The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Control Southern

Suwanee, United States

B

51-100 Employees

1956

Key takeaway

Control Southern is a leading provider of automation and process control solutions in the Southeast, with a focus on improving operational reliability and performance. Their expertise includes SCADA systems, which are essential for enhancing the efficiency and safety of manufacturing plants.

Reference

Product

SCADA Systems

DAQ Electronics

Parsippany-Troy Hills, United States

B

51-100 Employees

1975

Key takeaway

DAQ Electronics specializes in the automation of complex processes for SCADA (Supervisory Control and Data Acquisition) applications, emphasizing user-friendly configuration and interoperability. With a history of over 45 years, DAQ has pioneered distributed processing for SCADA, providing advanced remote terminal units (RTUs) that enhance power monitoring and distribution for electric utilities.

Reference

Product

SCADA - DAQ Electronics - Integrated Solutions for Security and SCADA

Control Associates, Inc.

Allendale, United States

B

101-250 Employees

1933

Key takeaway

Control Associates, in collaboration with Emerson, focuses on designing and implementing real-time digital transformation solutions that enhance decision-making and operational efficiency. Their approach includes the integration of SCADA systems, which are essential for providing real-time access to actionable information, thereby improving business agility in response to market changes and supply chain disruptions.

Reference

Product

SCADA Systems

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Northeast Controls Inc

Town of Clifton Park, United States

B

51-100 Employees

1967

Key takeaway

NECI specializes in industrial automation and digital transformation, offering solutions that address process and data integration challenges across various industries, including power and manufacturing. Their expertise in SCADA systems enhances their ability to deliver integrated solutions that improve efficiency and optimize resources.

Reference

Product

SCADA Systems

Proconex

Royersford, United States

B

251-500 Employees

1948

Key takeaway

Proconex offers a comprehensive range of Process Automation Control Systems and related technologies, highlighting their expertise in SCADA systems. As a leading provider in the Mid-Atlantic region and an exclusive Emerson Impact Partner, Proconex connects customers with advanced automation solutions tailored for various industries.

Reference

Product

SCADA Systems

Cornerstone Controls

Cincinnati, United States

B

101-250 Employees

1935

Key takeaway

Cornerstone Controls offers extensive experience in automation solutions, which includes Supervisory Control Data Acquisition (SCADA) Systems, highlighting their commitment to enhancing customer business results through reliable and professional services. As an Emerson Impact Partner, they provide a centralized point for sales and applied engineering in this domain.

Reference

Product

SCADA Systems

Novaspect

Schaumburg, United States

B

251-500 Employees

1936

Key takeaway

Novaspect is dedicated to enhancing customer performance through innovative technology applications, including SCADA systems. Their commitment to effective processes and local services positions them as a valuable partner in the process control industry.

Reference

Product

SCADA Systems

Dorsett Controls

Yadkinville, United States

B

51-100 Employees

1956

Key takeaway

The company offers intelligent SCADA systems designed for various applications, ensuring reliability and efficiency through their custom-built hardware and software. Their SCADA IO Universal Controller is particularly highlighted as a flexible and reliable solution for remote applications.

Reference

Product

SCADA IO Universal Controller | Dorsett Controls

The SCADA IO is a flexible and reliable controller built for remote applications and well-equipped for use with solar or battery-backed power.

Lakeside Process Controls

Mississauga, Canada

A

251-500 Employees

1952

Key takeaway

Lakeside is a Canadian employee-owned company that has been providing innovative automation solutions since 1952, including Supervisory Control Data Acquisition (SCADA) systems. As a recognized market leader and a member of the Emerson Impact Partner Network, Lakeside optimizes process efficiency and ensures reliability and safety across various industries.

Reference

Product

SCADA Systems

Experitec, Inc.

Prairie Village, United States

B

11-50 Employees

-

Key takeaway

Experitec is dedicated to enhancing the performance and reliability of industrial operations, which aligns with the objectives of a Supervisory Control Data Acquisition (SCADA) system. Their commitment to innovative solutions and deep understanding of customer needs positions them as a valuable partner for those seeking to implement or improve their SCADA systems.

Reference

Product

SCADA Systems

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

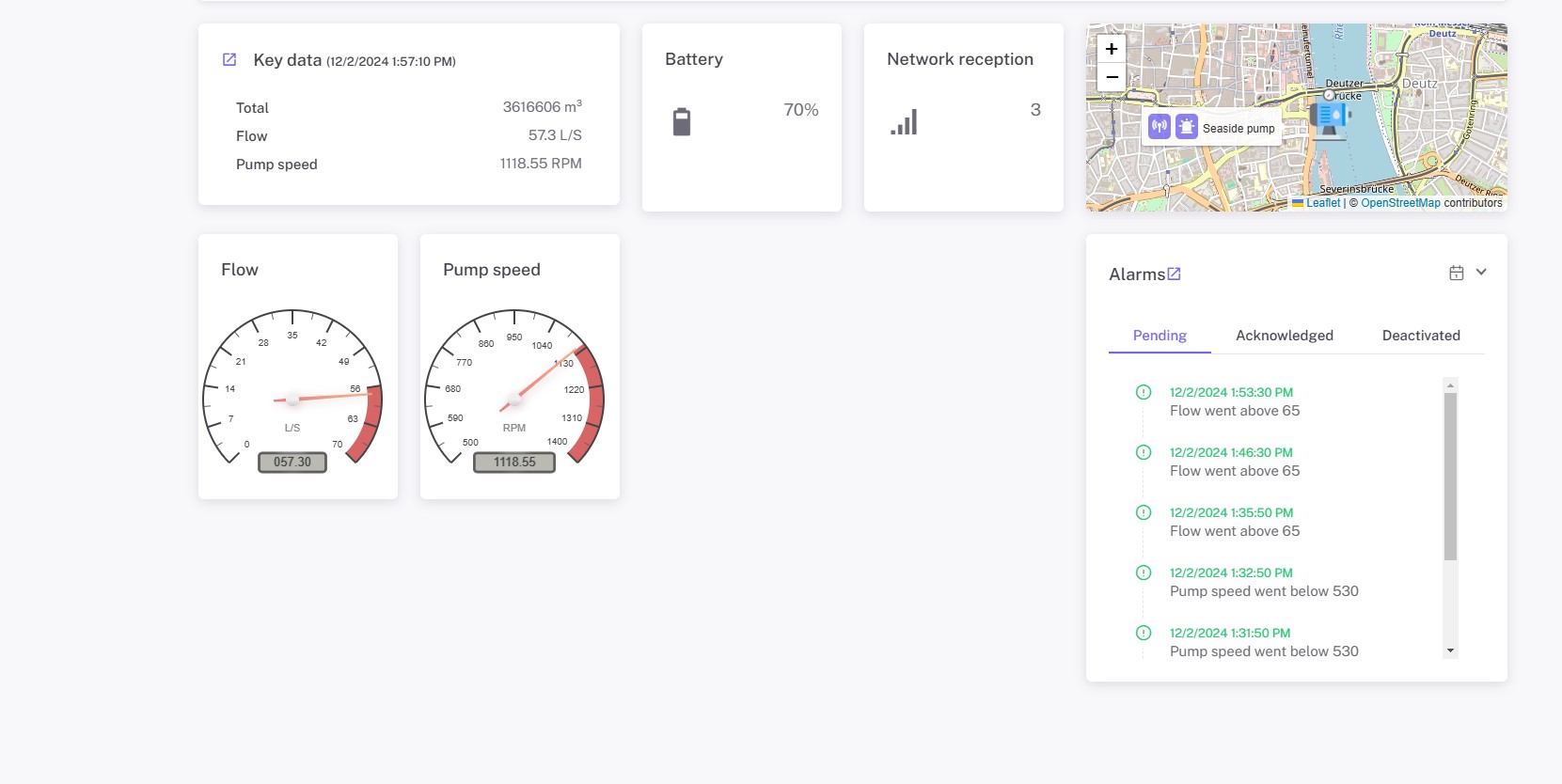

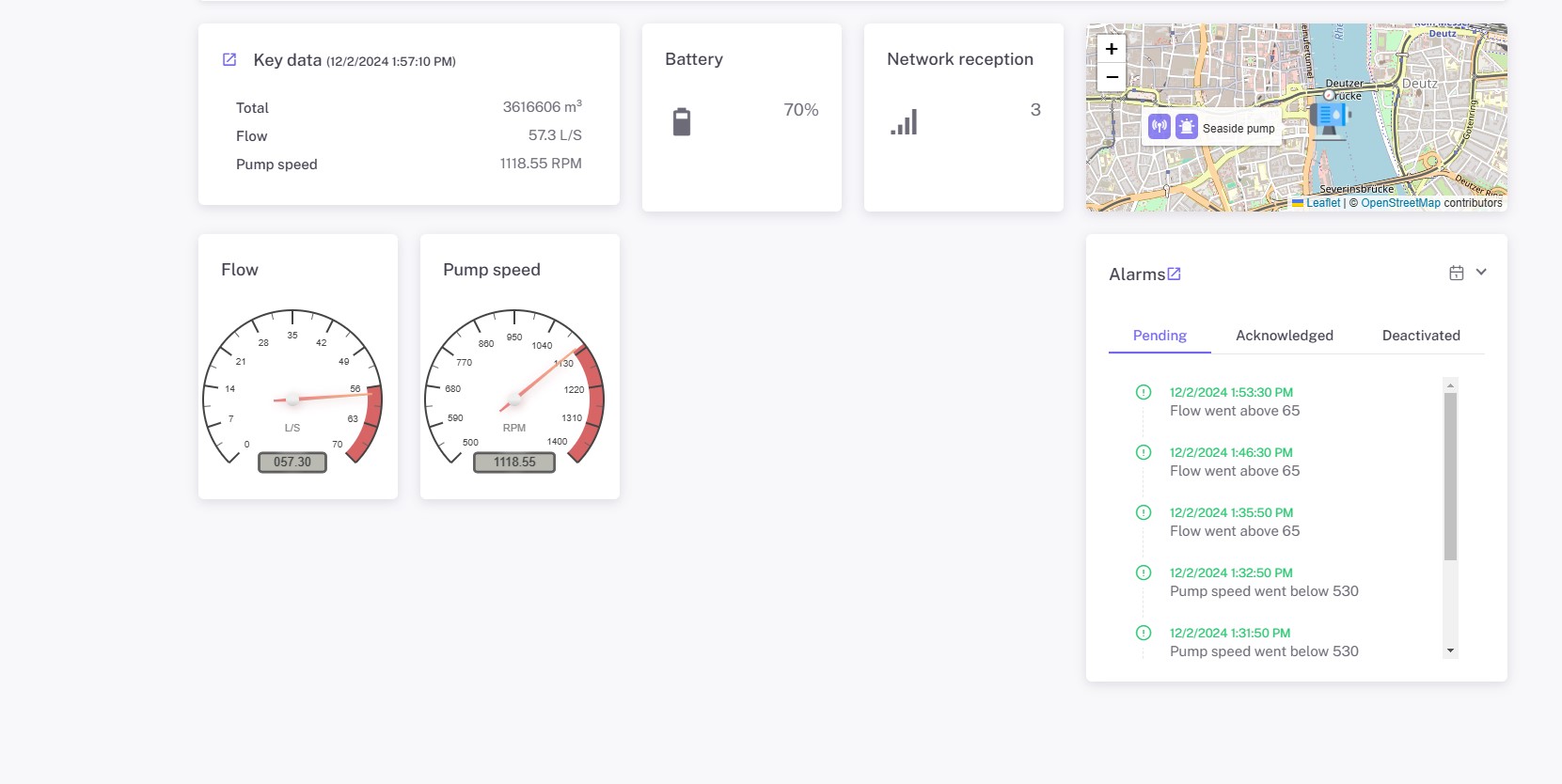

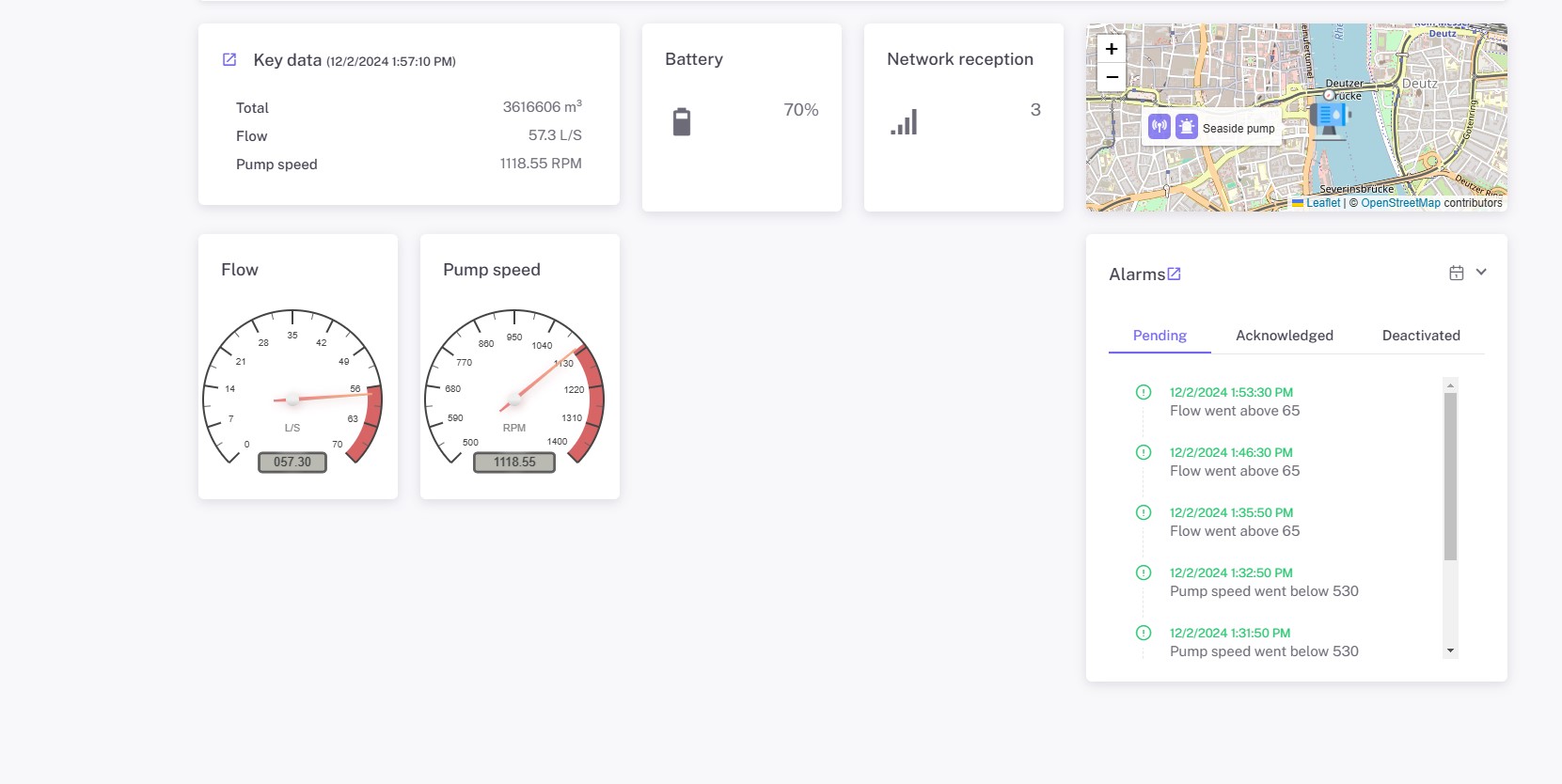

Web-Based Monitoring System for Fluids

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Real time water usage/treatment monitoring

Water treatment, Waste water, Water utilities, Water processing industries

Web-Based Monitoring System for Fluids Nexon Data's cutting-edge web-based monitoring system is designed specifically to meet the demands of fluid management and control. This versatile platform provides a comprehensive suite of tools to ensure efficient and reliable monitoring, including: Interactive Dashboard: A user-friendly interface offering a centralized view of key metrics and system status. Real-Time Mapping: A dynamic map that displays the locations of monitored assets, allowing instant visualization and easy navigation. Charts & Gauges: Detailed visualizations for critical parameters such as flow rates, pressure, and levels, enabling quick and accurate data interpretation. Alarm System: A robust alert mechanism that notifies users of anomalies or critical events, ensuring swift response to potential issues. Protocol Flexibility: The system supports a wide range of industrial communication protocols, such as Modbus (RTU/TCP), OPC UA, BACnet, MQTT, and PROFINET, enabling seamless integration with various PLCs, sensors, and IoT devices Mobile Applications: The upcoming Android and iOS applications are designed to provide on-the-go access to system insights, notifications, and controls. Users will benefit from: - Real-Time Updates: Access live data and alarms directly from mobile devices. - Push Notifications: Instant alerts for critical events, ensuring swift action anytime, anywhere. - Optimized UI: A sleek and intuitive interface tailored for mobile screens to ensure a seamless experience. With its focus on intuitive design, advanced functionality, and cross-platform accessibility, this system empowers users to optimize fluid management processes, enhance operational efficiency, and minimize downtime. Tailored for industries like water, chemical, and manufacturing, this solution delivers precision and reliability, whether accessed via web or mobile.

Use case

Real time water usage/treatment monitoring

Water treatment, Waste water, Water utilities, Water processing industries

Web-Based Monitoring System for Fluids Nexon Data's cutting-edge web-based monitoring system is designed specifically to meet the demands of fluid management and control. This versatile platform provides a comprehensive suite of tools to ensure efficient and reliable monitoring, including: Interactive Dashboard: A user-friendly interface offering a centralized view of key metrics and system status. Real-Time Mapping: A dynamic map that displays the locations of monitored assets, allowing instant visualization and easy navigation. Charts & Gauges: Detailed visualizations for critical parameters such as flow rates, pressure, and levels, enabling quick and accurate data interpretation. Alarm System: A robust alert mechanism that notifies users of anomalies or critical events, ensuring swift response to potential issues. Protocol Flexibility: The system supports a wide range of industrial communication protocols, such as Modbus (RTU/TCP), OPC UA, BACnet, MQTT, and PROFINET, enabling seamless integration with various PLCs, sensors, and IoT devices Mobile Applications: The upcoming Android and iOS applications are designed to provide on-the-go access to system insights, notifications, and controls. Users will benefit from: - Real-Time Updates: Access live data and alarms directly from mobile devices. - Push Notifications: Instant alerts for critical events, ensuring swift action anytime, anywhere. - Optimized UI: A sleek and intuitive interface tailored for mobile screens to ensure a seamless experience. With its focus on intuitive design, advanced functionality, and cross-platform accessibility, this system empowers users to optimize fluid management processes, enhance operational efficiency, and minimize downtime. Tailored for industries like water, chemical, and manufacturing, this solution delivers precision and reliability, whether accessed via web or mobile.

A Supervisory Control Data Acquisition (SCADA) System is a crucial technology used for monitoring and controlling industrial processes. It allows operators to gather real-time data from remote locations, which facilitates efficient management of operations such as electricity generation, water treatment, and manufacturing. With a SCADA system, users can visualize data through graphical interfaces, enabling them to make informed decisions quickly. SCADA systems typically comprise hardware components like sensors and control units, along with software applications that process and display the collected data. This integration helps in identifying issues, optimizing performance, and ensuring safety in various industrial environments. Overall, SCADA systems play a vital role in enhancing operational efficiency and reliability in critical infrastructure sectors.

A SCADA system operates by collecting real-time data from various sensors and devices located throughout an industrial facility. This data is transmitted to a central control system, where it is processed and visualized for operators. The system allows for monitoring and control of equipment such as pumps, valves, and motors, facilitating efficient management of processes. In industrial applications, SCADA systems utilize a combination of hardware and software components. The hardware includes remote terminal units (RTUs) and programmable logic controllers (PLCs), which gather data and send it to a human-machine interface (HMI). The HMI provides operators with a graphical representation of the system, enabling them to make informed decisions and respond quickly to any anomalies or operational changes. This real-time monitoring enhances productivity, safety, and reliability in industrial environments.

1. Human-Machine Interface (HMI)

The HMI is the user interface that allows operators to interact with the SCADA system. It displays data visually, enabling users to monitor and control processes effectively.

2. Supervisory System

This component is responsible for gathering data from field devices and sending commands to those devices. It processes the information and makes it available for analysis and decision-making.

3. Remote Terminal Units (RTUs)

RTUs are hardware devices located in the field that collect data from sensors and transmit it back to the supervisory system. They play a vital role in remote monitoring and control.

4. Programmable Logic Controllers (PLCs)

PLCs are used to automate processes and control machinery. They can be integrated into a SCADA system to provide real-time data and control capabilities.

5. Communication Infrastructure

This includes the networks and protocols that facilitate the transfer of data between the various components of the SCADA system. Reliable communication is essential for effective monitoring and control.

1. Enhanced Monitoring

Implementing a SCADA system provides real-time monitoring of industrial processes. This allows operators to quickly identify and respond to issues, ensuring optimal performance and minimizing downtime.

2. Improved Data Collection

A SCADA system facilitates the collection of large amounts of data from various sources. This data can be analyzed to improve decision-making, optimize operations, and enhance overall efficiency.

3. Increased Automation

With SCADA, many manual processes can be automated, reducing the likelihood of human error. This leads to increased reliability and consistency in operations, ultimately improving productivity.

4. Enhanced Reporting

SCADA systems offer advanced reporting capabilities, enabling operators to generate detailed reports on system performance. This information is valuable for regulatory compliance, performance analysis, and strategic planning.

5. Remote Access

A significant advantage of SCADA systems is the ability to access and control operations remotely. This feature allows for better management of resources and quicker response times, even from distant locations.

A SCADA system significantly enhances operational efficiency by enabling real-time monitoring and control of industrial processes. By collecting and analyzing data from various sensors and devices, it allows operators to identify issues quickly, minimizing downtime and reducing maintenance costs. Furthermore, the automation of routine tasks streamlines operations, leading to faster decision-making and improved resource management. With advanced analytics and reporting capabilities, a SCADA system provides insights that enable continuous improvement and optimization of processes, ultimately boosting productivity and reducing operational risks.

Some interesting numbers and facts about your company results for Supervisory Control Data Acquisition (SCADA) System

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 9675 |

| Average amount of employees | 101-250 |

| Oldest suiting company | 1933 |

| Youngest suiting company | 1975 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Supervisory Control Data Acquisition (SCADA) System

What are related technologies to Supervisory Control Data Acquisition (SCADA) System?

Based on our calculations related technologies to Supervisory Control Data Acquisition (SCADA) System are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Supervisory Control Data Acquisition (SCADA) System?

The most represented industries which are working in Supervisory Control Data Acquisition (SCADA) System are IT, Software and Services, Other, Automation, Electronics and Electrical engineering, Oil, Energy and Gas

How does ensun find these Supervisory Control Data Acquisition (SCADA) System Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.