The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Infinite Data

Warsaw, Poland

B

11-50 Employees

2014

Key takeaway

InfiniteDATA is focused on empowering enterprise-scale customers to achieve digital transformation through automation. Their product, AutomateNOW!, is designed to enhance efficiency and support decision-making at all organizational levels, positioning the company as a key player in the global automation market.

Reference

Core business

Enterprise Automation Software AutomateNOW! - InfiniteDATA

zapple.tech

Krakow, Poland

B

11-50 Employees

2011

Key takeaway

Zappletech is a leading automation testing company with over ten years of experience in delivering effective automation solutions that enhance QA efficiency. Their comprehensive Automation Testing Service includes assessments, planning, and custom solution development, making it easier to integrate automated tests into continuous delivery processes.

Reference

Core business

Automation Testing Company - Best Automation Testing - 100% focused on Test Automation Outsourcing

Automation testing company Zappletech covers all types of apps, platforms and devices. Best company for automation testing which provide full cycle automation testing.

auditomat®

Katowice, Poland

B

11-50 Employees

-

Key takeaway

The company offers auditomat®, a tool that automates audit processes, significantly enhancing the efficiency of lean managers and production managers in maintaining quality standards. With features that provide immediate access to audit documentation and results, it streamlines the work of those responsible for compliance and audits.

Reference

Core business

auditomat® | Audit processes automation

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Robotec.AI

Warsaw, Poland

B

11-50 Employees

2019

Key takeaway

Robotec.ai is a software company specializing in high-tech solutions for automated vehicles, with expertise in robotics, software development, and machine learning. They are actively involved in advancing autonomous mobility through collaboration with automotive partners.

Reference

Service

Robotics - Robotec.ai

Unified Factory

Warsaw, Poland

B

51-100 Employees

2009

Key takeaway

The company specializes in customer service and sales automation software, utilizing artificial intelligence to enhance support across various channels like phone, chat, and social media. Their product, Menerva AI, offers a unified solution for automating customer interactions, demonstrating over 20 years of industry experience and operation in more than 21 countries.

Reference

Core business

Unified Factory – Customer Service Automation & Support Software

Wedoautomation

Czechowice-Dziedzice, Poland

B

1-10 Employees

-

Key takeaway

WeDoAutomation is a dynamic company focused on enhancing its competitiveness by providing a wide range of services in industrial automation and Information Technology. Their mission is to develop and implement solutions that integrate these two fields, emphasizing their commitment to automation software.

Reference

Core business

WeDoAutomation

ROBOMATIQ

Warsaw, Poland

B

11-50 Employees

2018

Key takeaway

The company specializes in automation through online programming of industrial robots, offline simulations, and the development of PLC-based control systems and SCADA virtualization systems. Their experienced team offers solutions that enhance efficiency and reduce costs, making them a valuable resource for automation software needs.

Reference

Core business

Automotive – robomatiq | Robot and PLC programming / Simulations / Laser measurements

ANT

Krakow, Poland

B

11-50 Employees

2006

Key takeaway

ANT Solutions specializes in providing innovative software solutions, including Manufacturing Execution Systems (MES) and Production Data Management Systems (PDMS), aimed at enhancing productivity and efficiency in manufacturing processes through digital transformation. Their commitment to customized IT solutions and cloud manufacturing helps factories increase efficiency, reduce costs, and improve product quality.

Reference

Product

Products - ANT Solutions - Software for Modern Factory

See our solutions - Products - Modern industries expect high-tech software solutions to meet actual market requirements and changes. ANT is facing with it thanks to modular build...

Rhenus Automation

Nadarzyn, Poland

B

251-500 Employees

2017

Key takeaway

Rhenus Automation specializes in process automation, offering Robotic Process Automation (RPA) solutions that enable robots to perform tasks automatically, similar to human employees. Their expertise in intelligent automation enhances supply chain efficiency and decision-making through digital transformation.

Reference

Product

Digital Workforce

Strategon.pl - Internet Advertising & E-commerce Experts

Warsaw, Poland

B

1-10 Employees

-

Key takeaway

The company offers smart automation solutions such as custom chatbots and AI tools that simplify and optimize business processes, ultimately promoting growth and improving communication.

Reference

Core business

AI Automation Agency | STRATEGON.PL

Skuteczna reklama internetowa dla Twojej firmy. Pozyskamy dla Ciebie nowych Klientów, pomożemy wejść na nowe rynki, rozwiniemy Twój biznes w Internecie.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

NFT Game Development Services

Go to product

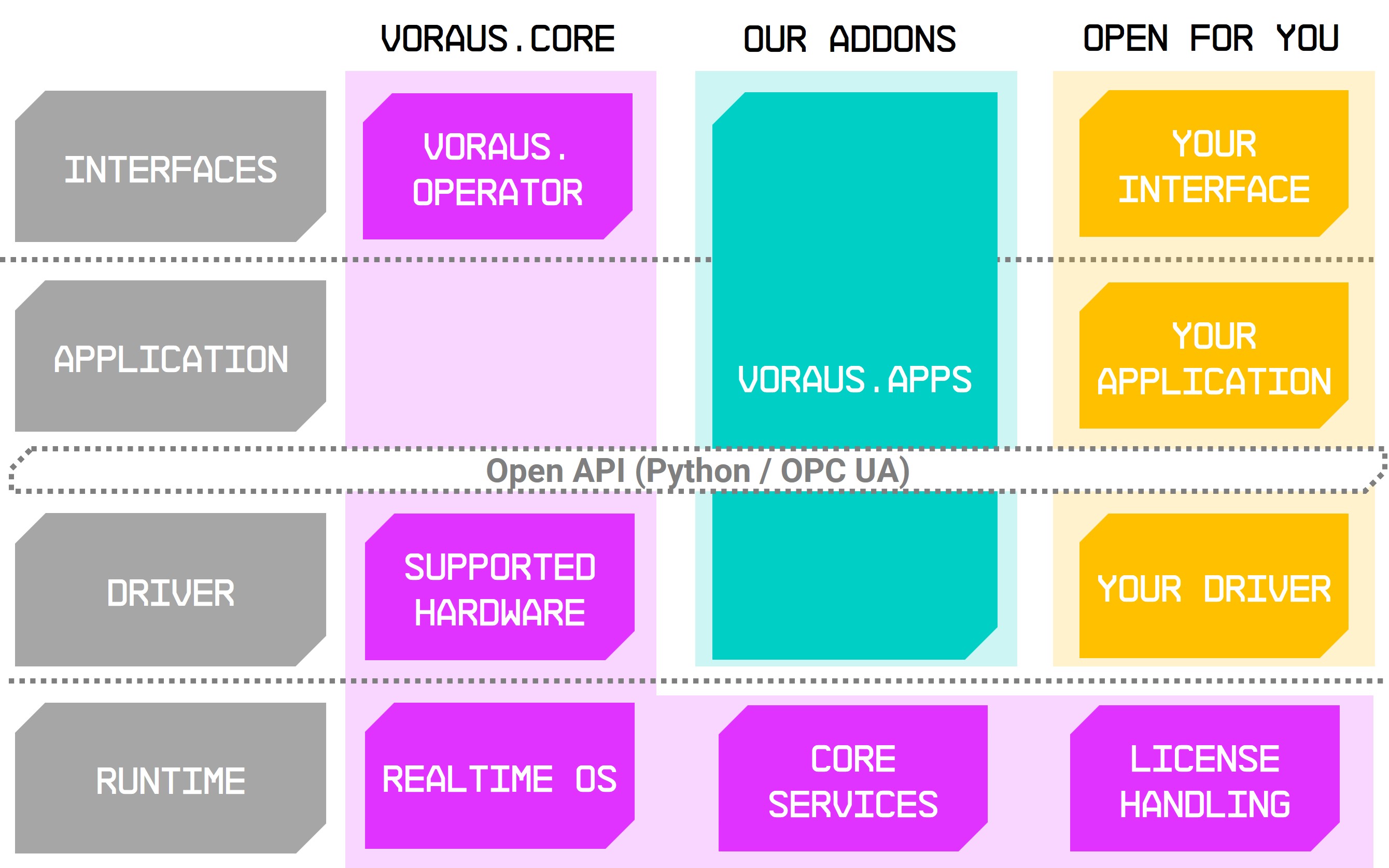

Product

voraus.core

Go to product

Service

OnPrintShop

Go to product

Product

edbic

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Continuous monitoring

Manufacturing

The challenge Blickle has always prided itself on the superior quality of its wheels and castors. To further enhance this quality with modern technology, the company decided to migrate its production processes to Industry 4.0 standards. This planned transition should have minimal impact on the three-shift production operation, while maintaining flexibility and openness for future digitalization initiatives. The solution Blickle IT developed a concept to enable a sustainable and gradual transformation. At the heart of the strategy is edbic, which enables condition monitoring. Acting as a central data hub, edbic seamlessly extracts data from the machines, transfers it to the ERP system and provides full production transparency. The result With the implementation of edbic, machine data no longer reaches IT incomplete or delayed. Immediate data analysis enables rapid problem resolution. Automatic punching presses are monitored to determine output results, missing parts, quantities and more. By eliminating most of the Excel lists previously used, edbic has significantly streamlined operations. In polyurethane production, edbic identifies and corrects problems, contributing to Blickle's high quality castors and wheels. In addition, edbic is now being used beyond production, facilitating connections to payment providers in the web shop and establishing a communication link with SAP. Outlook for the future Blickle plans to further refine the system by using machine data comparison for predictive maintenance. In addition, the company is considering implementing the compacer IoT gateway to take communication between machines and the ERP system to a new level of automation.

Use case

IoT gateway and Industry 4.0 application

Industry 4.0, Manufacturing

The challenge: BURKHARDT+WEBER is renowned for its expertise in large machining centres. Headquartered in Reutlingen, Germany, the company has a global presence and supplies its products to customers around the world who place a premium on quality. For 130 years, BURKHARDT+WEBER has focused on developing state-of-the-art production solutions for the demanding machining of steel, cast iron and titanium components. The development of these machining centres is the collaborative work of interdisciplinary teams, and all essential components, as well as in-house developments, are manufactured within the company. The compacer IoT solution, built on the edbic platform, is planned for future integration into BURKHARDT+WEBER machining centres. The installation of the compacer IoT gateway enables data collection from the machine's control system. In the long term, BURKHARDT+WEBER machines will offer a wide range of data that can be examined in real time to provide a detailed overview of the machine's condition and efficiency on a dashboard. The solution: An IoT hub will process the collected data, enabling a variety of assessments and ensuring that the operator is kept informed at all times. With machines connected to the compactor solution, condition monitoring is possible, paving the way for the implementation of predictive maintenance. With this approach, BURKHARDT+WEBER enables its customers to successfully implement upcoming digital transformation projects within their production processes.

Use case

Automation

All

Here we are talking about automation, what google calls toil, annoying repetitive tasks that eat up your time preventing you from focusing on what matters. Software engineering can help you automate these tasks and focus. You can sleep well at night knowing you will not be disturb since you have implemented automation with the support of Clair Services.

Use case

Talleys

Food, Beverage

Working with our Italian partner Automha and local Racking Partner StorePro, PHS Innovate’s scope included all the racking, automation equipment and conveyors in and surrounding the Cool store. The system scans wrapped and labelled pallets and communicates with Talley’s inventory system to retrieve details for the pallet. The system then stores the pallets in rack locations based on Batch and date for optimised future retrieval. When a truck or container load is needed, Talley’s inventory system communicates with our automated handling system to request specific pallets. Our solution then retrieves and delivers the requested pallets to a designated area for the forklift driver to load into the truck or container.

Use case

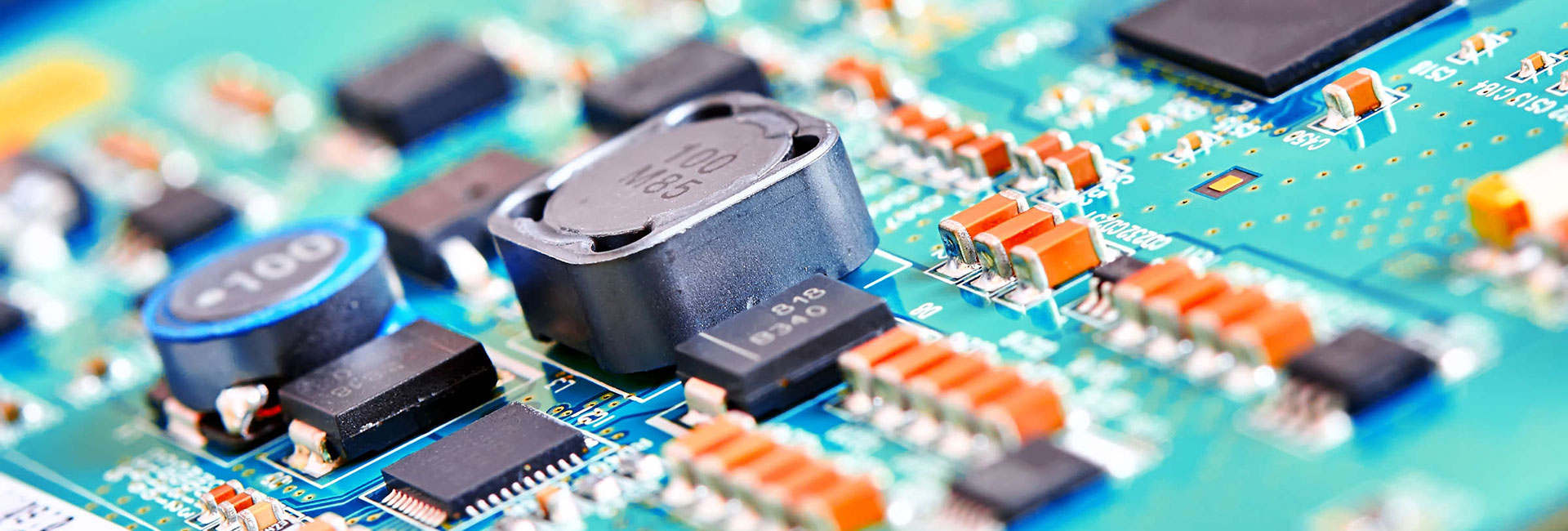

Custom Electronic Design

automotive, E-mobility, automation, industrial automation, machinery, industrial machinery, smart industry, industry 4.0

Electronic design frameworks Electronic design starts from the component layout specification. Also, it consists in the definition of interconnections and PCB technology. Finally, component selection is formalized (BOM, Bill of Material), such as the circuit schematics and the layout of PCB traces (gerber file). If the Electronc Systems is composed of multiple circuit boards, electronic design includes the description of the interconnection schemes, and the instructions for the wiring manufacturing. Adgenera develops electronic circuits tailored and suitable for any application. It selects the most valuable technology for the peculiar field of application, in order to ensure the maximum reliability. Electronic design frameworks Custom-designed electronic solutions can be found in many sectors, covering various fields of application and meeting Client needs. The most frequent requests are: design “from the scratch” miniaturization of an existing circuit board cost Reduction electronic board update, when components are no longer available engineering a prototypal board, either partially or completely working functional improvement (for example, adding a wireless interface) performance improvement (for example, power consumption reduction) Other elements increase the complexity of the electronic design: legacy firmware for the previous version of board need for a custom / legacy interface to other electronic existing systems availability of the components on the market within a certain amount of time project constraints due to standards or certifications The steps of the Electronic Design Electronic design aims to respond to the request of designing and producing electronic circuit boards. First, the customer is interviewed on the characteristics of the electronic system to be designed.. The customer is actively involved to identify the best design choices. This preliminary phase leads to the correct identification of development times and costs, allowing the customer to verify the compliance with his needs and to create a preliminary project planning. Now the electronic scheme can be designed. Specific skills of our designers are applied to correctly select and size the components. Once the scheme has been designed, the electronic components available on the market are selected. Then, they will be soldered to the electronic board during its production phase. We select the most suitable package of components depending on the layout, the space available and the type of application. This design phase leads a draft of the BOM (Bills of Materials) necessary to supply and solder the right components. The electronic components chosen are placed on the board surface. Their positions strictly match design constraints principles to guarantee the correct functioning of the electronic system. Usually several alternative arrangements are evaluated. Finally, the chosen one is the one that leads to the best result once the electronic card is produced. Once the components are finally placed in the board, it is necessary to draw the connections (tracks) that appropriately connect the pins of the components themselves. The tracks design needs to follow many rules and best practices: although there are infinite ways to connect the chosen components, only a few solutions guarantee a good quality card. The preliminary electronic design project is ready: the first board samples are created to check the functionality and performance of the designed electronic system in the laboratory. During the tests, the laboratory instrumentation verifies that each quantity measurable on the card corresponds to the value theoretically calculated during the electronic scheme design.

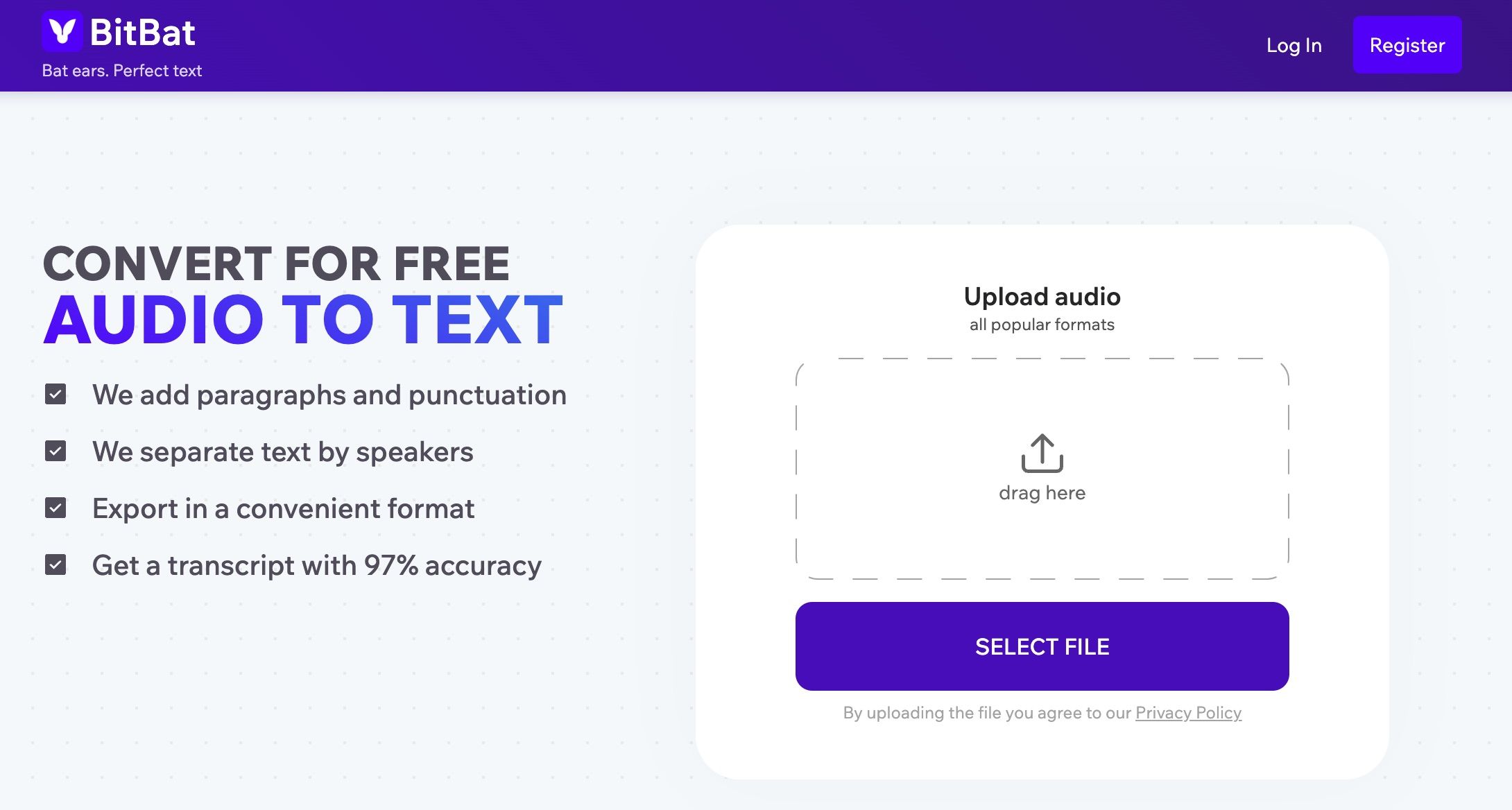

Use case

Bitbat for Journalists

journalists

Journalistic Interviews: Effortlessly convert recorded interviews into text, facilitating quicker content analysis and story development. Content Creation: Transcribe podcasts, webinars, and other audio content to create accessible text versions for diverse audiences. Academic Research: Transform lecture recordings and discussions into text for easier review and citation. Market Research: Transcribe focus group sessions and consumer interviews to extract valuable insights efficiently.

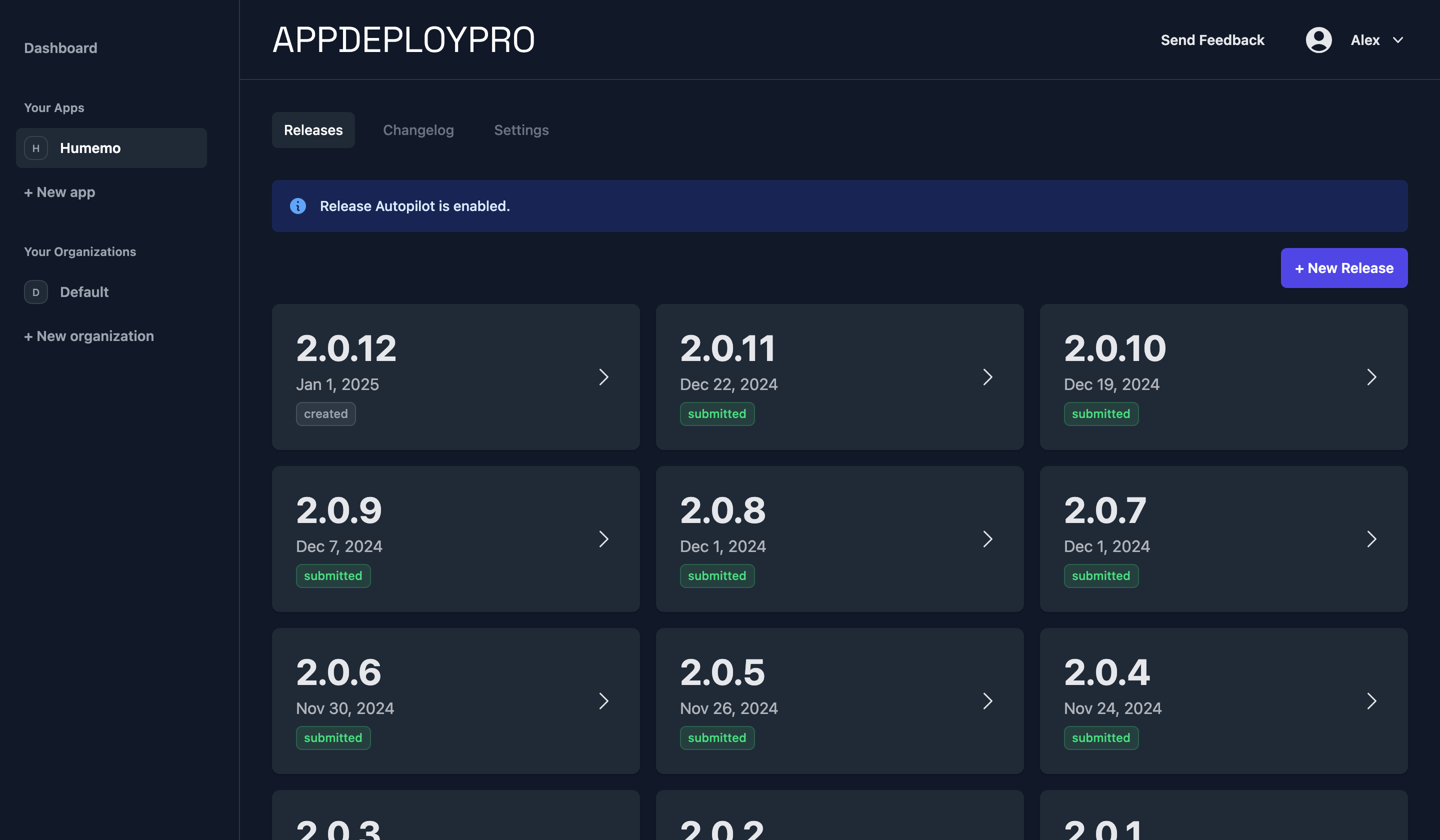

Use case

AppDeployPro for Mobile App Release Management

Automation, Software

AppDeployPro streamlines the mobile app deployment process, helping developers easily release their applications by automating submissions to the Google Play Store, with expansion plans for the Apple App Store. The platform offers an intuitive user interface paired with developer-friendly APIs, Release Autopilot for setting up release cadences automatically, and seamless GitHub integration for build management and upload automation. By significantly reducing manual tasks involved in app store submissions, AppDeployPro allows developers to prioritize coding efforts over administrative release tasks. Designed especially for mobile engineers, it tracks app release versions efficiently through an integrated changelog, ensuring transparency and historical visibility of app iterations.

Use case

Product Wizard for Online Shop

Machinery & Equipment Manufacturing, Medical Equipment Manufacturing, Specialized Manufacturing, Industrial Component Manufacturing, Materials Manufacturing

Our AI agent can seamlessly integrate into existing online shops through simple website and email integration, requiring minimal IT resources while preserving existing sales processes. It enables customers to self-navigate complex product selection directly through your shop interface, automatically generating qualified quotes based on documented requirements. This implementation reduces transaction costs by 60%, delivers qualified responses in minutes instead of days, and creates 20% additional capacity by automating repetitive tasks, allowing your sales engineers to focus on high-value activities.

Use case

Continuous monitoring

Manufacturing

The challenge Blickle has always prided itself on the superior quality of its wheels and castors. To further enhance this quality with modern technology, the company decided to migrate its production processes to Industry 4.0 standards. This planned transition should have minimal impact on the three-shift production operation, while maintaining flexibility and openness for future digitalization initiatives. The solution Blickle IT developed a concept to enable a sustainable and gradual transformation. At the heart of the strategy is edbic, which enables condition monitoring. Acting as a central data hub, edbic seamlessly extracts data from the machines, transfers it to the ERP system and provides full production transparency. The result With the implementation of edbic, machine data no longer reaches IT incomplete or delayed. Immediate data analysis enables rapid problem resolution. Automatic punching presses are monitored to determine output results, missing parts, quantities and more. By eliminating most of the Excel lists previously used, edbic has significantly streamlined operations. In polyurethane production, edbic identifies and corrects problems, contributing to Blickle's high quality castors and wheels. In addition, edbic is now being used beyond production, facilitating connections to payment providers in the web shop and establishing a communication link with SAP. Outlook for the future Blickle plans to further refine the system by using machine data comparison for predictive maintenance. In addition, the company is considering implementing the compacer IoT gateway to take communication between machines and the ERP system to a new level of automation.

When exploring the Automation Software industry in Poland, several key considerations come into play. The country has become a significant player in the European tech landscape, driven by a skilled workforce and a growing number of startups and established companies in automation. Regulatory frameworks are evolving, with the government supporting innovation through various incentives, which can create favorable conditions for new entrants. However, challenges such as a competitive market and the need for continuous adaptation to technological advancements are prevalent. Environmental concerns are increasingly influencing the industry, as companies strive to develop sustainable automation solutions that minimize ecological impact. Additionally, the global market relevance of Polish automation software firms is rising, as they often cater to international clients, helping local companies expand beyond borders. Collaboration between businesses, academia, and research institutions fosters innovation, while the integration of Industry 4.0 principles enhances operational efficiency. Prospective investors and entrepreneurs should also consider the local market's demand for automation solutions across various sectors, including manufacturing, logistics, and healthcare, as these areas present numerous opportunities for growth and development in the automation software sector.

Some interesting numbers and facts about your company results for Automation Software

| Country with most fitting companies | Poland |

| Amount of fitting manufacturers | 96 |

| Amount of suitable service providers | 74 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 2006 |

| Youngest suiting company | 2019 |

Some interesting questions that has been asked about the results you have just received for Automation Software

What are related technologies to Automation Software?

Based on our calculations related technologies to Automation Software are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Automation Software?

The most represented industries which are working in Automation Software are IT, Software and Services, Automation, Other, Consulting, Manufacturing

How does ensun find these Automation Software Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.