The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

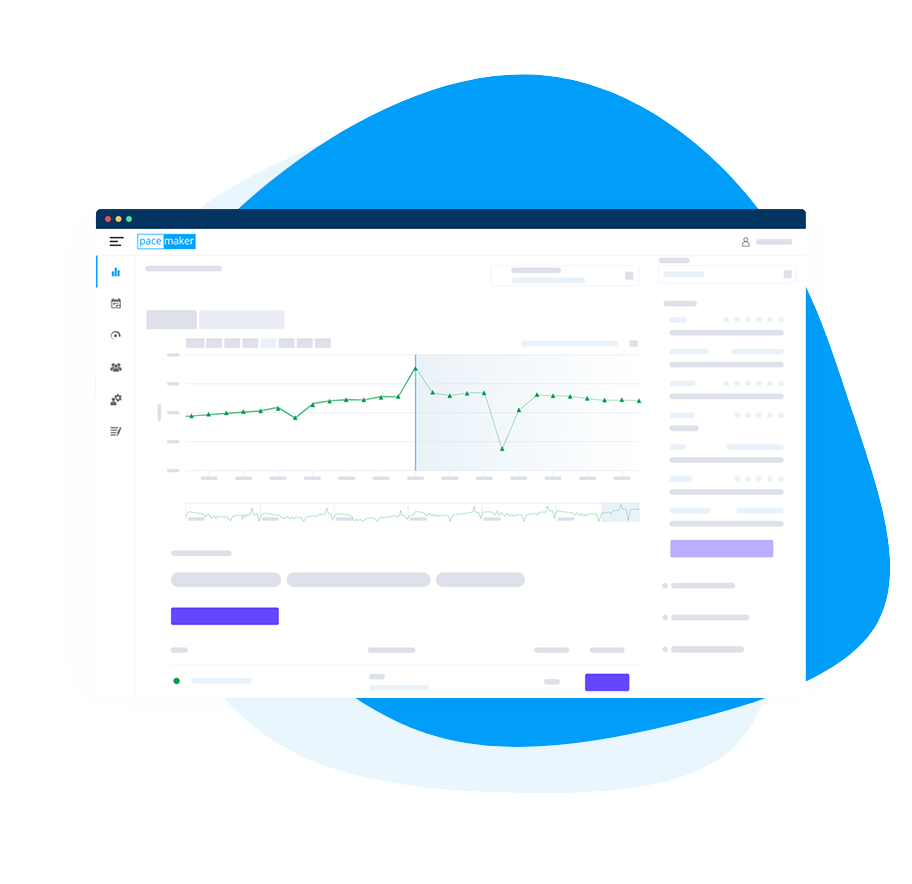

pacemaker.ai

Münster, Germany

A

11-50 Employees

2022

Key takeaway

The company's goal is to automate demand forecasting and achieve high precision in predictions. By leveraging machine learning technology from pacemaker.ai, they significantly enhance the accuracy of demand forecasts, optimize planning processes, and promote sustainable growth.

Reference

Service

Demand Forecasting

Our AI-supported forecasts help you to reduce stock shortages and overstocks so that sales losses are avoided. pacemaker.ai optimises and automates your forecasts using state-of-the-art machine learning algorithms. Our demand forecasting software provides you with highly accurate forecasts with over 90% accuracy in your desired system or as a .csv export. Our demand forecasting uses historical sales data, and factors from external influencing factors and predicts future demand so that you can make better data-based decisions along your supply chain and to forecast inventory, staffing requirements, and more. Our products can lead to over 30% more efficiency along the supply chain thanks to 1000+ external influencing factors in our DataHub. Benefit from fully automated, reliable forecasts and understand which factors have a lasting impact on your results. Create insightful what-if-analyses by calculating the effects of changes in influencing factors. Integrate upcoming events and promotions, such as discounts, seasons, promotional campaigns, or major events. Find out immediately about potential changes in your forecasts. Our Horizons module takes into account fluctuations in the supply chain. We can bring you to AI-powered in 6 weeks, starting with an initial consultation, moving to a data thinking workshop and then finally the onboarding.

Westphalia DataLab

Münster, Germany

A

51-100 Employees

2017

Key takeaway

The company offers a demand forecasting solution that utilizes artificial intelligence to analyze historical sales data and external factors, enabling accurate predictions of future demand. This capability helps businesses make informed, data-driven decisions for a more efficient and sustainable supply chain.

Reference

Core business

AI-based solutions for your supply chain

Our award winning AI solution collects, organizes, and analyzes supply chain data to accurately forecast future demand and enable data-driven decisions.

Forecast

United States

B

1-10 Employees

2005

Key takeaway

Forecast, Inc. specializes in demand forecasting by providing clients with advanced tools for data intelligence and capacity planning. Their extensive experience and strong relationships with key industry players enhance their ability to tailor solutions to specific forecasting needs.

Reference

Core business

Forecast, Inc. | Learn more about Forecast, Inc.'s services.

Forecast, Inc. was founded in 2005 and has experience with dozens of communities and airports throughout the world. Our Business is Anticipating Yours

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

FORECAST SOLUTIONS PLANNING LIMITED

Stockport, United Kingdom

A

1-10 Employees

-

Key takeaway

Forecast Solutions specializes in demand planning and forecasting, offering a range of services that include statistical analysis and training courses designed to enhance understanding of forecasting principles and methods. Their expertise in building forecasting solutions in Excel and focus on practical training makes them well-equipped to support businesses in effective demand forecasting.

Reference

Core business

Sales Forecasting Solutions Demand Planning Services

ForecastWatch

Dublin, United States

B

11-50 Employees

2003

Key takeaway

ForecastWatch, a leading weather forecast monitoring company, provides innovative atmospheric analytics software and services that enhance decision-making for various industries affected by weather. Their focus on forecast accuracy analytics helps organizations evaluate their own forecasts, ultimately impacting revenue and risk mitigation.

Reference

Service

Services – ForecastWatch

ShipmentBot

Kirkland, United States

B

1-10 Employees

-

Key takeaway

ShipmentBot utilizes various forecasting methods to deliver insights that simplify decision-making, ensuring your inventory remains in stock through its advanced forecasting and sales algorithms.

Reference

Product

Battle-Tested: ML Forecasting | ShipmentBot.com

Dataviva

Atlanta, United States

B

11-50 Employees

2020

Key takeaway

Dataviva offers a robust suite of demand forecasting tools specifically designed for retailers, featuring a demand-pattern recognition engine that ensures reliable forecasts for any product, channel, or location. With advanced AI algorithms and seamless integration, Dataviva enhances planning decisions and addresses complex forecasting challenges effectively.

Reference

Product

Demand Forecasting - Dataviva | Dataviva | Next-Gen Retail Planning

A powerful suite of Demand Forecasting tools built for retailers and with retailers that is built specifically for the toughest retail forecasting problems. Our demand-pattern recognition engine guarantees reliable forecasts for any product, channel or location, regardless of its demand history.

Fuse Inventory

Los Angeles, United States

B

1-10 Employees

2016

Key takeaway

Fuse utilizes advanced predictive demand forecasting algorithms that consider various factors such as sales trends, seasonality, and marketing efforts, enabling businesses to optimize inventory and enhance performance against goals.

Reference

Core business

About

Fuse pulls data from every step in your supply chain to generate demand forecasts, sales reports, PO recommendations, and more.

Hakio

Aarhus, Denmark

A

11-50 Employees

2022

Key takeaway

Hakio's advanced algorithms utilize real-time data to provide accurate demand forecasting, helping retailers anticipate trends and manage inventory effectively. This capability reduces excess stock and prevents stockouts, ultimately streamlining processes and enhancing product availability.

Reference

Core business

#1 Demand forecasting software for fashion retailers | Hakio

Make well-informed decisions, and transform uncertainty into your strategic advantage with AI-powered forecasts.

Demand & Supply Planning

Paris, France

A

1-10 Employees

2005

Key takeaway

The company specializes in demand forecasting through its training for SAP IBP courses, highlighting the use of statistical methods to estimate demand effectively. Their expertise in demand and supply planning can help sales representatives and supply chain professionals enhance their forecasting practices.

Reference

Core business

Fastprod - Demand Forecasting

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Demand Forecasting

Go to product

Service

GoFact Cloud Based Portal

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Forecasting methodology in the insulation material industry through AI integration

Dämmaterial, Dämmaterial Industrie, Insulation Material, insulation material industry, supplier, construction, construction industry

In the complex industrial landscape of insulation materials, in which multiple market segments and diverse product lines coexist, precise forecasting and strategic planning based on this is essential. For a multinational manufacturer in this sector, forecasting plays a critical role, as it is the basis for budget distribution across the various departments. Previous forecasting methods relied on manual calculations and the use of Excel-based solutions, which often only work with simple averages. This high level of manual and personnel effort not only limited the accuracy of the forecasts, but also their timeliness and frequency. The forecasting methods were also vulnerable to unpredictable market changes, which often led to delays in the supply chain. The introduction of an AI-based forecasting tool marked a turning point for the manufacturer. This advanced tool not only uses internal historical data, but also integrates external influencing factors such as special calendar events, past and future expected inflation indices and building permits into its analyses. As a result of this comprehensive data integration, the accuracy of forecasts was significantly increased to 91.4%.The increased forecast accuracy led to numerous positive effects on operations. A more reliable forecast enabled a more efficient and targeted budget allocation, which made it possible to achieve significant cost savings. Improved predictability and speed of response to market changes also contributed to a reduction in delivery times. The implementation of AI technology thus strengthened operational safety and sustainably improved the company's competitiveness.By using innovative AI technologies in forecasting practice, the insulation material manufacturer was not only able to optimize its processes, but also make it more adaptive and resilient to market fluctuations. This case study impressively demonstrates how technological advances can be used specifically to solve specific industry-specific challenges in order to promote operational efficiency and economic stability.

Use case

Aerospace supply chain planning

Aerospace, industrial, industry, supply chain, aerospace industry, supplier

Customers from various industrial sectors, including original equipment and the aftermarket, are facing similar challenges. A specific example of this is a supplier to leading aerospace companies. It must predict the developments of over 4,000 material types in various market segments. For one of its main end customers, the planning processes were previously carried out manually and exclusively using Excel. In the past, this method of planning led to inaccurate results, which in turn led to both inventory shortages and excessive inventories. To overcome these challenges, pacemaker.ai provides a solution that provides automated, regularly updated forecasts. These forecasts serve as a basis for replenishment planning and help to precisely define the quantities to be purchased at the level of individual products.The planning is based on a forecast period of 18 months, during which the delivered materials are carefully reviewed. An important feature of the pacemaker.ai solution is the implementation of a five-level grouping structure. Within this structure, Cluster A materials are given priority, with a total of 215 articles being prioritized based on ABC/XYZ analysis.The current accuracy of pacemaker.ai's predictions is over 80%. Continuously refining and adjusting these forecasts is a key part of pacemaker.ai's commitment. This shows the company's efforts to constantly optimize its customers' supply chains and maximize their efficiency through innovative approaches in data analysis and machine learning.The integration of advanced, data-driven forecasting tools such as those from pacemaker.ai can significantly help solve traditional supply chain planning problems. The use of automated systems not only improves the accuracy and efficiency of inventory management, but also prevents costly overstocks and shortages. This represents enormous added value for suppliers in highly dynamic industries such as aerospace.

Use case

Revolutionizing sales forecasting in the filter industry with AI-based solutions

filter industry, oil filters, air filters, automotive industry, automotive, filter, filters, filter supplier, suppliers, supplier

A leading supplier in the automotive industry faced significant difficulties in predicting monthly sales of oil and air filters for the B2B market in Europe, Russia and the UK. The volatility of the “call-off” data for these products was exceptionally high and showed fluctuations of up to 80%. The previous forecasting methods were based primarily on manual calculations by a team of four employees. This approach often led to inaccuracies, particularly for products with low sales volumes, which in turn was offset by high inventories. These inventories represented a significant capital commitment of billions. With these challenges in mind, the company turned to pacemaker.ai, a specialist in AI-powered forecasting technologies. Pacemaker.ai developed an advanced machine learning system that was specifically configured for the supplier's needs. This system integrated not only historical sales data, but also industry-specific influencing factors such as motor vehicle registrations, pollen count data and air pollution indices into the analysis. The introduction of the automated demand forecasting solution fundamentally transformed the company's sales forecasting. The forecast accuracy was significantly increased, which led to a reduction in forecast error of an impressive 41%. This improvement extended across a portfolio of 2000 products. In addition, manual planning effort was significantly reduced, which enabled employees to focus on more strategic tasks.Automation and increased accuracy of sales forecasts enabled the company to manage its inventory more efficiently and free up capital that had previously been tied up in oversized inventory volumes. These resources can now be invested in innovative projects and the further development of the product range. The success of this project demonstrates the potential of AI-based technologies to transform and sustainably improve traditional business processes.

Use case

Optimizing logistics planning through AI-driven forecasting technology

logistics, warehouse, tire, tires, logistics planning, warehouse opeations, delivery

Every year, our customer is faced with the daunting task of managing logistics for the delivery of millions of tires. Efficient planning of personnel and other resources necessary for warehouse operation requires extremely precise forecasts of the expected output quantities of goods. The previous method, based on monthly forecasts from the client, required extensive manual entries in Excel spreadsheets. These were supplemented with our own assessments in order to create a useful planning basis. However, the high expenditure of time and the poor quality of forecasts led to customer dissatisfaction. To address these challenges, pacemaker.ai has developed a tailor-made solution that not only improves the accuracy of forecasts but also significantly simplifies the planning process. By implementing advanced forecasting methods that forecast daily and weekly output volumes for each coming month, the forecast error was reduced by an impressive 18%.Integration of relevant influencing factorsThe new forecasting method uses a variety of data sources, including historical sales data as well as information on holidays, holidays, weather conditions and seasonal fluctuations. These factors play a decisive role in predicting output quantities and contribute to further increasing accuracy.Automation and increased efficiencyThe daily and automatically updated forecasts are made available to the customer, which reduces manual effort to a minimum. This increase in efficiency enables customers to better plan resources and react more quickly to changes in demand.Future prospects and further plansBy using this innovative technology, our customer was able to strengthen its position in the highly competitive logistics market. The successes of the new forecasting methods motivate further exploration of additional uses of AI in other areas of the company. Overall, this case clearly shows how the use of artificial intelligence and machine learning in logistics planning not only improves forecast accuracy, but can also significantly increase operational efficiency.

Use case

Automobile manufacturer predicts sales of over 500,000 items

automotive, automobile, automobile manufacturing, automotive industry, car, car industry

A leading German automotive manufacturer was confronted with fluctuating demand in its after-sales business and was increasingly dissatisfied with the previous approach to predicting these developments. In search of an improved solution, the company decided to implement pacemaker.ai, a provider of transparent forecasting technologies.The forecasting method used up to that point was developed internally and was based primarily on trend analyses. However, this method had recently lost accuracy. An additional problem was that the expertise required to carry out and adjust forecasts was largely concentrated with just one person in the company, increasing the risk of loss of knowledge and dependency.The transition to pacemaker.ai offered a solution that not only improved forecasting quality, but also more broadly distributed knowledge of predictive methods within the company and thus made it less susceptible to staffing bottlenecks. As a result of this strategic change, the automotive manufacturer was able to create a more robust and transparent planning basis, which ultimately led to more efficient management of the after-sales area. pacemaker.ai has developed a comprehensive forecasting system for a manufacturer that includes both long-term and short-term forecasts for around 500,000 SKUs. The long-term forecasts are designed to help the original equipment manufacturer (OEM) plan product life cycles. These forecasts cover a period of 15 years and are therefore particularly valuable for strategic decisions and long-term planning processes.In parallel, the short-term forecast provides the OEM with operational and medium-term planning support. These forecasts cover a period of two years and provide monthly forecasts that enable the company to respond flexibly to market demands and production conditions.It is noteworthy that all forecasts created by Pacemaker.ai have significantly exceeded the expected accuracy values. This underscores the effectiveness and reliability of the predictive methods and technologies used by Pacemaker.ai. By integrating these precise forecasting solutions, the OEM can not only optimally allocate its resources, but also strengthen its market position through efficient and targeted production planning.

Use case

Optimizing inventory planning in the automotive supplier industry

automotive supplier, automotive supplier industry, supplier, automobile supplier

The customer, who works as an original equipment manufacturer in the automotive industry, also offers automotive parts on the aftermarket. The planning challenges for this customer are complex. On the one hand, incomplete time series due to newly introduced products make forecast accuracy difficult. On the other hand, the highly volatile ordering behavior of OEMs (original equipment manufacturers) leads to further complications. These factors make reliable planning increasingly difficult.In the customer's previous approach, planning was carried out by regularly, manually importing data into a central Excel spreadsheet. However, this method proved to be time-consuming and inefficient. The forecasts created in Excel were often inaccurate and only available at a very rough level of aggregation. These inaccuracies in turn had negative effects on warehousing. There were often both excess inventory, which caused unnecessary costs, and out-of-stock situations, which led to supply bottlenecks and potentially lost sales.The need to optimize this planning process is obvious. A more efficient and accurate method could not only save time, but also improve the accuracy of forecasts and optimize inventory levels to minimize both overstocks and shortages. pacemaker.ai has developed tailor-made forecasts for the customer, which meet the various requirements and range from model series to SKU (stock keeping unit) level. These forecasts are structured through various filter levels, which include plants, production lines and material types.pacemaker.ai's predictions are configured to be made on a monthly basis. The accuracy of these forecasts varies depending on the level of aggregation, with the prediction accuracy exceeding 85% in some cases and as much as 95% in others. This high level of precision in forecasts enables customers to make more efficient and precise planning and decisions in the production process.

Use case

Optimizing supply chain management through precise forecasting models in the textile industry

textile, textile industry, fashion, retail sector, retail logistics, logistics services, textile logistics

A well-known logistics service provider, which works exclusively for a leading fashion company in the textile retail sector, is facing significant challenges. The company employs around 1000 people who service eight distribution centers in Germany and Austria. The main problem currently lies in the highly fluctuating incoming goods caused by suppliers. These irregularities lead to inaccuracies in forecasting and significantly impair predictability. In particular, the lack of delivery reliability on the part of suppliers makes efficient process planning in the logistics center difficult. In order to improve the reliability of forecasts and enable more effective planning, a detailed evaluation of suppliers was first carried out with regard to their delivery reliability. This made it possible to model expected schedule accuracy and corresponding delivery time windows specifically for each supplier. In addition, additional variables such as vacation periods, public holidays and inventory periods were included in the models. By integrating these factors into an advanced machine learning model, the customer was not only able to increase predictive accuracy, but also optimize personnel planning and the use of warehouse capacities. The model also supports smarter management of supplier relationships by allowing early adjustments in delivery plans to prevent bottlenecks and increase efficiency. The introduction of this technology has enabled the logistics company to make its operations much more agile and responsive. With improved forecast accuracy and optimized resource allocation, the company is now able to react more flexibly to market changes and increase customer satisfaction through timely deliveries. In light of these successes, the company plans to expand the application of machine learning models to other areas of its supply chain in order to effectively master future challenges.

Use case

Optimizing manual processes to more automation

Fashion Retail, Retail

Software for Lifestyle Brands and Retailers. Better insights, bigger output. GoFact is designed for lifestyle brands and retailers. As such, we're part of the lifestyle business. We're a design studio doing software. GoFact is software that supplies and organizes analytics from every point of sale – without Excel sheets and endless emailing – and transforms them into insights you can act on.

Use case

Forecasting methodology in the insulation material industry through AI integration

Dämmaterial, Dämmaterial Industrie, Insulation Material, insulation material industry, supplier, construction, construction industry

In the complex industrial landscape of insulation materials, in which multiple market segments and diverse product lines coexist, precise forecasting and strategic planning based on this is essential. For a multinational manufacturer in this sector, forecasting plays a critical role, as it is the basis for budget distribution across the various departments. Previous forecasting methods relied on manual calculations and the use of Excel-based solutions, which often only work with simple averages. This high level of manual and personnel effort not only limited the accuracy of the forecasts, but also their timeliness and frequency. The forecasting methods were also vulnerable to unpredictable market changes, which often led to delays in the supply chain. The introduction of an AI-based forecasting tool marked a turning point for the manufacturer. This advanced tool not only uses internal historical data, but also integrates external influencing factors such as special calendar events, past and future expected inflation indices and building permits into its analyses. As a result of this comprehensive data integration, the accuracy of forecasts was significantly increased to 91.4%.The increased forecast accuracy led to numerous positive effects on operations. A more reliable forecast enabled a more efficient and targeted budget allocation, which made it possible to achieve significant cost savings. Improved predictability and speed of response to market changes also contributed to a reduction in delivery times. The implementation of AI technology thus strengthened operational safety and sustainably improved the company's competitiveness.By using innovative AI technologies in forecasting practice, the insulation material manufacturer was not only able to optimize its processes, but also make it more adaptive and resilient to market fluctuations. This case study impressively demonstrates how technological advances can be used specifically to solve specific industry-specific challenges in order to promote operational efficiency and economic stability.

Demand forecasting involves predicting future customer demand for products or services based on historical data, market trends, and various influencing factors. This analytical process helps businesses optimize inventory levels, manage supply chains effectively, and align production schedules with expected demand. Accurate demand forecasting relies on statistical models and advanced algorithms that analyze patterns in sales data, seasonality, and external influences such as economic conditions or consumer behavior. By leveraging these insights, companies can make informed decisions, reduce costs, and improve customer satisfaction through timely product availability.

Demand forecasting enhances supply chain efficiency by accurately predicting customer demand for products. This accuracy allows businesses to optimize inventory levels, reducing excess stock and minimizing stockouts. When companies understand future demand patterns, they can better align production schedules and distribution strategies, resulting in smoother operations and lower operational costs. Additionally, effective demand forecasting leads to improved collaboration among supply chain partners. Sharing accurate forecasts enables suppliers and manufacturers to adjust their processes and resources accordingly. This synchronization reduces lead times and enhances responsiveness to market changes, ultimately driving overall supply chain performance and customer satisfaction.

In the realm of demand forecasting, several key methods are employed to enhance accuracy and efficiency.

1. Quantitative Methods

These methods rely on historical data and statistical techniques. Time series analysis, regression analysis, and econometric models fall under this category. They utilize past sales data to identify trends and patterns, thus predicting future demand.

2. Qualitative Methods

Qualitative forecasting incorporates expert opinions, market research, and consumer insights. Techniques such as focus groups, surveys, and the Delphi method are common. These approaches are particularly useful when data is scarce or when launching new products, as they capture subjective factors influencing demand.

Employing a combination of these methods often yields the best results, allowing organizations to navigate market uncertainties effectively.

Effective demand forecasting is crucial for businesses as it helps them anticipate customer needs and adjust their operations accordingly. By accurately predicting future demand, companies can optimize inventory levels, reducing the risk of overstocking or stockouts. This leads to improved cash flow management and enhanced customer satisfaction, as products are available when needed. Additionally, demand forecasting supports strategic planning and resource allocation, enabling businesses to make informed decisions about production, staffing, and budgeting. With the right insights, companies can also identify market trends and adapt their offerings, ensuring they remain competitive in a dynamic marketplace.

Technology significantly enhances the accuracy of demand forecasting through advanced data analytics and machine learning algorithms. By leveraging large datasets, companies can analyze historical sales patterns, market trends, and consumer behavior more effectively. These technologies enable the identification of complex patterns that traditional methods may overlook. Moreover, real-time data integration from various sources, such as social media and point-of-sale systems, allows for a more dynamic and responsive forecasting process. This adaptability ensures that forecasts are continually refined, leading to improved accuracy. Additionally, cloud-based solutions facilitate collaboration and data sharing across departments, further enhancing the reliability of demand forecasting efforts.

Some interesting numbers and facts about your company results for Demand Forecasting

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 7948 |

| Amount of suitable service providers | 7745 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 2003 |

| Youngest suiting company | 2022 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Demand Forecasting

What are related technologies to Demand Forecasting?

Based on our calculations related technologies to Demand Forecasting are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Who are Start-Ups in the field of Demand Forecasting?

Start-Ups who are working in Demand Forecasting are pacemaker.ai, Hakio

Which industries are mostly working on Demand Forecasting?

The most represented industries which are working in Demand Forecasting are IT, Software and Services, Logistics, Supply Chain and Transportation, Other, Consulting, Marketing Services

How does ensun find these Demand Forecasting Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.