The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

TMT Machinery

Japan

A

501-1000 Employees

2002

Key takeaway

TMT MACHINERY, INC. is a leading global provider of advanced synthetic fiber machinery, offering a range of spinning, drawing, and winding systems designed to meet diverse needs. Their commitment to R&D and engineering ensures they support customers in embracing new innovations and varieties in machinery.

Reference

Core business

TMT Machinery, Inc

SHIN MEIWA KIKO K.K.

Japan

A

- Employees

-

Key takeaway

The company offers a diverse selection of machinery, ranging from the latest models to used general-purpose machines, and features the largest exhibition hall, 'Machine Plaza,' in the Tokai area, allowing customers to inspect and operate the equipment. Their commitment to customer satisfaction is reflected in their approach to helping clients choose the best products from their extensive inventory.

Reference

Core business

会社案内 | 中古工作機械販売・メンテナンスなら新明和機工

Hitachi Construction Machinery

Tokyo, Japan

A

10001+ Employees

1970

Key takeaway

HCMA specializes in the design, engineering, manufacturing, and servicing of Hitachi construction machinery, highlighting their commitment to technology and support through a network of experienced dealers. They recently began leading the sales and service efforts for Hitachi's construction and mining equipment in North America.

Reference

Product

Hitachi Construction Machinery Americas Inc Equipment

See the full line of compact, construction and mining available from Hitachi Construction Machinery Americas Inc.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

WinRoad RTS

Tokyo, Japan

A

1-10 Employees

2019

Key takeaway

The company, WinRoad RTS, is a specialized robotic technology provider in the Middle East and Africa, focusing on Japanese robot technology. They offer support for developing custom robotic systems and starting robotic businesses, making them a valuable resource for machinery-related innovations.

Reference

Core business

Robot Technology Provider | WinRoad RTS | Japan

A robotic company specializes in providing Japanese robot technology to the Middle East and Africa.

Komatsu

Tateyama, Japan

A

10001+ Employees

1921

Key takeaway

Komatsu is a leading manufacturer of construction, mining, forestry, and industrial heavy equipment, highlighting its expertise in machinery that powers societal development and infrastructure. With a commitment to innovation and quality, Komatsu creates value through advanced manufacturing technologies.

Reference

Product

Electric | Komatsu

Matsuura Machinery

Fukui, Japan

A

251-500 Employees

1935

Key takeaway

Matsuura Machinery Ltd is a key player in the machinery industry, with multiple locations in England, Germany, and Japan, highlighting its global presence and expertise.

Reference

Core business

Matsuura Machinery Corporation

YASDA PRECISION TOOLS K.K.

Satosho, Japan

A

251-500 Employees

-

Key takeaway

YASDA focuses on delivering ultra-precision machining through its advanced YASDA MICRO CENTER, designed to meet the growing demand for high-quality milling. Their commitment to continuous development and innovative automation solutions ensures the highest accuracy and stability in machining processes.

Reference

Product

YASDA - Automation

Highest accuracy machining x Stability for long term x Innovative software = YASDA’s automation solution.

(株)ハイボット

Tokyo, Japan

A

11-50 Employees

2004

Key takeaway

Hibot's HiBox platform integrates autonomous Smart Tools with advanced data management and real-time visualization, enhancing inspection and maintenance processes. Their robots provide exceptional mobility for inspections in challenging environments, making them a valuable asset for predicting infrastructure failures.

Reference

Service

Services | Hibot

Hibot Website

Mujin, Inc.

Tokyo, Japan

A

101-250 Employees

2011

Key takeaway

Mujin Corp specializes in advanced industrial automation and intelligent robotics solutions, enabling efficient and damage-free automated storage and order fulfillment. Their MujinController platform empowers robots to autonomously manage various applications, enhancing operational efficiency in production environments.

Reference

Core business

Company | Mujin Corp

At Mujin, we combine our rich history of excellence with proven innovation to bring you advanced industrial automation and intelligent robotics solutions that work.

Toshiba Mitsubishi-Electric Industrial Systems Corporation

Tokyo, Japan

A

1001-5000 Employees

2003

Key takeaway

TMEIC provides a wide range of industrial solutions, including advanced automation systems and variable frequency drives, which are essential components in modern machinery. Their focus on innovative technologies and collaborative development ensures that they can meet the diverse needs of various industrial applications globally.

Reference

Core business

TMEIC | Technology, Products and Automation Solutions for Industries Worldwide

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

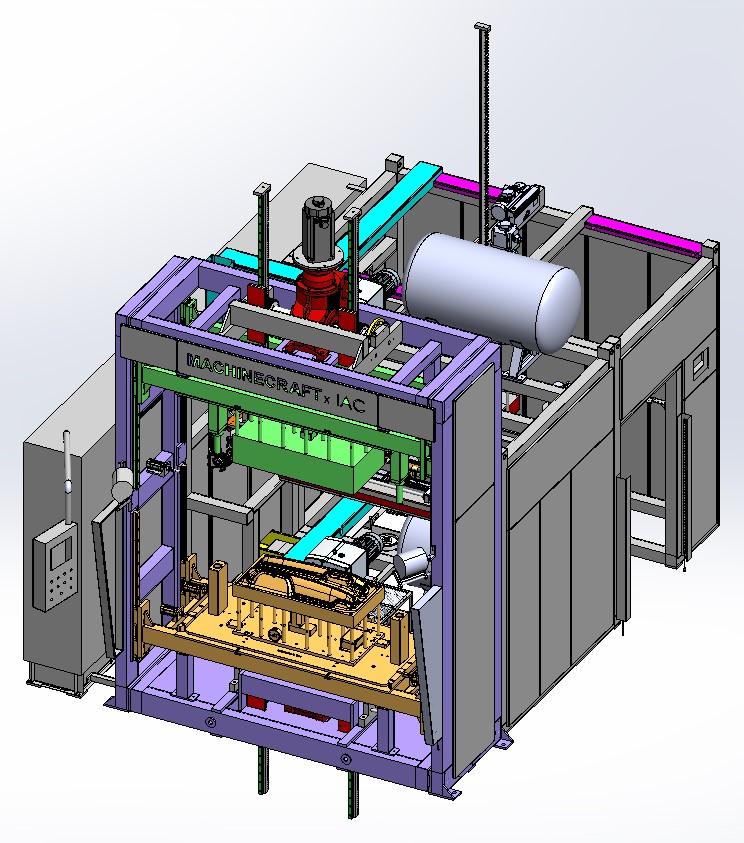

IMG Thermoforming Machine

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Japan's machinery industry is characterized by several key considerations that are essential for anyone researching this sector. The country is known for its advanced technology and innovation, making it a global leader in high-precision machinery, robotics, and automation equipment. However, understanding the stringent regulations surrounding industrial standards and safety compliance is crucial. Companies must navigate complex environmental regulations, particularly in light of Japan's commitment to sustainability and reducing carbon emissions. Challenges in the industry include an aging workforce and increasing competition from emerging markets, which can impact labor availability and cost structures. Opportunities exist in areas such as smart manufacturing and Industry 4.0 technologies, where Japanese firms are investing heavily to enhance productivity and efficiency. Furthermore, collaboration between industries and research institutions promotes innovation and strengthens the competitive landscape. Global market relevance is significant, as Japan's machinery exports play a vital role in the economy. The country's strategic position in Asia allows for access to rapidly growing markets, making it an attractive location for foreign investments and partnerships. Understanding these dynamics is essential for anyone looking to engage with the machinery industry in Japan.

Some interesting numbers and facts about your company results for Machinery

| Country with most fitting companies | Japan |

| Amount of fitting manufacturers | 7 |

| Amount of suitable service providers | 5 |

| Average amount of employees | 501-1000 |

| Oldest suiting company | 1921 |

| Youngest suiting company | 2019 |

Some interesting questions that has been asked about the results you have just received for Machinery

What are related technologies to Machinery?

Based on our calculations related technologies to Machinery are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Machinery?

The most represented industries which are working in Machinery are Machinery Manufacturing, Automation, Other, Wholesale

How does ensun find these Machinery Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.