The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Machinebazar.com

Berlin, Germany

A

1-10 Employees

-

Key takeaway

Machinebazar.com has been a leading platform for over 25 years, connecting buyers and sellers in the used machinery industry, offering a wide range of information and competitive prices.

Reference

Core business

Machinebazar Europe Leading Used Machines Seller & Buyer

3Axis Group GmbH

Dusseldorf, Germany

A

11-50 Employees

-

Key takeaway

The company specializes in metal processing machinery, including lathes, milling machines, and machining centers, offering verified equipment at competitive prices. With extensive market experience, they facilitate the purchase and sale of various types of machining machinery, ensuring a safe and informed buying process.

Reference

Core business

Used industrial machinery and Top offers • 3axis Group

▷ Do you need a second hand and used industrial machinery that is as good as new? At 3axis Group we have them for you Come in and have a look!

TMQS GmbH

Büchen, Germany

A

11-50 Employees

2001

Key takeaway

TMQS has been a reliable partner in the tobacco industry since 2001, initially selling quality spare parts for tobacco machines and evolving into a full solutions provider. Their experienced team ensures high-grade products and services, highlighting their commitment to the machinery sector.

Reference

Product

Machinery Archives - TMQS

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

DipMax Export GmbH

Berlin, Germany

A

1-10 Employees

2020

Key takeaway

Dipmax Export Company specializes in selling construction equipment and machinery for the earthmoving industry worldwide, offering a diverse selection at fair prices. If you can't find the specific equipment you need, they encourage you to reach out for assistance in locating it.

Reference

Core business

A selection of machinery we can provide for you

Holtmann Fahrzeug- & Maschinenbau GmbH

Moers, Germany

A

11-50 Employees

1982

Key takeaway

The company specializes in providing a high-quality range of machinery tailored to the specific needs of steel and cast iron plants, including advanced deslagging machines and telehandlers. Their robust and multifunctional equipment is designed to meet industrial demands, ensuring efficient operations.

Reference

Product

Special machines and equipment

Hansa Tradepoint

Hamburg, Germany

A

1-10 Employees

-

Key takeaway

Hansa Tradepoint is a trusted supplier of high-quality machinery and solar production lines, ensuring that all products meet stringent safety standards. They also provide expert installation support and a wide range of specialized equipment for sale and rental, making them a key player in the machinery market.

Reference

Core business

Heavy Equipment | Hansa Tradepoint | Germany

Welcome to Hansa Tradepoint, a trusted heavy equipment and machinery supplier. Hansa Tradepoint offers high-quality machinery and solar production lines and connects you with industry experts, whom we regularly work with, to help install the machines at the most competitive prices in the market.

InterMachinery GmbH

Hochdorf-Assenheim, Germany

A

1-10 Employees

-

Key takeaway

INTERMACHINERY specializes in trading recycling machines and represents major companies in the sector, offering a diverse portfolio that includes new and used high-quality machines like mobile shredders and screening plants.

Reference

Product

GIPOBAC – INTERMACHINERY GmbH

GRANIT PARTS

Heeslingen, Germany

A

1001-5000 Employees

1923

Key takeaway

The company offers 250,000 spare parts for construction machinery, highlighting its extensive inventory and reliability as a partner for businesses in need of agricultural and construction equipment.

Reference

Service

Construction machinery & telehandlers

Maschinenbautechnik Hohenlockstedt GmbH

Hohenlockstedt, Germany

A

1-10 Employees

-

Key takeaway

The company highlights its role as a portal for machinery, providing quick access to manufacturers and service providers in the industry. Notably, it features companies like GK Werkzeugmaschinen GmbH and KNUTH Werkzeugmaschinen GmbH, which offer a range of machine tools and automation solutions for effective and precise production processes.

Reference

Core business

Maschinen.de Das Portal für Maschinen

Kamp Machinetechniek

Schüttorf, Germany

A

1-10 Employees

-

Key takeaway

Kamp Machinetechniek is a supplier of Houfek machines for the Benelux region, highlighting their confidence in Houfek's significant presence in the Netherlands.

Reference

Core business

AANBIEDINGEN Kamp Machinetechniek machinehandel

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

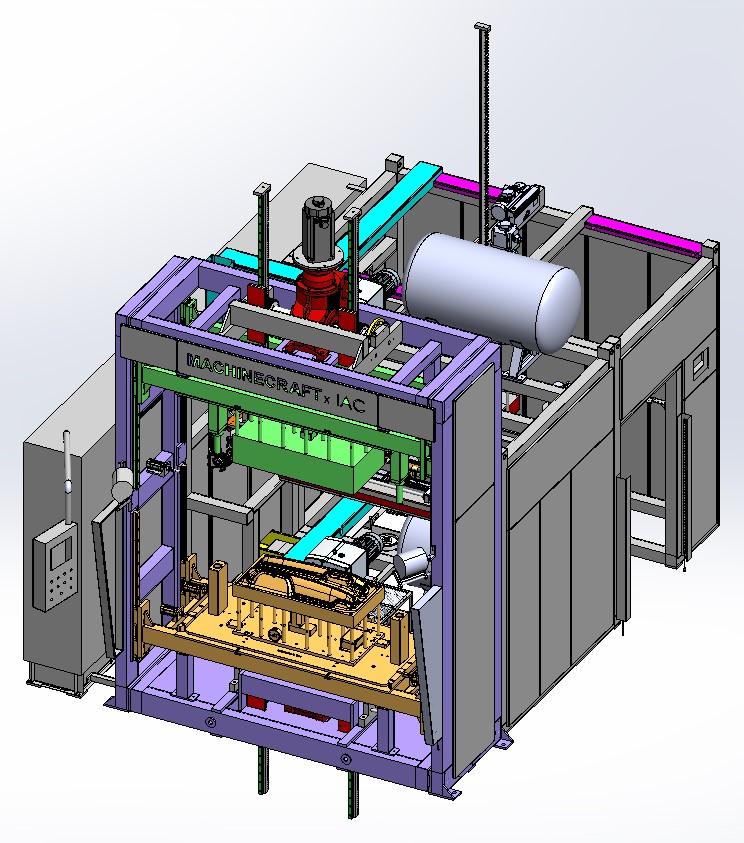

IMG Thermoforming Machine

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

When exploring the machinery industry in Germany, several key considerations are paramount. The country is known for its high-quality engineering and robust manufacturing capabilities, making it a global leader in this sector. Researching companies requires an understanding of the stringent regulations that govern machinery production, including safety standards and environmental legislation. Germany's focus on sustainability has led to increased investments in eco-friendly technologies, creating opportunities for innovation and growth within the industry. Additionally, the competitive landscape is characterized by a mix of established players and emerging startups, each vying for market share in a rapidly evolving environment. The challenges include adapting to digital transformation, where automation and Industry 4.0 practices are becoming increasingly vital. Global market relevance is significant, as Germany exports a substantial portion of its machinery, meaning that international trade dynamics and economic conditions can impact local businesses. Moreover, potential investors and companies must consider the skilled labor market, as the industry relies on a highly trained workforce to maintain its competitive edge. Understanding these factors will provide a comprehensive view of the opportunities and challenges within Germany's machinery industry, informing strategic decisions for anyone looking to engage in this dynamic market.

Some interesting numbers and facts about your company results for Machinery

| Country with most fitting companies | Germany |

| Amount of fitting manufacturers | 827 |

| Amount of suitable service providers | 1058 |

| Average amount of employees | 1-10 |

| Oldest suiting company | 1923 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Machinery

What are related technologies to Machinery?

Based on our calculations related technologies to Machinery are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Machinery?

The most represented industries which are working in Machinery are Other, Machinery Manufacturing, Manufacturing, IT, Software and Services, Automation

How does ensun find these Machinery Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.