The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

POH LI HENG BUILDING CONSTRUCTION PTE LTD

Singapore

C

1-10 Employees

-

Key takeaway

The company is expanding its range of machinery to meet diverse client needs, offering comprehensive services for various construction tasks, including demolition and land preparation.

Reference

Core business

pohliheng.com – Machinery rental and trading

Powerplus Group Inc. USA

Singapore

C

501-1000 Employees

-

Key takeaway

POWERPLUS Group Inc. is a prominent manufacturer and supplier of heavy machinery, including bulldozers, motor graders, wheel loaders, and excavators. Their commitment to stringent industry standards ensures that every machine is built to high specifications, providing exceptional value to clients.

Reference

Core business

FINEST RANGE OF MACHINERY - Power Plus

Tractors Singapore Limited

Singapore

C

251-500 Employees

1966

Key takeaway

The company is offering a variety of Caterpillar machinery and parts, highlighting current promotions that provide great deals for customers.

Reference

Product

Machines | Tractors Singapore

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

EQT Yard

Singapore

C

1-10 Employees

2020

Key takeaway

EQT Yard is a specialized online marketplace for construction assets, including used heavy equipment, spare parts, and building materials. The platform enhances procurement and efficiency by allowing businesses to buy, sell, and trade various heavy machinery and related products.

Reference

Core business

Heavy Equipment , Spare Parts & Materials Marketplace - EQT Yard

Used Heavy Equipment, Spare Parts and Building Materials for sale. Easy Heavy Equipment Financing and Hassle-Free Delivery / Freight services.

Cosma Technology

Singapore

C

251-500 Employees

2000

Key takeaway

Cosma Technology specializes in cutting room automation and innovative machinery solutions for the fashion industry, including advanced cutting and labeling machines. Their commitment to integrating cutting-edge technology and data-driven approaches enhances productivity and minimizes errors in production processes.

Reference

Core business

Cosma Technology Cutting Solutions | Smart machinery & Software

Cosma Technology a fully automated Cutting room solution company focused on cutting room automation and inventing new technology for the fashion industry.

Bema International Pte Ltd

Singapore

C

11-50 Employees

-

Key takeaway

BEMA INTERNATIONAL PTE LTD is a reputable machinery and equipment company specializing in the piling, foundation, and construction sectors. They offer a range of used and new machinery for rent and sale, emphasizing quality and prompt service.

Reference

Core business

BEMA INTERNATIONAL PTE LTD

Flexmech Group of Companies

Singapore

C

51-100 Employees

1983

Key takeaway

Flexmech, now part of TRITAN INDUSTRIES, emphasizes its expertise in advanced manufacturing solutions, including precision tooling and machine tools trading. With a focus on Industry 4.0, they are launching a machine condition reporting system designed to enhance production efficiency.

Reference

Core business

FlexMech Engineering

SMT Technology

Singapore

C

11-50 Employees

-

Key takeaway

The company specializes in retrofitting SME machinery and system upgrades to enhance manufacturing efficiency, particularly for high-mix low-volume job orders. With over 20 years of experience, they focus on reducing labor reliance and addressing space constraints through innovative Industry 4.0 solutions.

Reference

Core business

Industry 4.0 Technology Solution, digital factory & IoT

Hand Plus Robotics

Singapore

C

1-10 Employees

2018

Key takeaway

Hand Plus Robotics specializes in providing software-powered flexible robotic systems that can enhance automation in manpower-intensive businesses, addressing various needs through state-of-the-art technologies. Their 1+ Platform enables tailored robotic solutions, emphasizing their commitment to automation and sustainability.

Reference

Product

Solutions | Hand Plus Robotics

Ichi Seiki

Singapore

C

51-100 Employees

1988

Key takeaway

The company aims to be Asia's most reliable partner for metalworking machinery and engineering solutions, focusing on creating value and enhancing productivity for the industries it serves.

Reference

Product

By Function | Ichi Seiki – Equipment and Engineering Solutions

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

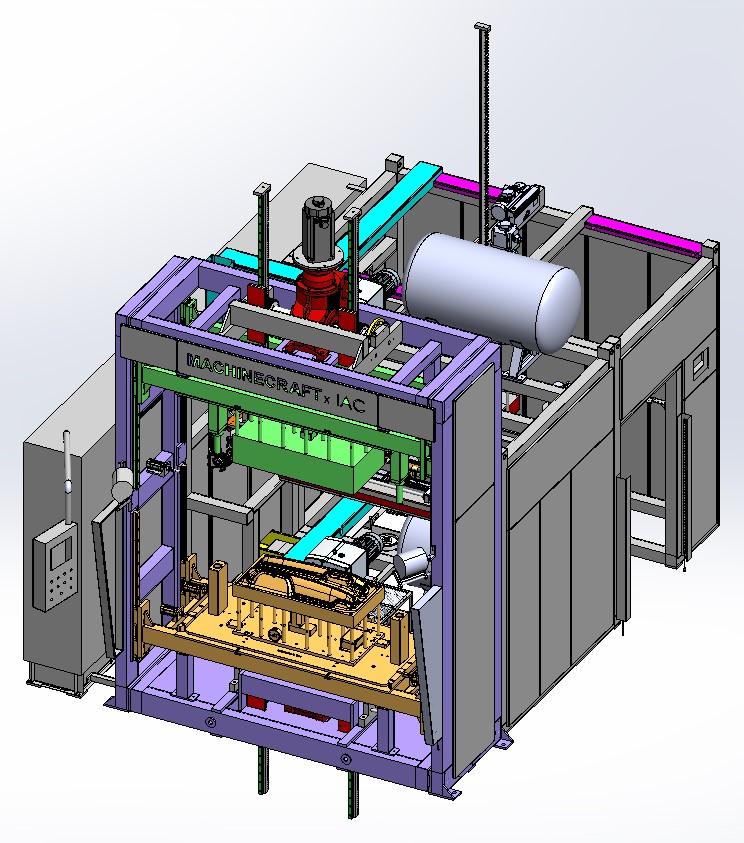

IMG Thermoforming Machine

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

When exploring the machinery industry in Singapore, several key considerations come into play. Regulatory compliance is crucial, as the country has stringent safety and environmental standards that manufacturers must adhere to. This includes obtaining necessary certifications and ensuring products meet local and international quality benchmarks. Additionally, understanding the challenges of a competitive landscape is important, as Singapore serves as a regional hub for machinery and equipment, attracting numerous global players. Opportunities exist in sectors like precision engineering and automation, driven by advancements in technology and rising demand for smart manufacturing solutions. Environmental concerns are also increasingly relevant, with a strong push towards sustainable practices and green technology, aligning with Singapore's commitment to reducing carbon emissions. Moreover, being aware of the global market relevance of Singapore's machinery sector is essential, as it plays a significant role in the supply chains of various industries across Southeast Asia. Companies looking to enter this market should conduct thorough research on the local market dynamics and potential partnerships to navigate the complexities effectively.

Some interesting numbers and facts about your company results for Machinery

| Country with most fitting companies | Singapore |

| Amount of fitting manufacturers | 43 |

| Amount of suitable service providers | 37 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1966 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Machinery

What are related technologies to Machinery?

Based on our calculations related technologies to Machinery are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Machinery?

The most represented industries which are working in Machinery are Automation, Manufacturing, Other, Construction, Machinery Manufacturing

How does ensun find these Machinery Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.