The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Artesis Technology Systems

Turkey

C

11-50 Employees

1999

Key takeaway

Artesis offers a variety of intelligent condition monitoring products, including the Motor Condition Monitor (e-MCM) and Plant Condition Monitor (e-PCM), which are designed for real-time monitoring and predictive maintenance of critical AC rotating equipment. Their advanced solutions enhance operational efficiency and prevent production interruptions through effective anomaly detection and maintenance planning.

Reference

Product

e-MCM - Artesis

The Artesis e-MCM is a powerful online condition monitoring, predictive maintenance and power meter tool intended for critical AC rotating equipment.

Syscor

Çan, Turkey

C

11-50 Employees

2008

Key takeaway

Syscor's FR-Tracker™ 2.0 system provides condition monitoring for floating roofs on aboveground storage tanks, offering early warnings to prevent accidents. Additionally, their HC-Tracker™ system detects liquid hydrocarbons in water bodies, supporting environmental responsibility and safety in operations.

Reference

Core business

Syscor Controls & Automation

Seven Sensor

Turkey

C

11-50 Employees

2012

Key takeaway

SEVEN Sensor Solutions offers advanced photovoltaic monitoring systems that enable real-time condition monitoring of electricity production. Their weather stations and various sensors provide critical meteorological data, helping operators quickly identify and address any malfunctions or performance issues.

Reference

Service

Installation & Commissioning Services | Seven Sensor

Seven Solar provides installation, remote setup and commissioning services after sales. We also provide installation supervision services globally.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Sensemore

Turkey

C

1-10 Employees

2018

Key takeaway

Sensemore provides advanced condition monitoring solutions that leverage the latest technology and AI to optimize machinery performance and reliability. Their comprehensive system includes sensors and data analysis, enabling users to monitor equipment health and predict potential failures, ultimately promoting sustainable production and reducing operational costs.

Reference

Core business

Sensemore | Healthy Machines, Sustainable Business

Sensemore is a reliability-focused asset management platform with hardware, software and AI-powered tools designed for machine health analysis

TorkCheck

Konak, Turkey

C

51-100 Employees

-

Key takeaway

TorkCheck, a company of Mağdenli, specializes in condition monitoring through their comprehensive wind turbine service. Their trained technicians utilize advanced techniques, including thermal imaging and torque equipment, to ensure the integrity of electrical connections and mechanical alignments, ensuring reliable and safe operations.

Reference

Service

Check and Report - Torkcheck Wind Turbine Service and Consulting CO.

6 Check and Report Tork Control Electrical Connection Control Alignment Our trained technicians check all fastener & bolts by suitable torque equipment, generator alignment, view cable connections by a thermal camera. The locations which require rope

DVM IoT Solutions

Turkey

C

1-10 Employees

2014

Key takeaway

DVM IoT Solutions offers an innovative suite that leverages IoT and real-time data for advanced asset management and environmental monitoring, specifically enhancing liquid and gas tank monitoring through intelligent forecasting and dynamic rules.

Reference

Core business

DVM IoT Solutions

Monitera

Turkey

C

11-50 Employees

2009

Key takeaway

Monitera specializes in professional social media monitoring and reporting, making it well-suited for condition monitoring related to brand presence and user engagement. Their continuous improvement of products and services, driven by feedback from leading brands and agencies, underscores their commitment to providing timely and relevant content analysis.

Reference

Core business

Monitera : Professional Social Media Solutions

Web & Social Media Monitoring and Reporting

innovatist

Turkey

C

11-50 Employees

-

Key takeaway

The company's IoT solutions provide real-time monitoring for critical infrastructures, enabling solar system operators to proactively address issues and enhance energy production. This approach simplifies the integration of IT and OT data, making raw data more accessible and addressing the users' need for instant condition monitoring of their devices.

Reference

Product

Real-time Monitoring | Innovatist | Innovation, Science, Technology

Selecta Global Consulting

Turkey

C

11-50 Employees

-

Key takeaway

The company specializes in environmental solutions, particularly in wetstock monitoring systems for multinational oil companies, which directly relates to condition monitoring. Their dedicated analysts provide daily site monitoring, enhancing loss detection services through an accredited SIR algorithm.

Reference

Service

Services – Professional Fuel Loss Detection

Turning Data and Insights into Action As loss detection became an increased concern for oil companies through its financial, technical, environmental and safety-related impact, sites have the need …

PdMechanics

Turkey

C

1-10 Employees

-

Key takeaway

Pdmechanics enables efficient condition monitoring for production machinery in the chemical industry through accurate risk assessments and early fault detection. By utilizing wireless sensor solutions and advanced data analytics, Pdmechanics enhances the reliability of equipment, allowing maintenance teams to take proactive actions and significantly reduce unplanned downtime.

Reference

Core business

Kestirimci Bakım - Pdmechanics

PdMechanics’in uçtan uca kestirimci bakım çözümü ve erken arıza teşhisleri ile plansız duruşların önüne geçin, üretim gücünüzü artırın.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

OndoSense apex radar sensor (E)

Go to product

Product

edbic

Go to product

Product

edpem

Go to product

Service

OperAID

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

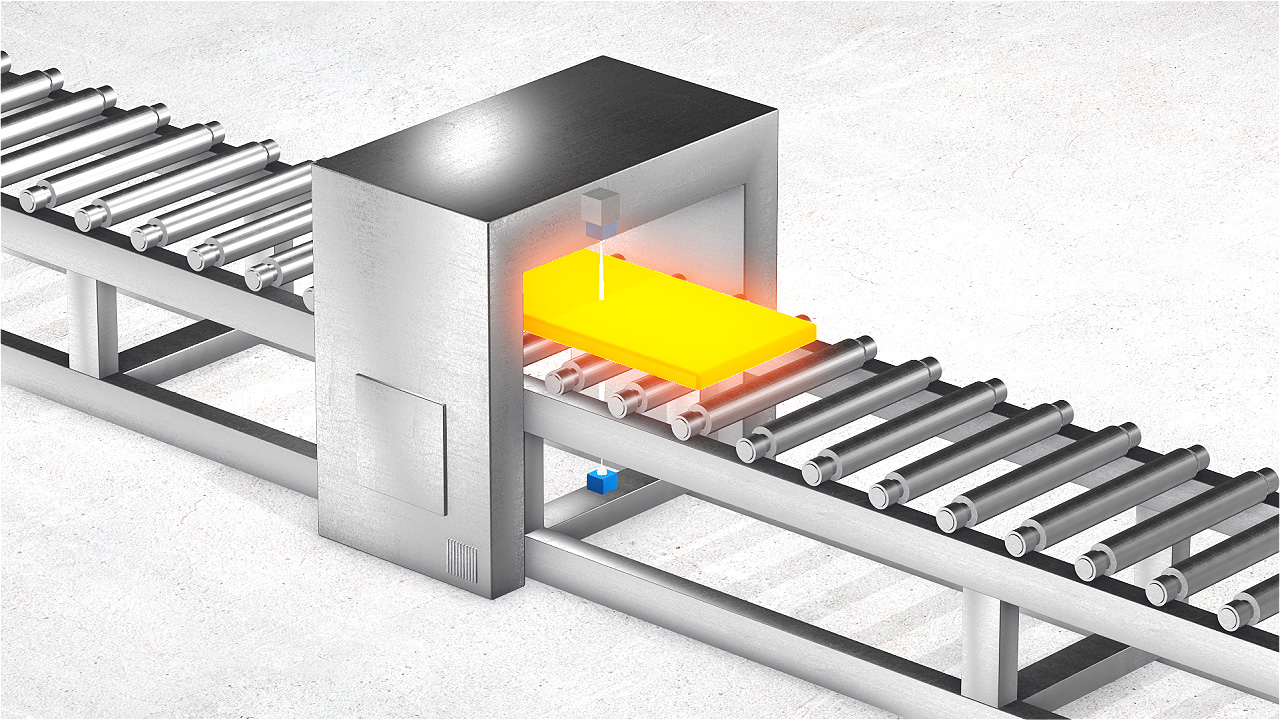

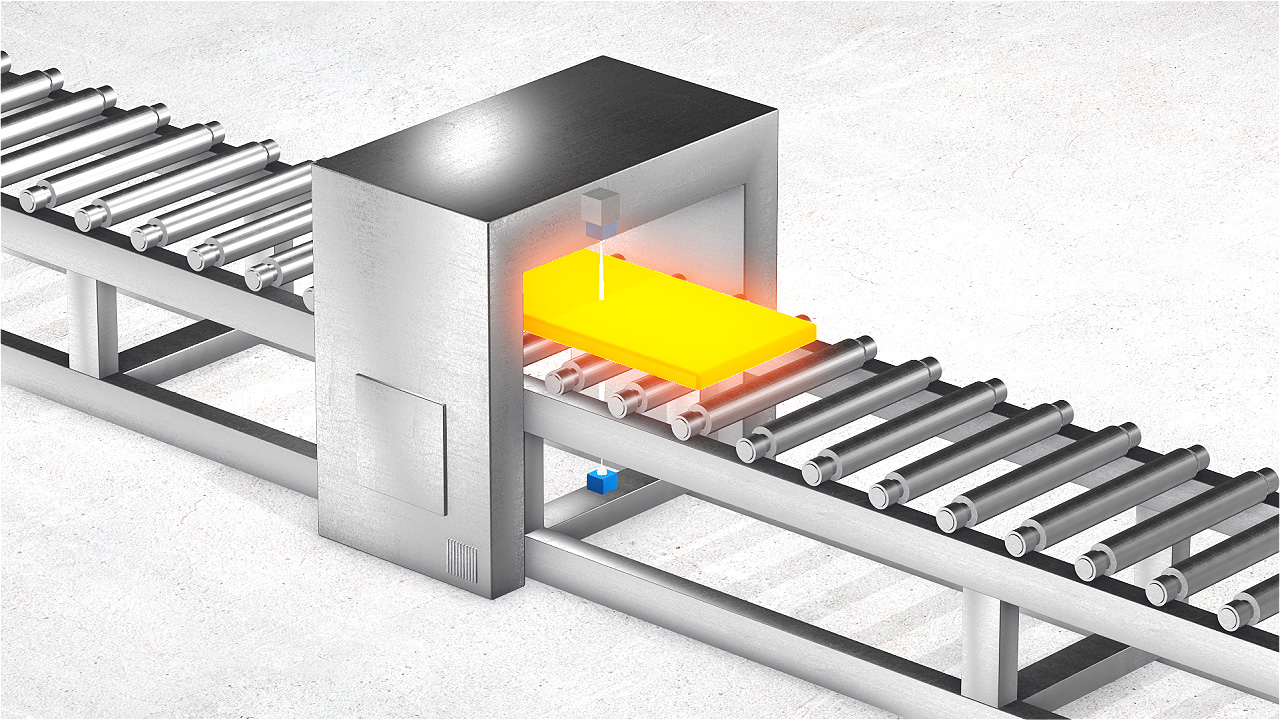

Thickness measurement of metal products

steel, metal, aluminium, aluminum, copper

Our radar sensor solution determines the thickness and the thickness profile of steel plates, steel strips or steel slabs (up to 1600 °C hot) with an accuracy of up to ±10 µm on the roller conveyor. Thanks to robust radar technology, sophisticated signal processing and intelligent radar algorithms, OndoSense radar sensors achieve this high level of precision in thickness measurement even under the difficult production conditions of the steel industry with smoke, steam, dirt, vibrations, fire and extreme temperatures.

Use case

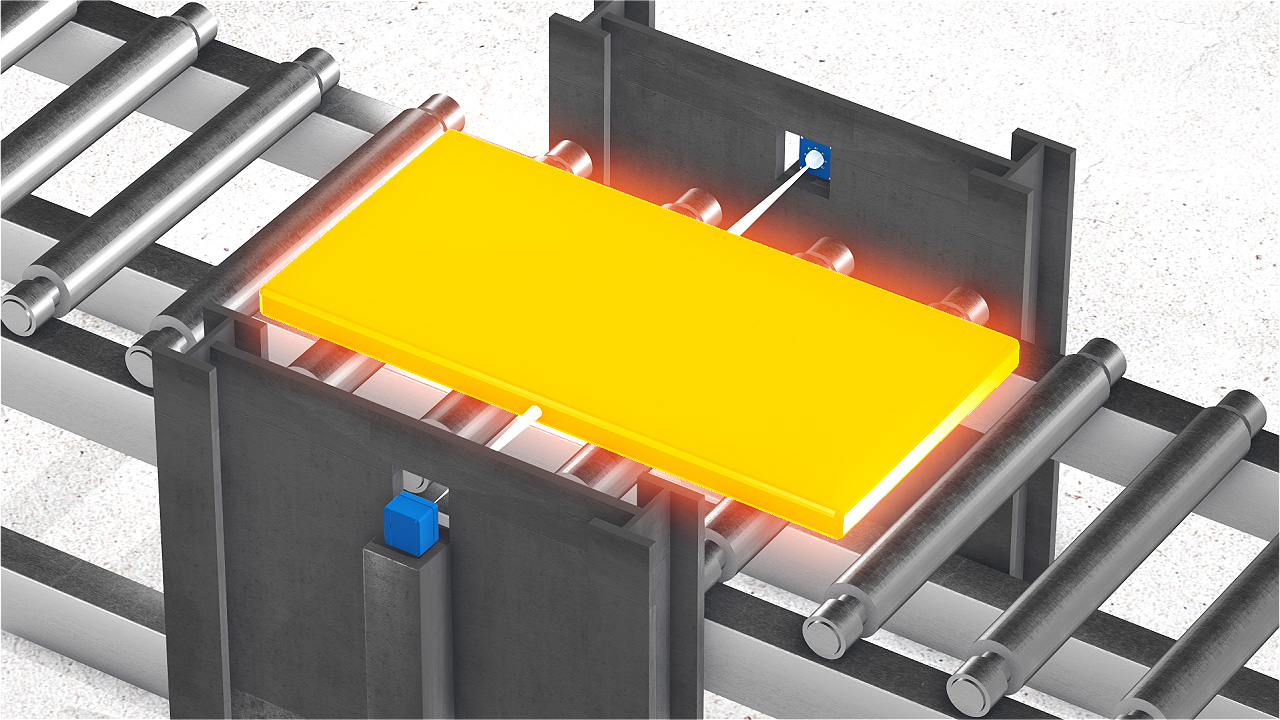

Width measurement of metal products

metal, steel, copper, aluminium, aluminum

The OndoSense radar sensor solution determines the width of steel plates, steel strips or steel slabs (up to 1600 °C hot) with an accuracy of up to ±300 µm. Thanks to robust radar technology, sophisticated signal processing and smart radar algorithms, our radar sensors offer this high precision in width measurement even in the extreme production environments of the metal and steel industry with steam, dirt, smoke, fire, vibrations and extreme temperatures.

Use case

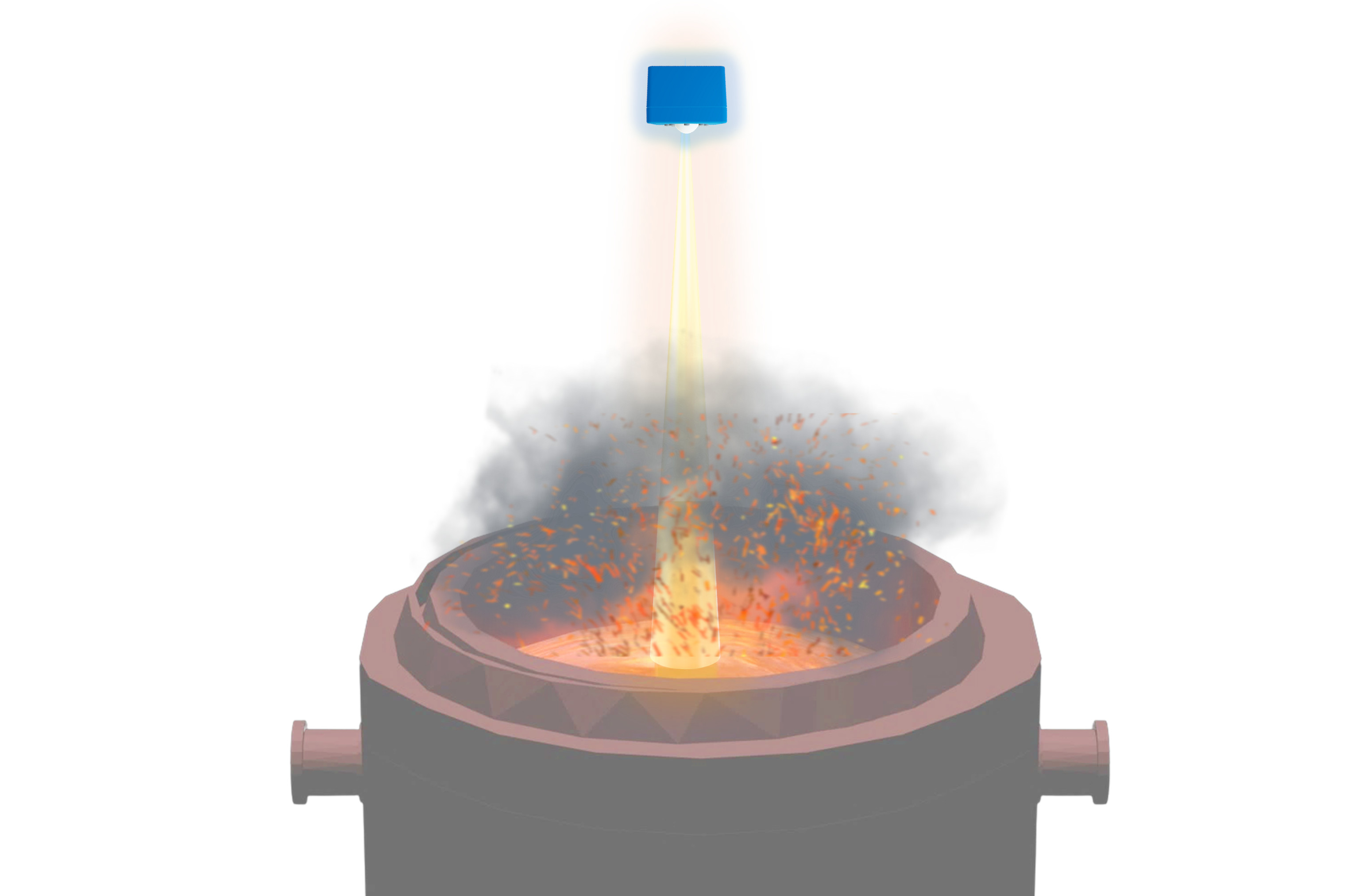

Molten metal level measurement

metal, steel, copper, aluminium, aluminum

With the OndoSense radar sensors, the fill level of liquid steel or aluminum can be measured contact-free with sub-millimeter accuracy, even at metal temperatures of up to 1600 degrees Celsius. Dust, steam, smoke, vibrations and strong heat radiation have no influence on the high precision and reliability of the radar-based molten metal level monitoring. Active cooling of the level radar is usually not necessary.

Use case

Continuous monitoring

Manufacturing

The challenge Blickle has always prided itself on the superior quality of its wheels and castors. To further enhance this quality with modern technology, the company decided to migrate its production processes to Industry 4.0 standards. This planned transition should have minimal impact on the three-shift production operation, while maintaining flexibility and openness for future digitalization initiatives. The solution Blickle IT developed a concept to enable a sustainable and gradual transformation. At the heart of the strategy is edbic, which enables condition monitoring. Acting as a central data hub, edbic seamlessly extracts data from the machines, transfers it to the ERP system and provides full production transparency. The result With the implementation of edbic, machine data no longer reaches IT incomplete or delayed. Immediate data analysis enables rapid problem resolution. Automatic punching presses are monitored to determine output results, missing parts, quantities and more. By eliminating most of the Excel lists previously used, edbic has significantly streamlined operations. In polyurethane production, edbic identifies and corrects problems, contributing to Blickle's high quality castors and wheels. In addition, edbic is now being used beyond production, facilitating connections to payment providers in the web shop and establishing a communication link with SAP. Outlook for the future Blickle plans to further refine the system by using machine data comparison for predictive maintenance. In addition, the company is considering implementing the compacer IoT gateway to take communication between machines and the ERP system to a new level of automation.

Use case

IoT gateway and Industry 4.0 application

Industry 4.0, Manufacturing

The challenge: BURKHARDT+WEBER is renowned for its expertise in large machining centres. Headquartered in Reutlingen, Germany, the company has a global presence and supplies its products to customers around the world who place a premium on quality. For 130 years, BURKHARDT+WEBER has focused on developing state-of-the-art production solutions for the demanding machining of steel, cast iron and titanium components. The development of these machining centres is the collaborative work of interdisciplinary teams, and all essential components, as well as in-house developments, are manufactured within the company. The compacer IoT solution, built on the edbic platform, is planned for future integration into BURKHARDT+WEBER machining centres. The installation of the compacer IoT gateway enables data collection from the machine's control system. In the long term, BURKHARDT+WEBER machines will offer a wide range of data that can be examined in real time to provide a detailed overview of the machine's condition and efficiency on a dashboard. The solution: An IoT hub will process the collected data, enabling a variety of assessments and ensuring that the operator is kept informed at all times. With machines connected to the compactor solution, condition monitoring is possible, paving the way for the implementation of predictive maintenance. With this approach, BURKHARDT+WEBER enables its customers to successfully implement upcoming digital transformation projects within their production processes.

Use case

Continuous monitoring

Airport, Logistics

The challenge: A leading provider of ground services and cargo handling wanted to offer comprehensive solutions to the aviation industry. To drive innovation in key areas such as service, quality and reliability, the company wanted to improve visibility and communication through integration and networking across departments. Monitoring irregularities in process flows was critical to optimizing ground handling services. Working with multiple service providers and their disparate IT systems, which varied between airports and internal departments, was a challenge, while maintaining uninterrupted operations throughout the project. The solution: This multi-stage project used edpem, a process event monitoring tool, as the primary solution for monitoring ground services. To ensure fast aircraft turnaround times, the critical path in the process flow needed to be measured and monitored, especially when processes were transferred between suppliers. edpem recorded multiple events, including parking, disembarking completion, cleaning, catering, fuelling, crew boarding and loading completion. Service Level Agreements (SLAs) were tracked and monitored, and causes of delays identified and improved. Ground handling services were optimized by assessing service duration and process flow irregularities. In addition to monitoring traditional EDI processes, visualized reports improved reporting efficiency and facilitated faster decision-making. Key results included reduced turnaround times and fewer disruptions to flight operations. Our client: A major European airport provides ground services to approximately 265 million passengers annually and manages 4.6 million tonnes of global air cargo. Several warehouses are IATA CEIV certified for pharmaceutical logistics. In 2019, its 64,000 employees operated at 300 airports in 47 countries on six continents.

Use case

Continuous monitoring

Logistics

The challenge: The pharmaceutical company works closely with logistics service providers. Due to the volatile nature of the sector's order book, it was difficult to accurately predict capacity utilization, leading to recurring problems with service providers during collection. Service providers need timely information on freight volumes, collection details and the appropriate mode of transport. A key challenge was the sharing of real-time transport data. Another key concern was tracking and tracing, which proved difficult due to incomplete integration of certain areas of the warehouse management system. In addition, real-time monitoring of internal and external departments and service providers was required to optimize logistics processes. The solution: edpem was implemented as an end-to-end monitoring solution to improve logistics processes. The monitoring covered the entire delivery process, from SAP order documents and invoices to final delivery. Connection and monitoring of the warehouse management system was also part of the scope. Comprehensive tracking of goods throughout the supply chain enabled quick retrieval of information without involving other departments, saving valuable time and resources. Optimal vehicle selection for parcel collection and product tracking by batch were achieved. Internal IT system security was ensured, as external partners could only access edpem without needing permissions for internal applications. Parcel scanning enabled customer order tracking and tracing, early problem identification and real-time notification of process owners. edpem tracked the entire shipping process from packaging to customer delivery. The automation of electronic data interchange (EDI) provided new opportunities for superior service and quality for customers and logistics providers. Our customer: A pharmaceutical company based in Germany provides "Made in Germany" products to patients worldwide, with almost all products manufactured at its headquarters in Baden-Baden and distributed through an extensive network. Its main focus is on the research and production of medicines based on natural ingredients. The company has achieved global growth and operates in 50 countries.

Use case

Remote Monitoring & Control

Remote Asset Monitoring, Remote Control, IIOT, IOT, Data Logging, Remote Terminal Unit, Process Control, Machine Control

Cellcon series of IoT Controllers are targeted towards Remote Monitoring & Control applications across various industries. They integrate HMI, Control, Data Logging & IOT Functionality and ideal for Asset Monitoring, Remote Control, Remote Data Acquisition and Logging applications. We provide complete Firmware and Cloud Application Development support for this product.

Use case

Thickness measurement of metal products

steel, metal, aluminium, aluminum, copper

Our radar sensor solution determines the thickness and the thickness profile of steel plates, steel strips or steel slabs (up to 1600 °C hot) with an accuracy of up to ±10 µm on the roller conveyor. Thanks to robust radar technology, sophisticated signal processing and intelligent radar algorithms, OndoSense radar sensors achieve this high level of precision in thickness measurement even under the difficult production conditions of the steel industry with smoke, steam, dirt, vibrations, fire and extreme temperatures.

The Condition Monitoring industry in Turkey presents unique opportunities and challenges that potential entrants should consider. First, understanding local regulations and standards is crucial, as Turkey has specific compliance requirements for industrial operations, particularly in sectors like manufacturing and energy. The increasing emphasis on predictive maintenance and asset management drives demand for condition monitoring technologies, creating a favorable market environment. However, the industry faces challenges such as a lack of skilled workforce and varying levels of technology adoption among different sectors, which can impact operational efficiency. Opportunities also arise from Turkey's strategic location as a bridge between Europe and Asia, facilitating access to international markets. The growing awareness of environmental sustainability and industry 4.0 further enhances the relevance of condition monitoring solutions, as companies seek to reduce downtime and improve energy efficiency. Analyzing the competitive landscape reveals a mix of local and international players, each offering various products and services. Keeping an eye on technological advancements, such as IoT and AI integration, will be essential for businesses aiming to stay ahead. Overall, potential investors or companies interested in this industry should conduct thorough market research and consider these factors to navigate the Turkish condition monitoring landscape successfully.

Some interesting numbers and facts about your company results for Condition Monitoring

| Country with most fitting companies | Turkey |

| Amount of fitting manufacturers | 33 |

| Amount of suitable service providers | 25 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1999 |

| Youngest suiting company | 2018 |

Some interesting questions that has been asked about the results you have just received for Condition Monitoring

What are related technologies to Condition Monitoring?

Based on our calculations related technologies to Condition Monitoring are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Condition Monitoring?

The most represented industries which are working in Condition Monitoring are IT, Software and Services, Oil, Energy and Gas, Manufacturing, Automation, Electronics and Electrical engineering

How does ensun find these Condition Monitoring Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.