The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Karllyammo Lennon De Souza

Natal, Brazil

C

1-10 Employees

-

Key takeaway

PREDMEC specializes in predictive maintenance for high-performance industries, offering comprehensive solutions that include equipment rental, inspections, and training. Their dynamic approach combines youthful energy with technical expertise, positioning them well to meet modern market demands.

Reference

Core business

Predmec

Engenharia, Manutenção e Treinamento

Conceito Soluções Preditivas

Paranaguá, Brazil

C

1-10 Employees

2017

Key takeaway

The company emphasizes the importance of predictive maintenance techniques like thermography and laser alignment, which help detect abnormalities and reduce downtime, waste, and costs. Regular oil analysis is also highlighted as a crucial tool for assessing equipment conditions.

Reference

Core business

Conceito Soluções Preditivas - Experiência, dedicação e técnica

EGF

Cosmópolis, Brazil

C

51-100 Employees

1989

Key takeaway

Engefaz Engenharia e Engefaz do Brasil has been a leader in predictive maintenance services in Brazil for years, providing technology and expertise that enhance results while ensuring cost-effectiveness and a solid return on investment. Their structured approach to predictive maintenance aligns with industry expectations, making them a trusted partner for companies like MD Papéis.

Reference

Core business

Engefaz

Desde 1989 Engenharia de Manutenção Líder em serviços de manutenção preditiva no Brasil Referência em manutenção industrial Há anos fornecendo tecnologia e serviços em manutenção para potencializar os resultados com o melhor custo benefício e garantia de retorno sobre investimento. Fale com um especialista Engenharia

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Dynamox

Florianópolis, Brazil

C

51-100 Employees

2007

Key takeaway

Dynamox specializes in predictive maintenance through its DynaPredict sensing system, which employs continuous asset monitoring with wireless sensors to assess machine health and perform spectral analysis. Their DynaNeo dashboard integrates this data, providing users with a visual management tool to enhance decision-making and process reliability.

Reference

Service

The DynaNeo

Manage maintenance processes in a visual and unified manner with a new solution. DynaNeo is a visual management dashboard that combines information from the DynaPredict environment into an integrated view, allowing for the calculation of process reliability based on user-defined indicators of interest.

VIBMASTER

Campo Bom, Brazil

C

11-50 Employees

2011

Key takeaway

VIBMASTER has over two decades of expertise in predictive maintenance and condition monitoring, aimed at enhancing machine availability and increasing production for its clients. Their services include vibration analysis, thermography, and laser alignment, making them a reference in the field.

Reference

Core business

Manutenção Preditiva e Monitoramento de Condição | VIBMASTER

A VIBMASTER presta serviços de Manutenção Preditiva, incluindo o monitoramento de condição e distribuição de equipamentos para indústrias da Região Sul!

SEA SERVICES

São Gonçalo, Brazil

C

11-50 Employees

2014

Key takeaway

The company provides predictive maintenance services for diesel engines and components, ensuring quick and effective support for clients nationwide.

Reference

Core business

Manutenção Diesel | Brasil | Sea Services

La empresa ofrece servicios de reparación y mantenimiento predictivo, preventivo y correctivo para motores y componentes diésel que operan en todo el país. Lo más rápido y seguro posible.

Delfos

Aquidauana, Brazil

C

1-10 Employees

2016

Key takeaway

Delfos provides software technology that enhances predictive maintenance through its advanced platform, which focuses on failure prediction and operational knowledge. Their system simplifies asset management and offers KPI reporting with industry-specific insights, making it essential for efficient renewable energy production.

Reference

Product

Platform - Delfos IM

Inove Preditiva

Sorocaba, Brazil

C

11-50 Employees

2009

Key takeaway

The company's text highlights its focus on online monitoring of key rotating equipment, which ensures reliable operation and minimizes downtime. Their ultrasonic inspection and cloud-based monitoring platform are integral to their predictive maintenance strategy, allowing for the detection of issues before they lead to failures.

Reference

Core business

Inove Preditiva – Soluções de Alto Desempenho

futurai

Vitória, Brazil

C

1-10 Employees

2020

Key takeaway

Futurai offers a predictive maintenance solution that enhances operational efficiency and safety by detecting failures in industrial processes without the need for sensor installation. This technology helps reduce production losses and increase asset availability across various industry segments.

Reference

Core business

Futurai | Diminua perdas de produção

Predição e diagnóstico de anomalias em processos industriais sem necessidade de instalação de sensores.

Multierri Comércio e Serviços Ltda

Cosmópolis, Brazil

C

1-10 Employees

2008

Key takeaway

The company specializes in predictive maintenance, utilizing thermal imaging and ultrasonic inspection to detect thermal anomalies and electrical defects in various equipment. Their services aim to prevent unplanned downtime, identify lubrication issues, and analyze the lifespan of critical components, ultimately reducing energy losses and maintenance costs.

Reference

Core business

Análise Termográfica | Multierri - Manutenção Preditiva | São Paulo

Especialista em Manutenção Preditiva, oferecendo serviços de Análise Termográfica, Termografia em Equipamentos Elétricos, Mecânicos e de Processo e Ultrassom em Sistemas Elétricos. Atendemos todo o Brasil com o melhor Custo x Benefício Possível.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

edpem

Go to product

Service

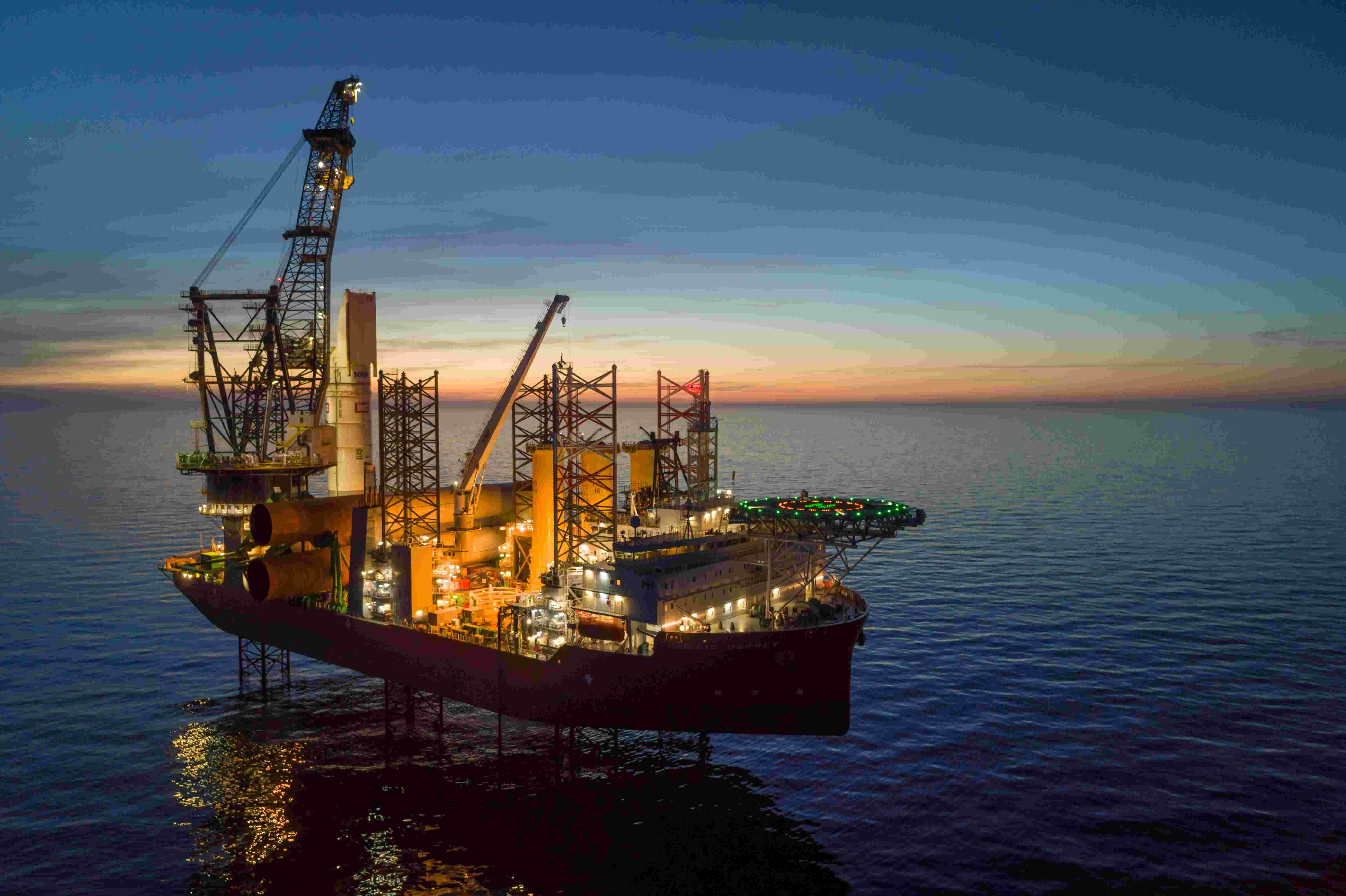

Offshore Converter Station Maintenance and Servicing

Go to product

Service

OperAID

Go to product

Service

Automotive Engineering

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Continuous monitoring

Airport, Logistics

The challenge: A leading provider of ground services and cargo handling wanted to offer comprehensive solutions to the aviation industry. To drive innovation in key areas such as service, quality and reliability, the company wanted to improve visibility and communication through integration and networking across departments. Monitoring irregularities in process flows was critical to optimizing ground handling services. Working with multiple service providers and their disparate IT systems, which varied between airports and internal departments, was a challenge, while maintaining uninterrupted operations throughout the project. The solution: This multi-stage project used edpem, a process event monitoring tool, as the primary solution for monitoring ground services. To ensure fast aircraft turnaround times, the critical path in the process flow needed to be measured and monitored, especially when processes were transferred between suppliers. edpem recorded multiple events, including parking, disembarking completion, cleaning, catering, fuelling, crew boarding and loading completion. Service Level Agreements (SLAs) were tracked and monitored, and causes of delays identified and improved. Ground handling services were optimized by assessing service duration and process flow irregularities. In addition to monitoring traditional EDI processes, visualized reports improved reporting efficiency and facilitated faster decision-making. Key results included reduced turnaround times and fewer disruptions to flight operations. Our client: A major European airport provides ground services to approximately 265 million passengers annually and manages 4.6 million tonnes of global air cargo. Several warehouses are IATA CEIV certified for pharmaceutical logistics. In 2019, its 64,000 employees operated at 300 airports in 47 countries on six continents.

Use case

Real-Time-Monitoring

Logistics

The challenge: The pharmaceutical company works closely with logistics service providers. Due to the volatile nature of the sector's order book, it was difficult to accurately predict capacity utilization, leading to recurring problems with service providers during collection. Service providers need timely information on freight volumes, collection details and the appropriate mode of transport. A key challenge was the sharing of real-time transport data. Another key concern was tracking and tracing, which proved difficult due to incomplete integration of certain areas of the warehouse management system. In addition, real-time monitoring of internal and external departments and service providers was required to optimize logistics processes. The solution: edpem was implemented as an end-to-end monitoring solution to improve logistics processes. The monitoring covered the entire delivery process, from SAP order documents and invoices to final delivery. Connection and monitoring of the warehouse management system was also part of the scope. Comprehensive tracking of goods throughout the supply chain enabled quick retrieval of information without involving other departments, saving valuable time and resources. Optimal vehicle selection for parcel collection and product tracking by batch were achieved. Internal IT system security was ensured, as external partners could only access edpem without needing permissions for internal applications. Parcel scanning enabled customer order tracking and tracing, early problem identification and real-time notification of process owners. edpem tracked the entire shipping process from packaging to customer delivery. The automation of electronic data interchange (EDI) provided new opportunities for superior service and quality for customers and logistics providers. Our customer: A pharmaceutical company based in Germany provides "Made in Germany" products to patients worldwide, with almost all products manufactured at its headquarters in Baden-Baden and distributed through an extensive network. Its main focus is on the research and production of medicines based on natural ingredients. The company has achieved global growth and operates in 50 countries.

Use case

Continuous monitoring

Airport, Logistics

The challenge: A leading provider of ground services and cargo handling wanted to offer comprehensive solutions to the aviation industry. To drive innovation in key areas such as service, quality and reliability, the company wanted to improve visibility and communication through integration and networking across departments. Monitoring irregularities in process flows was critical to optimizing ground handling services. Working with multiple service providers and their disparate IT systems, which varied between airports and internal departments, was a challenge, while maintaining uninterrupted operations throughout the project. The solution: This multi-stage project used edpem, a process event monitoring tool, as the primary solution for monitoring ground services. To ensure fast aircraft turnaround times, the critical path in the process flow needed to be measured and monitored, especially when processes were transferred between suppliers. edpem recorded multiple events, including parking, disembarking completion, cleaning, catering, fuelling, crew boarding and loading completion. Service Level Agreements (SLAs) were tracked and monitored, and causes of delays identified and improved. Ground handling services were optimized by assessing service duration and process flow irregularities. In addition to monitoring traditional EDI processes, visualized reports improved reporting efficiency and facilitated faster decision-making. Key results included reduced turnaround times and fewer disruptions to flight operations. Our client: A major European airport provides ground services to approximately 265 million passengers annually and manages 4.6 million tonnes of global air cargo. Several warehouses are IATA CEIV certified for pharmaceutical logistics. In 2019, its 64,000 employees operated at 300 airports in 47 countries on six continents.

In the Predictive Maintenance industry in Brazil, several key considerations are crucial for effective research and decision-making. The regulatory environment can be complex, as compliance with local and international standards is essential for operational legitimacy. Companies must navigate environmental regulations, particularly relevant in sectors like manufacturing and energy, where sustainability practices are increasingly under scrutiny. Additionally, the Brazilian market presents unique challenges, including infrastructure limitations and varying levels of technology adoption across industries. However, these challenges also create opportunities for innovative solutions tailored to local needs, such as IoT and AI technologies for better predictive analytics. The competitive landscape is evolving, with both established players and emerging startups vying for market share, emphasizing the importance of understanding competitors' offerings and market positioning. Furthermore, Brazil's growing economy and increasing investments in industrial modernization signal a promising future for predictive maintenance, particularly in sectors such as agriculture, oil and gas, and transportation. Engaging with local industry networks and attending relevant trade shows can provide valuable insights and connections, enhancing one's understanding of market dynamics and potential partnerships. Overall, thorough research into these various factors will equip anyone interested in the predictive maintenance sector in Brazil with the knowledge necessary to navigate this promising yet complex landscape effectively.

Some interesting numbers and facts about your company results for Predictive Maintenance

| Country with most fitting companies | Brazil |

| Amount of fitting manufacturers | 10 |

| Amount of suitable service providers | 13 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1989 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Predictive Maintenance

What are related technologies to Predictive Maintenance?

Based on our calculations related technologies to Predictive Maintenance are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Predictive Maintenance?

The most represented industries which are working in Predictive Maintenance are IT, Software and Services, Manufacturing, Oil, Energy and Gas, Automation, Retail

How does ensun find these Predictive Maintenance Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.