The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

UTS Machinery‘’Universal Thermoforming Systems’’

Turkey

C

1-10 Employees

2019

Key takeaway

The company emphasizes its commitment to providing high-quality European machinery at competitive prices, highlighting the ease of converting between moulds and the rapid delivery of original parts to minimize downtime. Their experienced service team ensures prompt support, enhancing the overall value and availability of your systems.

Reference

Service

Services – UTS Machinery

Machina3D

Ümraniye, Turkey

C

1-10 Employees

2021

Key takeaway

Machina specializes in advanced manufacturing methods such as 3D printing, CFD analysis, and algorithmic design, which are applicable across various industries including automotive and defense. Their focus on Design for Additive Manufacturing (DfAM) enhances the efficiency of 3D printing processes.

Reference

Core business

Machina 3D - Utilizing Advanced Engineering and Manufacturing

Machina is utilizing additive manufacturing and advanced engineering applications

Nesto Machine

İnegöl, Turkey

C

11-50 Employees

-

Key takeaway

Nesto Machinery Industry Company specializes in the machinery sector, offering advanced technology and efficient products. With a focus on customer satisfaction and 24/7 service, they provide solutions in spare parts and after-sales support.

Reference

Service

Service - Nesto Machine

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

SAGU Engineering

Turkey

C

11-50 Employees

-

Key takeaway

SAGU Engineering is a trusted machinery parts supplier with over 14 years of experience in industrial manufacturing. They offer machine construction services across various industries, including construction, maritime, aviation, and more, ensuring high-quality production and effective project management.

Reference

Service

Industrial Machine Manufacturer - Construction Machinery | SAGU

SAGU Engineering is trusted machining manufacturer. We provide machine construction services for a wide range of industries: construction, maritime and off-shore industries, machinery and equipment manufacturing, aviation components, aluminium machining, conveying systems, petrochemical industry, waste processing and recycling industry.

AIM Heavy Machinery Inc.

Yenimahalle, Turkey

C

1-10 Employees

2018

Key takeaway

AIM HEAVY MACHINERY INC. specializes in the heavy machinery industry, offering a wide range of machinery and over 180,000 spare parts for leading brands like Caterpillar, Komatsu, Hitachi, and Volvo. Their extensive inventory includes new, remanufactured, and used parts, along with attachments and servicing solutions, making them a comprehensive resource for construction and industrial equipment needs.

Reference

Core business

AIM HEAVY MACHINERY +90 312 385 3536 | HEAVY EQUIPMENT

AIM is a global quality supplier of new genuine, OEM, alternative and reman parts for Caterpillar, Komatsu, Hitachi, Volvo and many more http://aimheavymachinery.com

Rockways Makina Ltd

Esenler, Turkey

C

1-10 Employees

2019

Key takeaway

ROCKWAYS MACHINERY leverages over twenty-two years of experience in the machine-making industry, offering a range of services including the sale, installation, and maintenance of advanced machinery systems. Their expertise encompasses the renovation of programmed machines and the supply of various metalworking machines, such as laser cutting and milling tools.

Reference

Core business

rockways.com

Sell, install, maintain and train on Syntec systems Renovation of programmed machines and replacement of old systems Renewal of traffic jams Replace the spandle romans Repair of mechanical parts and reset accuracy Static and dynamic error handling Transport, assembly and installation of machinery Configure the output of the code to the machines up to 5 axes Agents of programmed metalworking machines: Laser cutting machines and Chinese plasma Machine tools milling and boring Shearing machines and wire cutting Cutting and operating tools

Technic Machines

Turkey

C

1-10 Employees

2011

Key takeaway

The company specializes in providing industrial machine solutions, particularly in metalworking and plastic processing, and emphasizes its commitment to customer satisfaction through detailed research and a comprehensive follow-up process from order confirmation to installation. Their construction profile roll forming machine is designed for high productivity in roll forming profile production.

Reference

Service

Services - Technic Machines

With the support of our good relationships with suppliers, we can meet many different demands from our current portfolio. If we can not response requests of our customers from our portfolio, we make market research according to their requests and try to find best solution for our customers. 1 Guarantee: Every supplier has different guarantee

Muzer Makina San. ve Tic.

Turkey

C

51-100 Employees

1960

Key takeaway

Muzer specializes in turnkey and customized tobacco processing machinery, offering complete design and project management to meet customer requirements. Their experienced team, along with a dedicated R&D department, focuses on enhancing productivity and cost efficiency through advanced engineering technologies.

Reference

Service

Services - Muzer Makina

OYS CNC

Osmangazi, Turkey

C

11-50 Employees

2011

Key takeaway

The company specializes in five-axis CNC milling machinery, which operates continuously and produces highly accurate molds, enhancing product line expansion. Their expertise in CNC machinery and metalworking indicates a strong capability in advanced manufacturing processes.

Reference

Product

Products

CNC Machinery Builder Metalworking and Composite Working

ٍٍِِSAB FPM Filling & Packaging Machines

Başakşehir, Turkey

C

51-100 Employees

1993

Key takeaway

SAB F.P.M, a prominent manufacturer of filling and packaging machines since 1993, emphasizes quality and precision in its production, utilizing advanced CNC machining and PLC technologies.

Reference

Product

Horizontal Machines Archives - SAB F.B.M

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

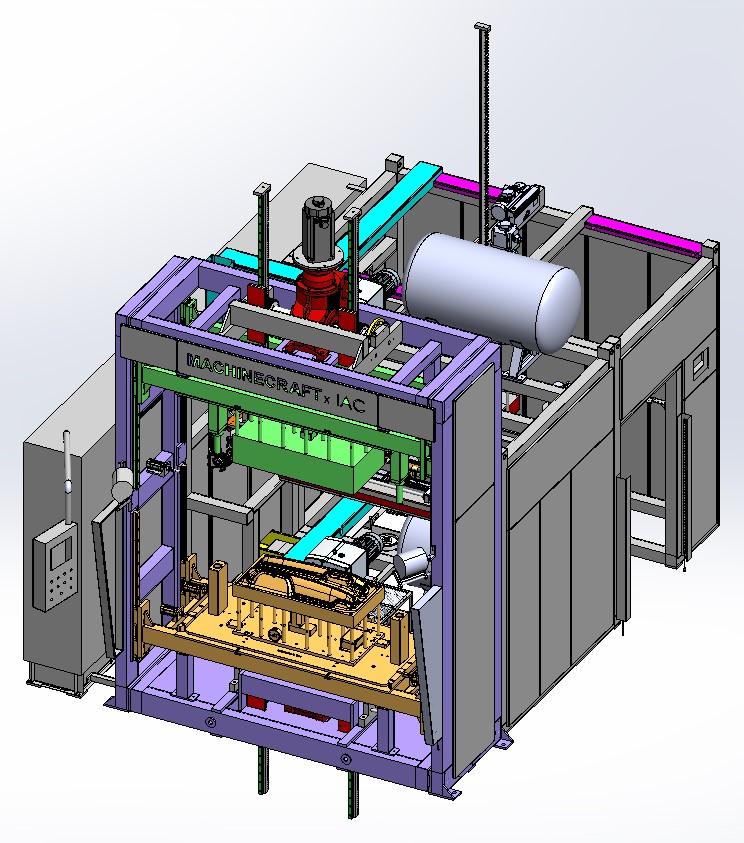

IMG Thermoforming Machine

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

When exploring the machinery industry in Turkey, several key considerations come into play. The sector benefits from Turkey's strategic location, serving as a bridge between Europe and Asia, which enhances trade opportunities. Local companies often focus on manufacturing agricultural, construction, and industrial machinery, with a growing emphasis on innovation and technology. However, navigating local regulations is crucial, as compliance with safety and environmental standards can impact operational efficiency. The competitive landscape features a mix of established firms and emerging startups, with many companies seeking to enhance their global market relevance by adopting advanced technologies like automation and IoT. Challenges include fluctuating economic conditions and currency volatility, which can affect pricing and investment decisions. Additionally, environmental concerns are becoming increasingly significant, with companies encouraged to adopt sustainable practices to meet both local and international standards. Opportunities exist in exports, as demand for Turkish machinery is rising in various regions due to competitive pricing and quality. Understanding the local market dynamics, including consumer preferences and government incentives for industrial growth, is essential for making informed decisions in this vibrant sector.

Some interesting numbers and facts about your company results for Machinery

| Country with most fitting companies | Turkey |

| Amount of fitting manufacturers | 107 |

| Amount of suitable service providers | 79 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1960 |

| Youngest suiting company | 2021 |

Some interesting questions that has been asked about the results you have just received for Machinery

What are related technologies to Machinery?

Based on our calculations related technologies to Machinery are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Who are Start-Ups in the field of Machinery?

Start-Ups who are working in Machinery are Machina3D

Which industries are mostly working on Machinery?

The most represented industries which are working in Machinery are Machinery Manufacturing, Manufacturing, Construction, IT, Software and Services, Automation

How does ensun find these Machinery Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.

The settings can be adjusted at any time or all cookies can be accepted.