The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Prompt Solution

Richmond, United States

B

11-50 Employees

-

Key takeaway

Prompt Solutions specializes in integrated Predictive Maintenance (iPdM) services, offering comprehensive solutions that optimize operations for various industries, including oil and gas. Their expertise in Vibration Analysis, Infrared Thermography, and other advanced monitoring techniques supports effective predictive maintenance programs.

Reference

Service

Predictive Maintenance Services - Prompt Solutions Co., Ltd

PdM Specialists

United States

B

1-10 Employees

2006

Key takeaway

PdM Specialists is dedicated to helping customers achieve their performance goals through timely reporting of equipment condition, utilizing both route-based and remote monitoring. They offer comprehensive predictive maintenance training programs, equipping employees with essential skills to proactively maintain assets and enhance operational efficiency.

Reference

Service

Predictive Maintenance Training — PdM Specialists

PdM Specialists offers both on-site and remote training programs to teach and mentor your employees in the concepts of predictive maintenance.

Collaborating Solutions

Excelsior, United States

B

1-10 Employees

2014

Key takeaway

The company emphasizes its innovative approach to predictive maintenance by leveraging cloud and mobile technologies, making it accessible for organizations of all sizes to monitor their machines effectively and reduce costs as they scale.

Reference

Core business

PREDICTIVE MAINTENANCE – Wireless and Cloud-based - Collaborant Solutions

We are the first company to harness the cloud and mobile so that any company can do predictive maintenance every day from anywhere.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Automatic Controls Co

Town of Massena, United States

B

1-10 Employees

-

Key takeaway

The company offers a variety of predictive maintenance sensors and systems, highlighting their expertise in providing intelligent instruments and measurement equipment for this purpose.

Reference

Product

Predictive Maintenance — Products

Mitek Analytics

Palo Alto, United States

B

1-10 Employees

-

Key takeaway

Mitek focuses on enhancing supply chain management through advanced analytics, providing observability in maintenance and operations. Their expertise, supported by the US Air Force, directly relates to predictive maintenance, making it a key aspect of their analytics offerings.

Reference

Service

Predictive Maintenance – Mitek Analytics

New England Spintech, LLC

Spencer, United States

B

1-10 Employees

2007

Key takeaway

New England SpinTech offers specialized Predictive Maintenance Services that are designed to protect assets and reduce maintenance costs through accurate assessment and machine condition trending. With over 80 years of combined experience, the company emphasizes the importance of these services in maintaining operational efficiency.

Reference

Service

Predictive Maintenance Services for Accurate Assessment - NE SpinTech

Condition Monitoring Analytics LLC

Theodore, United States

B

1-10 Employees

2017

Key takeaway

Condition Monitoring Analytics specializes in designing Predictive Maintenance (PdM) programs, enhancing equipment reliability by providing early warnings of potential failures. Their services utilize various technologies, including vibration analysis and infrared thermography, to monitor equipment conditions effectively.

Reference

Service

Predictive Maintenance Services - CMA

Predictive Maintenance programs incorporate a host of technologies including vibration, infrared, ultrasound motor testing to identify equipment conditions.

Power-MI

Pembroke Pines, United States

B

1-10 Employees

2016

Key takeaway

Power-MI offers a comprehensive solution for managing predictive maintenance through its integration with CMMS software, allowing for automated data management and work-order creation. This enables users to efficiently implement and track condition-based maintenance strategies, ultimately optimizing machine reliability and demonstrating the return on investment of their maintenance efforts.

Reference

Core business

Power-MI | Cloud condition monitoring

Cloud condition monitoring

Machine Diagnostics LLC

Memphis, United States

B

1-10 Employees

-

Key takeaway

Machine Diagnostics offers comprehensive predictive maintenance solutions across the United States, ensuring that clients have access to accurate and timely information to optimize their equipment. Their certified technicians focus on reducing costs and increasing productivity by preventing problems before they occur.

Reference

Core business

Best Predictive Maintenance Solutions | Machine Diagnostics

Turn to us for the best predictive maintenance solutions. We help you avoid costly repairs by keeping your machines optimized.

Uptake Technologies

Chicago, United States

B

251-500 Employees

2014

Key takeaway

Uptake specializes in predictive maintenance by transforming underutilized data into actionable insights that help prevent failures before they occur. Their analytics platform integrates work orders and sensor intelligence, enabling companies to reduce maintenance costs, enhance uptime, and make informed business decisions.

Reference

Core business

Predictive Maintenance | Uptake

Uptake is a leader in predictive analytics software-as-a-service (SaaS), working to translate data into smarter operations.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

edpem

Go to product

Service

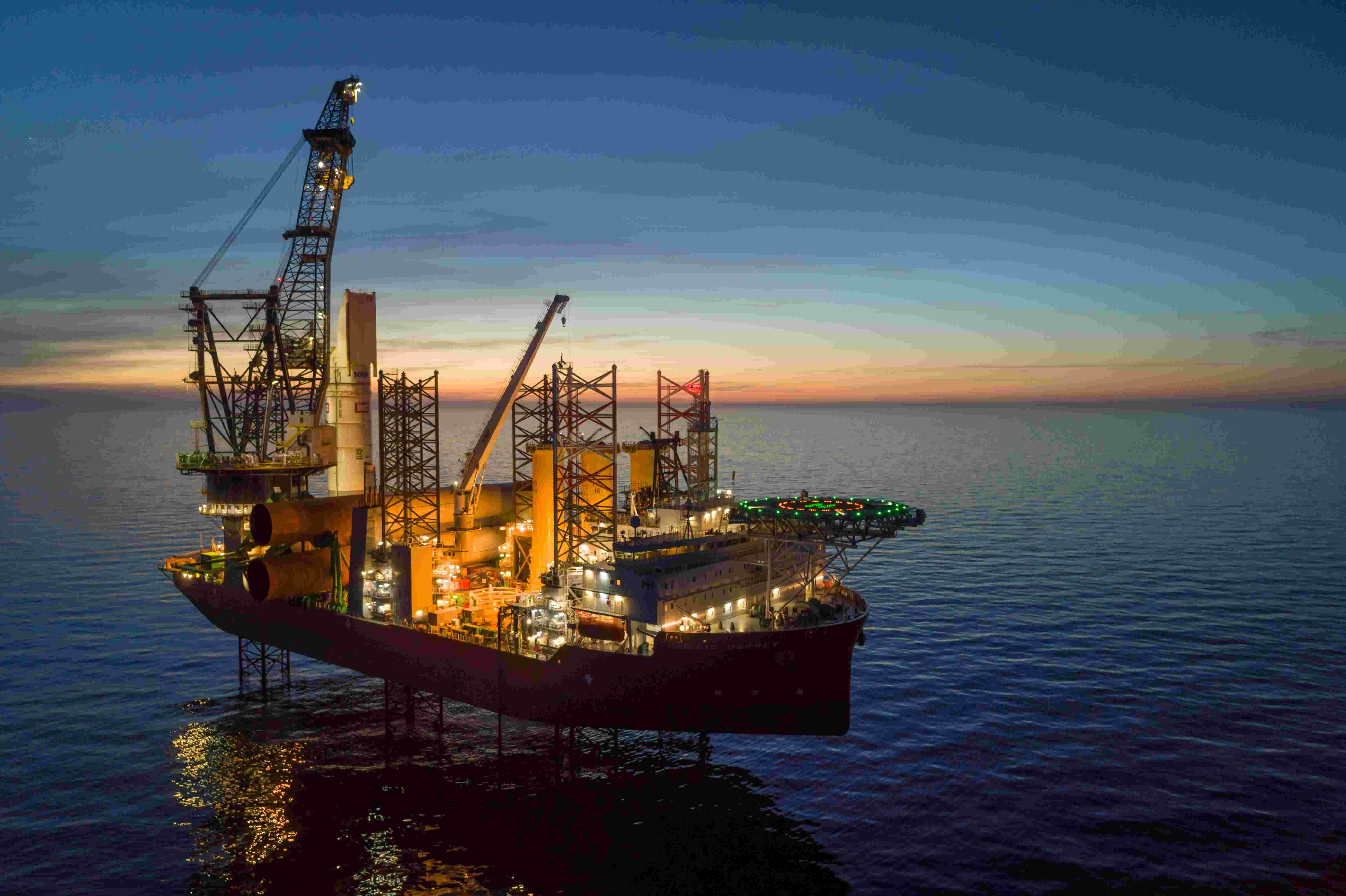

Offshore Converter Station Maintenance and Servicing

Go to product

Service

OperAID

Go to product

Service

Automotive Engineering

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Continuous monitoring

Airport, Logistics

The challenge: A leading provider of ground services and cargo handling wanted to offer comprehensive solutions to the aviation industry. To drive innovation in key areas such as service, quality and reliability, the company wanted to improve visibility and communication through integration and networking across departments. Monitoring irregularities in process flows was critical to optimizing ground handling services. Working with multiple service providers and their disparate IT systems, which varied between airports and internal departments, was a challenge, while maintaining uninterrupted operations throughout the project. The solution: This multi-stage project used edpem, a process event monitoring tool, as the primary solution for monitoring ground services. To ensure fast aircraft turnaround times, the critical path in the process flow needed to be measured and monitored, especially when processes were transferred between suppliers. edpem recorded multiple events, including parking, disembarking completion, cleaning, catering, fuelling, crew boarding and loading completion. Service Level Agreements (SLAs) were tracked and monitored, and causes of delays identified and improved. Ground handling services were optimized by assessing service duration and process flow irregularities. In addition to monitoring traditional EDI processes, visualized reports improved reporting efficiency and facilitated faster decision-making. Key results included reduced turnaround times and fewer disruptions to flight operations. Our client: A major European airport provides ground services to approximately 265 million passengers annually and manages 4.6 million tonnes of global air cargo. Several warehouses are IATA CEIV certified for pharmaceutical logistics. In 2019, its 64,000 employees operated at 300 airports in 47 countries on six continents.

Use case

Real-Time-Monitoring

Logistics

The challenge: The pharmaceutical company works closely with logistics service providers. Due to the volatile nature of the sector's order book, it was difficult to accurately predict capacity utilization, leading to recurring problems with service providers during collection. Service providers need timely information on freight volumes, collection details and the appropriate mode of transport. A key challenge was the sharing of real-time transport data. Another key concern was tracking and tracing, which proved difficult due to incomplete integration of certain areas of the warehouse management system. In addition, real-time monitoring of internal and external departments and service providers was required to optimize logistics processes. The solution: edpem was implemented as an end-to-end monitoring solution to improve logistics processes. The monitoring covered the entire delivery process, from SAP order documents and invoices to final delivery. Connection and monitoring of the warehouse management system was also part of the scope. Comprehensive tracking of goods throughout the supply chain enabled quick retrieval of information without involving other departments, saving valuable time and resources. Optimal vehicle selection for parcel collection and product tracking by batch were achieved. Internal IT system security was ensured, as external partners could only access edpem without needing permissions for internal applications. Parcel scanning enabled customer order tracking and tracing, early problem identification and real-time notification of process owners. edpem tracked the entire shipping process from packaging to customer delivery. The automation of electronic data interchange (EDI) provided new opportunities for superior service and quality for customers and logistics providers. Our customer: A pharmaceutical company based in Germany provides "Made in Germany" products to patients worldwide, with almost all products manufactured at its headquarters in Baden-Baden and distributed through an extensive network. Its main focus is on the research and production of medicines based on natural ingredients. The company has achieved global growth and operates in 50 countries.

Use case

Continuous monitoring

Airport, Logistics

The challenge: A leading provider of ground services and cargo handling wanted to offer comprehensive solutions to the aviation industry. To drive innovation in key areas such as service, quality and reliability, the company wanted to improve visibility and communication through integration and networking across departments. Monitoring irregularities in process flows was critical to optimizing ground handling services. Working with multiple service providers and their disparate IT systems, which varied between airports and internal departments, was a challenge, while maintaining uninterrupted operations throughout the project. The solution: This multi-stage project used edpem, a process event monitoring tool, as the primary solution for monitoring ground services. To ensure fast aircraft turnaround times, the critical path in the process flow needed to be measured and monitored, especially when processes were transferred between suppliers. edpem recorded multiple events, including parking, disembarking completion, cleaning, catering, fuelling, crew boarding and loading completion. Service Level Agreements (SLAs) were tracked and monitored, and causes of delays identified and improved. Ground handling services were optimized by assessing service duration and process flow irregularities. In addition to monitoring traditional EDI processes, visualized reports improved reporting efficiency and facilitated faster decision-making. Key results included reduced turnaround times and fewer disruptions to flight operations. Our client: A major European airport provides ground services to approximately 265 million passengers annually and manages 4.6 million tonnes of global air cargo. Several warehouses are IATA CEIV certified for pharmaceutical logistics. In 2019, its 64,000 employees operated at 300 airports in 47 countries on six continents.

When exploring the Predictive Maintenance industry in the United States, several key considerations emerge. The regulatory landscape is crucial, as compliance with standards set by agencies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) can significantly impact operations. Additionally, understanding the technological challenges associated with integrating IoT devices, machine learning algorithms, and data analytics is essential. Companies must also navigate the competitive landscape, which includes both established players and innovative startups, each offering unique solutions. Opportunities abound as industries increasingly recognize the cost-saving benefits of predictive maintenance to reduce downtime and extend equipment lifespan. However, organizations must address environmental concerns, particularly in terms of waste management and energy consumption, as they implement predictive maintenance strategies. The global market relevance is another factor, as the U.S. industry is interconnected with international trends and developments, influencing local strategies and innovations. Ultimately, a comprehensive understanding of these aspects will provide valuable insights for those interested in entering or investing in the predictive maintenance sector.

Some interesting numbers and facts about your company results for Predictive Maintenance

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 1961 |

| Amount of suitable service providers | 2355 |

| Average amount of employees | 1-10 |

| Oldest suiting company | 2006 |

| Youngest suiting company | 2017 |

Some interesting questions that has been asked about the results you have just received for Predictive Maintenance

What are related technologies to Predictive Maintenance?

Based on our calculations related technologies to Predictive Maintenance are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Predictive Maintenance?

The most represented industries which are working in Predictive Maintenance are IT, Software and Services, Other, Oil, Energy and Gas, Manufacturing, Automation

How does ensun find these Predictive Maintenance Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.