The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

MAP Elektronik Ticaret ve Veri Hizmetleri A.Ş.

Turkey

C

11-50 Employees

1997

Key takeaway

MAP specializes in data integration by collecting, processing, and distributing over 150 million EDI messages annually, which enhances communication between business partners. Their expertise in B2B and internal integrations has significantly improved order management, enabling a seamless flow of critical data.

Reference

Product

Marketplace Integration EDIJET - MAP

EDIJET Marketplace Integration is developed for manufacturers who want to market their products in different marketplaces in the developing e-commerce world.

JFORCE

Ümraniye, Turkey

C

51-100 Employees

2003

Key takeaway

JFORCE is a leading technology and software development company that specializes in providing high-performance data integration solutions, particularly in the context of hybrid cloud environments. Their expertise in Java technologies, e-business, business intelligence, and data warehousing positions them to support clients' digital transformation through effective integration and middleware strategies.

Reference

Product

Integration and Middleware | Solution | JFORCE | Cognitive IT Architecture for Digital Journey

Unite

Turkey

C

251-500 Employees

1998

Key takeaway

Unite is a leading provider of Intelligent Automation as a Service, dedicated to enhancing organizational efficiency and driving digital transformation. Their Intelligent Digital Automation (IDA) platform incorporates the latest IA tools, enabling organizations to rethink their operations and leverage technology for significant improvements.

Reference

Product

Technology Partners

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

T5 Systems "The Integration & API Company"

Yenimahalle, Turkey

C

1-10 Employees

2017

Key takeaway

T5 Systems, in collaboration with Software AG, offers a comprehensive Digital Business Platform that emphasizes integration and real-time analytics, essential for effective data integration. Their focus on APIs further enhances the ability to connect systems and improve customer experiences, making them a key player in the data integration landscape.

Reference

Core business

API | ESB | T5 Systems

API | ESB | T5 Systems

Coopera Consulting Group

Ataşehir, Turkey

C

51-100 Employees

2018

Key takeaway

The company emphasizes its expertise in data integration through its role as a Digital Transformation Partner. By providing consultancy and end-to-end solutions that combine IoT, Big Data Analytics, and Cloud Computing, they enhance process management and decision-making for businesses.

Reference

Core business

Business Process Management | Coopera Consulting

Coopera Consulting Group is an innovative IT system integrator and consultancy company serving digital solutions for corporate enterprises across EMEA Region in various diciplines such as; Process Automation, Process Optimization and Big Data Analytics

VIZIO AI

Turkey

C

1-10 Employees

-

Key takeaway

The company is dedicated to empowering organizations through high-quality data services and products, enabling them to unlock the hidden value of their data. Their commitment to regular updates and tailored solutions ensures that clients can confidently navigate their data journey.

Reference

Product

BI Dashboard Development - Vizio AI | Discover our service packages

We understand your needs, come up with unique solutions, and stand by our services.

Intellica

Turkey

C

51-100 Employees

2006

Key takeaway

Intellica focuses on unlocking the full potential of data through innovative management tools and solutions, which is central to their mission of driving data-driven growth and value across various industries. With a global presence and experience in large-scale projects, Intellica positions itself as a leader in data integration and management.

Reference

Core business

Intellica – Business Intelligence Consultancy

Intech Consulting

Turkey

C

11-50 Employees

2006

Key takeaway

Intech Consulting specializes in data integration through its expert consulting services on the MuleSoft platform, recognized as a leading integration solution. With significant experience in implementing Salesforce and MuleSoft products, the company helps organizations optimize performance and achieve their digital transformation goals.

Reference

Service

Services | Intech Consulting

Intech Consulting provides value-added consulting services for our Salesforce.com & MuleSoft customers on their digital transformation journeys.

CloudAIMS

Turkey

C

1-10 Employees

-

Key takeaway

The company specializes in assisting organizations with their digital transformation and digitalization efforts, focusing on strategic planning and software integrations. They emphasize the importance of creating a reliable single source of truth for critical information, which directly relates to effective data integration.

Reference

Core business

Digitalization, Asset Information Management, EPCI Handover Management • cloudaims

Helping companies on their Digital Transformation & Digitalization path through strategic planning, turn-key software implementation and integrations.

Runibex Technology Group

Ataşehir, Turkey

C

51-100 Employees

1988

Key takeaway

Runibex Technology specializes in data integration by providing skilled resources and best practices for the migration, management, and optimization of Cloud, SAP, and eCommerce systems. Their focus on innovative Cloud-based solutions and continuous investment in research and development ensures that they meet current and future business requirements effectively.

Reference

Core business

Cloud service providers, SAP service providers - Runibex Technology

Cloud service providers and SAP service providers combined to help migrate, manage and optimise your Cloud, SAP and ecommerce systems.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

edbic

Go to product

Service

Data Engineering Services

Go to product

Service

Graphic Design Services

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

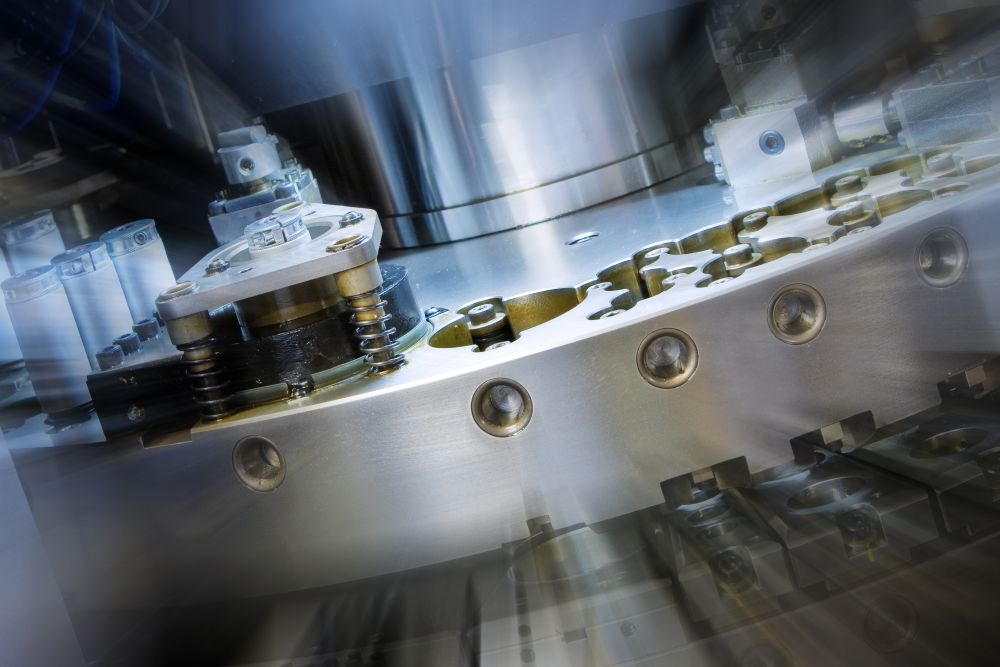

Continuous monitoring

Manufacturing

The challenge Blickle has always prided itself on the superior quality of its wheels and castors. To further enhance this quality with modern technology, the company decided to migrate its production processes to Industry 4.0 standards. This planned transition should have minimal impact on the three-shift production operation, while maintaining flexibility and openness for future digitalization initiatives. The solution Blickle IT developed a concept to enable a sustainable and gradual transformation. At the heart of the strategy is edbic, which enables condition monitoring. Acting as a central data hub, edbic seamlessly extracts data from the machines, transfers it to the ERP system and provides full production transparency. The result With the implementation of edbic, machine data no longer reaches IT incomplete or delayed. Immediate data analysis enables rapid problem resolution. Automatic punching presses are monitored to determine output results, missing parts, quantities and more. By eliminating most of the Excel lists previously used, edbic has significantly streamlined operations. In polyurethane production, edbic identifies and corrects problems, contributing to Blickle's high quality castors and wheels. In addition, edbic is now being used beyond production, facilitating connections to payment providers in the web shop and establishing a communication link with SAP. Outlook for the future Blickle plans to further refine the system by using machine data comparison for predictive maintenance. In addition, the company is considering implementing the compacer IoT gateway to take communication between machines and the ERP system to a new level of automation.

Use case

IoT gateway and Industry 4.0 application

Industry 4.0, Manufacturing

The challenge: BURKHARDT+WEBER is renowned for its expertise in large machining centres. Headquartered in Reutlingen, Germany, the company has a global presence and supplies its products to customers around the world who place a premium on quality. For 130 years, BURKHARDT+WEBER has focused on developing state-of-the-art production solutions for the demanding machining of steel, cast iron and titanium components. The development of these machining centres is the collaborative work of interdisciplinary teams, and all essential components, as well as in-house developments, are manufactured within the company. The compacer IoT solution, built on the edbic platform, is planned for future integration into BURKHARDT+WEBER machining centres. The installation of the compacer IoT gateway enables data collection from the machine's control system. In the long term, BURKHARDT+WEBER machines will offer a wide range of data that can be examined in real time to provide a detailed overview of the machine's condition and efficiency on a dashboard. The solution: An IoT hub will process the collected data, enabling a variety of assessments and ensuring that the operator is kept informed at all times. With machines connected to the compactor solution, condition monitoring is possible, paving the way for the implementation of predictive maintenance. With this approach, BURKHARDT+WEBER enables its customers to successfully implement upcoming digital transformation projects within their production processes.

Use case

Digital retrofit at a manufacturer

Electrical installation technology

The challenge: Our customer has an individually analog 30t punching and bending machine in use, which must not be interfered with in the control process. Small hairline cracks in the large drive wheel can lead to a machine failure, resulting in a production stop. Due to the high storage costs, the spare part is not kept in stock. It can take up to three weeks to order and deliver the new part. In order to avoid a machine breakdown, it should be digitally connected to the current production environment and in future the condition of the gearwheel should be analyzed by means of condition monitoring and a breakage better predicted. Our customer's goal was therefore to make the machine IoT-ready with a digital retrofit in order to reduce machine downtimes and increase machine utilization times. The solution: Digital activation of the existing system was unavoidable, which is why sensors were initially installed by the customer to detect the gear breakage. The vBox from Fraunhofer IPT processes the sensor signals and sends the data to the compacer data platform edbic. Among other things, structure-borne noise, vibration, temperature, torque and current are measured. Increased current consumption, which can be a sign of excessive load due to friction and a lack of lubricant, is detected. However, the collected and evaluated data also reveals smaller cracks. The frequency spectrum and other values are recorded, compared and examined for outliers in real time. If an outlier, such as a crack, is detected, an alarm is generated and employees are informed. They can take action if necessary and production downtime can be avoided. Our customer: a German market leader in the field of electrical installation technology and global market leader in SCHUKO® sockets, produces at two locations in Germany and exports to more than 60 countries. In order to further expand its brand leadership and establish innovations in the smart home sector, the company is taking on new digital challenges.

Use case

Business and IoT integration in Antwerp Euroterminal

Ports

The challenge: The implementation of a new Terminal Operating System (TOS) offered our customer the unique opportunity to rethink the entire IT landscape. Accelerating the digital transformation and reducing the workload became key target definitions. The aim was to meet the ever-changing internal and customer requirements, while offering high-quality services to end customers. The most important factors were maintaining a high level of customer satisfaction and a clear commitment to maximum security. The existing system landscape had grown with the company and was therefore very heterogeneous and poorly integrated. This had led to high maintenance and administration costs. Integration projects were only implemented when necessary and integration problems were solved by in-house developments. This led to silo thinking and resulted in increasingly fragmented and isolated knowledge. It became clear that networking the respective systems with suitable tools would create immediate added value and greater transparency. In addition to the "classic" challenges of integration projects, our customer emphasized that the topic of IoT integration was very important to them. Particular attention should be paid to finding the right speed and the right tools for the changeover. A software platform that would enable them to connect their B2B partners and their applications electronically and provide a solid basis for the planned IoT integration would therefore be far ahead of all competing offerings. The solution: The customer decided to use the compacer edbic platform as a B2B/IoT gateway. The integration platform acts as a central "data hub" for our customer and the applications of its trading partners. It has since become the core of all operational and logistical flows. edbic was supplemented in a second step by edpem to introduce business process monitoring (BPM). A whole series of integration projects were implemented in a very short space of time. Some of these were "traditional" B2B projects designed to enable the exchange of EDI, XML and proprietary data with the applications of trading partners and third parties by converting and transmitting the data transparently. In addition, a large number of applications were connected via edbic. The system for shift planning and management of terminal workers was linked to the access control system for the port, enabling automated payroll and significantly relieving the HR department of day-to-day tasks. Integration with the customer's ERP environment, on the other hand, partially automated order acceptance, fulfillment and billing. New capabilities were also added, such as the generation of data records for structured test scenarios, automated access control based on shift planning and visitor appointments, and much more. However, the port operator wanted to go one step further and tackle its first IoT project. For the pilot project, sensor data from the terminal's various weighing and measuring systems was published via edbic. A typical use case is measuring the verified gross mass (VGM) to comply with SOLAS requirements. The data obtained is now automatically fed into higher-level systems such as the TOS or stowage planning for loading ships, where it is available for further processing, analysis and visualization. The network of surveillance cameras has been connected to a perimeter security system, which enables the early detection of intruders. The comparison of number recognition events (ANPR) with access control information and TOS transactions makes anomalies visible, improves traffic management and increases security - a key concern in port terminals. All of this is controlled by edbic. This new level of digitalization makes everyday terminal logistics easier and significantly increases the efficiency of the port.

Use case

EDI in electronics wholesale

Wholesale

The challenge: Due to a lack of transparency in communication, there are always gaps in the transfer of know-how between the active shareholders. A standardized communication structure between customers and business partners must therefore be established. Among other things, this should also contain information on delivery information and ensure greater transparency within the business processes. One challenge, for example, was the lack of visibility of goods availability, which needed to be resolved. The solution: In addition to establishing central IT services, the aim was to create a modern communication concept for Europe-wide business processes using EDI so that all shareholders in Europe can access all data in a shared database. compacer was commissioned to develop, set up and operate a fully integrated B2B industry platform for the group of companies. In addition to the EDI component with integrated supplier onboarding portal, this was also to cover the topic of e-invoicing. An e-invoicing platform was to be established that implements e-billing, signed PDF, e-mail distribution and ZUGFeRD in practice. Our customer: is a market community in electrical wholesale and a group of companies that operates internationally in 26 countries. More than 230 independently cooperating electrical wholesalers now belong to the association. Almost every shareholder is an independent family business. The aim is to strengthen the future of wholesalers. That is why the company's focus is also on cooperation with the individual manufacturers. This is also the reason why a central e-commerce platform had to be set up and expanded.

Use case

Replacement of Legacy Systems

Logistics

The challenge: Our customer was in a very difficult situation: the existing data integration software was outdated, extensions from the provider were no longer possible and support for the software had also been discontinued. As a result, they were looking for a successor that would meet the criteria for a modern data and integration platform, e.g. through web services, and enable a high data throughput. The decisive factor for the customer was full integration into the IBM/AS400/DB2/MQ system environment while adhering to the specified budget and schedule and the modernization and development of a data integration platform for EDI services as a group application with separate systems for development and testing. The solution: The decisive arguments for choosing compacer were, on the one hand, the price and also the time savings that compacer had estimated for the migration project with its model-based and automated project approach. Even the customer's internal service provider would not have been able to implement this in this time frame or with the budget that had been included. On the other hand, the customer was also impressed by the diverse possibilities and flexibility of the compacer data and integration platform edbic during an on-site reference appointment. The migration not only involved the automated porting of around 1,500 mappings and the associated EDI message connections, but also 2,400 partner connections, with the premise that this should have no impact on the connected business partners. Result: Thanks to our model-based project method and close-meshed project controlling, we were easily able to keep to the project timeframe and the specified budget in this migration project. This also made it possible for us to provide the customer with flexible support wherever possible, absorb work peaks on the customer side and gradually take on additional tasks for the customer. We saw this as a great vote of confidence. But it was not only the compacer project method and the successful cooperation that had a positive influence on the speed of the project. Thanks to our established, model-based approach and the automation by means of tool-supported porting of message structures and processes, conversion times and manual sources of error were drastically reduced. This has reduced the migration and testing effort by 80% to 90% compared to the usual manual approach. By using the compacer data integration platform edbic, our customer can now set up processes more easily in day-to-day operations, reuse modules and monitor processes and their interaction more effectively. This significantly increases IT efficiency. The system load is currently 2 million data records per working day (8 hours) and a peak load of 1 million/hour, whereby the system is designed for up to 7 million data records per day. The customer was impressed not only by the flexibility and adaptability of the platform, but above all by its speed. The next step is to implement the diverse possibilities of web services with edbic.

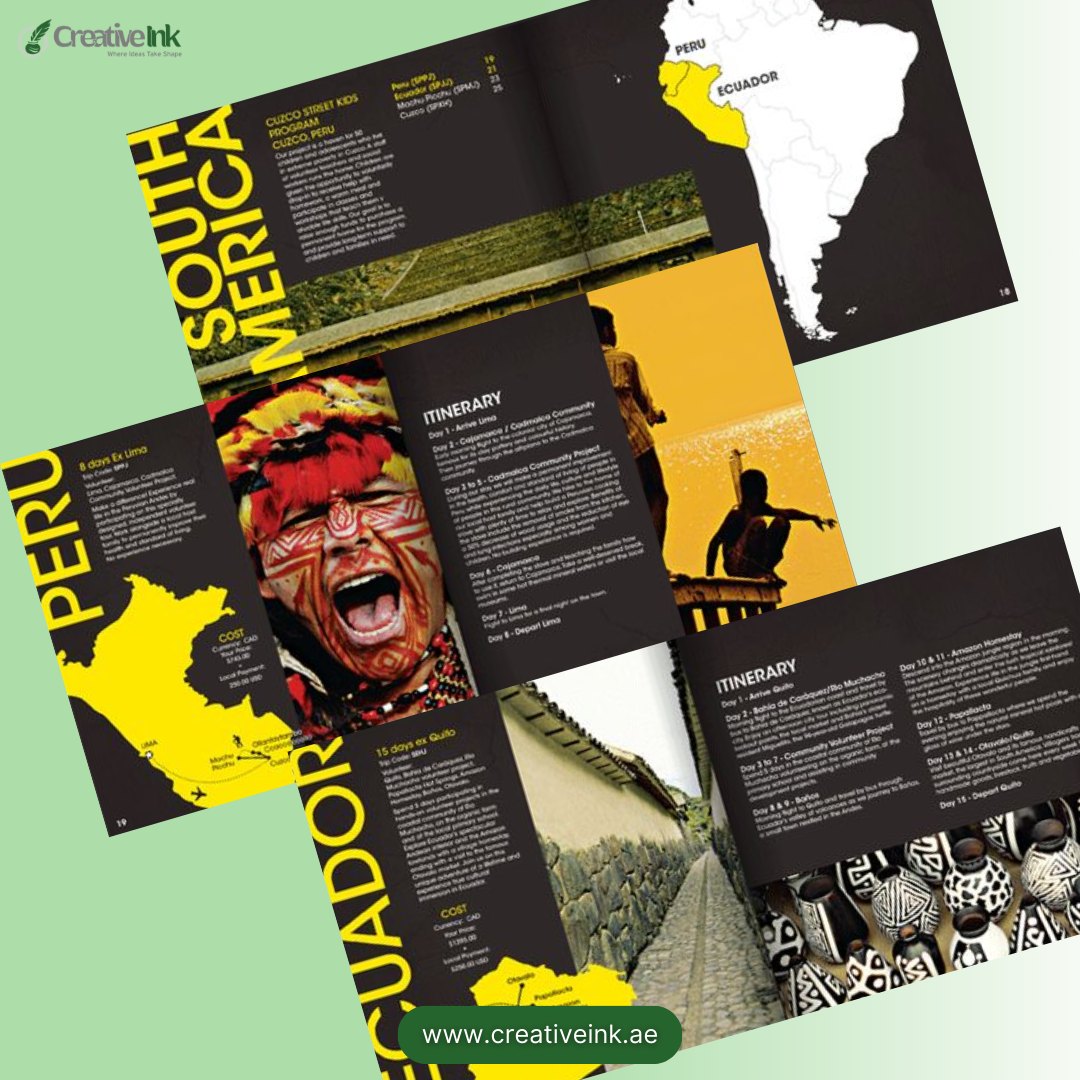

Use case

Business Design & Prints

Business Industry, Printing industry

A Great First Impression! In a world where people have many options, you make your business distinctive with business cards. Creative Ink is based in Dubai and aims to introduce you better in the first go without even exchanging words. Simply customized business cards and win your customer instantly.

Use case

Continuous monitoring

Manufacturing

The challenge Blickle has always prided itself on the superior quality of its wheels and castors. To further enhance this quality with modern technology, the company decided to migrate its production processes to Industry 4.0 standards. This planned transition should have minimal impact on the three-shift production operation, while maintaining flexibility and openness for future digitalization initiatives. The solution Blickle IT developed a concept to enable a sustainable and gradual transformation. At the heart of the strategy is edbic, which enables condition monitoring. Acting as a central data hub, edbic seamlessly extracts data from the machines, transfers it to the ERP system and provides full production transparency. The result With the implementation of edbic, machine data no longer reaches IT incomplete or delayed. Immediate data analysis enables rapid problem resolution. Automatic punching presses are monitored to determine output results, missing parts, quantities and more. By eliminating most of the Excel lists previously used, edbic has significantly streamlined operations. In polyurethane production, edbic identifies and corrects problems, contributing to Blickle's high quality castors and wheels. In addition, edbic is now being used beyond production, facilitating connections to payment providers in the web shop and establishing a communication link with SAP. Outlook for the future Blickle plans to further refine the system by using machine data comparison for predictive maintenance. In addition, the company is considering implementing the compacer IoT gateway to take communication between machines and the ERP system to a new level of automation.

When exploring the Data Integration industry in Turkey, several key considerations should be taken into account. The regulatory landscape is crucial; compliance with local data protection laws, particularly the Personal Data Protection Law (KVKK), is essential for companies handling sensitive information. The industry faces challenges such as a shortage of skilled professionals, which can hinder the implementation of advanced data integration solutions. However, there are significant opportunities, especially as Turkish businesses increasingly prioritize digital transformation and seek to leverage big data analytics for competitive advantage. The competitive landscape features both local and international players, with many companies offering innovative solutions tailored to various sectors, including finance and healthcare. Understanding the unique needs of these sectors is vital for success. Environmental concerns are becoming more relevant as companies look to adopt sustainable practices in their operations, which can influence data integration strategies. On a global scale, Turkey's position as a bridge between Europe and Asia provides a strategic advantage, allowing for potential partnerships and access to diverse markets. Overall, thorough research on these factors will equip individuals with a comprehensive understanding of the Data Integration industry in Turkey and its evolving dynamics.

Some interesting numbers and facts about your company results for Data Integration

| Country with most fitting companies | Turkey |

| Amount of fitting manufacturers | 45 |

| Amount of suitable service providers | 47 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1988 |

| Youngest suiting company | 2018 |

Some interesting questions that has been asked about the results you have just received for Data Integration

What are related technologies to Data Integration?

Based on our calculations related technologies to Data Integration are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Data Integration?

The most represented industries which are working in Data Integration are IT, Software and Services, Other, Administration, Computer Hardware, Consulting

How does ensun find these Data Integration Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.