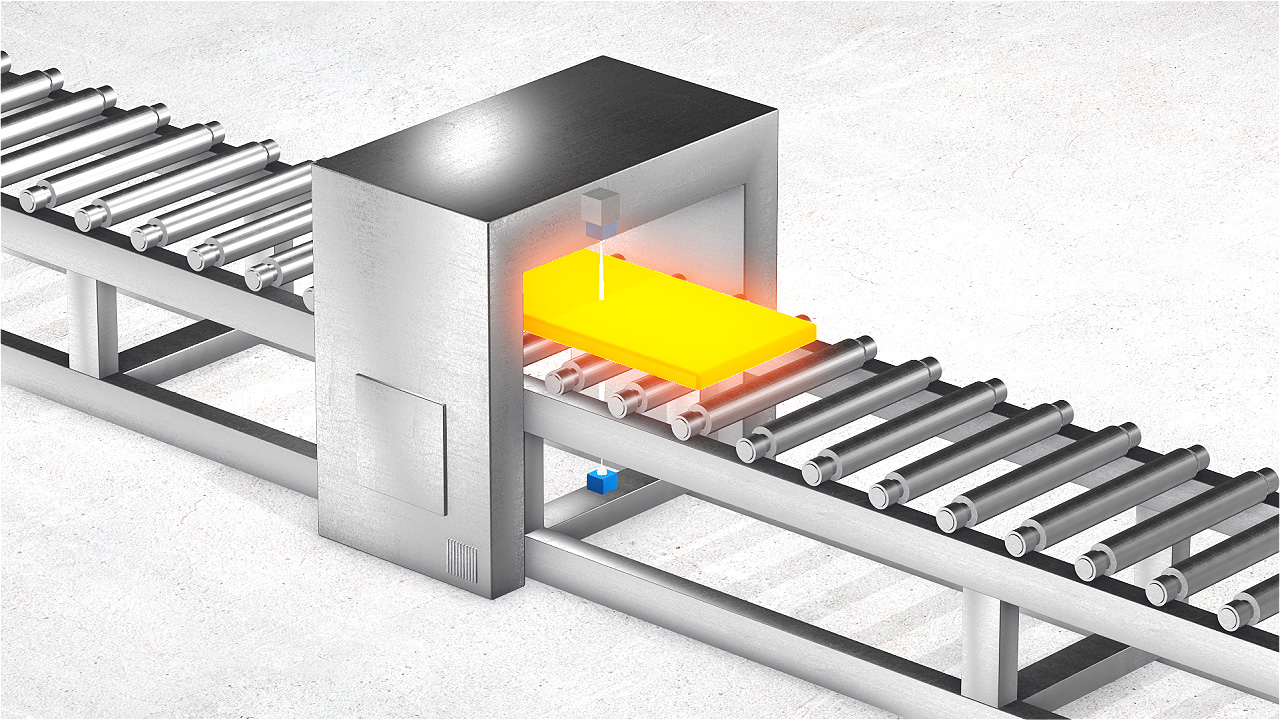

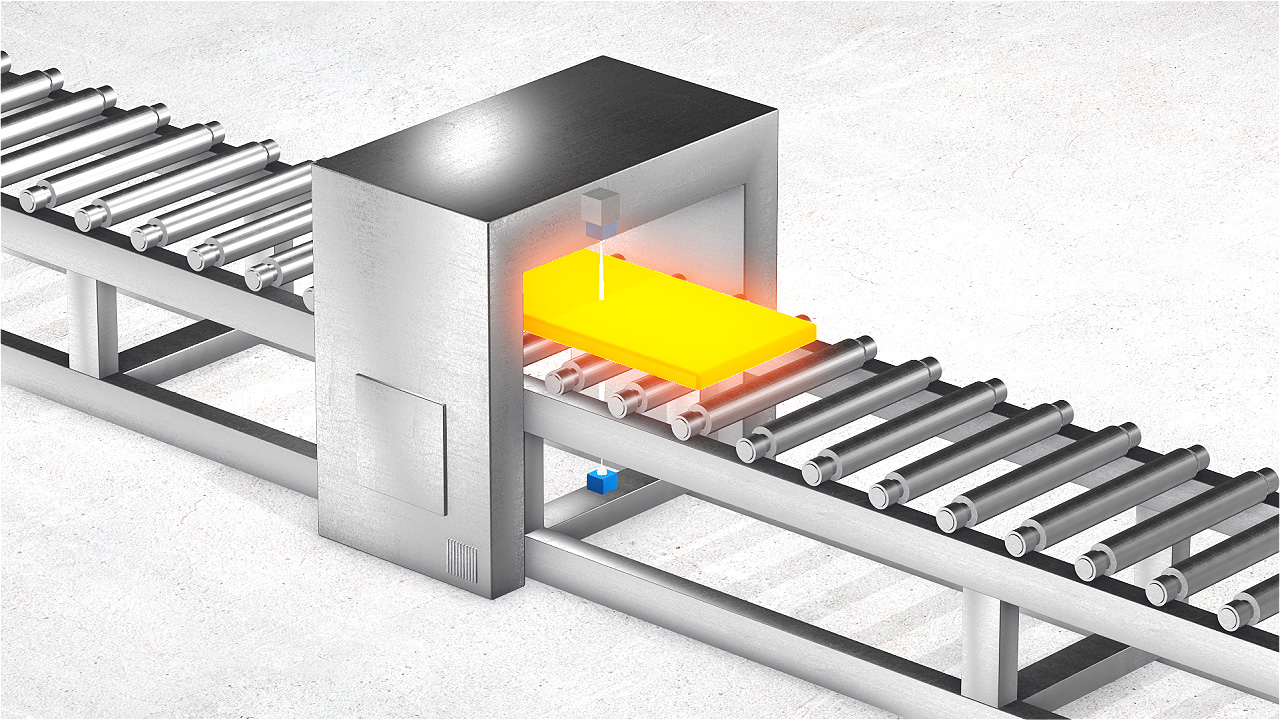

Thickness measurement of metal products

steel, metal, aluminium, aluminum, copper

Our radar sensor solution determines the thickness and the thickness profile of steel plates, steel strips or steel slabs (up to 1600 °C hot) with an accuracy of up to ±10 µm on the roller conveyor. Thanks to robust radar technology, sophisticated signal processing and intelligent radar algorithms, OndoSense radar sensors achieve this high level of precision in thickness measurement even under the difficult production conditions of the steel industry with smoke, steam, dirt, vibrations, fire and extreme temperatures.

Use case

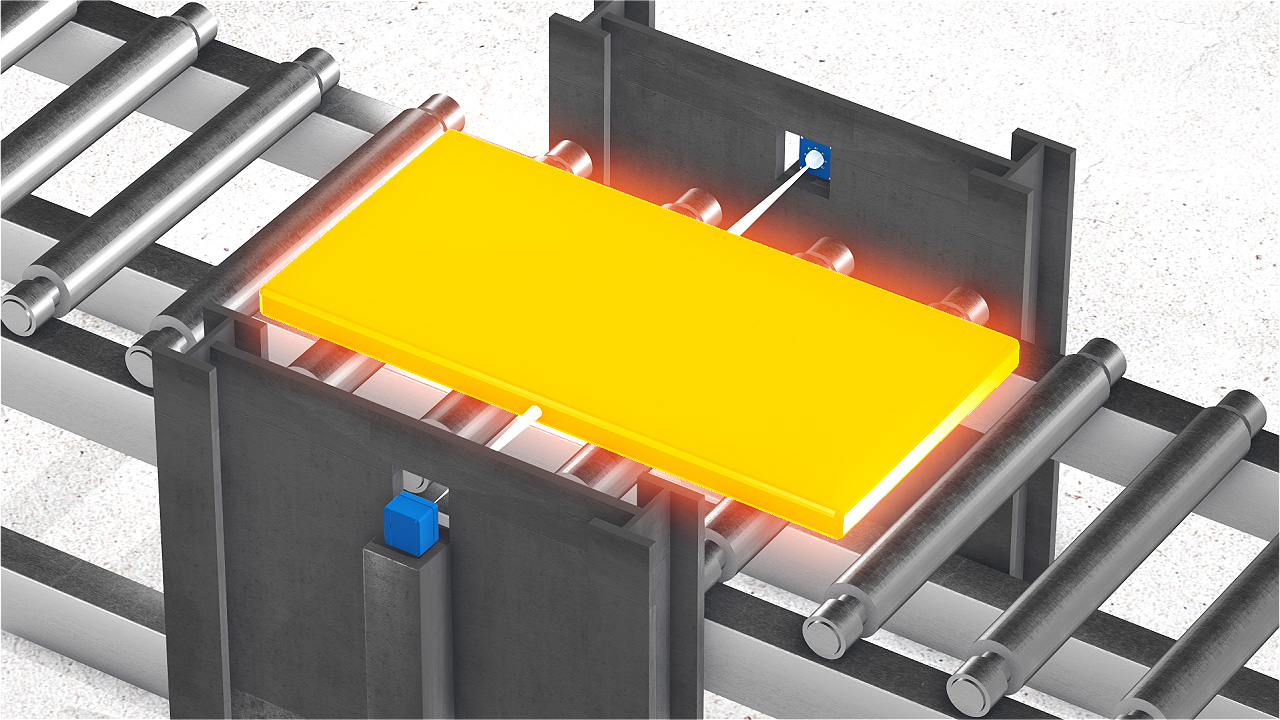

Width measurement of metal products

metal, steel, copper, aluminium, aluminum

The OndoSense radar sensor solution determines the width of steel plates, steel strips or steel slabs (up to 1600 °C hot) with an accuracy of up to ±300 µm. Thanks to robust radar technology, sophisticated signal processing and smart radar algorithms, our radar sensors offer this high precision in width measurement even in the extreme production environments of the metal and steel industry with steam, dirt, smoke, fire, vibrations and extreme temperatures.

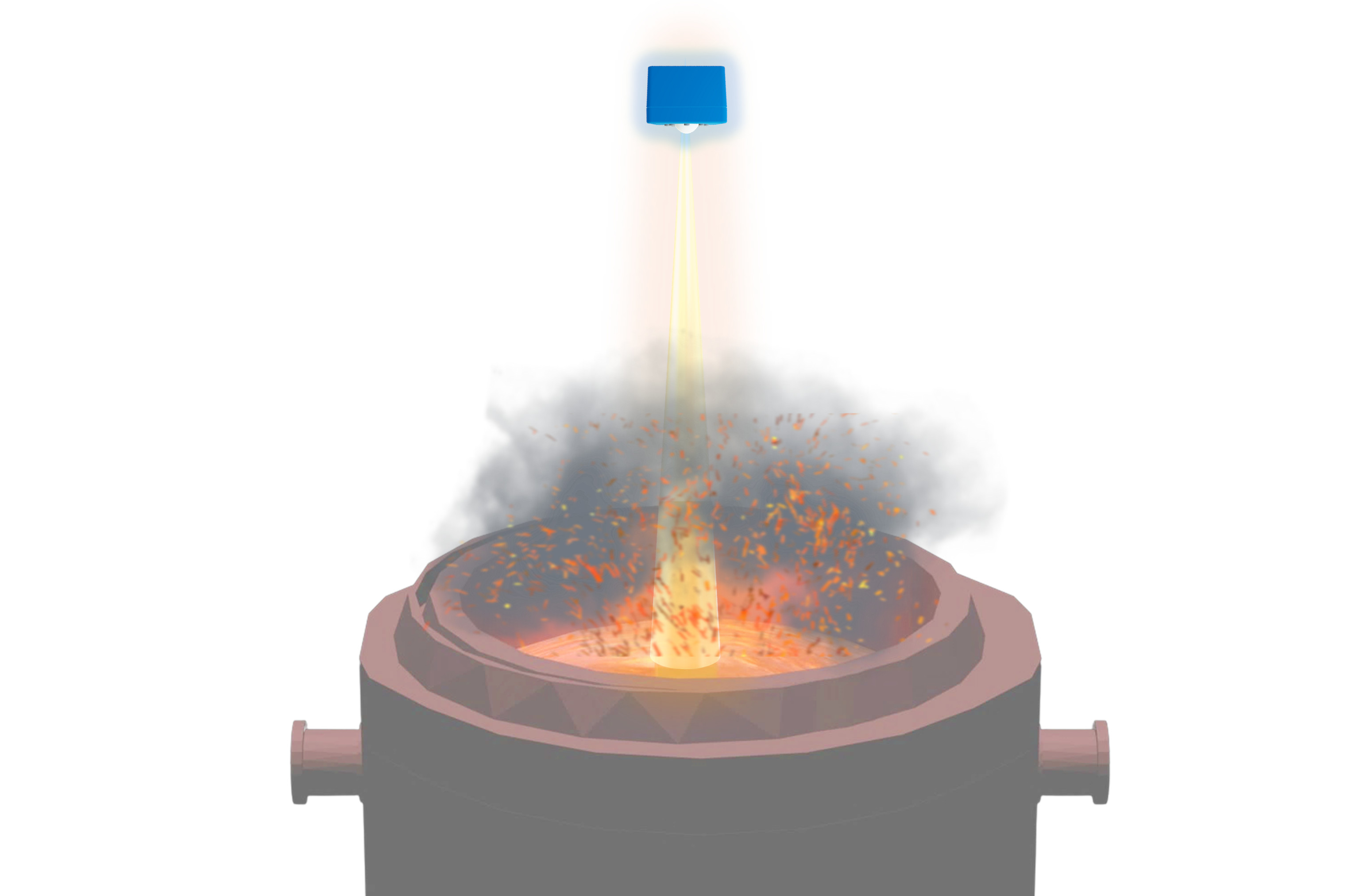

Use case

Molten metal level measurement

metal, steel, copper, aluminium, aluminum

With the OndoSense radar sensors, the fill level of liquid steel or aluminum can be measured contact-free with sub-millimeter accuracy, even at metal temperatures of up to 1600 degrees Celsius. Dust, steam, smoke, vibrations and strong heat radiation have no influence on the high precision and reliability of the radar-based molten metal level monitoring. Active cooling of the level radar is usually not necessary.

Use case

Continuous monitoring

Manufacturing

The challenge Blickle has always prided itself on the superior quality of its wheels and castors. To further enhance this quality with modern technology, the company decided to migrate its production processes to Industry 4.0 standards. This planned transition should have minimal impact on the three-shift production operation, while maintaining flexibility and openness for future digitalization initiatives. The solution Blickle IT developed a concept to enable a sustainable and gradual transformation. At the heart of the strategy is edbic, which enables condition monitoring. Acting as a central data hub, edbic seamlessly extracts data from the machines, transfers it to the ERP system and provides full production transparency. The result With the implementation of edbic, machine data no longer reaches IT incomplete or delayed. Immediate data analysis enables rapid problem resolution. Automatic punching presses are monitored to determine output results, missing parts, quantities and more. By eliminating most of the Excel lists previously used, edbic has significantly streamlined operations. In polyurethane production, edbic identifies and corrects problems, contributing to Blickle's high quality castors and wheels. In addition, edbic is now being used beyond production, facilitating connections to payment providers in the web shop and establishing a communication link with SAP. Outlook for the future Blickle plans to further refine the system by using machine data comparison for predictive maintenance. In addition, the company is considering implementing the compacer IoT gateway to take communication between machines and the ERP system to a new level of automation.

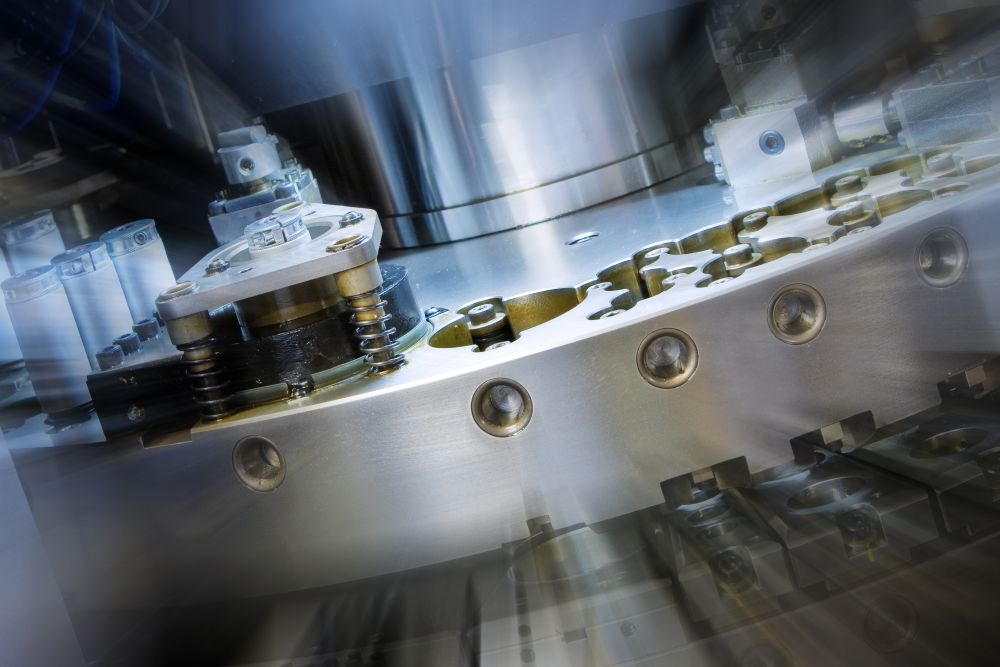

Use case

IoT gateway and Industry 4.0 application

Industry 4.0, Manufacturing

The challenge: BURKHARDT+WEBER is renowned for its expertise in large machining centres. Headquartered in Reutlingen, Germany, the company has a global presence and supplies its products to customers around the world who place a premium on quality. For 130 years, BURKHARDT+WEBER has focused on developing state-of-the-art production solutions for the demanding machining of steel, cast iron and titanium components. The development of these machining centres is the collaborative work of interdisciplinary teams, and all essential components, as well as in-house developments, are manufactured within the company. The compacer IoT solution, built on the edbic platform, is planned for future integration into BURKHARDT+WEBER machining centres. The installation of the compacer IoT gateway enables data collection from the machine's control system. In the long term, BURKHARDT+WEBER machines will offer a wide range of data that can be examined in real time to provide a detailed overview of the machine's condition and efficiency on a dashboard. The solution: An IoT hub will process the collected data, enabling a variety of assessments and ensuring that the operator is kept informed at all times. With machines connected to the compactor solution, condition monitoring is possible, paving the way for the implementation of predictive maintenance. With this approach, BURKHARDT+WEBER enables its customers to successfully implement upcoming digital transformation projects within their production processes.

Use case

Digital retrofit at a manufacturer

Electrical installation technology

The challenge: Our customer has an individually analog 30t punching and bending machine in use, which must not be interfered with in the control process. Small hairline cracks in the large drive wheel can lead to a machine failure, resulting in a production stop. Due to the high storage costs, the spare part is not kept in stock. It can take up to three weeks to order and deliver the new part. In order to avoid a machine breakdown, it should be digitally connected to the current production environment and in future the condition of the gearwheel should be analyzed by means of condition monitoring and a breakage better predicted. Our customer's goal was therefore to make the machine IoT-ready with a digital retrofit in order to reduce machine downtimes and increase machine utilization times. The solution: Digital activation of the existing system was unavoidable, which is why sensors were initially installed by the customer to detect the gear breakage. The vBox from Fraunhofer IPT processes the sensor signals and sends the data to the compacer data platform edbic. Among other things, structure-borne noise, vibration, temperature, torque and current are measured. Increased current consumption, which can be a sign of excessive load due to friction and a lack of lubricant, is detected. However, the collected and evaluated data also reveals smaller cracks. The frequency spectrum and other values are recorded, compared and examined for outliers in real time. If an outlier, such as a crack, is detected, an alarm is generated and employees are informed. They can take action if necessary and production downtime can be avoided. Our customer: a German market leader in the field of electrical installation technology and global market leader in SCHUKO® sockets, produces at two locations in Germany and exports to more than 60 countries. In order to further expand its brand leadership and establish innovations in the smart home sector, the company is taking on new digital challenges.

Use case

Business and IoT integration in Antwerp Euroterminal

Ports

The challenge: The implementation of a new Terminal Operating System (TOS) offered our customer the unique opportunity to rethink the entire IT landscape. Accelerating the digital transformation and reducing the workload became key target definitions. The aim was to meet the ever-changing internal and customer requirements, while offering high-quality services to end customers. The most important factors were maintaining a high level of customer satisfaction and a clear commitment to maximum security. The existing system landscape had grown with the company and was therefore very heterogeneous and poorly integrated. This had led to high maintenance and administration costs. Integration projects were only implemented when necessary and integration problems were solved by in-house developments. This led to silo thinking and resulted in increasingly fragmented and isolated knowledge. It became clear that networking the respective systems with suitable tools would create immediate added value and greater transparency. In addition to the "classic" challenges of integration projects, our customer emphasized that the topic of IoT integration was very important to them. Particular attention should be paid to finding the right speed and the right tools for the changeover. A software platform that would enable them to connect their B2B partners and their applications electronically and provide a solid basis for the planned IoT integration would therefore be far ahead of all competing offerings. The solution: The customer decided to use the compacer edbic platform as a B2B/IoT gateway. The integration platform acts as a central "data hub" for our customer and the applications of its trading partners. It has since become the core of all operational and logistical flows. edbic was supplemented in a second step by edpem to introduce business process monitoring (BPM). A whole series of integration projects were implemented in a very short space of time. Some of these were "traditional" B2B projects designed to enable the exchange of EDI, XML and proprietary data with the applications of trading partners and third parties by converting and transmitting the data transparently. In addition, a large number of applications were connected via edbic. The system for shift planning and management of terminal workers was linked to the access control system for the port, enabling automated payroll and significantly relieving the HR department of day-to-day tasks. Integration with the customer's ERP environment, on the other hand, partially automated order acceptance, fulfillment and billing. New capabilities were also added, such as the generation of data records for structured test scenarios, automated access control based on shift planning and visitor appointments, and much more. However, the port operator wanted to go one step further and tackle its first IoT project. For the pilot project, sensor data from the terminal's various weighing and measuring systems was published via edbic. A typical use case is measuring the verified gross mass (VGM) to comply with SOLAS requirements. The data obtained is now automatically fed into higher-level systems such as the TOS or stowage planning for loading ships, where it is available for further processing, analysis and visualization. The network of surveillance cameras has been connected to a perimeter security system, which enables the early detection of intruders. The comparison of number recognition events (ANPR) with access control information and TOS transactions makes anomalies visible, improves traffic management and increases security - a key concern in port terminals. All of this is controlled by edbic. This new level of digitalization makes everyday terminal logistics easier and significantly increases the efficiency of the port.

Use case

EDI in electronics wholesale

Wholesale

The challenge: Due to a lack of transparency in communication, there are always gaps in the transfer of know-how between the active shareholders. A standardized communication structure between customers and business partners must therefore be established. Among other things, this should also contain information on delivery information and ensure greater transparency within the business processes. One challenge, for example, was the lack of visibility of goods availability, which needed to be resolved. The solution: In addition to establishing central IT services, the aim was to create a modern communication concept for Europe-wide business processes using EDI so that all shareholders in Europe can access all data in a shared database. compacer was commissioned to develop, set up and operate a fully integrated B2B industry platform for the group of companies. In addition to the EDI component with integrated supplier onboarding portal, this was also to cover the topic of e-invoicing. An e-invoicing platform was to be established that implements e-billing, signed PDF, e-mail distribution and ZUGFeRD in practice. Our customer: is a market community in electrical wholesale and a group of companies that operates internationally in 26 countries. More than 230 independently cooperating electrical wholesalers now belong to the association. Almost every shareholder is an independent family business. The aim is to strengthen the future of wholesalers. That is why the company's focus is also on cooperation with the individual manufacturers. This is also the reason why a central e-commerce platform had to be set up and expanded.

Use case

Replacement of Legacy Systems

Logistics

The challenge: Our customer was in a very difficult situation: the existing data integration software was outdated, extensions from the provider were no longer possible and support for the software had also been discontinued. As a result, they were looking for a successor that would meet the criteria for a modern data and integration platform, e.g. through web services, and enable a high data throughput. The decisive factor for the customer was full integration into the IBM/AS400/DB2/MQ system environment while adhering to the specified budget and schedule and the modernization and development of a data integration platform for EDI services as a group application with separate systems for development and testing. The solution: The decisive arguments for choosing compacer were, on the one hand, the price and also the time savings that compacer had estimated for the migration project with its model-based and automated project approach. Even the customer's internal service provider would not have been able to implement this in this time frame or with the budget that had been included. On the other hand, the customer was also impressed by the diverse possibilities and flexibility of the compacer data and integration platform edbic during an on-site reference appointment. The migration not only involved the automated porting of around 1,500 mappings and the associated EDI message connections, but also 2,400 partner connections, with the premise that this should have no impact on the connected business partners. Result: Thanks to our model-based project method and close-meshed project controlling, we were easily able to keep to the project timeframe and the specified budget in this migration project. This also made it possible for us to provide the customer with flexible support wherever possible, absorb work peaks on the customer side and gradually take on additional tasks for the customer. We saw this as a great vote of confidence. But it was not only the compacer project method and the successful cooperation that had a positive influence on the speed of the project. Thanks to our established, model-based approach and the automation by means of tool-supported porting of message structures and processes, conversion times and manual sources of error were drastically reduced. This has reduced the migration and testing effort by 80% to 90% compared to the usual manual approach. By using the compacer data integration platform edbic, our customer can now set up processes more easily in day-to-day operations, reuse modules and monitor processes and their interaction more effectively. This significantly increases IT efficiency. The system load is currently 2 million data records per working day (8 hours) and a peak load of 1 million/hour, whereby the system is designed for up to 7 million data records per day. The customer was impressed not only by the flexibility and adaptability of the platform, but above all by its speed. The next step is to implement the diverse possibilities of web services with edbic.

Use case

Continuous monitoring

Airport, Logistics

The challenge: A leading provider of ground services and cargo handling wanted to offer comprehensive solutions to the aviation industry. To drive innovation in key areas such as service, quality and reliability, the company wanted to improve visibility and communication through integration and networking across departments. Monitoring irregularities in process flows was critical to optimizing ground handling services. Working with multiple service providers and their disparate IT systems, which varied between airports and internal departments, was a challenge, while maintaining uninterrupted operations throughout the project. The solution: This multi-stage project used edpem, a process event monitoring tool, as the primary solution for monitoring ground services. To ensure fast aircraft turnaround times, the critical path in the process flow needed to be measured and monitored, especially when processes were transferred between suppliers. edpem recorded multiple events, including parking, disembarking completion, cleaning, catering, fuelling, crew boarding and loading completion. Service Level Agreements (SLAs) were tracked and monitored, and causes of delays identified and improved. Ground handling services were optimized by assessing service duration and process flow irregularities. In addition to monitoring traditional EDI processes, visualized reports improved reporting efficiency and facilitated faster decision-making. Key results included reduced turnaround times and fewer disruptions to flight operations. Our client: A major European airport provides ground services to approximately 265 million passengers annually and manages 4.6 million tonnes of global air cargo. Several warehouses are IATA CEIV certified for pharmaceutical logistics. In 2019, its 64,000 employees operated at 300 airports in 47 countries on six continents.

Use case

Real-Time-Monitoring

Logistics

The challenge: The pharmaceutical company works closely with logistics service providers. Due to the volatile nature of the sector's order book, it was difficult to accurately predict capacity utilization, leading to recurring problems with service providers during collection. Service providers need timely information on freight volumes, collection details and the appropriate mode of transport. A key challenge was the sharing of real-time transport data. Another key concern was tracking and tracing, which proved difficult due to incomplete integration of certain areas of the warehouse management system. In addition, real-time monitoring of internal and external departments and service providers was required to optimize logistics processes. The solution: edpem was implemented as an end-to-end monitoring solution to improve logistics processes. The monitoring covered the entire delivery process, from SAP order documents and invoices to final delivery. Connection and monitoring of the warehouse management system was also part of the scope. Comprehensive tracking of goods throughout the supply chain enabled quick retrieval of information without involving other departments, saving valuable time and resources. Optimal vehicle selection for parcel collection and product tracking by batch were achieved. Internal IT system security was ensured, as external partners could only access edpem without needing permissions for internal applications. Parcel scanning enabled customer order tracking and tracing, early problem identification and real-time notification of process owners. edpem tracked the entire shipping process from packaging to customer delivery. The automation of electronic data interchange (EDI) provided new opportunities for superior service and quality for customers and logistics providers. Our customer: A pharmaceutical company based in Germany provides "Made in Germany" products to patients worldwide, with almost all products manufactured at its headquarters in Baden-Baden and distributed through an extensive network. Its main focus is on the research and production of medicines based on natural ingredients. The company has achieved global growth and operates in 50 countries.

Use case

Remote Monitoring & Control

Remote Asset Monitoring, Remote Control, IIOT, IOT, Data Logging, Remote Terminal Unit, Process Control, Machine Control

Cellcon series of IoT Controllers are targeted towards Remote Monitoring & Control applications across various industries. They integrate HMI, Control, Data Logging & IOT Functionality and ideal for Asset Monitoring, Remote Control, Remote Data Acquisition and Logging applications. We provide complete Firmware and Cloud Application Development support for this product.

Use case

Thickness measurement of metal products

steel, metal, aluminium, aluminum, copper

Our radar sensor solution determines the thickness and the thickness profile of steel plates, steel strips or steel slabs (up to 1600 °C hot) with an accuracy of up to ±10 µm on the roller conveyor. Thanks to robust radar technology, sophisticated signal processing and intelligent radar algorithms, OndoSense radar sensors achieve this high level of precision in thickness measurement even under the difficult production conditions of the steel industry with smoke, steam, dirt, vibrations, fire and extreme temperatures.

When exploring the Condition Monitoring industry in Israel, several key considerations come into play. The country has a robust technological landscape, making it a fertile ground for innovation in condition monitoring solutions. Familiarity with local regulations and standards is essential, as compliance with both national and international guidelines can impact business operations. Israel's emphasis on cybersecurity also poses a challenge, as condition monitoring systems must ensure data integrity and protection against cyber threats. Opportunities in the market are driven by the growing demand for predictive maintenance across various sectors, including manufacturing, energy, and transportation. The increasing adoption of IoT technologies facilitates real-time monitoring, thus enhancing operational efficiency. However, potential entrants should be aware of the competitive landscape, which includes both established companies and startups that are continuously innovating. Environmental concerns also play a role, as Israel faces challenges related to water scarcity and energy efficiency. Companies that can offer sustainable solutions may find a competitive edge. Additionally, the global relevance of the Israeli market cannot be overlooked, as partnerships and collaborations with international players can provide valuable insights and access to broader markets. Overall, understanding these dynamics is crucial for anyone looking to navigate the condition monitoring industry in Israel effectively.

Some interesting numbers and facts about your company results for Condition Monitoring

| Country with most fitting companies | Israel |

| Amount of fitting manufacturers | 62 |

| Amount of suitable service providers | 28 |

| Average amount of employees | 1-10 |

| Oldest suiting company | 2007 |

| Youngest suiting company | 2021 |

Some interesting questions that has been asked about the results you have just received for Condition Monitoring

What are related technologies to Condition Monitoring?

Based on our calculations related technologies to Condition Monitoring are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Who are Start-Ups in the field of Condition Monitoring?

Start-Ups who are working in Condition Monitoring are Greazly, Sensorz

Which industries are mostly working on Condition Monitoring?

The most represented industries which are working in Condition Monitoring are IT, Software and Services, Other, Automation, Electronics and Electrical engineering, Medical

How does ensun find these Condition Monitoring Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.