The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Cobots

Gqeberha, South Africa

C

1-10 Employees

2018

Key takeaway

Cobots (PTY) Ltd focuses on providing innovative collaborative solutions, specifically through their range of collaborative robots designed to enhance productivity and improve operational quality. Their products aim to uplift workplace morale and help companies optimize their manufacturing processes.

Reference

Core business

Home - Cobots

cobots catalogueProduct Categories Collaborative Robot Shop Now Collaborative Robot Accessories Shop Now Vision Systems Shop Now Industrial Robot Accessories Shop Now Mobile Robot Shop Now Mobile Robot Accessories Shop Now Platforms Shop Now Software Shop Now About usEnhancing manufacturing through collaborative robotsCobots (PTY) Ltd motivation and aspiration is to bring innovative collaborative solutions to the

COBOTS-SOLUTIONS

Joué-lès-Tours, France

A

1-10 Employees

2020

Key takeaway

Cobots-Solutions is the exclusive importer of JAKA® collaborative robots in France, Belgium, and Switzerland, providing expertise in the selection and integration of these advanced robots into production lines. They also offer innovative flexible actuators from Soft Robot Tech that mimic human grasping actions, capable of handling various objects, enhancing automation solutions for complex and fragile products.

Reference

Product

Cobots Pro Serie - Cobots Solutions

The water and dust resistant cobot pro serie. The easiest cobot to program and integrate into the most challenging work environments.

Cobot Intel

Canada

A

11-50 Employees

2018

Key takeaway

Cobot Intelligence Inc. specializes in the distribution, servicing, and training of Techman robots in the USA and Canada, highlighting their focus on collaborative robots (cobots) that provide smart, simple, and safe solutions for production needs. Their expertise and factory-certified technical team ensure effective implementation and training for clients in both commercial and industrial sectors.

Reference

Core business

Cobots | Techman Collaborative Robot Distributor US & Canada

Cobot Intel leading distributor of Collaborative Robots in the US & Canada. Specializes in servicing and training Collaborative Robots. Call Now

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Cobot

Berlin, Germany

A

11-50 Employees

-

Key takeaway

Cobot is a web-based coworking management application designed to streamline administrative tasks for coworking spaces, allowing managers to focus on building community. With a mission to support the growth and flourishing of coworking spaces, Cobot provides essential tools that connect with billing, accounting, and access platforms.

Reference

Core business

About Cobot – Company, Team & Values | Cobot

Cobot is a web-based coworking management application that dramatically eases administrative tasks to empower space managers, so they can focus on what really matters – time for their coworkers.

Cobot-it

Pennedepie, France

A

1-10 Employees

2021

Key takeaway

The company describes a "cobot" as a collaborative software that utilizes explainable artificial intelligence components to enhance the supervised industrialization of expertise. It serves as a digital companion that facilitates knowledge transfer from top experts to field teams, enabling them to become highly skilled advisors and ultimately adding personalized value during client consultations.

Reference

Core business

Cobot it

Démultipliez vos ventes grâce aux cobots de conseil. Nos cobots accompagnent vos conseillers et vos commerciaux dans leur quotidien. Vous répliquez le raisonnement de vos meilleurs experts et leur capacité à générer des conseils pertinents.

Cobots Online

United Kingdom

A

11-50 Employees

1994

Key takeaway

Cobots Online specializes in configuring and deploying collaborative robots (cobots) that enhance automation capabilities for manufacturers, particularly in high-mix low-volume production. Their user-friendly and versatile solutions streamline processes, boost productivity, and adapt to changing demands, making them accessible for companies of all sizes.

Reference

Core business

Cobots Online | Collaborative Robots | Manufacturing

Open Automation UK

United Kingdom

A

1-10 Employees

2020

Key takeaway

The company specializes in simplifying the integration of collaborative robots (cobots) into industrial processes, handling the complex tasks of wiring, mounting, and programming. Their approach ensures that these innovative robots can work safely alongside human operators, enhancing automation without the need for extensive technical expertise.

Reference

Core business

Open Automation UK | Low-cost Cobot Integration

Low-cost collaborative automation and bespoke process solutions. Open Automation is a UK-based provider and intergrator.

Cobot Services

St Albans, United Kingdom

A

11-50 Employees

-

Key takeaway

Cobot Services is at the forefront of cleaning innovation in the UK, introducing the first fully autonomous cleaning robot designed for facades, windows, and exteriors. Their advanced technology promises to enhance cleanliness and efficiency, operating continuously to ensure buildings maintain a pristine appearance.

Reference

Core business

About Us - Cobot Services

Excellence Unleashed Welcome to Cobot Services, the pioneers of revolutionary technology in the United Kingdom. We are proud to introduce the first fully autonomous facade, window, and exterior cleaning robot to the UK market. With our cutting-edge innovation, we are redefining the standards of cleanliness and efficiency in the industry.Our smart cleaning technology ensures impeccable

Robots & Cobots ApS

Galten, Denmark

A

1-10 Employees

-

Key takeaway

A cobot, or collaborative robot, is designed for direct interaction with humans in shared spaces, distinguishing it from traditional industrial robots that operate in isolation. Robots & Cobots, a distributor of Jaka in Denmark, Norway, Sweden, and Finland, emphasizes their expertise in helping businesses select and implement the right cobot to enhance production automation and collaboration.

Reference

Core business

Robots Cobots 🦾 robotter der arbejder godt sammen med mennesker

En cobot er en kollaborativ robot, der arbejder direkte sammen med mennesker i et fælles rum, eller hvor mennesker og robotter er i umiddelbar kontakt

WeCobot

Zwolle, Netherlands

A

1-10 Employees

2017

Key takeaway

WeCobot is a leader in cobot welding solutions, having evolved from custom-made projects to establishing international partnerships. Their commitment to innovation ensures that production processes in welding are faster, safer, and more efficient.

Reference

Core business

The industry standard for cobot welding solutions | WeCobot Welding Solutions

WeCobot creates a perfect synergy between technology, machine and operator. Not only to ensure production processes to be faster, safer and more efficient, but more fun as well.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

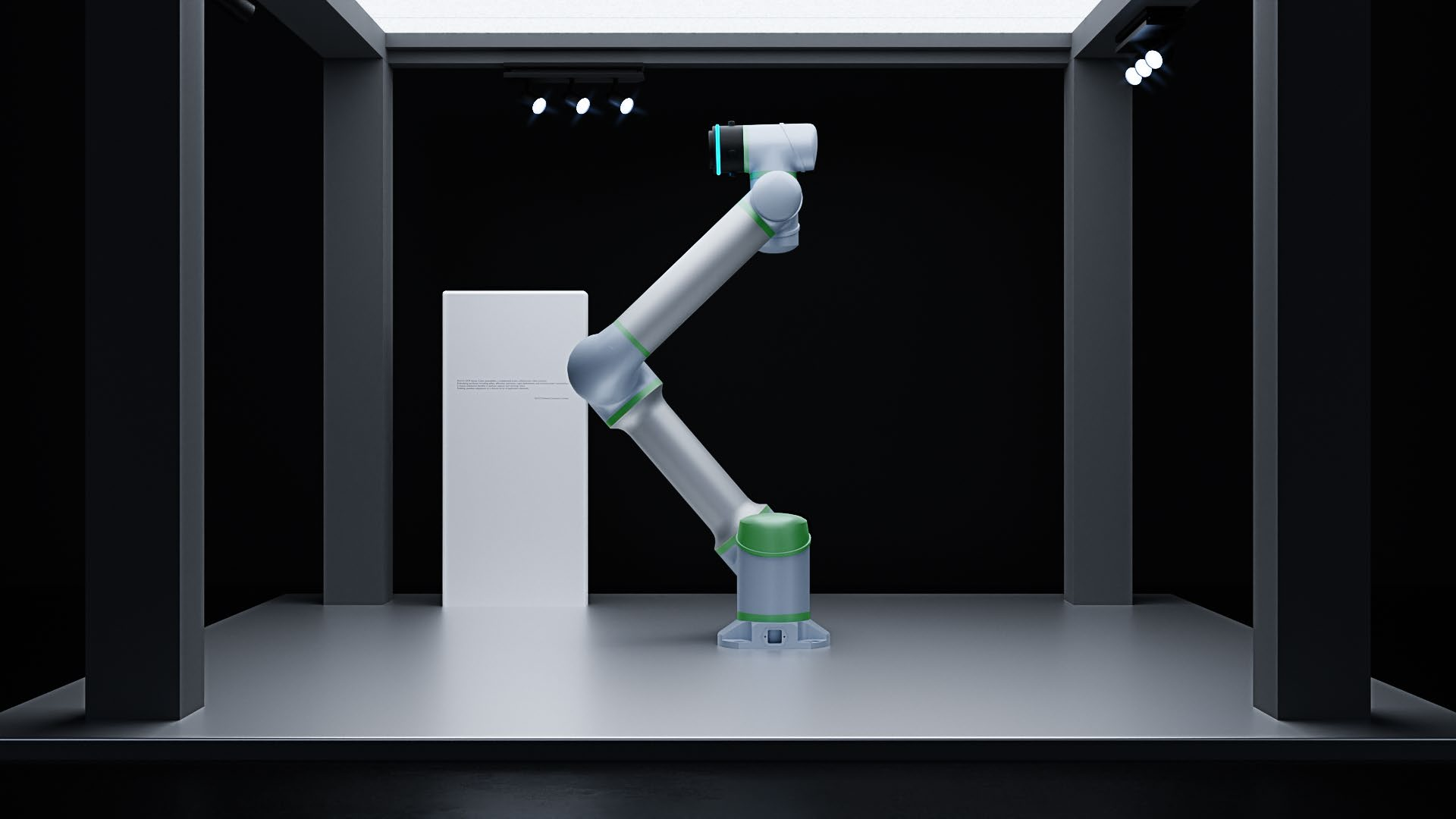

Collaborative Robot

Go to product

Cobots, or collaborative robots, are designed to work alongside humans in a shared workspace, enhancing productivity and safety. Unlike traditional industrial robots that operate in isolation, cobots are equipped with advanced sensors and AI technology, allowing them to safely interact with human workers. Their versatility is evident in various sectors, from manufacturing to healthcare, where they assist in tasks such as assembly, packaging, and even patient care. Cobots improve efficiency by taking over repetitive or ergonomically challenging jobs, enabling human workers to focus on more complex tasks.

Cobot technology enhances workplace efficiency by automating repetitive tasks and collaborating with human workers. These robots can perform various functions, such as assembly, packaging, and quality control, which allows employees to focus on more complex and creative aspects of their jobs. Furthermore, Cobots are designed to work alongside humans safely, reducing the risk of workplace injuries and increasing overall productivity. Their adaptability to different tasks and environments enables businesses to streamline operations, optimize workflows, and ultimately achieve higher output and quality in their processes.

1. Manufacturing

Cobots are widely used in the manufacturing sector, where they assist with tasks such as assembly, packaging, and quality control. Their ability to work alongside human operators increases efficiency and reduces the risk of workplace injuries.

2. Logistics

In logistics, cobots streamline processes like sorting, picking, and transporting goods. They enhance productivity by handling repetitive tasks, allowing human workers to focus on more complex operations.

3. Healthcare

The healthcare industry benefits from cobots in various ways, including assisting with surgery, managing inventory, and supporting patient care. Their precision and reliability improve overall healthcare delivery.

4. Agriculture

Agricultural operations utilize cobots for planting, harvesting, and monitoring crops. These robots help maximize yields while minimizing labor costs and reducing physical strain on workers.

5. Retail

In retail, cobots assist with inventory management and customer service. They can help restock shelves and provide information to customers, improving the shopping experience.

6. Food Service

Cobots in the food service industry aid in food preparation, cooking, and serving. They enhance efficiency and hygiene, allowing staff to concentrate on customer interactions.

Cobots, or collaborative robots, are designed with various safety features to ensure safe interaction with human operators. One key feature is force and torque sensing, which allows the robot to detect unexpected contact with humans or objects. When such contact occurs, the cobot can immediately stop or slow down its movements, minimizing the risk of injury. Another important safety aspect is speed and separation monitoring. This technology helps maintain a safe distance between the cobot and human workers. By continuously monitoring the proximity of people, the cobot can adjust its speed or halt operations when someone enters its working zone. These features work together to create a safer collaborative environment in various industrial applications.

Cobots are designed to work alongside humans and can easily integrate with existing systems in various environments. They typically utilize standardized communication protocols such as Ethernet/IP or OPC UA, which facilitate seamless interaction with machines, sensors, and other automation technologies. Additionally, many cobot models come with user-friendly interfaces and software development kits (SDKs) that allow for custom programming. This adaptability enables cobots to be configured for specific tasks while sharing data with existing systems for improved coordination. With their ability to operate safely in close proximity to human workers, cobots enhance productivity without the need for extensive modifications to current workflows.

Some interesting numbers and facts about your company results for Cobot

| Country with most fitting companies | United Kingdom |

| Amount of fitting manufacturers | 32 |

| Amount of suitable service providers | 21 |

| Average amount of employees | 1-10 |

| Oldest suiting company | 1994 |

| Youngest suiting company | 2021 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Cobot

What are related technologies to Cobot?

Based on our calculations related technologies to Cobot are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Who are Start-Ups in the field of Cobot?

Start-Ups who are working in Cobot are Cobot-it

Which industries are mostly working on Cobot?

The most represented industries which are working in Cobot are Automation, IT, Software and Services, Machinery Manufacturing, Manufacturing, Other

How does ensun find these Cobot Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.