The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Brand Machine AS

Oslo, Norway

A

- Employees

2016

Key takeaway

BrandMachine has extensive expertise in product design and development, sourcing, and production, making it well-equipped to handle various aspects of machinery development. With a focus on creating and developing brands and products, the company's experienced leadership enhances its capability in the sporting goods market.

Reference

Core business

About Us – Brand Machine

MECHMAN

Jørpeland, Norway

A

1-10 Employees

2008

Key takeaway

Mechman AS specializes in mechanical equipment and consulting services, contributing to effective production and product development, particularly in subsea buoyancy and industrial silicone and polyurethane products. With a focus on quality and safety, they offer expertise for both small and large tasks.

Reference

Core business

Mechman AS | Mechman AS

Promet AS NTS Group

Sola, Norway

A

11-50 Employees

1984

Key takeaway

NTS AMEGA offers advanced machining solutions, featuring state-of-the-art 5-axis machining centers and the latest CAD/CAM technology, ensuring superior quality and cost-effective solutions for a wide range of materials. Their expertise includes precision manufacturing, complex repairs, and specialized processes for the oil and gas industry.

Reference

Service

Services -

REPAIR - ADDITIVE MANUFACTURING - MOBILE WORKSHOPS

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

MSH Mechanical Solutions

Våler, Norway

A

51-100 Employees

1987

Key takeaway

The company offers a range of flexible machining services, including CNC lathes with rotary tools, 5-axis CNC MillTurn machines, and a large balancing machine. Their specialized mechanics enhance these services with expertise in condition monitoring and precision laser alignment, providing customers with a comprehensive solution.

Reference

Core business

Leverandør av mekaniske tjenester - Mekanisk Service Halden

#description

ThorMax AS

Ålesund, Norway

A

1-10 Employees

-

Key takeaway

Thormax AS has been involved in the sale and rental of machinery for construction, gardening, and landscaping since 2009, offering a range of equipment including excavators, mini dumpers, and compact loaders, along with attachments.

Reference

Core business

ThorMax AS

Siden 2009 har vi jobbet med utleie,salg og service av maskiner til bygg, hage og anlegg i Ålesund og omegn.

Metall-Maskin AS

Kristiansand, Norway

A

1-10 Employees

1982

Key takeaway

Metall-Maskin AS has been a comprehensive supplier of machinery and equipment for metal processing since 1982, emphasizing their reliability as a partner in this industry.

Reference

Core business

Hjem | Metall-Maskin

Almek Hydraulic Services AS

Stokke, Norway

A

1-10 Employees

1999

Key takeaway

Almek Hydraulic Services AS specializes in providing custom machinery and cable handling solutions for the oil, power, and seismic industries. With years of experience in design and production, they offer both rental and tailored equipment to meet project-specific needs.

Reference

Core business

Cable Handling Solutions | Almek Hydraulic Services AS | Vestfold og Telemark

Almek Hydraulic Services AS provides cable handling solutions and custom machinery for oil, power and seismic industries.

Parts AS

Bergen, Norway

A

1-10 Employees

2004

Key takeaway

The company is one of Norway's largest suppliers of glass for construction machinery, offering products for well-known brands like Volvo and Hitachi, along with a range of parts and equipment. They provide high-quality components, including filters and oil, specifically for construction machines and engines.

Reference

Core business

Deler og utstyr til anleggsmaskiner og motorer | Parts

Sany gravemaskiner, deler og utstyr, filter, glass til anleggsmaskiner og motorer, smøreolje, batterier fra ledende produsenter . Ta kontakt!

Toolserv AS

Stavanger, Norway

A

11-50 Employees

2007

Key takeaway

Toolserv provides third-party workshop services for equipment and has a strong focus on renting out new tools. With a team of experienced oil field personnel and mechanics, the company is well-equipped to support machinery needs.

Reference

Core business

Rental | Completion | Centralizer | Toolserv AS | Norway

Toolserv is a service provider. The company is a coalition of experienced oil field personnel and mechanics whose wide-ranging backgrounds offer a diverse skill-set. Toolserv is divided into four segments: Sales, Rental, Workshop and Engineering.

OGRI

Sande, Norway

A

1-10 Employees

2003

Key takeaway

The company specializes in machinery for transmission line stringing, including stringing machines and equipment for erecting lattice steel towers and laying underground cables.

Reference

Core business

OGRI | OGRI

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

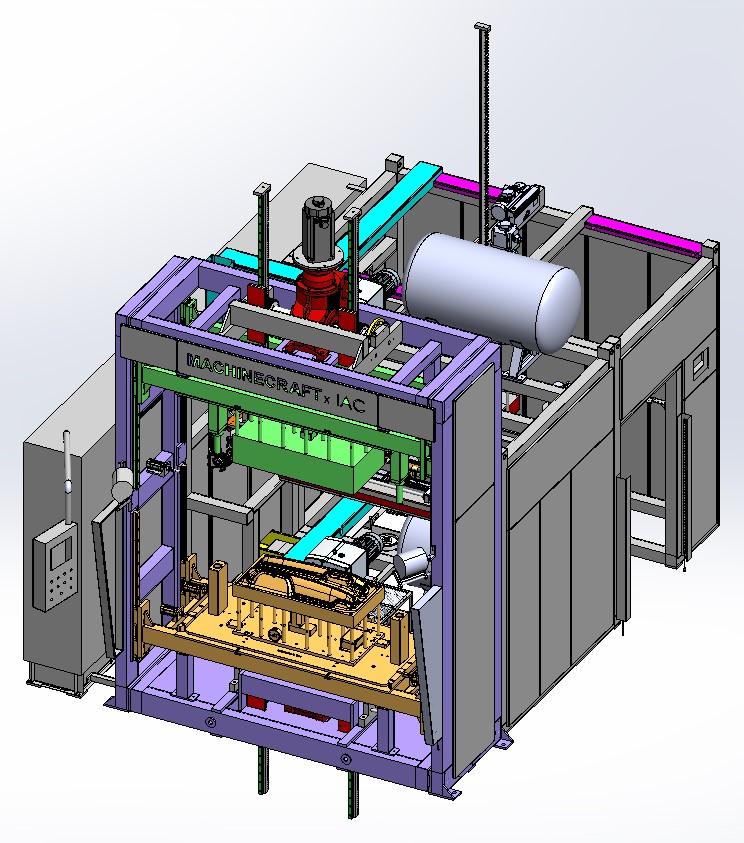

IMG Thermoforming Machine

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

When exploring the machinery industry in Norway, several key factors are essential for thorough research. The country boasts a robust manufacturing sector, heavily influenced by its commitment to sustainability and innovation. Companies in this industry must navigate strict environmental regulations, as Norway prioritizes eco-friendly practices and compliance with EU standards. The competitive landscape is characterized by a mix of established firms and emerging startups, often focusing on advanced technologies such as automation and robotics. Additionally, the machinery industry in Norway faces challenges like fluctuating raw material prices and a skilled labor shortage. However, opportunities abound, especially in renewable energy machinery, given Norway's strong emphasis on green technology. The global market relevance of Norwegian machinery firms is significant, as they often export to international markets, taking advantage of Norway's strategic position in the European economy. Understanding these dynamics, along with the potential for government incentives for innovation and sustainability, can provide valuable insights for anyone interested in entering or investing in this sector.

Some interesting numbers and facts about your company results for Machinery

| Country with most fitting companies | Norway |

| Amount of fitting manufacturers | 25 |

| Amount of suitable service providers | 31 |

| Average amount of employees | 1-10 |

| Oldest suiting company | 1982 |

| Youngest suiting company | 2016 |

Some interesting questions that has been asked about the results you have just received for Machinery

What are related technologies to Machinery?

Based on our calculations related technologies to Machinery are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Machinery?

The most represented industries which are working in Machinery are Oil, Energy and Gas, Machinery Manufacturing, Other, Construction, Manufacturing

How does ensun find these Machinery Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.