The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Apex Real Time Solutions

Midrand, South Africa

C

11-50 Employees

2006

Key takeaway

Apex Real Time Solutions provides advanced Warehouse Management Systems (WMS) that optimize inventory control and streamline operations, enhancing efficiency and productivity in warehouse environments.

Reference

Service

Apex Real Time Solutions

Transform your warehouse operations with Apex Real-Time Solutions' innovative warehouse control systems. Our state-of-the-art technology empowers businesses to achieve unparalleled accuracy and productivity in inventory management. Experience seamless integration and superior performance. Get in touch with us today to revolutionise your logistics processes.

inconso

Bad Nauheim, Germany

A

501-1000 Employees

-

Key takeaway

Inconso provides innovative software solutions designed to optimize supply chain processes, including comprehensive warehouse management. Their cloud solutions offer easy-to-use tools for planning, managing, and controlling logistics effectively.

Reference

Product

Warehouse Management

Warehouse Management System - warehousemanagementsystemsoftware.com

Bistrița, Romania

B

1-10 Employees

-

Key takeaway

The company offers cost-effective solutions for warehouse management systems (WMS), providing software that manages and controls key warehouse operations such as inventory receiving, order picking, and replenishment. Their custom WMS solutions can enhance efficiency and support business growth.

Reference

Core business

Warehouse management system software solutions

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Logipulse

Vadanappally, India

D

11-50 Employees

-

Key takeaway

Logipulse offers a comprehensive Warehouse Management System (WMS) that enhances logistics efficiency by automating and optimizing processes from pickup to delivery. Their software provides powerful tools for container management, ensuring better service and improved profitability for your business.

Reference

Product

Warehouse Management System - 3PL Solution & WMS Software

WebEquator Ltd

Maidenhead, United Kingdom

A

11-50 Employees

2012

Key takeaway

WebEquator specializes in custom software development and solutions, including expertise in Warehouse Management Systems. They offer comprehensive services from consultancy to integration and ongoing support, making them a valuable partner for businesses seeking tailored software solutions.

Reference

Service

Warehouse Management System | Consulting, Integration, Development

WCS (Worldwide Chain Stores)

Surrey Heath, United Kingdom

A

11-50 Employees

1969

Key takeaway

WCS offers advanced warehouse management solutions that enhance operational efficiency and adapt to modern supply chain challenges. Their CSnx Warehouse Management system supports complex distribution operations, ensuring high customer service and optimizing space utilization.

Reference

Product

Warehouse Management - WCS

Employing business logic, which has been developed and enhanced over a thirty year period, CSnx Warehouse Management drives high customer service through profitable distribution operations. This solution has the core functionality to support complex distribution operations without heavy implementation services overheads. Functionality spans receipt scheduling; receiving; sophisticated put-away rules to optimise the use of space; […]

Wisys LLC

Flowery Branch, United States

B

11-50 Employees

2009

Key takeaway

WiSys offers a comprehensive Warehouse Management System as part of its Agility Suite, designed to enhance efficiency in warehouse operations. Their focus on training and support ensures that teams are empowered to successfully implement warehouse automation, making the transformation process smoother.

Reference

Product

Warehouse Management System for Macola - Supply Chain Management Solutions for Macola and SAP Business One

Manhattan Associates

Atlanta, United States

B

1001-5000 Employees

1990

Key takeaway

Grupo Éxito significantly enhanced its delivery times and customer satisfaction by implementing Manhattan Active Omni, a cloud-native Warehouse Management System (WMS) that offers global inventory visibility and efficient order fulfillment. This adaptable system utilizes AI to optimize operational decisions, ensuring a seamless omnichannel experience throughout the buyer's journey.

Reference

Product

Warehouse Management System | Manhattan Associates

Our warehouse management system isn't just smart, it's adaptable. With powerful AI, the software helps you make better, faster operational decisions.

SC Codeworks

Columbus, United States

B

11-50 Employees

1998

Key takeaway

The company offers a comprehensive and customizable Warehouse Management System (WMS) called Warehouse Distribution Logistics System (WDLS), designed to enhance warehouse and logistics operations. With over 30 years of experience and a strong focus on professional support, they ensure that their WMS meets the sophisticated needs of high-volume facilities.

Reference

Core business

Home

proVisionWMS

Canada

A

51-100 Employees

2014

Key takeaway

ProVision WMS is a robust warehouse management system designed to enhance warehouse operations across Canada and the United States. Developed by experts, it addresses the challenges faced by operations managers, ultimately aiming to improve efficiency and profit margins.

Reference

Core business

ProVision WMS | Warehouse Management System | WMS Solutions

Discover more about ProVision WMS, a flexible warehouse management system solution for your warehouse operations that can improve your efficiencies.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

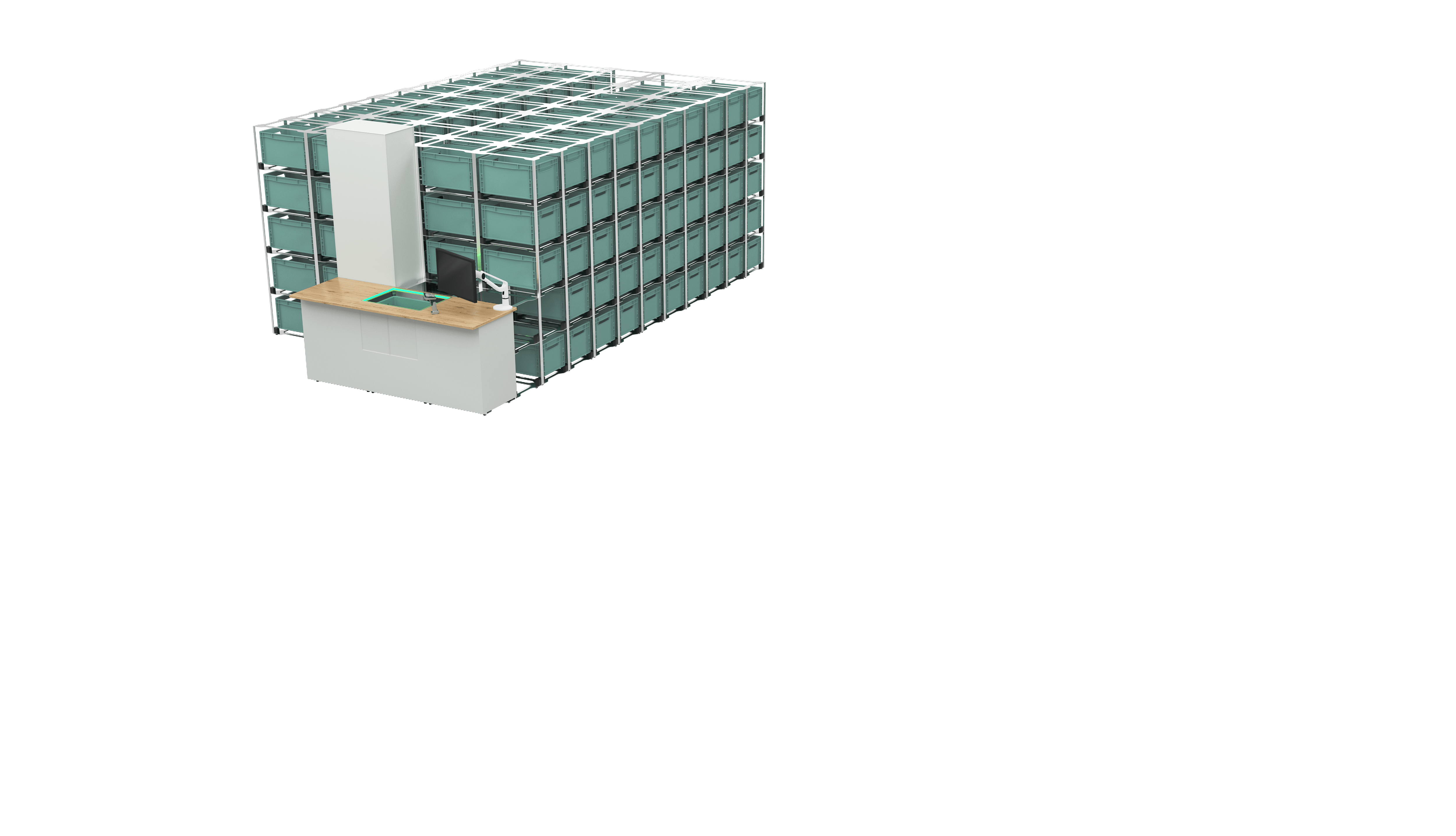

Cellgo automated warehouse

Go to product

Product

Cellgo warehouse lift

Go to product

Service

Rfid Octo+ Solutions Logistics Supply Chain

Go to product

Product

Automated Warehouse

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Talleys

Food, Beverage

Working with our Italian partner Automha and local Racking Partner StorePro, PHS Innovate’s scope included all the racking, automation equipment and conveyors in and surrounding the Cool store. The system scans wrapped and labelled pallets and communicates with Talley’s inventory system to retrieve details for the pallet. The system then stores the pallets in rack locations based on Batch and date for optimised future retrieval. When a truck or container load is needed, Talley’s inventory system communicates with our automated handling system to request specific pallets. Our solution then retrieves and delivers the requested pallets to a designated area for the forklift driver to load into the truck or container.

Use case

Workbenches and packing tables

industries, production, company, gastronomy, bakery, storage, pharmaceutical industry, craft, trade, working

Perfect for trades and workshops We offer generous work surfaces with integrated storage space for tools for craft businesses, workshops and DIY enthusiasts. Whether stationary or mobile - our workbenches and work tables guarantee ergonomic and functional working conditions. Discover our diverse solutions now and be inspired by our range. BRB will be happy to provide you with personalised advice for your individual requirements - for all-round successful business equipment!

Use case

Lockers and wardrobes

industries, warehouses, company, manufacturing , bakery, retail stores, storage, craft, repair service

Maximum choice and great benefits: Lockers, filing cabinets and wardrobes BRB Lagertechnik GmbH stands for high-quality and functional storage equipment. We offer a wide range of products that are used in numerous sectors, particularly in the area of lockers, filing cabinets and wardrobes. Whether in industry, trade or public facilities - our solutions ensure organisation, safety and convenience. Large selection for every need Our range includes: Lockers: In various sizes, materials and colours - perfect for staff rooms and changing rooms. Compartment lockers: Ideal for offices, schools and gyms to store personal belongings securely. Wardrobes: From simple hook rails to complete cloakroom systems for businesses and public buildings. Thanks to different configurations, materials and security features, you can choose exactly the solution that suits your needs. Industries that rely on our solutions Our lockers, locker cabinets and cloakrooms are used by companies and institutions in many sectors, including: Industry & trade: Secure storage for employees' work clothes and personal belongings. Healthcare: Hygienic locker solutions for hospitals and care facilities. Schools & universities: Space-saving and robust lockers for pupils and students. Sports & fitness centres: Practical solutions for members to store their valuables. Administrations & authorities: Secure filing systems for employees and visitors. With BRB Lagertechnik GmbH, you not only receive high-quality locker solutions, but also expert advice, customisation options and long-lasting quality. Contact us today to find the right solution for your requirements!

Use case

Steel cabinets

industries, production, logistics centres, manufacturing , logistics, storage, supermarkets, warehouse, chemical

Whether in the workshop, warehouse or office - steel cabinets are the silent helpers that ensure that everything has its place. They are not just storage solutions, but also contribute to efficiency and safety in companies. But not every cabinet is the same. Here is an overview of the different variants and why quality plays a decisive role. Which steel lockers are available? ✅ Sliding door lockers - perfect for tight spaces! Instead of bulky doors that take up space, the doors slide gently to the side. Ideal for workshops or offices with limited space. ✅ Material cupboards - Robust storage for work materials. Height-adjustable shelves ensure flexibility and optimum utilisation of storage space. ✅ Cleaning agent cupboards - safety first! Cleaning products don't just belong on a shelf, but in special cabinets with shelves for chemicals to minimise hazards. ✅ Cupboards with shelves - chaos is a thing of the past! These cabinets are the perfect solution for small parts such as screws, plugs or spare parts that need to be quickly to hand. ✅ Cupboards with transparent boxes - everything at a glance! Thanks to transparent boxes, you can immediately see where everything is - a real efficiency booster in workshops and storage rooms. Why quality is crucial: A steel cabinet is an investment - and as with any investment, quality counts. Why is that? ✔ Durability - high-quality steel constructions withstand even the toughest loads and are reliable in use for years. ✔ Protection against corrosion - Powder coatings or galvanised surfaces prevent rust and ensure that the cabinets can withstand harsh environments. ✔ Security - Lockable cabinets not only protect valuable tools, but also hazardous substances from unauthorised access. ✔ Flexibility - Companies change, and storage requirements change with them. Height-adjustable shelves and modular systems ensure that the cabinets grow with them. Steel cabinets are more than just metal boxes - they are indispensable organisational aids in any company. Whether for tools, cleaning products or small parts - the right choice of cabinet saves time, keeps things organised and increases safety. And those who invest in quality benefit from a solution that will last for decades.

Use case

Table and shelf trolleys

industries, warehouses, logistics centres, manufacturing , company, retail stores, supermarkets, workshops , repair service, workshops

Customised solutions for your requirements Whether small goods, heavy loads or sensitive goods - BRB supplies you with exactly the transport trolley that meets your requirements. With our comprehensive expertise and wide range of products, we are your reliable partner for every industry. - Optimised work processes: Fast, safe and efficient transport of all types of goods. - Broad product range: Devices in a wide variety of designs and versions - for every area of application. - Universally applicable: Whether in industry, warehousing, logistics or delivery - our transport equipment can be flexibly customised. - Ergonomic and energy-saving: Reduce physical strain with well thought-out designs and functionality. - Highest quality: Durable and stable designs that can withstand even the toughest demands.

Use case

Lift truck

industries, warehouses, manufacturing , crafts, company, storage, supermarkets, warehouse, repair service

Lift trucks are true all-rounders and are used in numerous industries. They facilitate the transport of heavy loads and enable efficient and safe working. They are particularly indispensable in warehouses, production facilities, DIY stores and logistics centres. They are also frequently used in supermarkets, furniture stores and retail outlets. A pallet truck helps wherever palletised goods need to be moved, stacked or relocated. They are suitable for loading and unloading transport vehicles and for internal goods distribution. Thanks to their easy handling and compact design, they can also be used in confined spaces without any problems. We offer you a large selection of pallet trucks in numerous variants - from classic hand pallet trucks and electric models to special stainless steel or scissor pallet trucks. All our pallet trucks are available at the best prices, delivered quickly and reliably. Which pallet truck is the best? Each model is optimised for specific requirements. Here is an overview: Pallet truck / hand pallet truck ✔Classic model with two metal tines Hydraulic lifting cylinder for manual operation ✔Also available as an electric version Tip: Our stainless steel pallet truck with a load capacity of 2,000 kg is ideal for food businesses. High lift pallet truck ✔For lifting loads to great heights ✔Perfect for stocking shelves Tip: High lift pallet truck with 2,500 mm lifting height and 1,000 kg load capacity in our shop. Scissor lift truck ✔Allows ergonomic working in an elevated position ✔Can also be used as a lifting table ✔Fork length: 1,150 mm Regulations & safety: Who is allowed to operate a pallet truck? Although pallet trucks are easy to operate, there are safety regulations: - Mandatory instruction: every employee must receive detailed instruction. - Accident prevention: Industrial trucks are involved in many industrial accidents. Forklift licence: Only required if the pallet truck offers a ride-on option. Whether a hand pallet truck, pallet stacker or scissor lift truck - the right model will make your day-to-day work much easier. Discover our extensive range and find the perfect pallet truck for your company - at an unbeatable price, delivered quickly and reliably!

Use case

Talleys

Food, Beverage

Working with our Italian partner Automha and local Racking Partner StorePro, PHS Innovate’s scope included all the racking, automation equipment and conveyors in and surrounding the Cool store. The system scans wrapped and labelled pallets and communicates with Talley’s inventory system to retrieve details for the pallet. The system then stores the pallets in rack locations based on Batch and date for optimised future retrieval. When a truck or container load is needed, Talley’s inventory system communicates with our automated handling system to request specific pallets. Our solution then retrieves and delivers the requested pallets to a designated area for the forklift driver to load into the truck or container.

A Warehouse Management System (WMS) is a software solution designed to optimize and streamline warehouse operations. It provides tools for inventory management, order fulfillment, and logistics, enabling businesses to track products throughout the supply chain. By automating processes such as stock tracking, picking, packing, and shipping, a WMS enhances efficiency and accuracy within the warehouse environment. This technology often integrates with other systems like Enterprise Resource Planning (ERP) and Transportation Management Systems (TMS) to provide a comprehensive view of the supply chain. With real-time data and analytics, companies can make informed decisions to improve inventory turnover and reduce operational costs.

A Warehouse Management System (WMS) significantly enhances inventory accuracy through real-time data tracking and automated processes. By utilizing barcode scanning and RFID technology, a WMS ensures that every item is accounted for as it moves in and out of the warehouse. This level of precision minimizes human error, as manual data entry is reduced or eliminated. Additionally, a WMS provides detailed visibility into inventory levels, locations, and movements. Users can easily access up-to-date information, allowing for better decision-making and stock management. With accurate tracking of stock levels and automatic alerts for low inventory, businesses can maintain optimal stock levels, thereby preventing overstocking or stockouts. This comprehensive approach leads to improved operational efficiency and greater customer satisfaction.

1. Inventory Control

A robust Warehouse Management System (WMS) must include advanced inventory control features. This ensures accurate tracking of stock levels, locations, and movements within the warehouse, minimizing errors and optimizing storage space.

2. Order Management

Effective order management capabilities are essential for processing orders efficiently. A WMS should facilitate picking, packing, and shipping processes, allowing for real-time updates and improved customer satisfaction.

3. Reporting and Analytics

Comprehensive reporting and analytics tools help in monitoring warehouse performance. These features provide insights into inventory turnover rates, order fulfillment times, and overall operational efficiency, enabling data-driven decision-making.

4. Integration Capabilities

Integration with other systems, such as ERP and transportation management systems, is vital. This connectivity allows for seamless data exchange, enhancing operational workflows and reducing manual data entry.

5. Labor Management

A WMS should include labor management features to track employee productivity and optimize workforce allocation. This ensures that labor resources are used efficiently, leading to improved productivity and reduced costs.

A Warehouse Management System (WMS) integrates with other software through application programming interfaces (APIs), enabling seamless data exchange and process coordination. This integration allows a WMS to communicate with enterprise resource planning (ERP) systems, transportation management systems (TMS), and customer relationship management (CRM) software, enhancing overall operational efficiency. For instance, when inventory levels are updated in the WMS, this information can automatically sync with the ERP system, ensuring accurate financial reporting and stock management. Additionally, integration with TMS allows for optimized shipping and logistics planning, while CRM connections help provide real-time order status updates to customers. By fostering collaboration among various software platforms, a WMS significantly improves supply chain visibility and responsiveness.

1. Increased Efficiency

Implementing a Warehouse Management System (WMS) streamlines operations by automating various tasks such as inventory tracking, order fulfillment, and shipment processing. This leads to reduced manual errors and faster turnaround times, ultimately enhancing productivity.

2. Improved Inventory Accuracy

A WMS provides real-time visibility into inventory levels and locations. This ensures that businesses can maintain optimal stock levels, reduce excess inventory, and minimize stockouts. Accurate inventory data helps in making informed purchasing decisions and enhances overall supply chain management.

Some interesting numbers and facts about your company results for Warehouse Management System

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1969 |

| Youngest suiting company | 2014 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Warehouse Management System

What are related technologies to Warehouse Management System?

Based on our calculations related technologies to Warehouse Management System are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Warehouse Management System?

The most represented industries which are working in Warehouse Management System are IT, Software and Services, Logistics, Supply Chain and Transportation, Other, Consulting, Automation

How does ensun find these Warehouse Management System Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.