The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

R&B

Ramat HaSharon, Israel

B

- Employees

1994

Key takeaway

R&B's CAMD solutions enhance the mold design process for engineers by offering advanced 3D CAD tools that streamline design, reduce errors, and lower production costs. With a vast library of components and comprehensive support, R&B equips professionals in the Mold & Die industry with the technology needed for efficient and cost-effective manufacturing.

Reference

Product

Manufacturing Tools | R&B

Pelmar Engineering Group

Ramat HaSharon, Israel

B

51-100 Employees

1966

Key takeaway

Pelmar Group specializes in providing pre-owned machinery and engineering solutions for the polymer industry, leveraging over 50 years of experience to enhance production efficiency. They also offer a "Machinery As a Service" model, allowing clients to focus on operational expenditures rather than capital expenditures.

Reference

Service

Machinery As a Service

Pelmar Group offers to Elite Clients the new concept of Service Rent Model which allows to focus on OPEX over CAPEX alternative.

G.B.M. AUTOMATION & ROBOTICS LTD

Kfar Saba, Israel

B

11-50 Employees

1979

Key takeaway

GBIM specializes in the automation and robotics sector, offering comprehensive solutions for the manufacturing and integration of high-speed mechanical assembly machines and dedicated manufacturing lines. Their serial manufacturing division also focuses on assembly and subcontracting, making GBIM a key player in providing advanced mechanical and electronic assembly solutions.

Reference

Service

Machining Division - GBM

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

C.M.D. ENGINEERING EQUIPMENT SUPPLIES CO. LTD.

Ramla, Israel

B

11-50 Employees

1900

Key takeaway

CMD is the Israeli distributor of a variety of construction and mining machinery, including HITACHI and BELL equipment. They also provide a comprehensive range of spare parts and services for all brands of construction machinery, making them a key player in the industry.

Reference

Core business

צ.מ.ד חברה לאספקת ציוד הנדסי

E.M.I INTEGRATED SYSTEMS LTD.

Beer Tuvia Regional Council, Israel

B

11-50 Employees

2005

Key takeaway

EMI Integrated Systems specializes in advanced manufacturing techniques, including high precision, 5-axis CNC machining, which enables them to produce complex parts with micro-millimeter accuracy. They offer tailored engineering solutions and close-tolerance contract manufacturing for various industries, including medical and aerospace, ensuring high quality and compliance with strict industry standards.

Reference

Core business

EMI Integrated Systems | Medical, High Tech & Aerospace | CNC

EMI Integrated Systems offers close-tolerance contract manufacturing, purpose machinery, precise machine components, jigs and fixtures for medical industry.

Albitech Ltd

Tel-Aviv, Israel

B

1-10 Employees

-

Key takeaway

Albitech specializes in consulting and programming solutions for multi-axis CNC machines, significantly enhancing productivity and reducing development costs for engineers and manufacturers. Their focus on advanced technologies aims to streamline processes and improve quality in the CAD/CAM departments.

Reference

Core business

Albitech – Open your business to a new dimension

G Engineering

Kfar Hess, Israel

B

1-10 Employees

-

Key takeaway

G ENGINEERING specializes in injection molding plastics technology, offering comprehensive engineering services from concept to production. Their expertise in mold design and the injection process allows them to create innovative, high-quality products, making them a key player in the machinery sector.

Reference

Service

Services | g-engineering

M.Y.G. TECH LTD

Modiin-Maccabim-Reut, Israel

B

1-10 Employees

2002

Key takeaway

MYG Tech LTD specializes in providing top-of-the-line semiconductor equipment and tools, focusing on wafer handling and process improvement. With a commitment to cost-effective solutions, they serve major semiconductor fabs and equipment manufacturers, offering a range of products including assemblies, spare parts, and accessories.

Reference

Core business

Home

MYG TECH is a global provider for Semiconductor equipment IndustryLearn Morelearn how to reduce wafer slipClick HereAdvanced tools for process improvement

Hi Cut

Hevel Modiin Regional Council, Israel

B

1-10 Employees

1985

Key takeaway

The company specializes in Electrical Discharge Machining (EDM), which is crucial for precision machining, allowing for highly accurate cuts in conductive materials of any hardness. Their milling machines offer faster cutting speeds, resulting in more precise parts and superior surface finishes.

Reference

Product

Hi-Cut 85' ltd. | CNC Machining

Fast & Accurate

mnics Ltd

Yokneam Ilit, Israel

B

11-50 Employees

-

Key takeaway

The company is a leading manufacturer specializing in high precision products and offers comprehensive solutions throughout the entire project lifecycle, from prototyping to advanced manufacturing. Their expertise includes full engineering support and a structured process for transitioning to mass production, highlighting their adaptability to customer needs.

Reference

Core business

m-nics – Manufacturer of the future

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

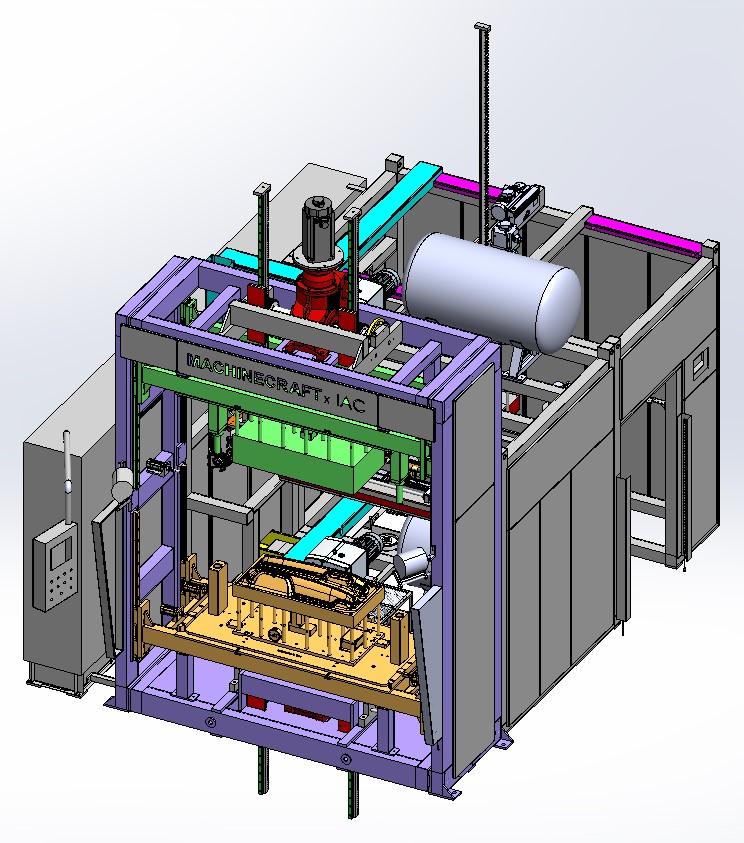

IMG Thermoforming Machine

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

When exploring the machinery industry in Israel, several key factors are essential to consider. The country is known for its advanced technology and innovation, particularly in areas such as automation and robotics. Regulations in Israel are stringent, focusing on safety and environmental sustainability, which can impact operational processes and costs. Challenges include high competition and the need for continuous technological upgrades to remain relevant in the global market. Opportunities are significant, especially in sectors like agricultural machinery and construction equipment, where Israeli companies innovate to address local and global demands. The competitive landscape is characterized by a mix of established firms and startups, with a growing emphasis on export markets. Environmental concerns are increasingly shaping industry practices, with a push towards sustainable solutions and energy efficiency. Understanding these dynamics can provide valuable insights into the potential for growth and collaboration in this vibrant sector. Additionally, being aware of the global market relevance of Israeli machinery products is crucial, as many companies aim to expand their reach beyond local borders.

Some interesting numbers and facts about your company results for Machinery

| Country with most fitting companies | Israel |

| Amount of fitting manufacturers | 15 |

| Amount of suitable service providers | 11 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1900 |

| Youngest suiting company | 2005 |

Some interesting questions that has been asked about the results you have just received for Machinery

What are related technologies to Machinery?

Based on our calculations related technologies to Machinery are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Machinery?

The most represented industries which are working in Machinery are Machinery Manufacturing, Other, Automation, Electronics and Electrical engineering, Manufacturing

How does ensun find these Machinery Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.