The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

E-Repair Srl Service Partner Siemens

Italy

B

11-50 Employees

2007

Key takeaway

E-Repair emphasizes its commitment to reducing plant downtime through its advanced repair processes and the availability of courtesy products, which aligns with the principles of predictive maintenance. Their qualified technicians utilize cutting-edge testing tools to restore electronic devices, ensuring optimal performance and functionality.

Reference

Service

Industry predictive maintenance

Aramis

Milan, Italy

B

1-10 Employees

2012

Key takeaway

ARAMIS srl specializes in developing advanced methodologies and algorithms for the analysis of industrial systems, making it well-equipped to address predictive maintenance challenges. With a focus on innovative statistical, artificial intelligence, and machine learning techniques, the company creates customized solutions that enhance reliability and availability for various industries.

Reference

Service

Predictive Maintenance - Aramis3d

OVER Machining Centers Europe

Pontenure, Italy

B

11-50 Employees

-

Key takeaway

The company offers a comprehensive suite of after-sales services, including predictive maintenance for CNC machining centers. They emphasize technical assistance and calibration to enhance precision, ensuring optimal performance.

Reference

Product

Predictive maintenance | Over Machining Centers

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Marelli Motor

Italy

B

- Employees

-

Key takeaway

Marelli Motori specializes in providing innovative solutions that enhance the efficiency and productivity of their customers' businesses. Their commitment to predictive diagnostics includes a comprehensive set of tests designed to protect machines from failure and downtime, making them a valuable partner in predictive maintenance.

Reference

Service

Predictive Diagnostics - Marelli Motori

A full set of predictive tests on all electrical and mechanical functional parameters is the most effective procedure available to protect machines from failure and down-time.

Alma Automotive

Bologna, Italy

B

11-50 Employees

2002

Key takeaway

Alma Automotive's WARNN system is designed for predictive maintenance, enabling the early detection of failures by analyzing input data to forecast the future health of machinery. This innovative approach enhances the reliability and performance of mechatronic systems through advanced telemetry and automation solutions.

Reference

Product

Predictive Maintenance System WARNN - Alma Automotive

The WARNN system helps to discover failures in advance, using input data to estimate future health indicators of observed machinery.

TOOLS for SMART MINDS

Castel Mella, Italy

B

1-10 Employees

1995

Key takeaway

The company focuses on enhancing production processes through innovative data collection and management solutions, with a strong commitment to predictive maintenance strategies that aim to boost production efficiency and extend machinery life cycles.

Reference

Product

Digital Factory AI.Tech - predictive maintenance strategy

Mc RegEm Srl

Italy

B

1-10 Employees

-

Key takeaway

McRegEm specializes in digital services, including the development and maintenance of IoT solutions, and highlights its focus on predictive maintenance. As a technological partner, McRegEm plays a key role in driving innovation and digital transformation for its clients.

Reference

Core business

McRegEm

Mecoil Diagnosi Meccaniche SrL

Florence, Italy

B

11-50 Employees

1989

Key takeaway

Mecoil specializes in lubricant oil analysis and emphasizes innovation and research for predictive maintenance. They offer predefined packages for oil analysis and provide training courses for certification in lubrication technology.

Reference

Core business

Mecoil, specialisti in analisi oli lubrificanti – Innovazione e ricerca per la Manutenzione Predittiva

Innovazione e ricerca per la Manutenzione Predittiva

RAMCUBE

Milan, Italy

B

11-50 Employees

1997

Key takeaway

RAMCUBE offers an Asset Management solution that supports maintenance services, emphasizing Maintenance Management and Asset Integrity.

Reference

Core business

MAINTENANCE MANAGEMENT & ASSET INTEGRITY | RAMCUBE

MPS Engineering S.r.l.

Mercato San Severino, Italy

B

11-50 Employees

2014

Key takeaway

MPS Engineering offers support to businesses in their digital transition, utilizing cutting-edge technologies and the expertise of their skilled technicians. Their strong focus on quality and innovation enables them to develop and provide advanced solutions tailored to meet the specific needs of clients, which may include predictive maintenance strategies for enhancing the durability and efficiency of industrial systems and automated warehouses.

Reference

Product

Maintenance - MPS Engigneering

MPS Maintenance DURABILITY AND EFFICIENCY OF INDUSTRIAL SYSTEMS AND AUTOMATED WAREHOUSES h24 7 su 7 call us

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

edpem

Go to product

Service

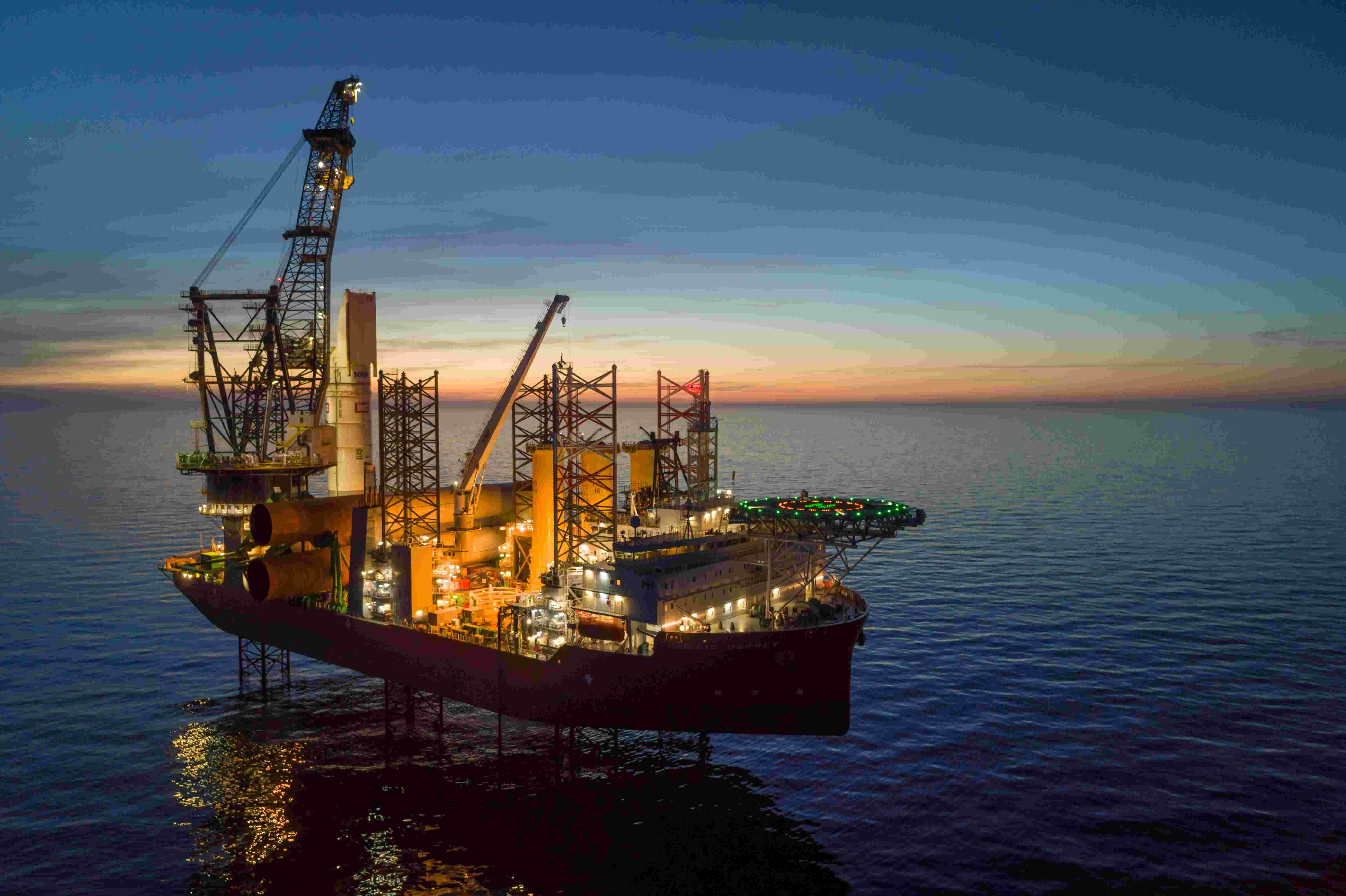

Offshore Converter Station Maintenance and Servicing

Go to product

Service

OperAID

Go to product

Service

Automotive Engineering

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Continuous monitoring

Airport, Logistics

The challenge: A leading provider of ground services and cargo handling wanted to offer comprehensive solutions to the aviation industry. To drive innovation in key areas such as service, quality and reliability, the company wanted to improve visibility and communication through integration and networking across departments. Monitoring irregularities in process flows was critical to optimizing ground handling services. Working with multiple service providers and their disparate IT systems, which varied between airports and internal departments, was a challenge, while maintaining uninterrupted operations throughout the project. The solution: This multi-stage project used edpem, a process event monitoring tool, as the primary solution for monitoring ground services. To ensure fast aircraft turnaround times, the critical path in the process flow needed to be measured and monitored, especially when processes were transferred between suppliers. edpem recorded multiple events, including parking, disembarking completion, cleaning, catering, fuelling, crew boarding and loading completion. Service Level Agreements (SLAs) were tracked and monitored, and causes of delays identified and improved. Ground handling services were optimized by assessing service duration and process flow irregularities. In addition to monitoring traditional EDI processes, visualized reports improved reporting efficiency and facilitated faster decision-making. Key results included reduced turnaround times and fewer disruptions to flight operations. Our client: A major European airport provides ground services to approximately 265 million passengers annually and manages 4.6 million tonnes of global air cargo. Several warehouses are IATA CEIV certified for pharmaceutical logistics. In 2019, its 64,000 employees operated at 300 airports in 47 countries on six continents.

Use case

Real-Time-Monitoring

Logistics

The challenge: The pharmaceutical company works closely with logistics service providers. Due to the volatile nature of the sector's order book, it was difficult to accurately predict capacity utilization, leading to recurring problems with service providers during collection. Service providers need timely information on freight volumes, collection details and the appropriate mode of transport. A key challenge was the sharing of real-time transport data. Another key concern was tracking and tracing, which proved difficult due to incomplete integration of certain areas of the warehouse management system. In addition, real-time monitoring of internal and external departments and service providers was required to optimize logistics processes. The solution: edpem was implemented as an end-to-end monitoring solution to improve logistics processes. The monitoring covered the entire delivery process, from SAP order documents and invoices to final delivery. Connection and monitoring of the warehouse management system was also part of the scope. Comprehensive tracking of goods throughout the supply chain enabled quick retrieval of information without involving other departments, saving valuable time and resources. Optimal vehicle selection for parcel collection and product tracking by batch were achieved. Internal IT system security was ensured, as external partners could only access edpem without needing permissions for internal applications. Parcel scanning enabled customer order tracking and tracing, early problem identification and real-time notification of process owners. edpem tracked the entire shipping process from packaging to customer delivery. The automation of electronic data interchange (EDI) provided new opportunities for superior service and quality for customers and logistics providers. Our customer: A pharmaceutical company based in Germany provides "Made in Germany" products to patients worldwide, with almost all products manufactured at its headquarters in Baden-Baden and distributed through an extensive network. Its main focus is on the research and production of medicines based on natural ingredients. The company has achieved global growth and operates in 50 countries.

Use case

Continuous monitoring

Airport, Logistics

The challenge: A leading provider of ground services and cargo handling wanted to offer comprehensive solutions to the aviation industry. To drive innovation in key areas such as service, quality and reliability, the company wanted to improve visibility and communication through integration and networking across departments. Monitoring irregularities in process flows was critical to optimizing ground handling services. Working with multiple service providers and their disparate IT systems, which varied between airports and internal departments, was a challenge, while maintaining uninterrupted operations throughout the project. The solution: This multi-stage project used edpem, a process event monitoring tool, as the primary solution for monitoring ground services. To ensure fast aircraft turnaround times, the critical path in the process flow needed to be measured and monitored, especially when processes were transferred between suppliers. edpem recorded multiple events, including parking, disembarking completion, cleaning, catering, fuelling, crew boarding and loading completion. Service Level Agreements (SLAs) were tracked and monitored, and causes of delays identified and improved. Ground handling services were optimized by assessing service duration and process flow irregularities. In addition to monitoring traditional EDI processes, visualized reports improved reporting efficiency and facilitated faster decision-making. Key results included reduced turnaround times and fewer disruptions to flight operations. Our client: A major European airport provides ground services to approximately 265 million passengers annually and manages 4.6 million tonnes of global air cargo. Several warehouses are IATA CEIV certified for pharmaceutical logistics. In 2019, its 64,000 employees operated at 300 airports in 47 countries on six continents.

When exploring the Predictive Maintenance industry in Italy, several key factors come into play. Regulatory compliance is crucial, as Italian and EU regulations dictate standards for safety and environmental sustainability. Companies must be aware of the Industry 4.0 framework, which encourages integration of digital technologies in manufacturing, enhancing predictive maintenance capabilities. The competitive landscape is evolving, with both established firms and startups vying for market share. Understanding the technological advancements, such as IoT and AI, is essential for identifying innovative solutions that can offer a competitive edge. Additionally, the Italian market presents unique challenges, including a diverse industrial base and varying levels of technology adoption among sectors. Opportunities abound, especially in industries like manufacturing, energy, and transportation, where predictive maintenance can significantly reduce downtime and operational costs. Environmental concerns are also prominent, as companies increasingly aim to minimize their carbon footprint through efficient maintenance practices. Overall, the global relevance of predictive maintenance is underscored by its potential to transform operations, making it a vital area for investment and development in Italy.

Some interesting numbers and facts about your company results for Predictive Maintenance

| Country with most fitting companies | Italy |

| Amount of fitting manufacturers | 118 |

| Amount of suitable service providers | 118 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1989 |

| Youngest suiting company | 2014 |

Some interesting questions that has been asked about the results you have just received for Predictive Maintenance

What are related technologies to Predictive Maintenance?

Based on our calculations related technologies to Predictive Maintenance are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Predictive Maintenance?

The most represented industries which are working in Predictive Maintenance are IT, Software and Services, Manufacturing, Oil, Energy and Gas, Machinery Manufacturing, Automation

How does ensun find these Predictive Maintenance Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.